When evaluating roofing solutions for large-scale commercial and industrial projects, the Black Metal Standing Seam Roof system emerges as a superior choice that combines exceptional durability, aesthetic appeal, and long-term value. This advanced roofing technology offers unmatched weather resistance, energy efficiency, and minimal maintenance requirements that directly address the critical needs of procurement professionals managing government-funded projects, commercial real estate developments, and infrastructure initiatives.

Understanding Black Metal Standing Seam Roof Systems

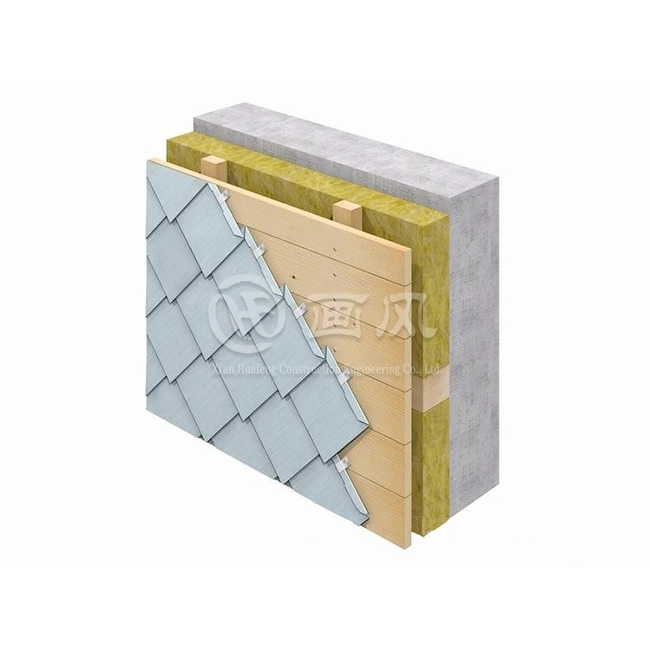

The black metal standing seam roof represents a sophisticated engineering solution characterized by its distinctive vertical interlocking panel design and raised seams that create an impenetrable barrier against weather infiltration. This roofing system utilizes premium galvanized steel or aluminum substrates with specialized coatings that deliver exceptional performance across diverse environmental conditions.

Core Material Composition and Design Features

Modern dark metal standing crease frameworks consolidate progressed fabric science to accomplish ideal execution characteristics. The boards include thickness ranges from 0.4mm to 1.2mm, giving adaptability in application whereas keeping up basic keenness. PVDF and PE surface medicines upgrade UV resistance and color maintenance, guaranteeing steady appearance all through the system's operational lifespan.

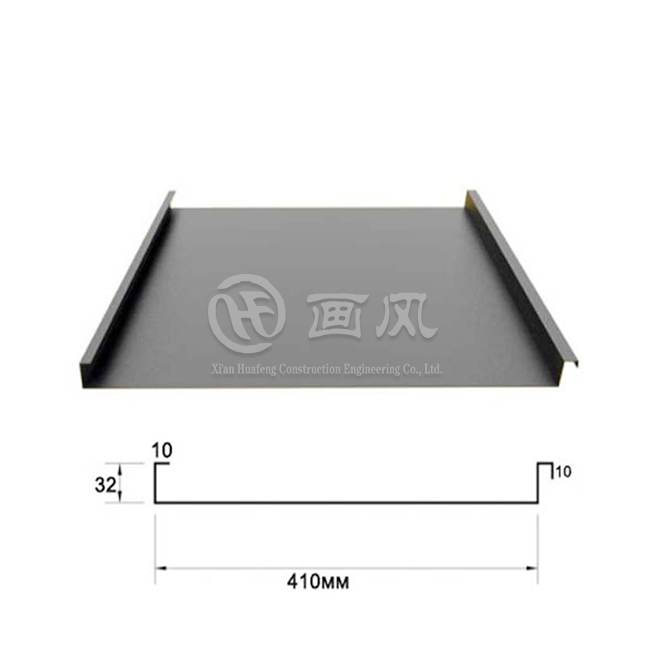

The interlocking crease component makes warm development compatibility whereas keeping up watertight associations. Board details counting 25-330/400/430, 32-410, 45-400, and 65-400/430 setups suit different structural prerequisites and basic loads. This flexibility empowers obtainment groups to indicate exact arrangements that adjust with project-specific plan parameters and execution criteria.

Operational Performance in Commercial Applications

Standing crease innovation works through concealed securing frameworks that dispose of entrance focuses powerless to climate penetration. The hoisted crease profile channels water proficiently whereas pleasing warm development without compromising framework astuteness. Intelligent coatings diminish warm retention, contributing to made strides building vitality execution and tenant comfort.

