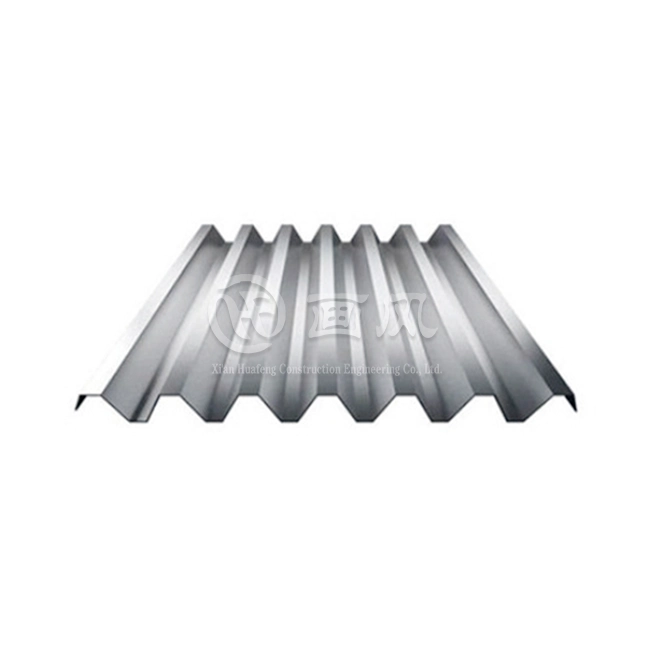

When searching for the optimal roofing and wall cladding solutions for large-scale construction projects, Classic Rib Corrugated Panel systems stand out as the premier choice among professional contractors and developers. These engineered metal panels combine exceptional structural integrity with aesthetic versatility, making them ideal for commercial complexes, transportation hubs, and government facilities. The distinctive ribbed profile provides superior strength-to-weight ratios while maintaining cost-effectiveness across diverse environmental conditions. Modern corrugated panels offer advanced coating technologies and customizable specifications that meet international standards, ensuring long-term performance reliability.

Understanding Classic Rib Corrugated Panels

Classic rib corrugated panels speak to a advanced advancement of conventional metal material innovation, built particularly for requesting commercial and mechanical applications. These boards include a particular wave design that makes upgraded basic solidness through geometric support, permitting them to span more noteworthy separations whereas keeping up remarkable load-bearing capacity.

Material Composition and Structural Properties

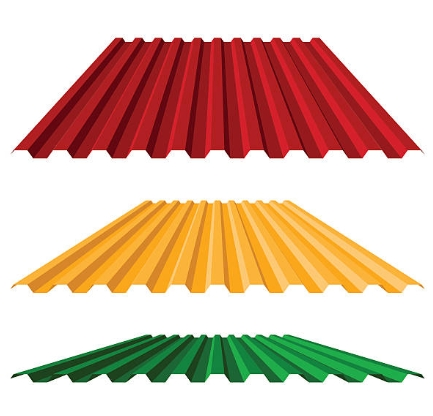

The boards are made essentially from galvanized steel, aluminum, or stainless steel substrates, with thickness ranges from 0.3mm to 1.2mm depending on application necessities. This fabric determination gives ideal erosion resistance whereas keeping up workability amid establishment. The folded profile makes a three-dimensional structure that disperses loads successfully over the board surface, lessening push concentrations and expanding benefit life. Advanced coating frameworks counting PE, HDP, and PVDF wraps up give extra security against natural debasement. These coatings experience thorough testing to guarantee grip quality, UV resistance, and color steadiness over amplified presentation periods. The combination of substrate fabric and defensive coating makes a comprehensive obstruction framework that performs dependably in unforgiving climates.

Applications Across Building Sectors

The flexibility of folded boards makes them appropriate for different development applications past conventional material. Divider cladding establishments advantage from the lightweight characteristics and ease of dealing with, decreasing auxiliary stacking necessities on building outlines. The boards exceed expectations in rural buildings, stockrooms, and fabricating offices where cost-effectiveness and toughness are vital considerations. Modern engineering applications progressively join folded boards for their tasteful request and plan adaptability. The ribbed surface makes curiously shadow designs and visual profundity that improve building exteriors. Color customization choices permit modelers to coordinated boards consistently with generally plan concepts whereas keeping up execution measures.

