Industrial facility managers face a critical challenge: choosing roofing materials that can withstand decades of harsh conditions while maintaining structural integrity and cost efficiency. When your warehouse roof fails during peak production season, or when corrosion compromises your facility's protection, the financial losses and operational disruptions can be devastating. The best ibr corrugated roofing sheets solve these pain points by delivering exceptional strength, weather resistance, and longevity specifically engineered for demanding industrial environments where failure is not an option.

Understanding IBR Corrugated Roofing Sheets for Industrial Applications

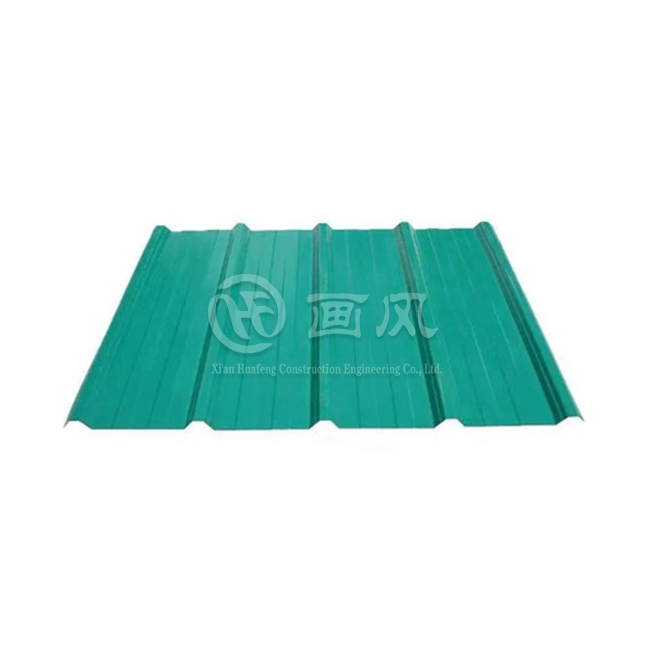

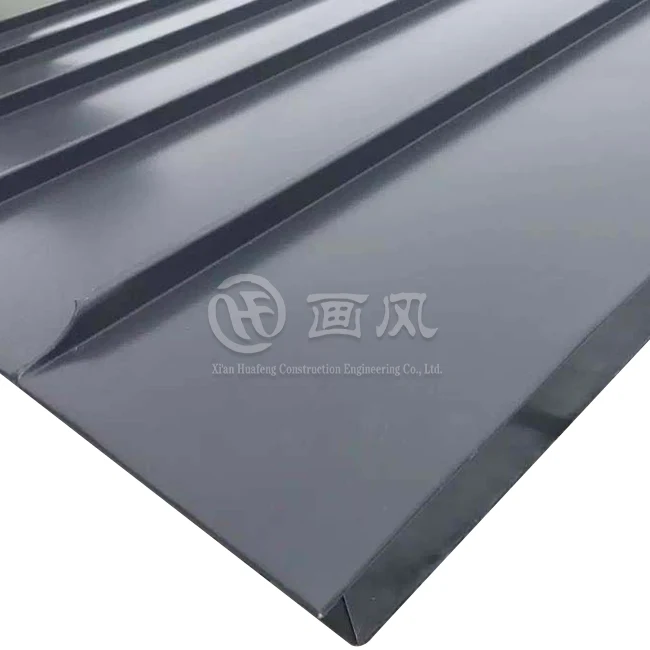

Industrial construction projects demand roofing solutions that go beyond basic protection. IBR corrugated roofing sheets, also known as Inverted Box Rib profiles, represent a significant advancement in metal roofing technology specifically designed to address the unique challenges of large-scale industrial facilities. The distinctive square-fluted profile of these ibr corrugated sheets creates a structural advantage that traditional corrugated profiles simply cannot match. The inverted box rib design functions as a series of miniature I-beams running the entire length of each sheet, dramatically increasing load-bearing capacity and spanning capabilities. This engineering innovation allows industrial facilities to reduce the number of structural supports required, lowering overall construction costs while maintaining superior strength. The deep ribs create definitive water channels that ensure rapid drainage, preventing the capillary action and water pooling that frequently plague industrial roofs and lead to premature failure and costly leak repairs.