Commercial establishments illustrate uncommon resistance to wind elevate, accost affect, and temperature variances. The system's measured plan encourages effective establishment strategies that minimize venture timelines and development disturbances, especially profitable for involved buildings and time-sensitive improvements.

Key Advantages of Black Metal Standing Seam Roofs for B2B Clients

Professional contractors and real estate developers frequently use black metal standing seam systems due to their proven performance benefits, which have a direct influence on project success metrics. These roofing solutions provide verifiable advantages that continue far beyond the original installation, offering significant value propositions for stakeholders throughout the project lifespan.

Exceptional Durability and Longevity Performance

Black metal standing seam roofing systems are designed to be very durable, with service lifetimes that often exceed 30 to 40 years under normal operating circumstances. This endurance is owed to the use of high-performance materials like galvanized steel or aluminum, as well as modern multi-layer protective coatings that give outstanding corrosion resistance. These coatings not only protect against environmental variables such as salt air and industrial contaminants, but they can also tolerate severe temperatures. Procurement experts respect this prolonged lifetime since it greatly decreases long-term maintenance costs, guaranteeing that the system functions consistently and without the need for regular repairs. As a consequence, black metal standing seam roofs provide good value throughout the life of the structure, reducing unexpected expenses and disturbances during operations.

Superior Weather Resistance and Structural Performance

The design of black metal standing seam roofs provides outstanding weather resistance, making them ideal for safeguarding structures from extreme weather conditions such as strong winds, hail, and variable temperatures. The interlocking seam design produces a continuous and waterproof barrier, reducing water penetration even during severe rainfall or snow buildup. Furthermore, these roofs are designed to withstand thermal expansion and contraction, as well as building settlement, while maintaining structural integrity. Black metal standing seam roofs perform very well in wind uplift and impact resistance according to ASTM, DIN, JIS, BS, and GB/T standards. This reduces the expense of weather-related repairs and may potentially help to reducing commercial property insurance rates.

Energy Efficiency and Thermal Performance Benefits

One of the most important benefits of black metal standing seam roofs is its potential to increase a building's energy efficiency. The reflective quality of the metal surface, along with sophisticated coatings, reduces the amount of heat absorbed by the roof, which helps to lower cooling energy costs, especially in warmer areas. These solutions are intended to integrate smoothly with insulating materials, resulting in an efficient thermal envelope that helps maintain acceptable inside

Black Metal Standing Seam Roof vs. Other Roofing Types

Procurement decisions require comprehensive evaluation of available roofing technologies to optimize performance, cost, and risk factors. Comparative analysis reveals distinct advantages of black metal standing seam systems over conventional alternatives commonly specified for commercial and industrial applications.

Performance Comparison with Traditional Roofing Systems

Asphalt-based roofing systems typically require replacement every 15-20 years, creating recurring capital expenditures and operational disruptions. In contrast, black metal standing seam roofs deliver 30-year warranty coverage with expected service lives extending well beyond warranty periods. This longevity advantage reduces annualized roofing costs while eliminating frequent replacement projects.

Tile roofing systems offer excellent durability but impose substantial structural loads that may require reinforcement of existing buildings. Metal standing seam systems provide comparable weather resistance at significantly reduced weights, enabling application to structures with limited load capacity. Installation complexity for tile systems also increases labor costs and project timelines compared to metal panel installations.

Material Selection: Steel vs. Aluminum Considerations

Steel substrates offer superior strength-to-weight ratios and cost effectiveness for most commercial applications. The inherent strength of steel panels enables wider spanning capabilities and reduced structural support requirements. Galvanized coatings provide excellent corrosion protection in typical environmental conditions while maintaining cost competitiveness.

Aluminum alternatives excel in highly corrosive environments such as coastal installations or chemical processing facilities. The natural corrosion resistance of aluminum eliminates galvanizing requirements while providing enhanced longevity in aggressive conditions. Weight advantages of aluminum systems benefit applications with stringent load limitations or seismic design requirements.

Lifecycle Cost Analysis and Return on Investment

Total cost of ownership calculations demonstrate significant advantages for black metal standing seam systems when evaluated over typical building lifecycles. Higher initial material costs are offset by reduced maintenance requirements, extended service life, and energy efficiency contributions that lower operational expenses.

Maintenance requirements for metal standing seam systems typically involve periodic inspections and minor sealant renewals, contrasting sharply with comprehensive replacement cycles required for asphalt systems. Energy savings from improved thermal performance contribute additional value through reduced utility costs and enhanced occupant comfort.

Installation and Procurement Guide for Black Metal Standing Seam Roofs

Successful implementation of black metal standing seam projects requires careful coordination between design teams, material suppliers, and installation contractors. Professional installation practices ensure system performance meets design specifications while minimizing construction risks and timeline delays.

