When choosing between Angle Lock Standing Seam Roof Panels and double lock systems, the key difference lies in their fastening mechanisms and installation complexity. Angle Lock Standing Seam Roof Panels utilize a mechanical locking system where panels connect through angled clips, providing superior thermal expansion accommodation and easier maintenance access. Double lock systems feature two-fold seam connections that create enhanced weather resistance but require more precise installation techniques. Both systems excel in commercial applications, yet each serves different project requirements based on building design, climate conditions, and long-term performance expectations.

Understanding the Core Differences Between Angle Lock and Double Lock Metal Roofing Systems

The architectural metal panels industry offers various standing seam metal roof configurations, each engineered for specific performance requirements. Professional contractors and real estate developers often face the critical decision between angle lock and double lock systems when specifying weatherproof roofing solutions.

Three fundamental distinctions separate these roof panel systems:

- Connection Methodology: Angle lock systems employ mechanical clips that secure panels through angled engagement, while double lock systems create weatherproof seals through folded seam connections.

- Installation Complexity: Angle lock installations typically require standard roof panel fastening tools, whereas double lock systems demand specialized seaming equipment for proper execution.

- Maintenance Accessibility: Angle lock configurations allow panel removal without disturbing adjacent sections, while double lock systems require sequential disassembly for repairs.

Test data from independent laboratories shows angle lock systems accommodate thermal expansion movements up to 15% more effectively than traditional double lock configurations. This performance advantage stems from the mechanical clip design that permits controlled panel movement without compromising the roof seam locking system integrity.If you manage large-scale commercial projects with varying thermal conditions, angle lock systems provide enhanced flexibility. Conversely, if your projects prioritize maximum weather seal performance in extreme climates, double lock systems may prove more suitable.

Installation Process and Labor Considerations

The roof panel installation process varies significantly between these two metal roofing systems. Understanding these differences helps project managers make informed decisions regarding timeline, labor costs, and quality control requirements for Angle Lock Standing Seam Roof Panels.

Angle lock installations typically follow these steps:

- Panel positioning and alignment verification

- Mechanical clip attachment to structural supports

- Panel engagement through angled locking mechanism

- Weather seal application at system interfaces

- Quality inspection and performance testing

Double lock installations require additional precision:

- Precise panel measurement and cutting

- Sequential seam formation using specialized equipment

- Dual-fold seam creation for enhanced weather protection

- Comprehensive seam testing for water penetration resistance

- Final system inspection and documentation

Labor efficiency studies indicate angle lock systems reduce installation time by approximately 20-25% compared to double lock alternatives. This time savings translates directly into project cost reductions and accelerated completion schedules.Experienced installation crews report fewer quality control issues with angle lock systems due to their forgiving tolerance requirements. Double lock systems demand greater precision but deliver superior performance in challenging weather conditions.If you prioritize installation speed and labor cost management, angle lock systems offer clear advantages. However, if your projects require maximum weatherproofing performance regardless of installation complexity, double lock systems provide superior protection.

Performance Analysis: Durability and Weather Resistance

Steel roof panels performance varies considerably based on their locking mechanism design and materials specification. Independent testing laboratories have conducted extensive evaluations comparing these systems under various environmental conditions.

Wind Resistance Performance:

- Angle lock systems: Tested up to 180 mph wind speeds with no panel displacement

- Double lock systems: Certified for wind loads exceeding 200 mph in optimal installations

- Both systems meet or exceed commercial building code requirements

Water Penetration Testing:

- Angle lock configurations: 99.8% water exclusion under simulated storm conditions

- Double lock systems: 99.95% water exclusion with properly executed seam formation

- Performance differences become negligible with quality installation practices

Thermal Expansion Accommodation:

- Angle lock systems demonstrate superior expansion joint performance

- Double lock systems require additional expansion provisions in longer panel runs

- Both systems maintain structural integrity through temperature cycling

Roof panel durability testing indicates comparable lifespans when properly specified and installed. Material quality, surface treatments, and maintenance practices influence longevity more significantly than locking mechanism design.Commercial roofing panels from both categories exhibit excellent corrosion resistance when manufactured with appropriate protective coatings. The key performance differentiator relates to specific project requirements rather than inherent system superiority.If you manage buildings subject to extreme temperature variations, angle lock systems provide enhanced thermal performance. Projects in hurricane-prone regions may benefit from double lock systems' superior wind resistance capabilities.

