Choosing the wrong metal cladding system can cost you thousands in maintenance and compromise your building's aesthetic appeal. When architects and contractors face facade design decisions, the debate between flat lock metal wall sheets and corrugated metal becomes critical. Flat Lock Metal Wall Sheets offer a seamless, monolithic appearance with concealed fasteners, creating contemporary architectural statements, while corrugated metal provides cost-effective durability with visible wave patterns. Understanding these fundamental differences between flat lock metal wall panels and corrugated systems helps you select the optimal cladding solution for your specific project requirements, budget constraints, and long-term performance expectations.

Understanding Flat Lock Metal Wall Sheets: Premium Architectural Cladding

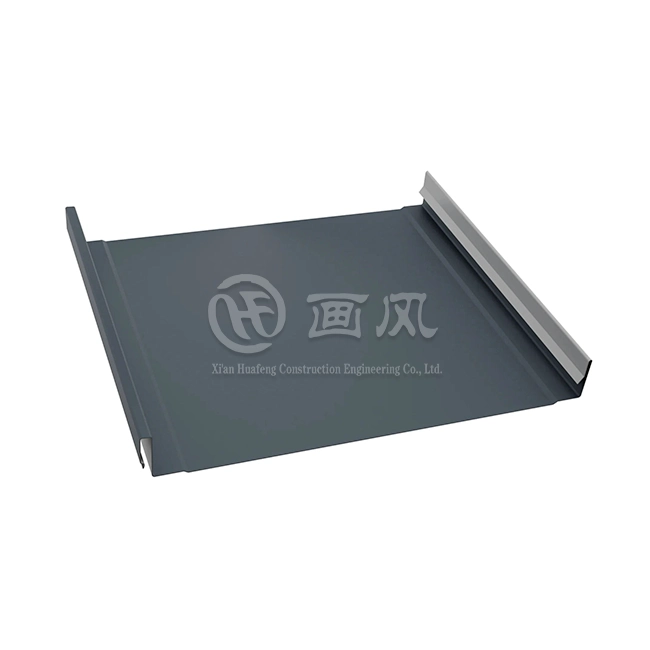

Flat lock metal wall panels represent a sophisticated architectural cladding system engineered for projects demanding exceptional aesthetics and weather resistance. These precision-manufactured panels create flush, seamless surfaces through an interlocking hook seam mechanism that eliminates visible fasteners. The system delivers a monolithic appearance highly valued in contemporary architecture, where clean lines and uninterrupted surfaces define modern design language. Xi'an Huafeng Construction Engineering Co., Ltd. specializes in manufacturing high-quality Flat Lock Metal Wall Sheets using advanced production techniques across three manufacturing facilities equipped with seven color coating production lines and more than forty specialized machines. The manufacturing process for flat lock metal wall panels involves precision bending and forming to create male and female interlocking edges. Installation utilizes concealed clips that secure panels to substrate structures without penetrating the visible surface. This hidden fastener approach not only enhances aesthetic appeal but significantly improves weather-tightness by eliminating potential leak points. Common materials for Flat Lock Metal Wall Sheets include aluminum-magnesium-manganese alloys, stainless steel grades 304 and 316, titanium-zinc, and copper, with thickness ranging from 0.4mm to 1.0mm depending on structural requirements and material selection. Panel widths typically span 100-400mm and can be customized to accommodate specific architectural visions.

Material Options and Performance Characteristics

Flat lock metal wall panels offer remarkable material versatility, allowing architects to specify cladding that aligns with both aesthetic vision and performance requirements. Aluminum alloys, particularly 3003, 3004, and 5052 grades, provide excellent corrosion resistance, lightweight properties, and superior formability for complex architectural shapes. These aluminum options accept various surface treatments including PVDF coatings, anodizing, and powder coating, delivering extensive color possibilities while maintaining weather resistance. Stainless steel variants, especially grades 304 and 316, offer exceptional durability and natural metallic aesthetics that develop attractive patinas over time without compromising structural integrity. Titanium-zinc and copper materials represent premium choices for flat lock metal wall panels, particularly in heritage restoration and high-end contemporary projects. Titanium-zinc develops a protective patina that enhances weather resistance while creating distinctive blue-gray aesthetics. Copper cladding transforms through natural oxidation processes, transitioning from bright metallic tones through brown phases to eventually achieve characteristic verdigris green patinas. These living finishes add temporal dimensions to architectural designs, with buildings evolving visually across decades. Xi'an Huafeng sources materials from certified suppliers including Alucosuper, YATAI, LIDAO for aluminum, BAOSTEEL for steel products, and NedZink for titanium-zinc applications, ensuring consistent quality through rigorous incoming material inspection protocols.

