When hurricane season approaches and wind speeds exceed 130 mph, building owners in coastal regions face a critical question: will your roof survive the storm? The devastating images of torn-off roofs and destroyed buildings after major hurricanes reveal a harsh truth—not all roofing systems are engineered to withstand extreme weather. Snap Clad Standing Seam Roof Panel systems have emerged as the superior solution for high-velocity wind zones, offering exceptional uplift resistance, concealed fastener protection, and proven performance in hurricane-prone regions where conventional roofing materials consistently fail.

Understanding High-Velocity Wind Zones and Their Roofing Challenges

High-velocity wind zones represent geographical areas where design wind speeds exceed 130 mph, typically found in coastal regions subject to hurricanes and tropical storms. These zones demand specialized building materials that can resist extraordinary uplift forces, wind-driven rain penetration, and impact from airborne debris. The Snap Clad Standing Seam Roof Panel system addresses these critical requirements through its engineered design that combines structural integrity with weather-tight performance. In these extreme environments, traditional roofing materials such as asphalt shingles, tiles, and even some metal systems experience catastrophic failures when exposed to hurricane-force winds that create massive negative pressure on roof surfaces. The unique challenge of high-velocity wind zones extends beyond simple wind speed calculations. These regions experience complex wind patterns that generate uplift pressures attempting to literally pull roofs from buildings, while simultaneously driving rain horizontally against vertical surfaces and creating hydrostatic pressure that forces water through even microscopic openings. The Snap Clad Standing Seam Roof Panel system counteracts these forces through its concealed clip fastening system that anchors panels securely to the structural deck while allowing controlled thermal expansion and contraction. The interlocking seam design creates a continuous weathertight barrier that prevents water infiltration even under the most severe wind-driven rain conditions common in tropical storm events.

Critical Performance Requirements for Hurricane-Resistant Roofing Systems

Building codes in high-velocity wind zones mandate specific performance standards that roofing systems must achieve to ensure structural safety and occupant protection during extreme weather events. The Snap Clad Standing Seam Roof Panel meets and exceeds these stringent requirements through comprehensive testing protocols that verify wind uplift resistance, water penetration resistance, and impact resistance from wind-borne debris. These performance standards are not merely theoretical specifications but practical requirements proven through decades of post-hurricane forensic analysis that consistently demonstrates the superior survival rate of properly installed standing seam metal roofing systems compared to alternative materials. Wind uplift ratings represent the most critical performance metric for roofing systems in hurricane zones, with Snap Clad Standing Seam Roof Panel systems achieving UL 90 and higher ratings that correspond to wind speeds exceeding 160 mph in properly engineered assemblies. This exceptional performance results from the mechanical interlock between panels, the concealed clip fastening system that prevents fastener pull-through, and the strategic clip spacing that distributes wind loads across the entire roof assembly. The system's floating clip design accommodates thermal movement without compromising structural attachment, while the raised seam profile prevents panel disengagement even under extreme uplift conditions that would cause snap-together systems to simply unsnap and fail catastrophically.