Cost Analysis and Long-Term Value Considerations

Project economics play crucial roles in roof panel profile selection for commercial and industrial applications. Total cost of ownership encompasses initial material costs, installation expenses, maintenance requirements, and expected service life of Angle Lock Standing Seam Roof Panels.

Initial Material Costs:

- Angle lock systems typically cost 8-12% less than comparable double lock configurations

- Specialized clip hardware adds approximately 5% to base panel costs

- Double lock systems require premium pricing due to manufacturing complexity

Installation Cost Factors:

- Angle lock installations reduce labor costs through simplified procedures

- Double lock systems require specialized equipment and experienced crews

- Total installation savings with angle lock systems range from 15-20%

Maintenance and Repair Considerations:

- Angle lock panels allow individual section replacement

- Double lock repairs often require extensive seam reconstruction

- Long-term maintenance costs favor angle lock configurations

Lifecycle Value Assessment:

Independent studies suggest comparable performance lifecycles for both systems when properly maintained. The economic advantage shifts toward angle lock systems for most commercial applications due to lower total ownership costs.Roof panel fabrication complexity affects lead times and project scheduling. Angle lock systems typically offer shorter manufacturing cycles, supporting accelerated project timelines.If you prioritize initial cost control and installation efficiency, angle lock systems deliver superior value propositions. Projects with unlimited budgets focused on maximum performance may justify double lock system premiums.

Application Suitability: Commercial vs Residential Projects

Different building types and usage patterns influence optimal metal roofing system selection. Understanding application-specific requirements helps ensure appropriate system specification for long-term performance success.

Large-Scale Commercial Buildings:

Both systems excel in office complexes, retail centers, and industrial facilities. Angle Lock Standing Seam Roof Panels offer maintenance advantages for buildings requiring frequent roof access. Double lock systems provide enhanced weather protection for critical facility applications.

Transportation Infrastructure:

Airport terminals and high-speed rail stations benefit from angle lock systems' thermal expansion capabilities. The mechanical locking mechanism accommodates structural movement without compromising weatherproof roofing performance.

Government and Institutional Projects:

Educational facilities and healthcare buildings often specify angle lock systems for their maintenance accessibility. Emergency repairs can be completed more efficiently without disrupting adjacent building operations.

Residential Metal Roofing Applications:

Snap-lock roofing variations of angle lock systems suit residential applications requiring aesthetic appeal with simplified maintenance. Double lock systems provide premium performance for luxury residential projects.

Harsh Environment Applications:

Coastal buildings and industrial facilities with aggressive atmospheric conditions may benefit from double lock systems' superior seam integrity. Enhanced weather seals justify additional installation complexity in challenging environments.Project-specific requirements should guide system selection rather than general preferences. Building usage patterns, maintenance capabilities, and environmental conditions significantly influence optimal roofing system choice.If you manage diverse building portfolios requiring standardized maintenance procedures, angle lock systems offer operational advantages. Specialized facilities with critical weather protection requirements may justify double lock system specifications.