Comparing Classic Rib Corrugated Panels with Other Roofing Solutions

Professional acquirement groups require comprehensive execution information to make educated choices almost material framework choice. Understanding how folded boards compare with elective arrangements makes a difference distinguish ideal applications and potential limitations.

Performance Metrics Analysis

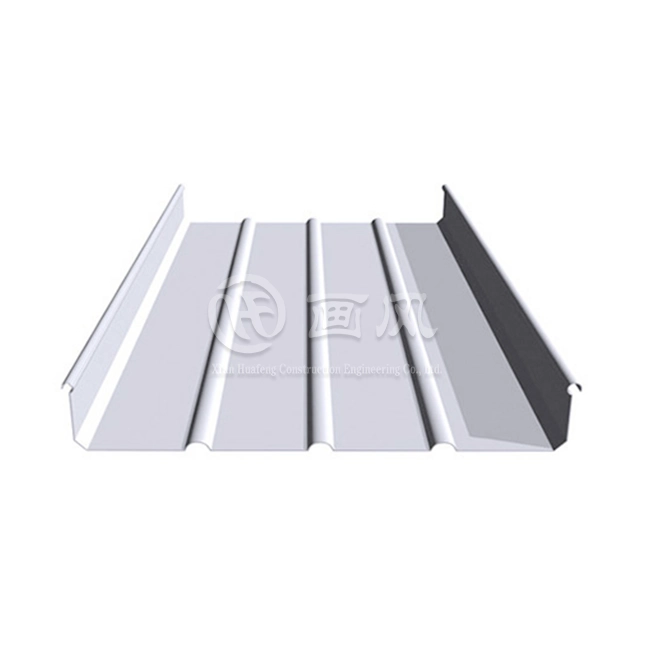

Standing crease metal material frameworks offer predominant climate fixing capabilities but require specialized establishment skill and higher fabric costs. Classic Rib Corrugated Panel folded boards give comparable solidness with rearranged establishment methods that decrease labor costs. The uncovered clasp plan of folded frameworks permits less demanding upkeep get to compared to concealed clasp alternatives.Trapezoidal boards offer comparable auxiliary characteristics but with diverse stylish profiles. The choice between layered and trapezoidal plans frequently depends on engineering inclinations or maybe than execution contrasts. Both frameworks give amazing wind elevate resistance and warm development accommodation.Smooth metal boards need the basic support given by layered profiles, constraining their crossing capabilities and requiring extra auxiliary back. Be that as it may, smooth boards may be favored for applications requiring negligible earth aggregation or upgraded cleaning efficiency.

Economic Considerations and Total Cost Analysis

Material costs for folded boards ordinarily speak to 15-25% investment funds compared to standing crease frameworks whereas keeping up comparable benefit life desires. Establishment labor necessities are diminished due to less difficult affixing strategies and less specialized apparatuses. These variables combine to make favorable add up to fetched of proprietorship calculations for budget-conscious projects.Energy proficiency characteristics shift based on coating determination and establishment points of interest. Intelligent coatings can diminish cooling loads in warm climates, whereas warm bridging contemplations influence warming effectiveness in cold districts. Legitimate assessment of these components guarantees ideal long-term operational costs.

How to Choose the Best Classic Rib Corrugated Panel for Your Project

Selecting appropriate corrugated panel specifications requires careful evaluation of project-specific requirements and environmental conditions. The decision process involves multiple technical considerations that directly impact system performance and longevity.

Material Specification Criteria

Panel thickness determination depends on basic necessities, traversing separations, and wind stack calculations. Thicker boards give more noteworthy auxiliary capacity but increment fabric costs and establishment weight. Designing examination decides least thickness prerequisites whereas optimizing cost-effectiveness. Coating choice essentially impacts toughness and upkeep necessities. PVDF coatings offer prevalent color maintenance and erosion resistance but command premium estimating. PE coatings give satisfactory execution for numerous applications at decreased costs. HDP coatings speak to an halfway alternative adjusting execution with financial considerations.