Technical Specifications and Material Composition

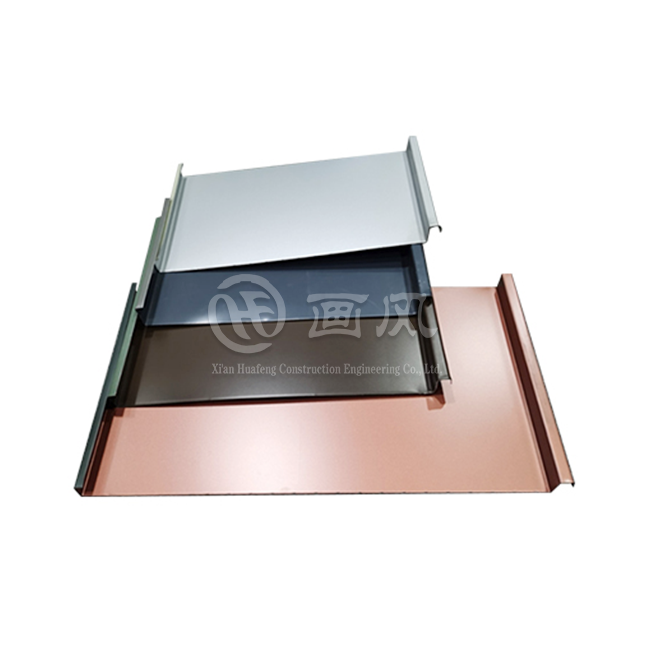

The performance characteristics of IBR corrugated roofing sheets derive from carefully engineered specifications that balance strength, durability, and practical installation requirements. Industrial-grade ibr corrugated sheets typically feature thickness ranges from 0.4mm to 1.2mm, with the most common industrial applications utilizing 0.47mm to 0.60mm gauges. This thickness variation allows engineers to precisely match material specifications to specific load requirements, purlin spacing, and environmental conditions. The effective coverage width generally ranges from 750mm to 1100mm, with 762mm and 686mm being the most prevalent in industrial applications. This width standardization facilitates efficient installation while ensuring proper overlap and weather sealing. The wave height typically measures between 30mm and 75mm, creating sufficient depth for effective water drainage while maintaining structural rigidity. Material composition plays an equally critical role in long-term performance. High-quality IBR corrugated roofing sheets utilize base materials including galvanized steel with zinc coating protection, galvalume steel combining zinc and aluminum for enhanced corrosion resistance, and color-coated steel with advanced protective coatings. The coating systems available include polyester coatings for standard protection, silicon-modified polyester for improved durability, and PVDF coatings for maximum weather resistance and color retention in harsh industrial environments.

Structural Performance Advantages for Industrial Facilities

The structural performance characteristics of IBR corrugated roofing sheets make them particularly suitable for the demanding conditions encountered in industrial roof projects. The corrugated structure significantly improves longitudinal bearing capacity, delivering excellent compression and bending resistance that allows these sheets to span greater distances between purlin supports compared to alternative roofing materials. This spanning capability can reduce overall structural steel requirements by up to thirty percent in some applications, translating directly to lower construction costs. Corrosion resistance represents another critical performance factor for industrial facilities, where exposure to chemicals, moisture, and atmospheric pollutants can rapidly degrade inferior roofing materials. The galvanized layer or advanced coating protection enables IBR corrugated roofing sheets to achieve service lifespans ranging from fifteen to thirty years depending on environmental conditions and maintenance practices. The waterproofing performance of these sheets stems from their large wave spacing design, which effectively guides rainwater away from the structure and prevents leakage at overlap joints when properly installed with appropriate sealants. Wind resistance capabilities allow properly installed ibr corrugated sheets to withstand typhoon-force winds exceeding level twelve on the Beaufort scale through mechanical interlocking or secure screw fixation to the purlin system. Fire safety represents another crucial consideration for industrial facilities, and the metal composition of IBR corrugated roofing sheets provides inherent fireproof properties with a Class A fire rating, offering superior protection compared to combustible roofing alternatives.