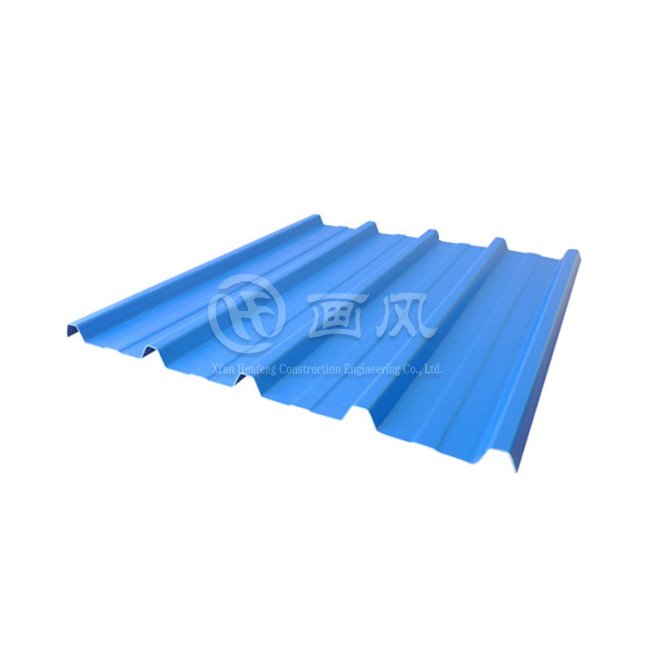

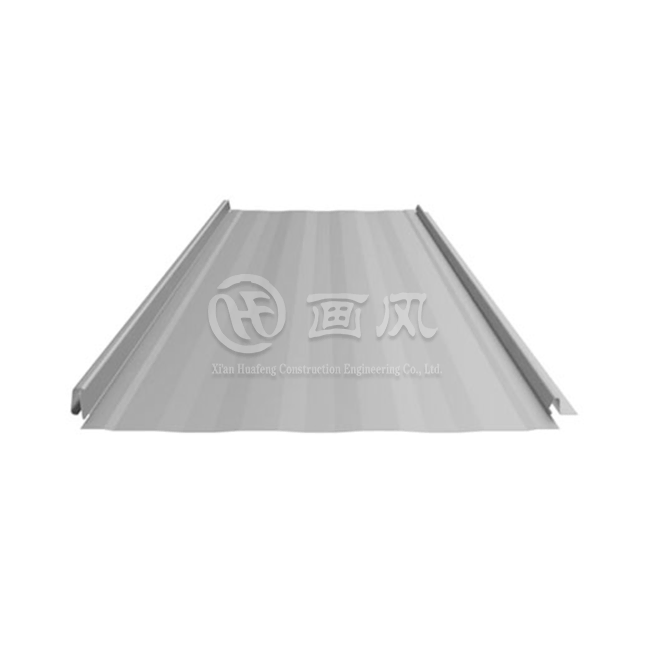

Snap Clad Standing Seam Panel Engineering for Wind Resistance

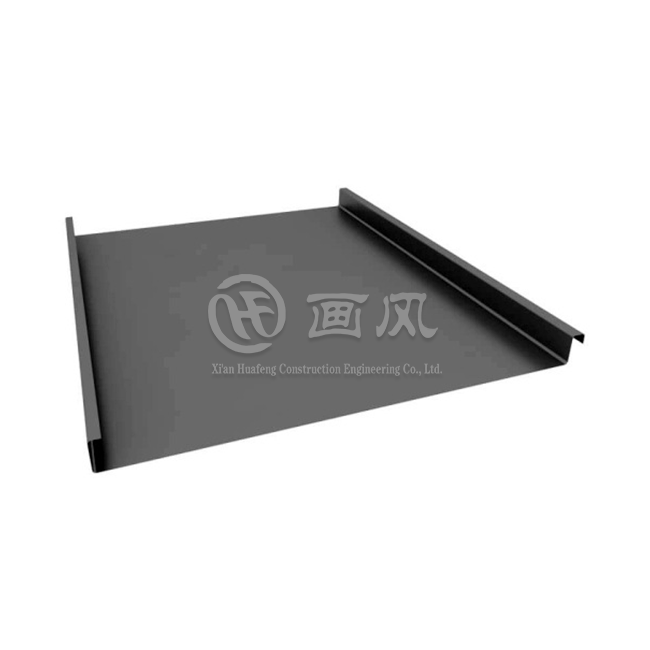

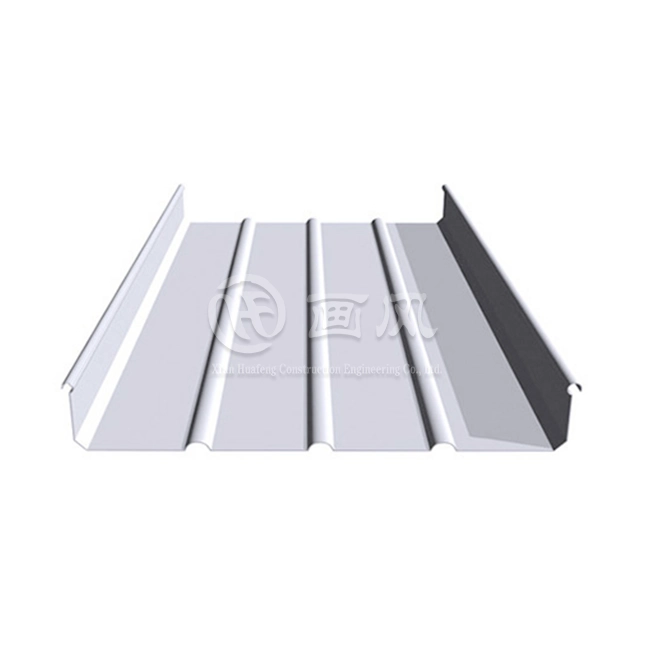

The engineering excellence of Snap Clad Standing Seam Roof Panel systems begins with their fundamental architectural design that prioritizes structural performance alongside aesthetic appeal. The system features a 45-50mm seam height that provides substantial mechanical advantage against wind uplift forces while creating the distinctive vertical shadow lines that define contemporary commercial architecture. This raised profile serves multiple critical functions: it increases the bending strength of each panel, creates a positive drainage path that channels water away from seams, and provides sufficient space for the concealed clip system that forms the structural backbone of the assembly's wind resistance capabilities. The concealed fastening system represents the single most important factor in the Snap Clad Standing Seam Roof Panel's superior wind performance in high-velocity zones. Unlike exposed fastener systems that create penetrations through the weathering surface and stress concentration points that can fail under repeated loading cycles, the concealed clip system attaches to the panel's male leg through a secure mechanical connection while fastening directly to the structural substrate. This configuration ensures that wind uplift forces are transmitted directly to the building structure without subjecting the panel material itself to fastener pull-through stresses that cause progressive failure during prolonged hurricane wind exposure.