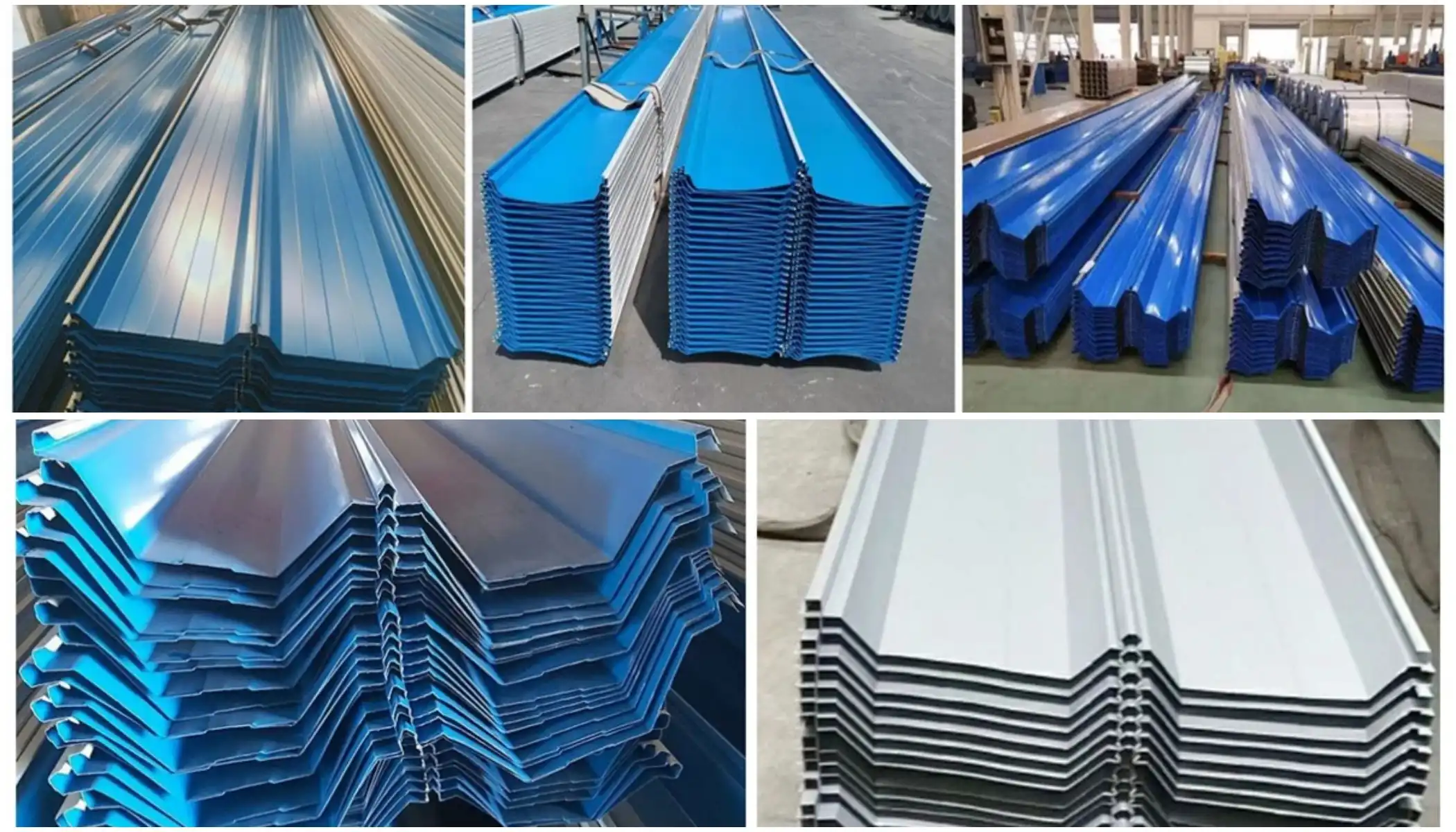

Key Advantages of HuaFeng's Angle Lock Standing Seam Roof Panels

HuaFeng Construction Engineering's angle lock solutions deliver superior performance through advanced engineering and manufacturing excellence. Our comprehensive approach addresses every aspect of commercial metal roofing requirements.

Manufacturing Excellence:

- 7 raw material production lines ensuring consistent panel quality and dimensional accuracy

- Over 20 specialized plate production machines supporting high-volume project requirements

- Advanced color coating systems providing durable finishes with 30-year warranty protection

- ISO9001 and ISO14000:14001 certifications guaranteeing international quality standards

Technical Innovation:

- 20+ registered patents demonstrating continuous product development and improvement