Installation Methodology and Best Practices

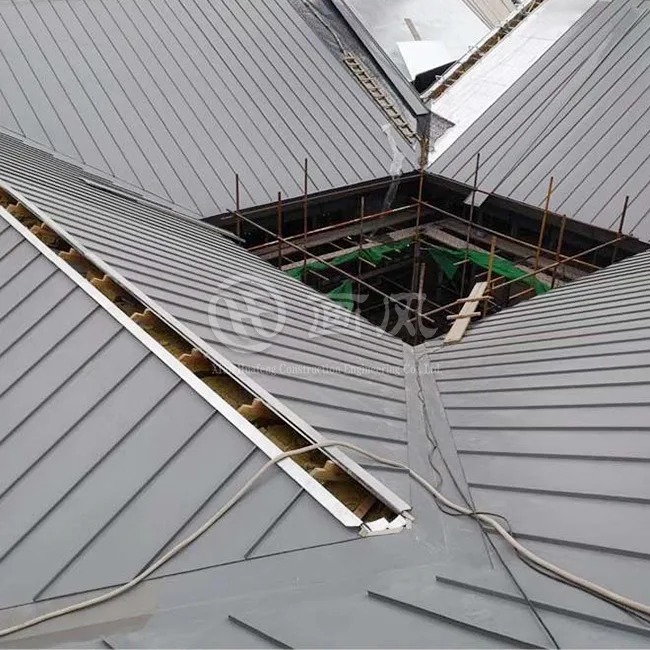

Successful industrial roofing projects require not only superior materials but also proper installation methodology that ensures long-term performance and weather protection. The lightweight design of IBR corrugated roofing sheets, typically weighing only five to ten kilograms per square meter, facilitates easier handling and faster installation compared to heavier roofing materials, reducing labor costs and project timelines. The sheets can be cut and drilled directly on-site using standard metalworking tools, allowing installers to adapt quickly to field conditions and architectural details. The fixing method employed significantly impacts the long-term weathertightness and durability of the roofing system. Industrial applications typically utilize self-tapping screws equipped with waterproof EPDM bonded washers to create watertight penetrations through the sheet profile. These fasteners must be installed through the crests of the corrugations at specified intervals, typically securing through every second crest on internal purlins and every crest at eaves and ridge locations. Hidden fastener systems offer an alternative approach for applications where aesthetics matter more, reducing visible penetrations and minimizing potential leak points. The overlap requirements for IBR corrugated roofing sheets follow established engineering standards to ensure weather protection. Longitudinal overlaps must extend at least two hundred millimeters, with sealant application required when roof slopes fall below ten degrees to prevent water infiltration. Horizontal overlaps typically span one to two corrugation peaks, secured with stitching screws at five hundred millimeter centers between purlins. Proper installation requires specialized tools including electric screwdrivers with adjustable torque settings to prevent over-tightening that can damage washers, accurate tape measures for precise layout, and metal cutting scissors or shears for clean edge cuts that maintain corrosion protection.