Material Selection and Specification for Coastal Applications

Material selection critically impacts the long-term performance of Snap Clad Standing Seam Roof Panel systems in high-velocity wind zones where salt-laden air accelerates corrosion of inferior materials. Xi'an Huafeng Construction Engineering Co., Ltd. manufactures Snap Clad panels from premium aluminum alloy, galvalume steel, stainless steel, copper, and titanium zinc substrates, with thickness options ranging from 0.5mm to 1.2mm to accommodate varying structural load requirements and wind exposure categories. The choice between these materials involves careful consideration of corrosion resistance, strength-to-weight ratios, thermal expansion characteristics, and life-cycle cost analysis specific to each project's unique location and performance requirements. For installations within 3000 feet of ocean shorelines, stainless steel grade 316 or aluminum alloy 5052 provide superior corrosion resistance against salt spray that would rapidly degrade standard galvanized steel substrates. The PVDF coating options available on Snap Clad Standing Seam Roof Panel products deliver exceptional UV resistance and color retention that maintains architectural appearance throughout the system's 30-year warranty period, while simultaneously providing a sacrificial barrier against atmospheric pollutants and industrial fallout. These premium coatings undergo rigorous salt spray testing exceeding 3000 hours to verify their protective capabilities in the harshest coastal environments where conventional paint systems fail within five to seven years of installation.