Installation Methods and Technical Advantages

The installation methodology for Flat Lock Metal Wall Sheets emphasizes precision and systematic execution to achieve flawless finished surfaces. Xi'an Huafeng's installation process begins with comprehensive site assessment and layout confirmation, ensuring proper substrate preparation and alignment references. Concealed clip systems are positioned according to engineering specifications, providing secure mechanical attachment while maintaining hidden fastener benefits. Panels interlock through carefully engineered male-female seam profiles, with each connection hammered or mechanically seamed to achieve weather-tight closure without visible hardware exposure. Technical advantages of flat lock metal wall panels extend beyond aesthetic considerations to encompass significant performance benefits. The concealed fastener system eliminates thermal bridging associated with through-panel penetrations, enhancing overall thermal performance of building envelopes. Weather resistance improves dramatically as interlocking seams create multiple barriers against water infiltration, while UV-resistant coatings protect against solar degradation. Maintenance requirements remain minimal throughout the system's service life, with periodic inspections and cleaning typically sufficient to maintain optimal performance. The modular nature of flat lock panels also facilitates repair or replacement of individual units without disturbing adjacent cladding, reducing long-term maintenance costs significantly.

Corrugated Metal: Traditional Durability with Distinctive Aesthetics

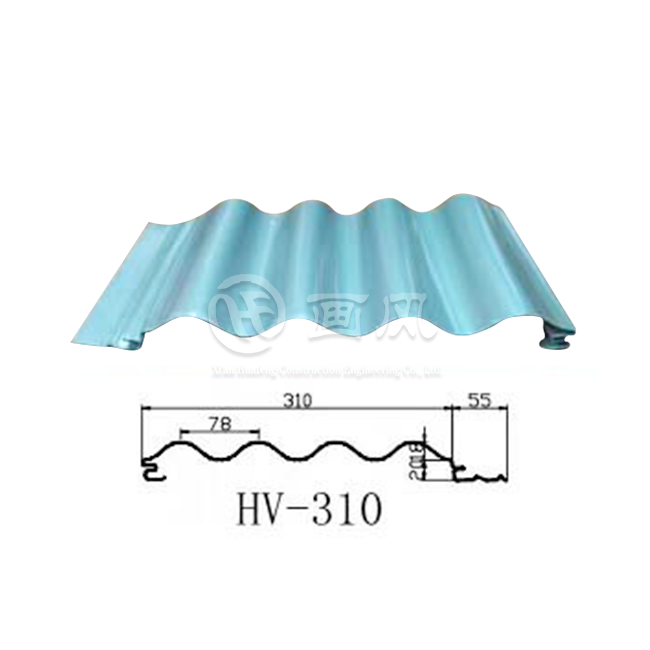

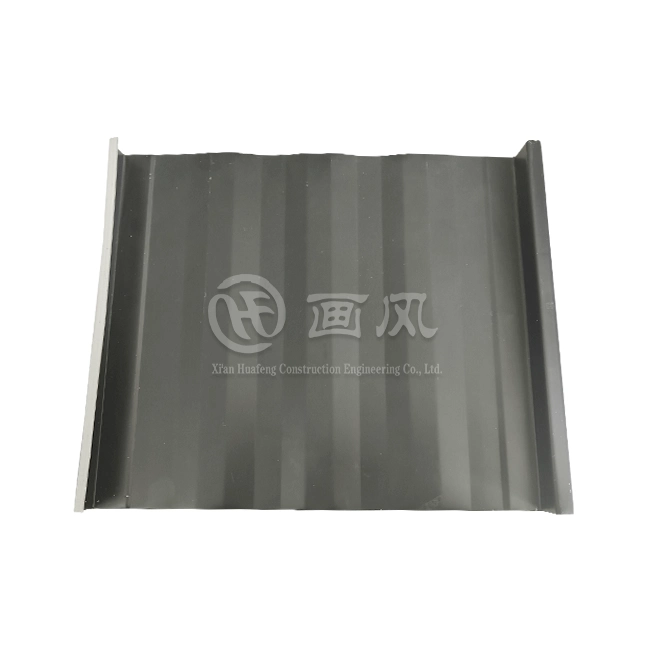

Corrugated metal roofing and wall systems have served construction industries globally for over a century, offering proven durability through distinctive wave-pattern profiles. The corrugation process creates alternating ridges and grooves through roll-forming operations, transforming flat metal coils into structurally reinforced panels. This geometric configuration enhances rigidity and load-bearing capacity without requiring thicker gauge materials, making corrugated metal economically efficient for large-scale applications. The characteristic wave pattern provides immediate visual recognition, evoking industrial, agricultural, and utilitarian architectural vocabularies that remain popular across residential, commercial, and agricultural building sectors. Manufacturing corrugated metal involves feeding metal coils through precision roll-forming machinery that progressively shapes panels into predetermined corrugation profiles. Standard profiles include rounded sinusoidal waves, trapezoidal configurations, and box-profile variations, each offering different structural properties and aesthetic expressions. Material options mirror those available for flat lock systems, including galvanized steel, galvalume-coated steel, aluminum, and color-coated variants. However, corrugated panels typically utilize somewhat lighter gauges compared to flat lock applications, with common specifications ranging from 0.5mm to 0.7mm thickness for wall applications and slightly heavier for roofing installations.