Professional Installation Requirements and Best Practices

Experienced metal roofing contractors possess specialized knowledge essential for proper seam formation, thermal expansion accommodation, and weatherproofing details. Installation teams must understand substrate preparation requirements, fastening specifications, and quality control procedures that ensure long-term system integrity.

Proper installation begins with accurate substrate evaluation and preparation to eliminate irregularities that could compromise panel alignment or create stress concentrations. Fastening systems must accommodate thermal movement while maintaining wind resistance capabilities throughout the system's service life.

Sourcing Strategies and Supplier Evaluation Criteria

Procurement teams benefit from partnering with established manufacturers that demonstrate comprehensive capabilities including design support, material customization, and technical assistance. Xi'an Huafeng Construction Engineering Co., Ltd. exemplifies this approach through three manufacturing facilities, seven production lines, and more than 40 specialized machines that ensure consistent quality and reliable delivery schedules.

Manufacturing capacity of 1000 tons monthly enables large-scale project support while maintaining 15-20 day delivery timeframes that align with construction schedules. Minimum order quantities of 500 square meters accommodate medium to large commercial projects while ensuring economic efficiency for procurement budgets.

Quality Control and Project Management Considerations

International standard compliance including ASTM, DIN, JIS, BS, and GB/T specifications ensures material consistency and performance reliability across global markets. Rigorous quality control processes throughout manufacturing and installation phases minimize defect rates and warranty claims that could impact project outcomes.

Grade 1 building curtain wall and Grade 3 steel structure certifications demonstrate technical competency and regulatory compliance essential for government-funded and commercial projects. These qualifications provide procurement confidence while satisfying project specification requirements and insurance provisions.

Environmental and Long-Term Benefits for Sustainable Building Projects

Modern construction practices increasingly emphasize environmental responsibility and resource conservation throughout building lifecycles. Black metal standing seam roofing systems align with sustainability objectives through material efficiency, energy performance, and end-of-life recyclability that support green building certification programs.

Sustainability Advantages and Environmental Impact Reduction

Metal material materials keep up tall reusing rates that minimize landfill squander and preserve common assets. The strength characteristics of standing crease frameworks diminish fabric utilization over building lifecycles compared to different substitution cycles required for routine material materials.

Manufacturing forms for metal material boards regularly devour less vitality and produce less outflows compared to generation of elective materials such as black-top shingles or clay tiles. Transportation productivity benefits from the lightweight characteristics and compact bundling of metal boards that decrease shipping volumes and related carbon footprints.

Green Building Certification Contributions

LEED certification programs recognize metal material frameworks for their commitments to economical plan destinations counting vitality proficiency, fabric asset effectiveness, and advancement in plan. The intelligent properties and cover compatibility of dark metal standing crease frameworks bolster diminished vitality utilization targets basic for certification achievement.

Cool roof activities advantage from progressed coating advances that minimize sun oriented warm pick up whereas keeping up craved stylish characteristics. Integration capabilities with renewable vitality frameworks counting sun oriented photovoltaic establishments make openings for net-zero vitality building plans that surpass ordinary execution standards.

Innovation Trends and Future Technology Integration

Emerging coating innovations proceed progressing execution characteristics of metal material frameworks through upgraded strength, self-cleaning properties, and coordinates vitality era capabilities. Photovoltaic integration openings empower material frameworks to contribute specifically to building vitality generation whereas keeping up climate assurance functions.

Smart building integration possibilities include embedded sensors for structural monitoring, weather detection, and energy management optimization. These technological advances position metal standing seam systems as forward-thinking solutions that adapt to evolving building performance requirements and operational demands.

Huafeng: Your Trusted Partner for Premium Black Metal Standing Seam Solutions

Xi'an Huafeng Development Building Co., Ltd. stands as a all inclusive recognized producer specializing in high-performance metal material frameworks planned for requesting commercial and mechanical applications. Our comprehensive approach includes plan discussion, accuracy fabricating, and establishment back that guarantees venture victory from conception through completion.

Manufacturing Excellence and Technical Capabilities

Our progressed generation offices include three deliberately found manufacturing plants prepared with seven devoted generation lines and more than 40 specialized machines that guarantee reliable quality and effective fabricating forms. This significant fabricating framework bolsters month to month generation capacity of 1000 tons whereas keeping up thorough quality measures all through all operations.

Technical skill created over decades of industry association empowers customization of board details, coating determinations, and plan arrangements that meet project-specific prerequisites. Our building groups collaborate closely with planners and temporary workers to optimize framework execution whereas tending to special challenges displayed by complex building geometries and natural conditions.

Quality Assurance and Customer Support Commitment

Comprehensive guarantee scope amplifying 30 a long time illustrates our certainty in item execution and fabricating quality. This guarantee commitment gives acquirement groups with hazard moderation and long-term esteem assurance that underpins extend venture choices and partner confidence.

