Are your screening operations plagued by frequent equipment failures, material clogging, and costly downtime? Industries worldwide face the challenge of processing abrasive materials efficiently while maintaining durability and throughput. Punched Plate Screens offer a robust solution to these persistent problems, delivering exceptional wear resistance and reliable performance across diverse industrial applications. This comprehensive guide explores how Punched Plate Screens revolutionize material separation, screening, and filtration processes in mining, construction, manufacturing, and beyond.

Mining and Quarrying Operations with Punched Plate Screens

Mining and quarrying industries demand screening solutions that can withstand extreme conditions, and Punched Plate Screens excel in these harsh environments. These robust screening media are specifically engineered to handle the intense abrasion and impact forces encountered when processing ore, gravel, rock, and other minerals. Unlike traditional woven wire screens that wear quickly under heavy loads, Punched Plate Screens manufactured from high-grade materials such as stainless steel, galvalume plate, and aluminum alloy provide superior longevity and consistent performance in scalping and primary screening applications. The versatility of Punched Plate Screens becomes evident in underground and surface mining operations where material flow consistency is critical. These screens feature customizable apertures ranging from 0.5mm to 100mm, with various hole configurations including round, square, hexagonal, and elongated slots that optimize material separation based on particle size distribution. The strategic placement of blank-out areas protects high-impact zones from oversize material while maintaining optimal throughput. With opening rates adjustable between 15% and 80%, operators can fine-tune screening efficiency to match specific ore characteristics and processing requirements.