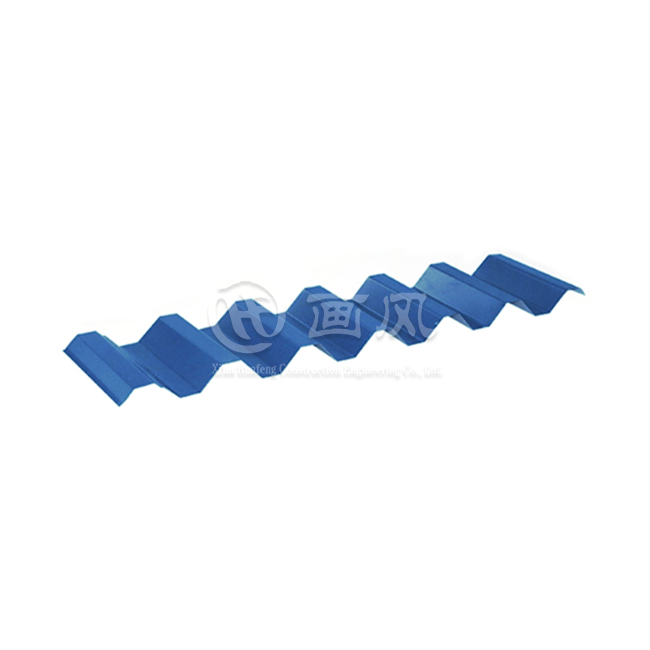

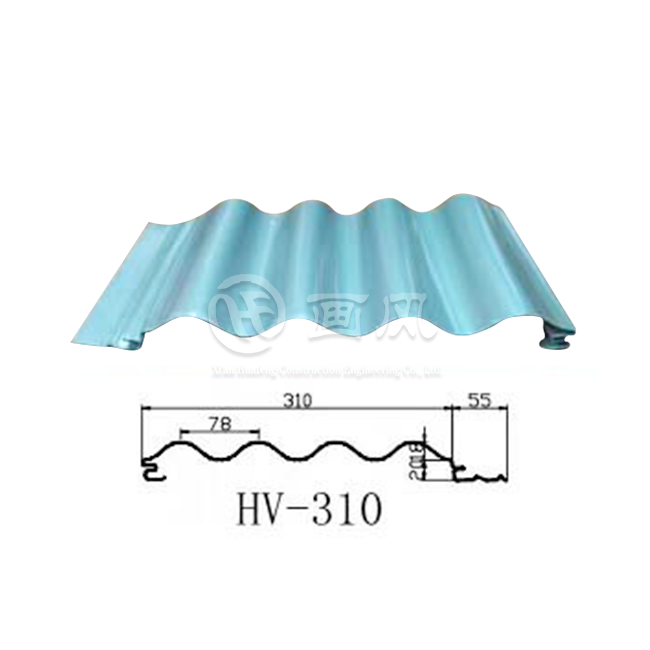

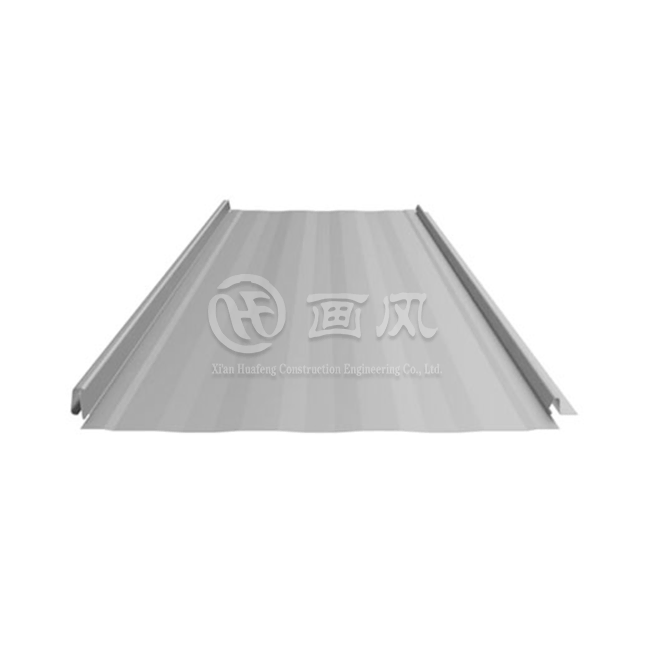

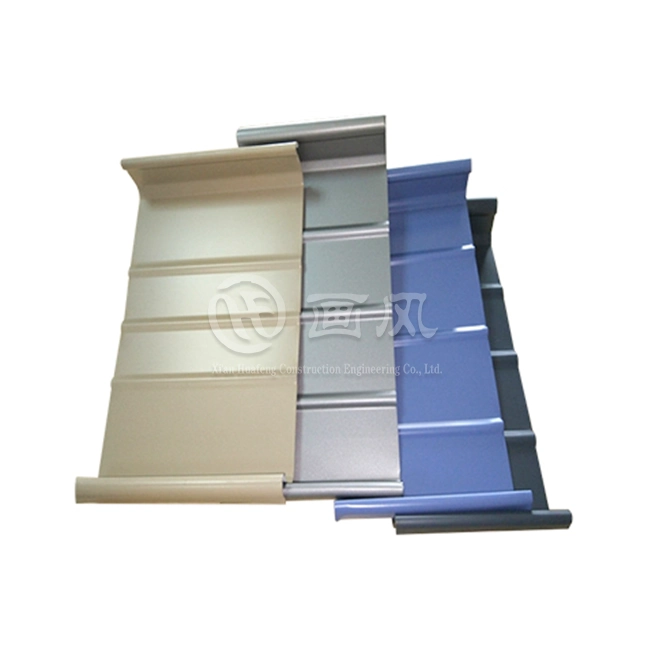

- Customizable panel widths from 300mm to 600mm accommodating diverse architectural requirements