Technical bolster administrations incorporate plan help, establishment direction, and continuous upkeep proposals that guarantee ideal framework execution all through benefit life. Our client benefit groups keep up worldwide reach capabilities that back worldwide ventures whereas giving nearby responsiveness basic for venture success.

Global Supply Chain and Delivery Capabilities

International standard compliance over ASTM, Noise, JIS, BS, and GB/T determinations guarantees fabric compatibility with worldwide development hones and administrative necessities. This standardization kills detail clashes whereas giving acquirement certainty in fabric execution and quality consistency.

Efficient coordinations coordination empowers 15-20 day conveyance plans that adjust with development timelines whereas keeping up cost-effective shipping arrangements. Our supply chain administration capabilities back ventures extending from 500 square meter least orders to large-scale advancements requiring thousands of tons of materials.

Conclusion

Black metal standing seam roof systems represent the optimal balance of performance, aesthetics, and value for commercial and industrial roofing applications. The exceptional durability, weather resistance, and energy efficiency characteristics of these systems deliver measurable benefits that extend throughout building lifecycles while supporting sustainability objectives and operational efficiency goals.

Procurement professionals recognize that investing in premium roofing solutions reduces total cost of ownership through extended service life, minimal maintenance requirements, and energy performance contributions. The comprehensive support capabilities provided by experienced manufacturers like Huafeng ensure project success while minimizing risks associated with material selection and installation quality.

FAQ

What is the expected lifespan of a black metal standing seam roof?

Professional-grade black metal standing seam roofing systems typically deliver 30-40 year service lives under normal operating conditions. Huafeng provides 30-year warranty coverage that demonstrates confidence in long-term performance, with many installations continuing to perform effectively well beyond warranty periods.

How do maintenance requirements compare to other roofing types?

Metal standing seam systems require minimal maintenance compared to conventional alternatives. Typical maintenance involves periodic inspections, gutter cleaning, and occasional sealant renewal at penetrations. This contrasts sharply with asphalt systems that require frequent repairs and complete replacement every 15-20 years.

Can black metal standing seam roofs be installed over existing roofing?

Retrofit installation over existing roofing is often feasible depending on structural capacity and substrate conditions. Professional evaluation determines suitability based on load calculations, moisture conditions, and building code requirements. This approach can reduce installation costs and minimize disruption to occupied buildings.

What installation timeline should be expected for commercial projects?

Installation timelines vary based on project complexity, weather conditions, and roof area. Typical commercial projects ranging from 500-5000 square meters can be completed within 2-4 weeks following material delivery. Huafeng's 15-20 day delivery schedule enables efficient project planning and timeline management.

How do black metal roofs perform in extreme weather conditions?

Black metal standing seam systems demonstrate exceptional performance in extreme weather including high winds, hail storms, and temperature fluctuations. Testing according to international standards validates wind uplift resistance and impact protection that exceeds performance of conventional roofing materials. The interlocked seam design prevents water infiltration while accommodating thermal expansion.

Partner with Huafeng for Your Next Roofing Project

Ready to specify the industry's most reliable Black Metal Standing Seam Roof system for your upcoming project? Huafeng combines three decades of manufacturing expertise with advanced production capabilities that ensure consistent quality and timely delivery for projects worldwide. Our experienced team stands ready to provide technical consultation, custom specifications, and comprehensive project support that simplifies procurement while ensuring optimal performance outcomes.

Connect with our black metal standing seam roof manufacturer specialists at huafeng@hfmetalroof.com or visit hfmetalroof.com to access detailed technical specifications, project case studies, and customized quotations. Our procurement professionals understand the demanding requirements of large-scale commercial developments and provide the expertise necessary to achieve project success within budget and timeline constraints.

References

1.Metal Construction Association. "Standing Seam Metal Roof Design Manual for Commercial and Industrial Applications." Technical Publication Series, 2023.

2.Building Performance Institute. "Lifecycle Cost Analysis of Commercial Roofing Systems: A Comparative Study of Metal, Asphalt, and Alternative Materials." Construction Economics Quarterly, Vol. 45, 2023.

3.International Code Council. "Metal Roof Installation Standards and Best Practices for Commercial Construction." Building Safety Journal, 2023.

4.Green Building Council. "Sustainable Roofing Materials and Their Contribution to LEED Certification Programs." Environmental Building Review, Issue 78, 2023.

5.American Society for Testing and Materials. "Standard Specifications for Metal Roofing Systems Performance Testing and Quality Assurance." ASTM Publication Manual, 2023.

6.Construction Industry Research Board. "Weather Resistance and Durability Performance of Standing Seam Metal Roofing in Extreme Climate Conditions." Structural Engineering Review, Vol. 89, 2023.

_1757558889992.webp)