Aggregate Processing and Construction Material Screening

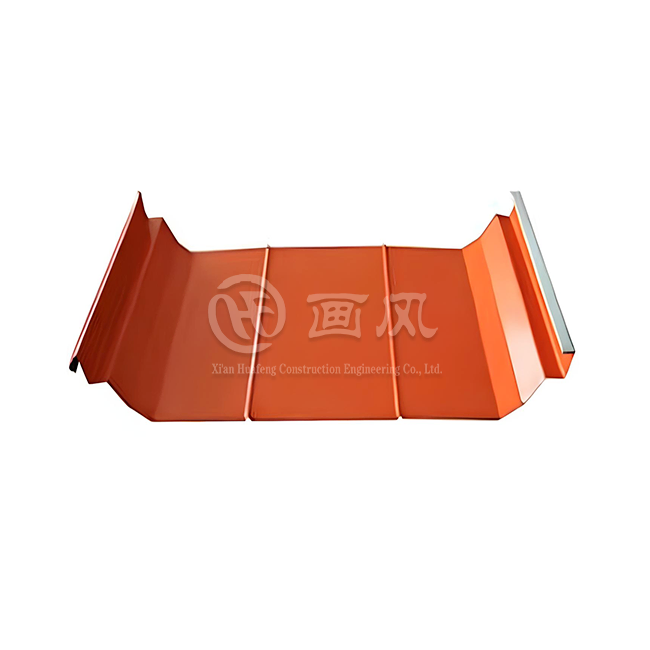

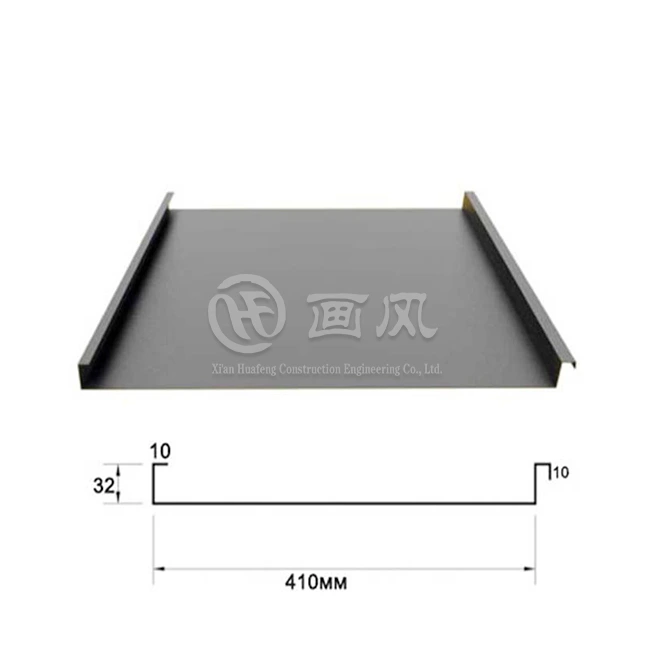

Construction and aggregate processing operations rely heavily on Punched Plate Screens for separating sand, gravel, crushed stone, and recycled materials. These applications demand precision screening coupled with durability, especially when handling angular aggregates that quickly degrade conventional screening media. Punched Plate Screens deliver exceptional performance in vibrating screen systems used for sizing and grading aggregates, ensuring consistent product quality while minimizing maintenance intervals and operational costs. The structural integrity of Punched Plate Screens makes them ideal for road construction and asphalt mixing plant operations where material consistency directly impacts final product quality. Xi'an Huafeng Construction Engineering Co., Ltd. manufactures these screens with plate thicknesses ranging from 0.5mm to 12mm, providing the necessary strength for heavy-duty applications. The screens' high-strength metal sheet stamping construction ensures impact resistance and pressure tolerance in heavy load environments. Surface treatments including spray painting, galvanizing, polishing, and anodizing enhance rust-proof and corrosion-resistant properties, extending service life even in challenging environmental conditions.

Food Processing and Agricultural Applications

Food processing industries increasingly adopt Punched Plate Screens for their hygienic properties and precise separation capabilities. These screens excel in sieving and sorting applications for grains, cereals, vegetables, and other agricultural products where contamination prevention is paramount. Manufactured from food-grade stainless steel (304/316), Punched Plate Screens meet stringent sanitary standards while providing reliable performance in removing impurities and foreign particles from food products during processing operations. The smooth surface characteristics of Punched Plate Screens facilitate easy cleaning and maintenance, critical factors in food processing environments where hygiene regulations are strict. The regular hole shape and uniform distribution enable high screening efficiency while preventing material buildup that could harbor bacteria or contaminants. Agricultural operations benefit from these screens in grain handling facilities, seed processing plants, and livestock feed production where consistent particle size separation ensures product quality and reduces waste. The customizable nature of Punched Plate Screens allows food processors to specify exact aperture sizes that match their separation requirements, from fine powder screening to larger particle classification.

Forestry and Wood Processing Industries

Forestry operations utilize Punched Plate Screens for separating and processing wood chips, bark, sawdust, and other forestry byproducts. These applications present unique challenges due to the fibrous and abrasive nature of wood materials, which can quickly clog conventional screening systems. Punched Plate Screens address these challenges through their anti-clogging design featuring tapered holes that prevent material binding. The ventilation and light transmission properties inherent in the opening design ensure continuous material flow while maintaining structural integrity under the demanding conditions of wood processing operations. Heavy-duty Punched Plate Screens manufactured from wear-resistant steel withstand the continuous impact and abrasion encountered in forestry equipment such as bark strippers, chipper screens, and biomass processing systems. The flexibility in material selection, including low carbon steel, copper, and galvanized sheet options, allows forestry operators to choose screens optimized for their specific processing environment. Xi'an Huafeng Construction Engineering Co., Ltd. provides customized solutions with various hole patterns and arrangements designed specifically for wood processing efficiency, ensuring maximum throughput while maintaining separation accuracy necessary for producing quality wood products and biomass fuel.

Manufacturing and Industrial Filtration Systems

Manufacturing sectors across automotive, ceramics, textiles, and petrochemical industries depend on Punched Plate Screens for critical sieving, filtering, and material separation processes. These screens perform essential functions in production lines where precise particle size control impacts product quality and process efficiency. The wear-resistant and durable construction of Punched Plate Screens manufactured from high-hardness steel or specialized coatings extends service life in continuous operation environments, reducing downtime and maintenance costs while ensuring consistent manufacturing output. Chemical processing and petrochemical facilities employ Punched Plate Screens in applications requiring separation of solids from liquids or gases, where corrosion resistance is paramount. Stainless steel Punched Plate Screens (316/304 grades) provide exceptional chemical compatibility while maintaining structural integrity under pressure and temperature variations. The precise screening capability with regular hole distribution ensures efficient filtration in pharmaceutical manufacturing for sieving and classifying pharmaceutical powders and granules during production processes. These screens integrate seamlessly into existing manufacturing equipment, providing flexible customization options for hole type, arrangement, and material selection that optimize specific production requirements.

