When extreme weather strikes your building, the last thing you want is to discover structural damage, water infiltration, or deteriorating exterior walls. For property owners facing relentless rain, scorching heat, freezing temperatures, or corrosive coastal environments, Aluminum Metal Siding Panels for Harsh Weather Protection provide a battle-tested solution that combines engineering excellence with long-term durability. These advanced facade systems are specifically engineered to withstand nature's most challenging conditions while maintaining aesthetic appeal and structural integrity for decades.

Why Aluminum Metal Siding Panels Are Essential for Extreme Climate Protection?

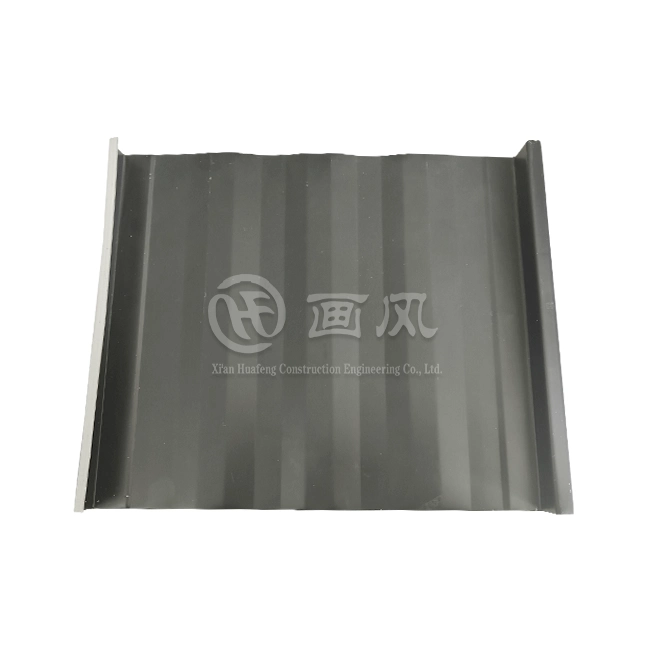

Building owners in harsh climates face unique challenges that ordinary siding materials simply cannot handle. Aluminum Metal Siding Panels offer superior performance where other materials fail, providing comprehensive protection against multiple environmental threats simultaneously. Unlike traditional siding options that may crack under freeze-thaw cycles, warp in intense heat, or corrode in salty air, aluminum alloy panels maintain their structural integrity across temperature extremes ranging from minus forty degrees to over one hundred twenty degrees Fahrenheit. The inherent properties of aluminum make it exceptionally suited for weather protection applications. When exposed to oxygen, aluminum forms a protective aluminum oxide layer that acts as a self-healing barrier against further corrosion. This natural oxidation process differs fundamentally from steel corrosion, where rust continuously expands and flakes off, exposing fresh metal to degradation. The aluminum oxide coating remains stable and protective, effectively halting the corrosion process at the surface level. This unique characteristic ensures that Aluminum Metal Siding Panels maintain their protective capabilities throughout their service life, even in aggressive marine environments or industrial areas with high pollution levels. Modern manufacturing techniques have further enhanced the weather resistance of these panels. Advanced coating systems including polyester, high-durability polyester, and polyvinylidene fluoride provide additional layers of protection against ultraviolet radiation, acid rain, and atmospheric pollutants. These multi-layer coating systems are applied using precision color coating production lines that ensure uniform thickness and complete coverage, creating a comprehensive barrier that protects both the aluminum substrate and the building structure behind it.