Quality Control During Installation

Industrial roofing projects demand rigorous quality control throughout the installation process to ensure the completed system meets performance specifications and warranty requirements. Pre-installation site preparation includes verifying that the purlin system meets design specifications for spacing, alignment, and levelness, as improper structural substrate preparation invariably leads to installation problems and potential performance issues. Each sheet should be visually inspected before installation to identify any manufacturing defects, coating damage, or dimensional irregularities that could compromise performance. During installation, experienced crews continuously monitor fastener placement, ensuring that screws penetrate through corrugation crests at proper angles perpendicular to the sheet surface, avoiding over-driven fasteners that compress washers excessively or under-driven fasteners that fail to create weathertight seals. Overlap alignment requires careful attention, with installers verifying that side laps maintain narrow flute uppermost orientation and that horizontal laps achieve specified minimum overlap dimensions. Upon completion, comprehensive water testing should be conducted before final acceptance, with particular attention to valley areas, penetrations, and transition details where leaks most commonly develop. This systematic approach to quality control during installation significantly extends the service life of IBR corrugated roofing sheets and minimizes maintenance requirements throughout the facility's operational lifetime.

Selecting the Right IBR Corrugated Sheets for Your Industrial Project

The selection process for IBR corrugated roofing sheets requires careful evaluation of multiple factors that influence both initial performance and long-term durability. Environmental conditions at the project location represent the primary consideration, as coastal areas with salt-laden air demand higher corrosion resistance than inland locations, typically requiring galvalume or zinc-aluminum coatings with additional protective paint systems. Industrial facilities located in regions with heavy snowfall require thicker gauge sheets capable of supporting accumulated snow loads without deflection or permanent deformation. High-wind zones necessitate enhanced fastening specifications and potentially heavier gauge materials to resist uplift forces. The structural requirements of the specific building design influence material selection significantly. Purlin spacing directly impacts the minimum sheet thickness required, with wider spans demanding heavier gauges to prevent excessive deflection. Buildings designed with longer roof spans between supports benefit from the superior spanning capabilities of IBR corrugated roofing sheets, but must specify appropriate thickness to ensure adequate structural performance. The intended building use also factors into the selection process, as facilities housing temperature-sensitive operations may benefit from reflective coating systems that reduce solar heat gain, while facilities with corrosive process emissions require enhanced coating protection. Budget considerations naturally influence material choices, but focusing exclusively on initial material cost often proves counterproductive when lifecycle costs including maintenance, energy efficiency, and longevity are properly evaluated. High-quality IBR corrugated roofing sheets with superior coatings and appropriate thickness typically deliver lower total cost of ownership despite higher initial investment.

Customization Options and Technical Support

Modern manufacturing capabilities enable extensive customization of IBR corrugated roofing sheets to meet specific project requirements. Length customization allows sheets to be produced in dimensions ranging from one meter to thirteen meters, enabling installers to minimize horizontal joints and reduce potential leak points. Custom lengths also reduce material waste and installation time by eliminating the need for field cutting on standard-length sheets. Color customization provides industrial facility managers with the ability to match corporate branding, improve aesthetic appeal, or implement color-coding systems for different building sections or functions. Advanced coating systems offer color choices spanning the entire RAL color spectrum, with options for glossy or matte finishes depending on architectural preferences. Pattern customization extends beyond simple corrugation profiles to include specialized embossed textures that enhance aesthetic appeal while maintaining structural performance. Design customization services provided by experienced manufacturers like Xi'an Huafeng Construction Engineering Co., Ltd. include comprehensive engineering support that begins with detailed analysis of architectural drawings, structural calculations for load-bearing requirements, and drainage system simulation to verify adequate water management. Technical teams work directly with project architects and engineers to optimize material specifications, minimize costs while maintaining performance standards, and ensure compatibility with other building envelope components. This collaborative approach to customization and technical support transforms the material selection process from a simple procurement transaction into a value-added engineering partnership that enhances project outcomes.