Structural Benefits and Cost Efficiency

The corrugated profile inherently provides exceptional structural strength through its geometry, allowing lighter materials to achieve impressive load-bearing performance. The alternating ridges function as continuous ribs running the panel length, dramatically increasing resistance to bending and deflection compared to equivalent flat sheets. This structural efficiency translates directly into material cost savings, as thinner gauge metals meet performance requirements that would demand heavier materials in flat configurations. For projects prioritizing budget optimization without sacrificing durability, corrugated metal delivers compelling value propositions. Installation simplicity represents another significant advantage of corrugated metal systems. Panels install through straightforward overlapping methods, with fasteners penetrating directly through panel crowns or valleys into supporting structures. This exposed fastener approach requires fewer specialized skills and tools compared to concealed fastener systems, reducing labor costs and installation timeframes. Contractors appreciate the forgiving nature of corrugated installation, where minor measurement variations prove less problematic than with precision-dependent systems like Flat Lock Metal Wall Sheets. The combination of lower material costs, simplified installation, and proven long-term performance makes corrugated metal particularly attractive for agricultural buildings, warehouses, industrial facilities, and budget-conscious residential projects.

Aesthetic Considerations and Application Contexts

Corrugated metal's visual character distinctly differs from the sleek minimalism achieved through flat lock metal wall panels. The wave pattern creates dynamic shadow lines that shift with sunlight angles, adding texture and movement to building facades. This dimensional quality appeals to design philosophies embracing industrial aesthetics, rustic architectural vocabularies, or contexts where traditional barn and warehouse character aligns with programmatic intentions. Contemporary architects increasingly specify corrugated metal for its authentic material expression, particularly in adaptive reuse projects or designs intentionally contrasting refined materials with more robust, utilitarian cladding systems. However, the exposed fastener requirement inherent to corrugated metal installation presents aesthetic and maintenance considerations absent from Flat Lock Metal Wall Sheets. Fastener heads remain visible across the cladding surface, creating regular patterns that some consider detracting from visual refinement. Color-matched fastener caps help mitigate this visual impact but cannot completely eliminate fastener visibility. More significantly, penetrations through panels create potential failure points where water infiltration, thermal expansion, and fastener degradation may compromise long-term performance. Proper installation with appropriate gaskets and regular maintenance inspections prove essential to preventing leaks and maintaining system integrity throughout service life.