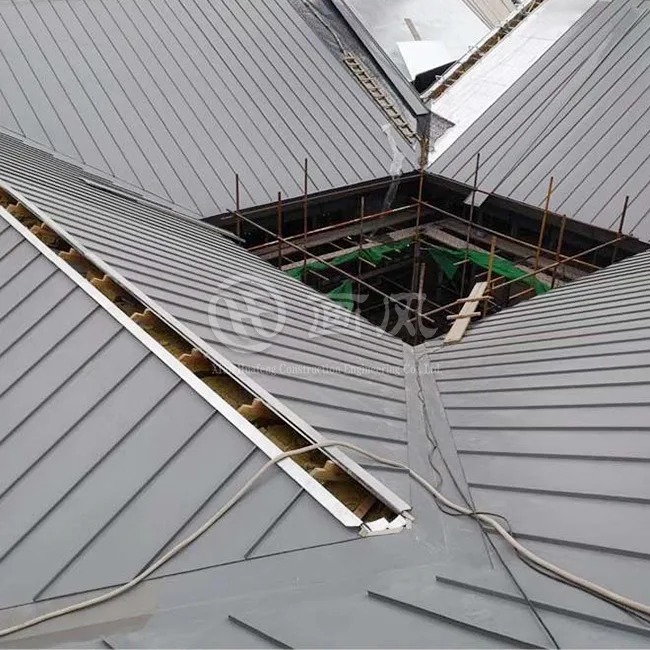

Installation Best Practices for Maximum Wind Performance

Proper installation techniques determine whether Snap Clad Standing Seam Roof Panel systems achieve their rated wind resistance or fail prematurely during storm events. The most critical installation parameter involves clip spacing, which must be engineered specifically for the project's wind exposure category, roof height, and building geometry. In high-velocity wind zones, Xi'an Huafeng Construction Engineering Co., Ltd. recommends maximum clip spacing of 450mm on center for standard roof areas, with enhanced spacing of 300mm or less along eaves, ridges, hips, and corners where wind pressures concentrate. The first clip at the eave must be positioned within 50-75mm of the panel end to prevent panel flutter that can propagate up the roof slope and cause progressive failure. Substrate preparation and structural adequacy represent equally important factors in achieving design wind resistance. The Snap Clad Standing Seam Roof Panel system requires a continuous structural deck capable of resisting the concentrated loads transmitted through clip fasteners, with minimum deck thickness and fastener specifications varying based on wind exposure calculations. In retrofit applications over existing metal decks, supplementary wood blocking or structural purlins may be required to provide adequate fastener holding strength, particularly when existing deck configurations do not align with required clip spacing intervals. Xi'an Huafeng Construction Engineering Co., Ltd. provides comprehensive installation guidance and on-site technical support to ensure that every Snap Clad Standing Seam Roof Panel installation achieves its full structural potential through adherence to engineered specifications and quality control procedures.

Comparative Analysis: Snap Clad vs. Alternative Wind-Resistant Roofing

When evaluating roofing options for high-velocity wind zones, building owners must consider both initial installation costs and long-term life-cycle economics that account for maintenance requirements, insurance premiums, and replacement frequency. Snap Clad Standing Seam Roof Panel systems command premium initial pricing compared to conventional asphalt shingles or through-fastened metal panels, yet deliver superior economic value through extended service life, minimal maintenance requirements, and documented insurance premium reductions of 20-35% in hurricane-prone regions. The system's proven track record of surviving Category 4 and 5 hurricane events without catastrophic failure translates to avoided replacement costs and business continuity that far outweigh the incremental investment in superior roofing technology. The mechanical performance advantages of Snap Clad Standing Seam Roof Panel systems become evident when examining post-hurricane damage assessments conducted by FEMA and insurance industry research organizations. These forensic studies consistently demonstrate that properly installed mechanically-seamed standing seam roofs substantially outperform snap-together systems that unsnap under high uplift pressures, exposed fastener panels that experience progressive fastener loosening and panel uplift, and architectural metal shingles that lack adequate attachment density to resist sustained wind loads. The continuous mechanical interlock of Snap Clad panels distributes wind forces across the entire roof assembly rather than concentrating stresses at discrete fastener points, resulting in dramatically improved structural redundancy and failure resistance.

Weather Tightness and Water Infiltration Prevention

Beyond pure wind resistance, Snap Clad Standing Seam Roof Panel systems excel at preventing water infiltration during hurricane events where horizontal rain and positive hydrostatic pressure overwhelm conventional roofing systems. The raised seam design creates a continuous water diversion path that channels precipitation away from the mechanical interlock, while the optional factory-applied sealant bead provides secondary protection against capillary water migration. This multi-barrier approach to weather resistance ensures that even if the primary seam interlock experiences minor water penetration during extreme storm conditions, the secondary sealant layer and concealed clip configuration prevent water from reaching the interior building envelope. The concealed fastener design of Snap Clad Standing Seam Roof Panel systems eliminates the primary water infiltration pathway that causes progressive deterioration of exposed fastener roofing in high-velocity wind zones. Through-fastened panels rely on rubber washers compressed beneath screw heads to create weathertight seals, yet these elastomeric components deteriorate rapidly under continuous UV exposure and thermal cycling, creating leak paths within five to ten years of installation. In contrast, Snap Clad panel fasteners remain completely protected beneath the standing seam assembly, isolated from weather exposure that would degrade their sealing integrity. This fundamental design advantage translates to maintenance-free weather resistance throughout the system's multi-decade service life, eliminating the expensive and labor-intensive fastener replacement programs required to maintain through-fastened panel systems in acceptable condition.