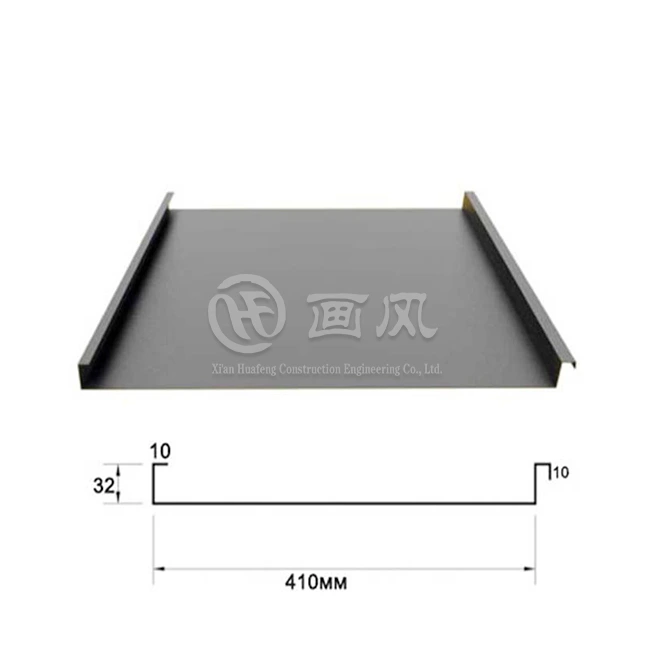

Customization and Procurement Advantages

Width customization from 600-1200mm permits optimization for particular building measurements and establishment effectiveness. Custom lengths decrease squander and minimize field cutting necessities. Color coordinating capabilities guarantee consistency with engineering determinations and brand requirements. The benefits of working with built up producers ended up apparent through steady quality control and solid conveyance plans. Companies like Xi'an Huafeng Development Building Co., Ltd. offer comprehensive customization administrations whereas keeping up generation capacity of 1000 tons month to month. Their 30-year guarantee gives extra certainty in item toughness and producer stability.

International Standards Compliance

Adherence to ASTM, DIN, JIS, BS, and GB/T standards ensures compatibility with global construction practices and regulatory requirements. These certifications facilitate project approval processes and provide quality assurance for international buyers. Compliance documentation supports warranty claims and insurance requirements throughout the building lifecycle.

Installation and Maintenance Best Practices for Classic Rib Corrugated Panels

Proper installation techniques are essential for achieving optimal panel performance and warranty compliance. Understanding best practices helps avoid common installation errors that can compromise system integrity.

Preparation and Handling Procedures

Classic Rib Corrugated Panel handling requires appropriate lifting equipment and techniques to prevent damage during transportation and positioning. Storage procedures must protect panels from contamination and mechanical damage while maintaining accessibility for installation crews. Substrate preparation includes verification of structural adequacy and proper drainage design.Safety protocols encompass fall protection systems, electrical hazard awareness, and weather monitoring procedures. Installation crews require training on panel-specific fastening techniques and sealant application methods. Quality control checkpoints throughout the installation process ensure compliance with manufacturer specifications.

Maintenance Strategies and Longevity

Routine inspection schedules should identify potential issues before they develop into major problems. Visual examination of fasteners, sealants, and panel surfaces helps detect early signs of wear or damage. Cleaning procedures remove accumulated debris that can cause premature deterioration or drainage problems.Preventive maintenance programs extend service life and maintain warranty coverage. These programs include fastener retorquing, sealant renewal, and coating touch-up procedures. Documentation of maintenance activities supports warranty claims and helps optimize future maintenance scheduling.

Procurement Insights: Navigating Suppliers, Pricing & Delivery

Successful procurement of corrugated panels requires understanding market dynamics and supplier capabilities. Strategic sourcing decisions impact project costs, quality outcomes, and delivery reliability.

Supplier Evaluation and Selection

Direct factory sourcing offers advantages in quality control, customization capabilities, and cost optimization. Manufacturers with multiple production facilities can provide geographic flexibility and reduced shipping costs. Production capacity verification ensures ability to meet project deadlines and volume requirements.Quality certifications including ISO 9001, ISO 14001, and CE marking indicate commitment to systematic quality management. These certifications provide confidence in product consistency and manufacturing process control. SGS testing verification adds independent validation of performance claims.