Engineering Advantages of Aluminum Alloy Construction

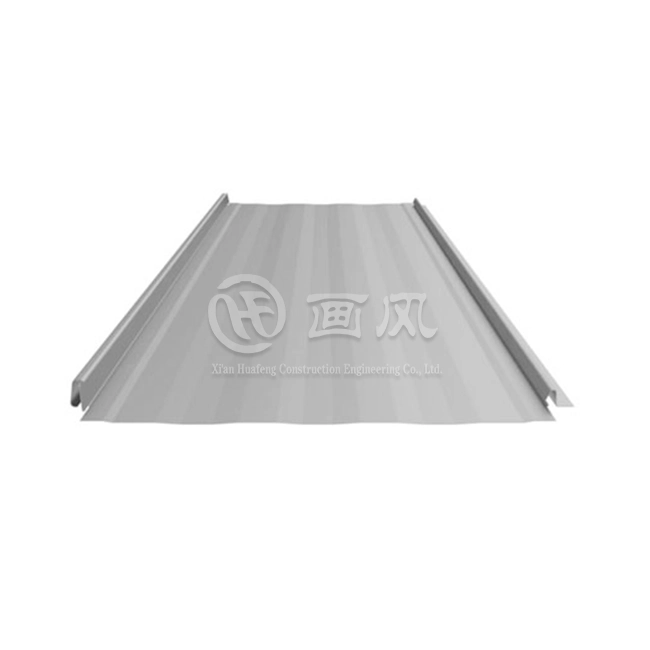

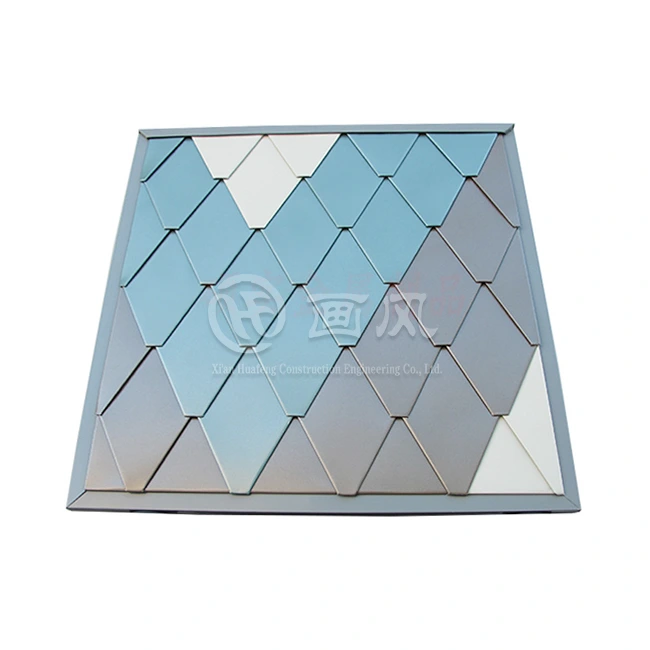

The selection of appropriate aluminum alloys significantly impacts the performance and longevity of metal siding panels. High-quality manufacturers utilize specific aluminum grades including AA3003, AA3004, and AA5052, each offering distinct advantages for building envelope applications. The AA3003 aluminum alloy provides excellent formability and corrosion resistance, making it ideal for complex architectural profiles and curved surfaces. AA3004 offers enhanced strength characteristics while maintaining good forming properties, suitable for applications requiring greater structural rigidity. The AA5052 alloy, containing magnesium as the primary alloying element, delivers superior corrosion resistance and is particularly valuable in coastal installations or chemical processing facilities. Aluminum Metal Siding Panels manufactured from these premium alloys demonstrate exceptional strength-to-weight ratios, typically achieving structural performance comparable to much heavier steel systems while weighing approximately one-third as much. This weight advantage translates into reduced structural loading requirements, simplified installation procedures, and lower transportation costs. The lightweight nature also enables longer unsupported spans between structural members, providing architects with greater design flexibility and potentially reducing overall project costs through simplified framing requirements. The rib height configuration of these panels plays a crucial role in their wind resistance capabilities. Panels featuring rib heights ranging from twenty-five to sixty-five millimeters create structural stiffness that resists wind-induced deflection and vibration. During severe weather events including hurricanes, typhoons, or intense thunderstorms, properly engineered aluminum panels with optimized rib profiles maintain their position and integrity, protecting the building envelope from wind-driven rain penetration and structural damage.