Xi'an Huafeng's Manufacturing Excellence and Quality Assurance

Xi'an Huafeng Construction Engineering Co., Ltd. operates three state-of-the-art manufacturing facilities equipped with seven color coating production lines, one laminating production line, and ten longitudinal and transverse shearing production lines, along with fully automatic punching equipment and more than 40 specialized machines dedicated to metal roofing production. This comprehensive manufacturing infrastructure enables the company to produce Snap Clad Standing Seam Roof Panel systems with exceptional dimensional accuracy, consistent material properties, and quality control standards that meet international ASTM, DIN, JIS, BS, and GB/T specifications. The company's raw material production plant in Anhui covers 200,000 square meters, while plate and accessories processing plants in Hangzhou and Xi'an provide distributed manufacturing capacity that ensures reliable supply and rapid delivery to projects throughout Asia and globally. The company's quality assurance protocols encompass every stage of Snap Clad Standing Seam Roof Panel production, from incoming raw material inspection through finished product packaging and delivery. Raw materials undergo comprehensive testing including salt spray resistance exceeding 3000 hours, adhesion testing, hardness verification, impact resistance evaluation, coating thickness measurement, acid resistance assessment, weather resistance validation, and color consistency analysis to ensure that only premium substrates enter production. Finished panel inspection verifies dimensional accuracy, flatness tolerances, proper seam formation, and coating integrity before panels receive protective packaging designed to prevent damage during transportation and installation. This rigorous quality control system, certified under ISO9001 and ISO14001 standards, ensures that every Snap Clad Standing Seam Roof Panel delivered to high-velocity wind zone projects meets the exacting specifications required for reliable long-term performance.

Customization Capabilities and Engineering Support

Xi'an Huafeng Construction Engineering Co., Ltd. provides comprehensive customization services that optimize Snap Clad Standing Seam Roof Panel systems for specific project requirements in high-velocity wind zones. The company's engineering team conducts detailed structural analysis including 3D modeling, load calculations, drainage system simulation, and material specification advisory services that ensure each installation achieves required wind resistance performance while satisfying architectural design intent. This engineering support extends through project drawing development, factory sample production, and processing drawing generation that facilitates efficient manufacturing and field installation of complex roof configurations including curved panels, tapered sections, and custom radius work that accommodates contemporary architectural expressions. The company's one-stop service model encompasses design consultation, material procurement from qualified suppliers including Alucosuper, YATAI, LIDAO aluminum products, BAOSTEEL and GUANZHOU steel, Baosteel and Tsingshan stainless steel, NedZink titanium zinc, and Chinalco copper, precision manufacturing, quality inspection, protective packaging, logistics coordination, and on-site installation supervision or direct construction services. This comprehensive approach ensures seamless project execution from initial concept through final acceptance, eliminating coordination challenges between multiple suppliers and contractors while maintaining consistent quality standards throughout the entire procurement and installation process. With supply capacity exceeding 1000 tons monthly and delivery timelines of 15-20 days for standard configurations, Xi'an Huafeng provides the responsive service and technical capability required for successful large-scale commercial, institutional, and industrial roofing projects in hurricane-prone regions.