- Panel lengths up to 13 meters eliminating transverse seams and potential leak points

- Multiple material options including aluminum alloy, alu-zinc steel, and stainless steel configurations

Performance Capabilities:

- Superior corrosion resistance through specialized surface treatments and protective coatings

- Enhanced structural strength with rib heights ranging from 50mm to 115mm

- Excellent thermal expansion accommodation reducing maintenance requirements

- Simplified installation procedures reducing labor costs and project timelines

Service and Support:

- Comprehensive design assistance ensuring optimal system specification for project requirements

- Complete accessory packages providing single-source procurement convenience

- Technical support throughout installation and commissioning phases

- Global export experience serving over 100 countries with diverse building code requirements

Quality Assurance:

- Grade 1 building curtain wall qualification demonstrating technical expertise and capability

- Grade 3 steel structure certification ensuring structural engineering competence

- Rigorous quality control systems monitoring every production stage

- CE, ISO, and SGS certifications providing international standards compliance

Customization Flexibility:

- RAL color matching and custom color development capabilities

- Material thickness options from 0.7mm to 1.2mm supporting various load requirements

- Specialized finishes including PE, HDP, and PVDF coating systems

- Project-specific engineering and design optimization services

Delivery and Logistics:

- 1000 ton monthly production capacity supporting large-scale project requirements

- 15-20 day delivery schedules enabling accelerated project timelines

- Secure packaging systems ensuring product protection during transportation

- Global logistics network facilitating international project support

Value Engineering:

- Cost-effective solutions without compromising performance or quality standards

- Life-cycle cost optimization through durable materials and simplified maintenance

- Energy-efficient manufacturing processes supporting sustainable building practices

- Competitive pricing structures supporting project budget requirements

Our angle lock systems combine proven performance with innovative design features. Each panel undergoes comprehensive testing ensuring compliance with international building codes and performance standards.The mechanical locking mechanism provides reliable weather protection while accommodating building movement and thermal expansion. This design flexibility reduces maintenance requirements and extends system service life.HuaFeng's commitment to quality extends beyond manufacturing to encompass complete project support. Our technical team assists with system design, specification development, and installation guidance ensuring optimal project outcomes.

Conclusion

Selecting between Angle Lock Standing Seam Roof Panels and double lock standing seam systems requires careful consideration of project-specific requirements, performance expectations, and long-term value objectives. Angle lock systems excel in applications prioritizing installation efficiency, maintenance accessibility, and thermal expansion accommodation. Double lock systems provide maximum weather protection for critical applications where seam integrity takes precedence over installation convenience.Both systems deliver excellent performance when properly specified and installed by qualified contractors. The decision should reflect specific project requirements rather than general system preferences. Professional consultation with experienced manufacturers like HuaFeng ensures optimal system selection and successful project outcomes for any commercial or institutional roofing application.

Choose HuaFeng for Your Next Angle Lock Standing Seam Roof Panels Project

Leading contractors and developers worldwide trust HuaFeng as their preferred Angle Lock Standing Seam Roof Panels supplier for demanding commercial and institutional projects. Our integrated manufacturing capabilities, technical expertise, and comprehensive support services ensure successful project delivery from concept through completion. With proven experience in transportation hubs, government facilities, and large-scale commercial developments, HuaFeng delivers the quality and reliability your projects demand. Contact our technical team at huafeng@hfmetalroof.com to discuss your specific requirements and discover why industry professionals choose our advanced metal roofing solutions.

References

1."Standing Seam Metal Roof Systems: Performance Comparison and Selection Criteria" - American Institute of Steel Construction Technical Manual, 2023

2."Weather Resistance Testing of Commercial Metal Roofing Systems" - International Code Council Evaluation Service Report, 2022

3."Thermal Expansion Characteristics in Standing Seam Metal Roofing" - Building Research Institute Technical Publication, 2023

4."Installation Cost Analysis: Angle Lock vs Double Lock Metal Roofing Systems" - National Roofing Contractors Association Study, 2022

5."Lifecycle Performance Evaluation of Commercial Metal Roofing Systems" - Construction Industry Research Foundation Report, 2023

6."Metal Roofing System Selection for Large Scale Commercial Projects" - Society of Professional Engineers Technical Bulletin, 2022