Critical Performance Comparisons: Weather Resistance and Longevity

Weather resistance capabilities differ substantially between flat lock metal wall panels and corrugated metal systems, primarily due to their contrasting fastening methodologies. Flat Lock Metal Wall Sheets employ concealed clip attachment systems where no fasteners penetrate the visible cladding surface. This design philosophy eliminates the most common failure mode affecting metal cladding systems—fastener deterioration and associated water infiltration. The interlocking seam profiles create labyrinth-style barriers that redirect water away from potential entry points, while properly executed installations effectively achieve zero-leakage performance even under extreme weather conditions including wind-driven rain and sustained moisture exposure. Corrugated metal's through-panel fastening represents an inherent vulnerability requiring careful installation technique and ongoing maintenance attention. Each fastener penetration creates a potential pathway for water infiltration, particularly as gaskets age, fasteners loosen through thermal cycling, or corrosion degrades metal-to-metal contact surfaces. While properly installed corrugated systems with high-quality fasteners and gaskets perform adequately under normal conditions, they remain fundamentally more vulnerable to weather-related failure compared to concealed fastener alternatives. This vulnerability becomes increasingly significant in coastal environments, areas experiencing severe storms, or applications where building orientation creates particularly challenging water management conditions.

Maintenance Requirements and Life-Cycle Costs

Long-term maintenance demands diverge significantly between these cladding approaches, directly impacting total ownership costs across building lifespans. Flat lock metal wall panels require minimal maintenance beyond periodic cleaning to remove accumulated dirt and environmental deposits. The absence of exposed fasteners eliminates ongoing inspection and replacement needs associated with gasket deterioration and fastener corrosion. Surface finishes like PVDF coatings maintain color stability and weather resistance for decades without requiring refinishing. Xi'an Huafeng provides 30-year warranties on Flat Lock Metal Wall Sheets, reflecting confidence in long-term performance and minimal maintenance requirements. Corrugated metal systems demand more active maintenance protocols to ensure sustained performance. Regular inspections should verify fastener integrity, checking for loose connections, deteriorated gaskets, and corrosion at penetration points. Fastener replacement becomes necessary as gaskets compress, weather exposure degrades materials, or thermal cycling loosens connections. Depending on environmental conditions and initial installation quality, significant fastener maintenance may become necessary within 10-15 years of initial installation. While individual fastener replacement costs remain modest, the cumulative expense across large cladding areas plus associated labor costs contribute to higher life-cycle expenditures compared to concealed fastener systems. For projects requiring minimal long-term maintenance interventions, Flat Lock Metal Wall Sheets deliver superior value despite higher initial costs.