Waste Management and Recycling Operations

Waste management facilities and recycling centers leverage Punched Plate Screens for efficient material separation and classification essential to modern recycling processes. These operations handle diverse waste streams containing mixed materials requiring size-based separation for proper recycling or disposal. Punched Plate Screens excel in waste sorting applications, separating materials based on size and composition while withstanding the impact of heavy or irregular waste items. The economical and efficient design proves more durable than woven screens with lower maintenance costs, making them ideal for high-volume waste processing operations. Energy and utilities sectors utilize Punched Plate Screens in power plants for water treatment, fuel processing, and waste management applications. The screens' versatility extends to drainage covers and functional flooring applications where structural strength combines with open area design for effective liquid-solid separation. The easy-to-clean and maintain surface characteristics reduce operational complexity, with smooth finishes that resist clogging and allow high-pressure washing when necessary. Xi'an Huafeng Construction Engineering Co., Ltd. supplies High Quality Punched Plate Screens with customized specifications meeting the demanding requirements of waste management operations, ensuring reliable long-term performance in challenging processing environments.

Conclusion

Punched Plate Screens represent a versatile, durable, and cost-effective solution for material screening across mining, construction, food processing, forestry, manufacturing, and waste management industries, delivering superior performance where conventional screening media fails under demanding conditions.

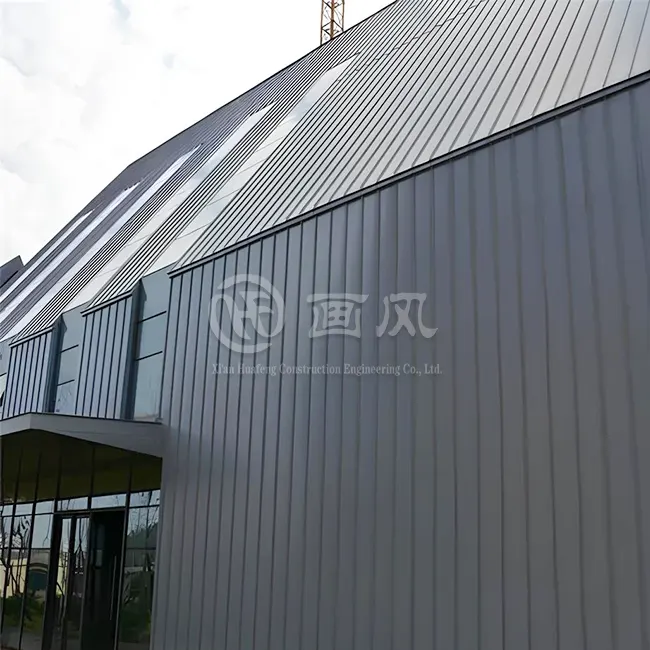

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

As a leading China Punched Plate Screens factory, China Punched Plate Screens supplier, and trusted China Punched Plate Screens manufacturer, Xi'an Huafeng Construction Engineering Co., Ltd. offers China Punched Plate Screens wholesale with competitive Punched Plate Screens price options. Established in 2018, we provide Punched Plate Screens for sale backed by extensive engineering design and construction experience. Our High Quality Punched Plate Screens are manufactured in state-of-the-art facilities featuring 7 raw material production lines and over 20 plate production machines, supported by more than 20 patent certificates and international certifications including CE, ISO9001, ISO14000:14001, and SGS. We collaborate with Fortune 500 companies, delivering one-stop procurement services from raw materials to accessories with customized production capabilities, design optimization services, raw material quality testing, multiple packaging options, and diverse transportation methods. Contact us today at huafeng@hfmetalroof.com to discuss your project requirements and discover how our expertise can transform your screening operations. Save this page for future reference when planning your next equipment upgrade.

References

1. "Industrial Screening Technology and Applications in Mineral Processing" - Authors: Thompson, R.J. and Mitchell, K.L., Society for Mining, Metallurgy & Exploration

2. "Perforated Metal Products: Manufacturing Processes and Industrial Applications" - Authors: Zhang, W., Chen, H., and Liu, X., International Journal of Advanced Manufacturing Technology

3. "Aggregate Processing and Screening Systems: A Practical Guide" - Authors: Morrison, D.A. and Patterson, J.R., National Stone, Sand & Gravel Association

4. "Food Processing Equipment Design and Sanitation Standards" - Authors: Singh, R.P. and Heldman, D.R., Academic Press Food Science and Technology Series

5. "Waste Management Technologies: Separation and Recycling Equipment" - Authors: Williams, P.T., Handbook of Waste Management and Resource Recovery