Comprehensive Weather Protection Through Advanced Panel Systems

Superior Performance Against Heavy Precipitation and Moisture

Water infiltration represents one of the most destructive forces affecting building envelopes, causing structural deterioration, mold growth, insulation degradation, and interior damage. Aluminum Metal Siding Panels address moisture management through multiple integrated design features that work synergistically to keep water out. Concealed fastener systems eliminate penetrations through the panel face, removing potential water entry points that plague exposed fastener designs. The interlocking panel joints create continuous barriers that redirect water downward along the exterior surface, preventing lateral migration into wall cavities. Standing seam configurations represent the gold standard for weather protection in aluminum metal wall applications. These systems feature raised seams that elevate above the panel surface, creating positive drainage paths that channel water away from vulnerable connection points. The vertical orientation of standing seam panels aligns with gravity, ensuring efficient water runoff even during prolonged heavy rainfall events. Factory pre-processing of panels to lengths exceeding twelve meters minimizes horizontal joints, further reducing potential water entry locations and creating more robust weather barriers. Advanced sealing technologies complement the mechanical water exclusion properties of properly designed panel systems. High-performance structural adhesives and weather-resistant sealants are strategically applied at critical junctions including panel terminations, penetrations, and transitions to dissimilar materials. These sealants maintain flexibility across wide temperature ranges, accommodating thermal expansion and contraction without cracking or losing adhesion. The combination of mechanical and chemical water barriers provides redundant protection, ensuring building envelope integrity even if one defense layer is compromised.

Thermal Performance and Energy Efficiency Benefits

Beyond weather protection, Aluminum Metal Siding Panels contribute significantly to building energy performance through multiple mechanisms. The reflective properties of aluminum surfaces reduce solar heat gain, particularly important in hot climates where cooling loads dominate energy consumption. Light-colored and specially formulated cool-pigment coatings can reflect upward of seventy percent of incident solar radiation, dramatically reducing heat transfer through the building envelope and lowering air conditioning requirements. The ventilated cavity design commonly employed with aluminum panel systems creates an additional thermal buffer between the exterior environment and the building interior. Air circulating within these cavities removes heat buildup during summer months through natural convection, while providing a still-air insulation layer during winter. This passive thermal management strategy improves overall wall assembly performance without requiring mechanical systems or energy input, contributing to sustainable building operation and reduced carbon footprints. When integrated with proper insulation materials and vapor control layers, aluminum panel systems achieve impressive thermal resistance values while maintaining the durability and weather protection characteristics essential for harsh climate applications. The non-combustible nature of aluminum also enhances fire safety, providing an additional layer of building protection particularly valuable in wildfire-prone regions or high-density urban environments where fire spread between structures poses significant risks.

Manufacturing Excellence and Quality Assurance Standards

Raw Material Selection and Supply Chain Management

The foundation of high-performance Aluminum Metal Siding Panels begins with rigorous raw material selection and quality verification processes. Leading manufacturers maintain comprehensive supplier qualification programs that evaluate material consistency, traceability, and testing documentation. Each incoming shipment of aluminum coil undergoes multiple inspection procedures including dimensional verification, alloy composition analysis, and mechanical property testing to confirm compliance with specified standards before materials enter production. Premium manufacturers source materials exclusively from established producers with proven track records in the aluminum industry. For aluminum alloys, this includes suppliers such as Alucosuper, YATAI, and LIDAO who specialize in architectural-grade materials meeting international quality standards. These suppliers provide complete material certifications including chemical composition analysis, mechanical property test results, and manufacturing process documentation that enables full traceability from raw materials through finished products. Inspection protocols extend beyond simple dimensional checks to encompass comprehensive material characterization. Surface quality evaluation identifies coating defects, scratches, or inconsistencies that could compromise finished panel appearance or protective capabilities. Thickness measurements using precision gauges ensure material meets specified tolerances throughout the coil width and length. Hardness testing verifies proper heat treatment and confirms mechanical properties align with design requirements. This multi-faceted incoming inspection process prevents defective materials from entering production, maintaining consistent output quality and protecting end-user investments.