Pricing Models and Cost Optimization

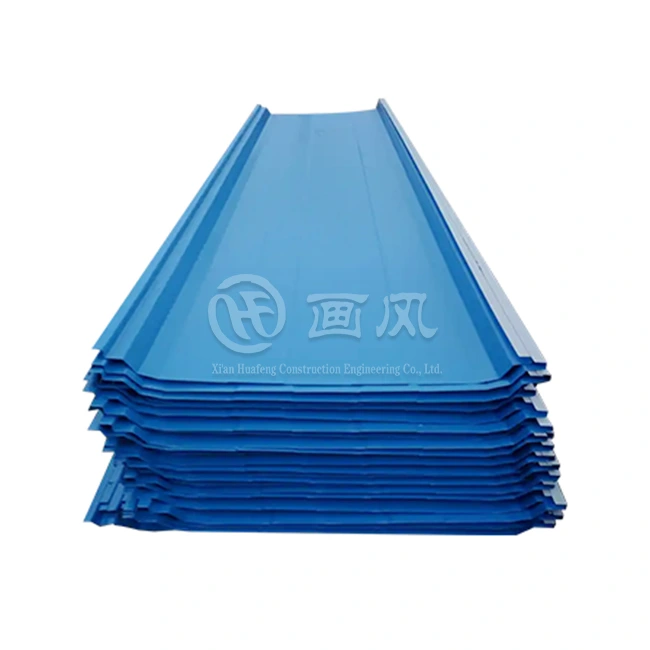

Volume discounts reward larger orders but require careful inventory management and cash flow planning. Minimum order quantities of 500 square meters align with typical commercial project sizes while maintaining economic efficiency. Lead times of 15-20 days support project scheduling while allowing adequate manufacturing time.Customization services including color matching, pattern selection, and dimensional optimization add value without significantly impacting delivery schedules. These services help differentiate projects and meet specific architectural requirements. The combination of standard products with custom options provides flexibility in procurement planning.

Xi'an Huafeng Construction Engineering Co., Ltd.: Your Trusted Manufacturing Partner

Xi'an Huafeng Construction Engineering Co., Ltd. leverages extensive expertise in manufacturing and supplying corrugated roofing solutions backed by robust quality certifications and advanced production capabilities. Established in 2018, the company has rapidly developed into a comprehensive provider of metal building envelope systems for commercial and industrial applications.

Manufacturing Excellence and Production Capacity

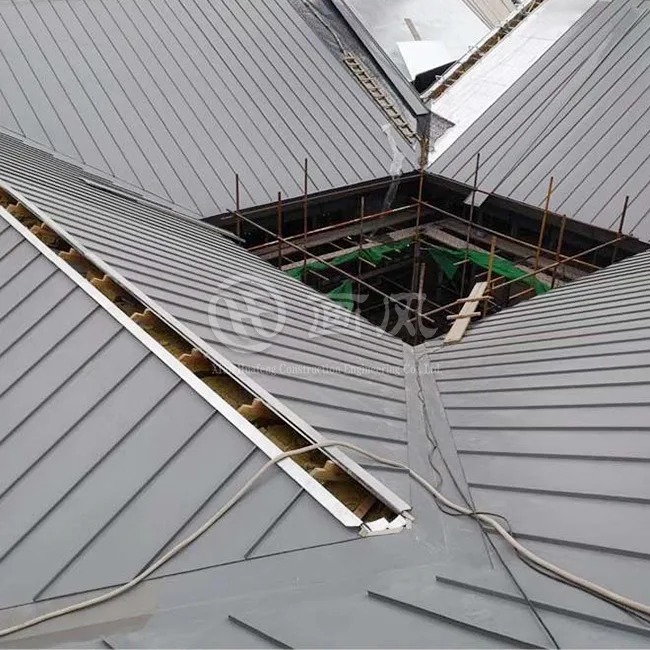

The company operates three manufacturing facilities with seven production lines and more than 40 specialized machines, ensuring consistent quality and reliable delivery schedules. This production infrastructure supports monthly output capacity of 1000 tons while maintaining flexibility for custom specifications. The Anhui facility covers 200,000 square meters and handles raw material production, while processing plants in Hangzhou and Xi'an focus on finished panel manufacturing.Advanced production equipment includes fully automatic punching lines, longitudinal and transverse shearing systems, and precision bending machines. These capabilities enable tight dimensional tolerances and consistent panel profiles that facilitate installation and ensure proper system performance. Seven color coating production lines provide comprehensive finishing options to match project specifications.