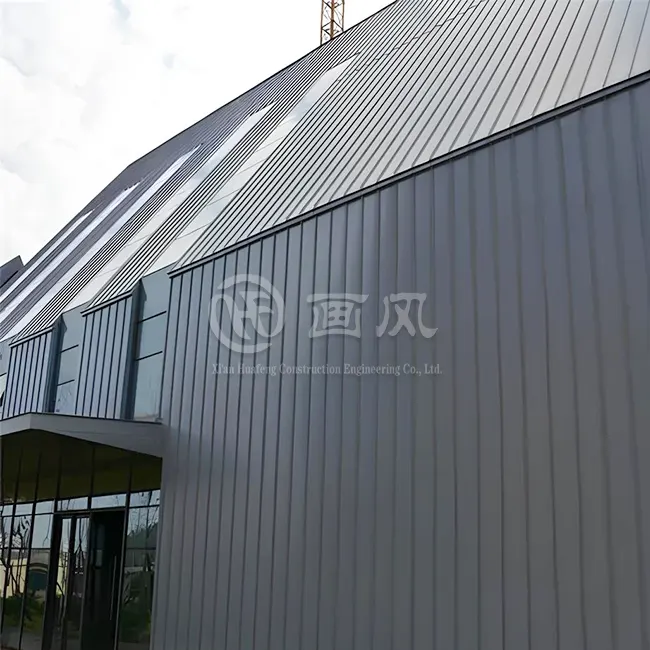

Proven Performance in Major Hurricane Events

The ultimate validation of Snap Clad Standing Seam Roof Panel performance in high-velocity wind zones comes from real-world hurricane survival and post-storm damage assessment studies. Major installations including the Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, Xi'an Station East Auxiliary Building, South Hall 2-2 of Jinghe New City International Culture and Art Center, and numerous other high-profile projects demonstrate the system's capability to protect critical infrastructure under extreme loading conditions. These project successes reflect the combined benefits of superior product engineering, precision manufacturing, and expert installation that characterize Xi'an Huafeng's comprehensive approach to metal roofing system delivery. Post-hurricane forensic investigations consistently identify installation quality as the differentiating factor between successful roof performance and catastrophic failure during extreme wind events. Even properly engineered Snap Clad Standing Seam Roof Panel systems will fail if installers deviate from specified clip spacing, use incorrect fastener types or sizes, position initial clips too far from panel ends, or fail to adequately seal perimeter details and penetrations. Xi'an Huafeng addresses these critical installation variables through comprehensive installer training, detailed installation manuals with section-specific assembly drawings, on-site technical supervision during critical installation phases, and final inspection protocols that verify compliance with engineering specifications before project acceptance. This quality-focused approach ensures that Snap Clad Standing Seam Roof Panel installations deliver their full rated wind resistance when hurricane-force winds inevitably test system performance.

Conclusion

Snap Clad Standing Seam Roof Panel systems provide unmatched protection for buildings in high-velocity wind zones through superior engineering, quality manufacturing, and proven performance in extreme weather events where inferior roofing systems consistently fail.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in Shaanxi Province in 2018 and recognized as a high-tech enterprise in 2020, specializes in comprehensive metal roofing solutions with first-level building curtain wall qualifications and third-level steel structure qualifications. Our three advanced factories operate seven raw material production lines and more than 40 specialized processing machines, producing standing seam metal roofing panels, aluminum-magnesium-manganese plates, titanium-zinc plates, corrugated panels, and complete roofing system accessories. We provide integrated services from structural 3D modeling and load analysis through precision roll-forming manufacturing with real-time quality control and raw material traceability, to seamless on-site installation with project management and safety compliance documentation. With more than 20 registered patents, ISO9001 and ISO14001 certifications, and successful completion of major projects including the Xiongan Station Commercial Body and Inner Mongolia Tongliao Art Museum, we deliver customized solutions backed by 30-year warranties and one-stop procurement from raw materials to accessories.

Partner with China's leading Snap Clad Standing Seam Roof Panel factory, supplier, and manufacturer for High Quality Snap Clad Standing Seam Roof Panel at competitive prices. Xi'an Huafeng offers Snap Clad Standing Seam Roof Panel for sale with wholesale pricing for large projects, complete engineering design experience, construction expertise, CE certification, SGS testing, and proven collaboration with Fortune 500 companies. Our design optimization services, raw material quality testing, customized production capabilities, multiple packaging options, and flexible transportation methods ensure your high-velocity wind zone project succeeds. Contact us at huafeng@hfmetalroof.com to discuss your requirements, request technical specifications, or schedule a factory visit. Bookmark this page for future reference when planning hurricane-resistant roofing projects.

References

1. Federal Emergency Management Agency. "Metal Roof Systems in High-Wind Regions: Recovery Advisory." FEMA Technical Bulletin Series.

2. Smith, T.L. and Johnson, M.R. "Wind Uplift Performance of Standing Seam Metal Roof Systems." Journal of Architectural Engineering, American Society of Civil Engineers.

3. Insurance Institute for Business & Home Safety. "Hurricane Wind Resistance Standards for Metal Roofing Systems." IBHS Technical Report Series.

4. Metal Construction Association. "Guide to Metal Roof System Design for High-Wind Applications." MCA Technical Publication.

5. Zhang, W. and Chen, L. "Comparative Analysis of Roofing System Performance in Coastal Hurricane Zones." International Journal of Structural Engineering Research.