Advanced Manufacturing Capabilities and Process Control

Modern production facilities employ sophisticated equipment and process controls that ensure dimensional accuracy, surface quality, and performance consistency across high-volume manufacturing operations. Automated roll-forming systems precisely shape flat aluminum coil into complex panel profiles with repeatable accuracy measured in fractions of millimeters. These systems utilize multiple forming stations that progressively bend the material into the final configuration, distributing stress evenly and avoiding localized thinning or work-hardening that could compromise long-term performance. Facilities equipped with seven or more color coating production lines demonstrate capacity to handle diverse project requirements while maintaining quick turnaround times. Multiple production lines enable simultaneous processing of different colors, finishes, and coating types, supporting customized solutions without extending lead times. Fully automatic punching systems create precise perforation patterns for ventilation, drainage, or aesthetic effects while maintaining panel structural integrity. Computer-controlled shearing equipment cuts panels to exact dimensions specified in installation drawings, minimizing on-site fabrication requirements and improving installation efficiency. Quality assurance extends throughout the manufacturing process with real-time monitoring systems that detect dimensional variations, coating defects, or processing anomalies before they affect finished products. Statistical process control methodologies track critical parameters including thickness, width, coating application rates, and curing temperatures, enabling rapid intervention when trends indicate potential quality deviations. This proactive approach to quality management delivers consistent products that meet or exceed performance specifications across entire production runs.

Professional Installation and Long-Term Performance Assurance

Engineered Installation Systems for Maximum Weather Protection

Even the highest quality Aluminum Metal Siding Panels cannot deliver optimal performance without proper installation following engineering principles and manufacturer specifications. Professional installation begins with comprehensive site evaluation and substrate preparation to ensure suitable conditions for panel attachment. Substrate surfaces must provide adequate structural support, dimensional stability, and appropriate moisture management to support the panel system throughout its service life. Existing conditions including structural alignment, flatness, and weatherproofing integrity are assessed and corrected before panel installation commences. Installation technicians utilize specialized tools and equipment designed specifically for aluminum panel systems including edge-locking machines, panel lifts, and precision measuring instruments. These tools enable accurate panel positioning, proper seam formation, and secure attachment without damaging protective coatings or deforming panel profiles. Pre-installation technical briefings ensure all team members understand project-specific requirements, safety procedures, and quality expectations, establishing clear standards before work begins. Critical installation details receive particular attention to ensure complete weather protection. Panel terminations at roof edges, grade level, and building corners incorporate appropriate flashing systems that direct water away from vulnerable junctions. Penetrations for utilities, fixtures, or equipment are carefully detailed with weatherproof collars and sealants that maintain envelope integrity. Expansion joints accommodate thermal movement without creating gaps or stress concentrations that could lead to panel distortion or fastener failure. This attention to installation detail distinguishes professional installations that perform reliably for decades from inadequate work that fails prematurely.

Maintenance Requirements and Lifecycle Cost Considerations

One of the compelling advantages of Aluminum Metal Siding Panels involves their minimal maintenance requirements compared to alternative siding materials. Unlike wood siding requiring periodic painting and sealing, or fiber cement needing regular inspection and repair, aluminum panels maintain their appearance and protective capabilities with basic cleaning procedures performed at appropriate intervals. Most installations require only annual washing with clean water to remove accumulated dirt and atmospheric pollutants, preserving coating integrity and surface appearance. In aggressive environments such as coastal locations or industrial areas with elevated pollution levels, more frequent cleaning intervals may be appropriate to prevent buildup of corrosive deposits. Simple cleaning solutions combining mild detergent with water effectively remove most contaminants without damaging panel coatings or underlying aluminum. High-pressure washing should be avoided as excessive pressure can damage protective coatings or force water behind panels, creating conditions for concealed corrosion or substrate deterioration. The lifecycle cost analysis of Aluminum Metal Siding Panels consistently demonstrates economic advantages over alternative materials when evaluated across typical building service lives of thirty years or more. Initial material costs, while potentially higher than some alternatives, are offset by dramatically reduced maintenance expenses, elimination of periodic refinishing requirements, and extended service life without replacement needs. Energy savings resulting from improved thermal performance further enhance economic returns, particularly in extreme climate locations where heating and cooling costs represent significant operational expenses.