Technical Innovation and Quality Assurance

Recognition as a high-tech enterprise in Shaanxi Province reflects the company's commitment to innovation and technical advancement. More than 20 registered patents for roofing systems demonstrate ongoing research and development efforts. Grade 1 building curtain wall and Grade 3 steel structure qualifications validate technical competency for complex projects.Quality management systems comply with ISO 9001 and ISO 14001 standards, providing systematic approaches to product quality and environmental responsibility. SGS certification adds independent verification of product performance and manufacturing consistency. These quality frameworks support the company's 30-year warranty program and ensure customer confidence.

Conclusion

Classic Rib Corrugated Panel systems provide exceptional value for professional construction teams managing large-scale commercial and industrial projects. The combination of structural performance, aesthetic versatility, and cost-effectiveness makes these panels ideal for diverse applications ranging from transportation hubs to government facilities. Modern manufacturing capabilities ensure consistent quality while customization options meet specific project requirements. Understanding selection criteria, installation best practices, and supplier capabilities enables informed procurement decisions that optimize long-term project success and building performance.

Frequently Asked Questions

What is the expected service life of corrugated metal panels?

Quality corrugated panels with proper coatings typically provide 25-40 years of reliable service depending on environmental conditions and maintenance practices. Manufacturers like Huafeng offer 30-year warranties that demonstrate confidence in product durability. Regular maintenance and prompt attention to minor issues can extend service life beyond warranty periods.

Can panels be customized for specific color and dimensional requirements?

Modern manufacturing processes support extensive customization including color matching, width adjustment from 600-1200mm, and length optimization up to 12 meters. Thickness ranges from 0.3-1.2mm accommodate different structural requirements. Custom orders typically add 2-3 weeks to standard delivery schedules but provide optimal project fit.

How do installation times compare with other roofing systems?

Corrugated panel installation generally proceeds 20-30% faster than standing seam systems due to simpler fastening procedures and reduced specialized tool requirements. Exposed fastener designs eliminate complex seaming operations while maintaining weather resistance. Proper planning and crew training optimize installation efficiency and quality outcomes.

Partner with Huafeng for Your Next Project

Ready to explore premium Classic Rib Corrugated Panel solutions for your upcoming construction project? Huafeng combines manufacturing excellence with comprehensive customer support to deliver optimal building envelope systems. Our technical team provides detailed specifications, installation guidance, and project-specific recommendations tailored to your requirements. Contact us at huafeng@hfmetalroof.com for personalized consultations, free samples, and competitive quotations from a trusted Classic Rib Corrugated Panel manufacturer. With proven expertise serving clients across 100+ countries and rapid 15-20 day delivery schedules, Huafeng stands ready to support your project success with reliable, innovative metal roofing solutions.

References

1. Metal Building Manufacturers Association. "Guidelines for Corrugated Metal Panel Design and Installation Standards." Technical Bulletin MB-2023, 2023.

2. American Society for Testing and Materials. "Standard Specification for Metallic Coated Steel Sheets for Building Construction Applications." ASTM A653/A653M-22, 2022.

3. Construction Industry Research and Information Association. "Performance Evaluation of Metal Roofing Systems in Commercial Applications." Technical Report C745, 2023.

4. International Building Code Council. "Metal Roof System Requirements for Commercial Construction." Chapter 15: Roof Assemblies and Rooftop Structures, 2024 Edition.

5. National Roofing Contractors Association. "Metal Panel Roof Systems Installation and Maintenance Best Practices." Professional Guidelines Series, 2023.

6. Building Research Establishment. "Lifecycle Assessment of Metal Building Envelope Systems: Performance and Sustainability Analysis." BRE Report 528, 2023.