Manufacturing Excellence and Quality Assurance

The quality and performance of IBR corrugated roofing sheets depends fundamentally on manufacturing excellence throughout the production process. Advanced production facilities incorporate multiple quality control checkpoints that verify material specifications, dimensional accuracy, and coating integrity. The manufacturing process begins with careful material procurement, where purchasing departments maintain approved vendor lists and require certified material test reports documenting chemical composition, mechanical properties, and coating characteristics. Incoming material inspection represents the first critical quality control point, where samples from each material lot undergo rigorous testing including appearance inspection to identify surface defects, dimensional verification to confirm thickness and width specifications, salt spray testing to evaluate corrosion resistance, adhesion testing to verify coating bonding strength, hardness testing to confirm material properties, impact resistance testing, film thickness measurement, acid resistance evaluation, weather resistance assessment, and color difference analysis to ensure consistency. These comprehensive inspection procedures prevent defective materials from entering the production stream, eliminating the costly problems that arise when substandard materials are discovered only after installation. The roll-forming production process itself incorporates real-time quality monitoring systems that continuously verify profile dimensions, corrugation accuracy, and surface finish quality. Modern production lines feature automated measurement systems that detect dimensional variations immediately, allowing operators to make instantaneous adjustments that maintain tight tolerances throughout production runs.

Finished Product Inspection and Packaging Standards

After completion of the roll-forming process, finished IBR corrugated roofing sheets undergo additional inspection procedures before packaging and shipment. Quality assurance personnel conduct thorough product appearance inspections to identify any surface scratches, coating damage, or cosmetic imperfections that could compromise performance or aesthetics. Dimensional inspection verifies that length, width, and profile specifications match customer requirements and industry standards. Flatness measurements detect any warping or twisting that could complicate installation or compromise weather sealing. Curvature assessment ensures that sheets maintain proper profile geometry without excessive deviation that could prevent proper nesting and overlap. Packaging methodology significantly impacts product condition upon delivery to the construction site. To facilitate efficient on-site handling and installation, finished products are typically divided into sections according to the roof plan, with each bundle containing sheets designated for a specific building area. Product identification cards attached to the outer packaging include detailed information such as section plans showing exactly where each bundle's contents should be installed, comprehensive product number lists for inventory verification, and material specifications for quality control confirmation. This systematic packaging approach eliminates confusion during installation, reduces material handling time, and minimizes the risk of installing incorrect materials in wrong locations. Secure packaging utilizing protective wrapping, sturdy banding, and appropriate blocking ensures that sheets arrive at the construction site in pristine condition, ready for immediate installation without damage-related delays or rejection.

Project Success Through Comprehensive Service

Industrial roofing projects achieve optimal outcomes when material supply is complemented by comprehensive design, engineering, and installation support services. Xi'an Huafeng Construction Engineering Co., Ltd. exemplifies this integrated service approach through their one-stop solution methodology that encompasses every phase of the project lifecycle. The design phase begins with thorough analysis of complete architectural engineering drawings, including floor plans, elevations, and node diagrams. Engineering teams identify feasible alternatives for different roof sections, considering factors such as slope requirements, structural loading, drainage patterns, and aesthetic objectives. Through collaborative communication with customers, the design team determines the most appropriate roof panel type for each area of the project, balancing performance requirements with budget constraints. Following material selection, the design department conducts detailed drawing development at one-to-one scale, creating comprehensive node details for different roof sections that address every installation condition including ridge connections, eave details, valley configurations, penetration flashings, and expansion joints. This detailed engineering work continues through multiple communication cycles until both parties achieve complete agreement, culminating in signed and sealed drawings that become the contractual basis for manufacturing and installation. Factory processing sample production represents another critical service component that eliminates misunderstandings and ensures customer satisfaction. Sample panels are produced based on confirmed parameters including board type, material composition, thickness specifications, surface treatment methodology, and color selection. After customer confirmation of size, material properties, color accuracy, and other parameters, the sample is sealed and retained as the definitive standard for subsequent production, inspection, and acceptance procedures.