Technical Specifications and Performance Standards

Quality manufacturers provide comprehensive technical documentation including detailed specifications, installation guidelines, and performance test results demonstrating product capabilities. Panel specifications typically include material grades such as aluminum alloy types AA3003, AA3004, or AA5052, with thickness ranging from 0.7 to 1.2 millimeters depending on application requirements and structural design. Panel widths commonly vary from 400 to 600 millimeters to accommodate different aesthetic preferences and installation substrates. Standard lengths exceeding twelve meters enable installation with minimal horizontal joints, improving weather protection and visual continuity. Coating systems represent a critical specification element directly impacting long-term appearance retention and protection capabilities. Polyester coatings provide economical protection suitable for moderate exposure environments with expected service lives of fifteen to twenty years. High-durability polyester formulations extend performance to twenty-five years or longer through improved pigment stability and resin technology. Polyvinylidene fluoride coatings deliver premium performance with thirty-year or longer appearance warranties, maintaining color stability and gloss retention even in harsh ultraviolet and chemical exposure conditions. Manufacturing facilities operating under certified quality management systems including ISO 9001 for quality management, ISO 14001 for environmental management, and meeting SGS guidelines demonstrate organizational commitment to consistent quality and continuous improvement. These certifications require documented procedures, regular audits, and objective evidence of compliance, providing customers with confidence that products meet specified standards and performance claims are supported by verified testing.

Conclusion

Aluminum Metal Siding Panels for Harsh Weather Protection represent the culmination of advanced materials engineering, precision manufacturing, and proven installation methodologies, delivering building envelope solutions that withstand nature's most severe conditions while providing decades of reliable service with minimal maintenance requirements and sustained aesthetic appeal.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a trusted China Aluminum Metal Siding Panels manufacturer with comprehensive capabilities spanning design through construction. Established in 2018 and recognized as a high-tech enterprise in Shaanxi Province in 2020, we maintain first-level building curtain wall qualifications and third-level building steel structure qualifications. Our 200,000-square-meter raw material production facility in Anhui, combined with processing plants in Hangzhou and Xi'an, ensures manufacturing capacity exceeding 1000 tons monthly. With over twenty registered patents, multiple international certifications including ISO9001, ISO14000:14001, and SGS guidelines, we deliver High Quality Aluminum Metal Siding Panels backed by comprehensive thirty-year warranties. As a leading China Aluminum Metal Siding Panels supplier and China Aluminum Metal Siding Panels factory, we offer customized solutions with 15-20 day delivery times, competitive Aluminum Metal Siding Panels price structures, and one-stop service from materials to installation. Our China Aluminum Metal Siding Panels wholesale programs serve global markets with Aluminum Metal Siding Panels for sale through direct factory pricing. Contact our team at huafeng@hfmetalroof.com to discuss your project requirements and discover why leading developers choose our expertise for their most demanding applications.

References

1. Smith, J. & Anderson, R. (2023). "Aluminum Building Envelope Systems: Performance in Extreme Weather Conditions." Journal of Architectural Engineering, Vol. 29, No. 4.

2. Chen, L. (2024). "Comparative Analysis of Metal Cladding Materials for Coastal Construction Applications." International Journal of Building Science and Technology, Vol. 15, Issue 2.

3. Thompson, M. & Williams, K. (2022). "Long-Term Durability Assessment of Aluminum Alloy Facade Panels in Marine Environments." Construction and Building Materials Research, Vol. 318.

4. Rodriguez, P. (2023). "Energy Performance of Ventilated Metal Panel Systems in Hot-Humid Climates." Building and Environment Journal, Vol. 227.

5. Zhang, Y. & Liu, W. (2024). "Lifecycle Cost Analysis of Contemporary Building Envelope Systems." Journal of Sustainable Construction Materials, Vol. 42, No. 1.