Design Flexibility and Architectural Applications

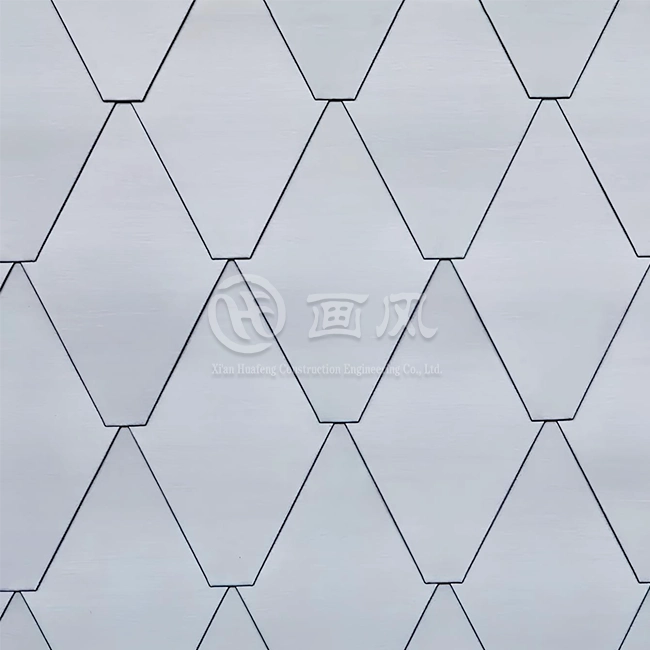

Architectural design flexibility represents a decisive factor when selecting between flat lock metal wall panels and corrugated alternatives, particularly for projects prioritizing aesthetic innovation and contemporary visual languages. Flat Lock Metal Wall Sheets accommodate extensive customization including rectangular, rhombus, trapezoid, and hexagonal panel configurations that enable creative pattern development and facade articulation. Architects can specify varying panel sizes, surface finishes, and material combinations to achieve unique visual effects impossible with standardized corrugated profiles. The flush surface created by interlocking flat panels provides ideal canvases for additional architectural treatments including perforations, embossing, and integrated shading devices. Notable architectural applications demonstrate the design potential of Flat Lock Metal Wall Sheets across diverse building typologies. The Louvre Abu Dhabi utilized 316L stainless steel flat lock panels for its iconic dome structure, with precision CNC cutting enabling complex geometric patterns creating the signature "rain of light" effect. Apple retail stores globally employ anodized aluminum flat lock systems achieving ultra-thin, monolithic appearances that reinforce brand identity through minimalist design language. The Whitney Museum in New York selected pre-weathered zinc flat lock cladding for its rain screen system, with angled panels creating dynamic shadow play enhancing the building's sculptural presence. These precedents illustrate how Flat Lock Metal Wall Sheets serve as premium architectural tools for projects where design excellence justifies investment in sophisticated cladding systems.

Corrugated metal finds optimal application in contexts valuing functional performance, cost efficiency, and industrial aesthetic character over refined minimalism. Agricultural buildings, warehouses, storage facilities, and utilitarian structures benefit from corrugated metal's structural efficiency and straightforward installation. Contemporary architects also specify corrugated cladding for residential projects embracing rustic or industrial design vocabularies, adaptive reuse developments maintaining heritage character, or compositions intentionally juxtaposing refined materials with more utilitarian elements. The textured surface and shadow patterns created by corrugation add visual interest in contexts where sleek minimalism might appear sterile or disconnected from site character.

Conclusion

Flat Lock Metal Wall Sheets and corrugated metal serve distinct architectural purposes, with selection depending on project priorities balancing aesthetics, performance, and budget. Flat lock systems deliver premium concealed-fastener elegance, superior weather resistance, and minimal maintenance for contemporary designs, while corrugated metal provides cost-effective durability with distinctive industrial character for functional applications.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a China Flat Lock Metal Wall Sheets factory, China Flat Lock Metal Wall Sheets supplier, and China Flat Lock Metal Wall Sheets manufacturer offering exceptional value through integrated design-production-installation capabilities. Established in 2018 and recognized as a Shaanxi Province high-tech enterprise with first-level building curtain wall qualifications and third-level steel structure certifications, we deliver High Quality Flat Lock Metal Wall Sheets through our 200,000-square-meter Anhui production facility and processing plants in Hangzhou and Xi'an. Our seven color coating production lines, ten shearing production lines, and more than forty specialized machines enable China Flat Lock Metal Wall Sheets wholesale production capacity exceeding 1,000 tons monthly with competitive Flat Lock Metal Wall Sheets prices.

Our one-stop service encompasses custom metal roof engineering with structural 3D modeling and drainage simulation, precision manufacturing with real-time quality control and raw material traceability from certified suppliers including BAOSTEEL and NedZink, and seamless installation with on-site project management ensuring zero-leakage performance. We provide design optimization, customized production accommodating unique specifications, and comprehensive quality testing including salt spray, adhesion, hardness, and weather resistance verification. With more than twenty registered patents, ISO9001, ISO14000:14001, and SGS certifications, plus successful project delivery for Xiongan Station, Xi'an International Convention Center, and numerous landmark structures, we offer Flat Lock Metal Wall Sheets for sale backed by 30-year warranties and Fortune 500 company collaboration experience. Contact us at huafeng@hfmetalroof.com to discuss your project requirements and discover how our expertise transforms architectural visions into enduring reality.

References

1. Newman, M. & Richardson, P. (2022). Modern Metal Cladding Systems: Design and Installation Practices. Architectural Press

2. Chen, L., Wang, H., & Zhang, Y. (2023). Performance Comparison of Concealed versus Exposed Fastener Metal Wall Systems. Journal of Building Envelope Design, 18(3), 245-262

3. Thompson, R. (2021). Metal Architecture: Materials, Fabrication and Details. Construction Publishing International

4. Anderson, K. & Martinez, S. (2024). Life-Cycle Cost Analysis of Premium Architectural Metal Cladding. Building Economics Review, 29(1), 78-95

5. Liu, J., Kumar, A., & Patel, D. (2023). Contemporary Facade Engineering: Technical Guide to Metal Panel Systems. International Construction Standards Institute