On-Site Support and Long-Term Maintenance

The value of comprehensive service extends beyond design and manufacturing to encompass on-site installation support and long-term maintenance guidance. Installation technicians visit construction sites in advance of material delivery to inspect work areas, verify that structural substrate meets specifications, and confirm that all necessary tools and auxiliary materials are available including specialized pliers, edge-locking machines, appropriate hammers, rivets, structural adhesive, screws, and various accessories. Pre-installation meetings bring together construction teams to thoroughly review work details, discuss critical quality points, and emphasize safety precautions. Throughout the installation process, experienced technicians provide guidance ensuring that proper techniques are followed, fasteners are correctly installed, overlaps meet specifications, and weathertightness is maintained. Upon installation completion, comprehensive on-site testing verifies zero-leakage performance before final acceptance. The customer review and acceptance process includes detailed inspection of the completed installation interface, with formal sign-off completing the acceptance procedures and initiating warranty coverage. Long-term maintenance guidance provided to customers or designated personnel ensures that the roofing system continues delivering optimal performance throughout its service life. Regular inspection protocols identify potential issues before they escalate into costly problems, cleaning procedures remove debris and contaminants that could compromise performance, and preventive maintenance activities extend system lifespan while minimizing lifecycle costs.

Conclusion

Industrial roof projects demand IBR corrugated roofing sheets that combine superior structural performance, exceptional durability, and reliable weather protection backed by comprehensive technical support throughout the project lifecycle.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in Shaanxi Province, China in 2018, stands as a leading China IBR corrugated roofing sheets manufacturer, China IBR corrugated roofing sheets supplier, and China IBR corrugated roofing sheets factory specializing in metal roofing systems, building curtain wall systems, and steel structure enclosure solutions. Recognized as a high-tech enterprise in Shaanxi Province in 2020, we hold first-level qualification for building curtain walls and third-level qualification for building steel structures. Our extensive manufacturing infrastructure includes a raw material production plant covering 200,000 square meters in Anhui, plus two plate and accessories processing plants located in Hangzhou and Xi'an. With seven color coating production lines, one laminating production line, ten longitudinal and transverse shearing production lines, fully automatic punching production lines, and more than forty shearing machines, presses, and bending machines, we maintain production capacity exceeding 1,000 tons per month. Our product portfolio features standing seam metal roofing panels, aluminum-magnesium-manganese plates, titanium-zinc plates, standing seam metal wall sheets, corrugated roofing and wall sheets, flat lock panels, roofing system accessories, and color aluminum and steel coils. We provide China IBR corrugated roofing sheets wholesale with High Quality IBR corrugated roofing sheets for sale at competitive IBR corrugated roofing sheets price points. Our comprehensive one-stop service encompasses custom engineering design with structural 3D modeling and load analysis, drainage system simulation, precision manufacturing with roll-forming systems and real-time quality control, and seamless installation with on-site project management and safety compliance documentation. We proudly maintain more than twenty registered patents for roofing systems, multiple trademark registrations, computer software certificates, and certifications including ISO9001, ISO14000:14001, and SGS guidelines compliance. Our commitment to green sustainable development drives continuous innovation in new materials and design methodologies that integrate architecture, technology, and aesthetics. Contact us today at huafeng@hfmetalroof.com to discuss your industrial roofing project requirements and discover how our expertise delivers exceptional value for your construction investment.

References

1. "Metal Roofing Materials: Selection and Specification Guide for Industrial Applications" by Johnson, R.T., American Society of Civil Engineers Press, 2023

2. "Structural Performance of Corrugated Steel Roofing Systems Under Environmental Loading" by Chen, L. and Williams, M.K., Journal of Structural Engineering, Volume 149, Issue 8, 2024

3. "Corrosion Protection Systems for Metal Building Envelopes in Industrial Environments" by Anderson, P.J., National Association of Corrosion Engineers, 2023

4. "Design Guidelines for Metal Roof and Wall Systems" by Thompson, D.R., Metal Construction Association Technical Manual, Fourth Edition, 2024

5. "Life Cycle Cost Analysis of Industrial Roofing Materials" by Martinez, S.A. and Brown, K.L., Building Research and Information Journal, Volume 52, Issue 3, 2025

(1)_1763110678300.webp)