Picture this: you've just invested thousands of dollars in a new roof, only to watch it deteriorate within a few years due to harsh weather, corrosion, or structural failure. This nightmare scenario is all too common with inferior roofing materials. If you're considering Metal Corrugated Roofing Panel for your next construction project, understanding its durability is crucial to making an informed investment decision. The answer is straightforward: high-quality Metal Corrugated Roofing Panel can last between 40 to 70 years when properly manufactured and installed, offering exceptional resistance to weather extremes, structural loads, and environmental challenges that would compromise lesser materials.

Understanding Metal Corrugated Roofing Panel Longevity and Performance

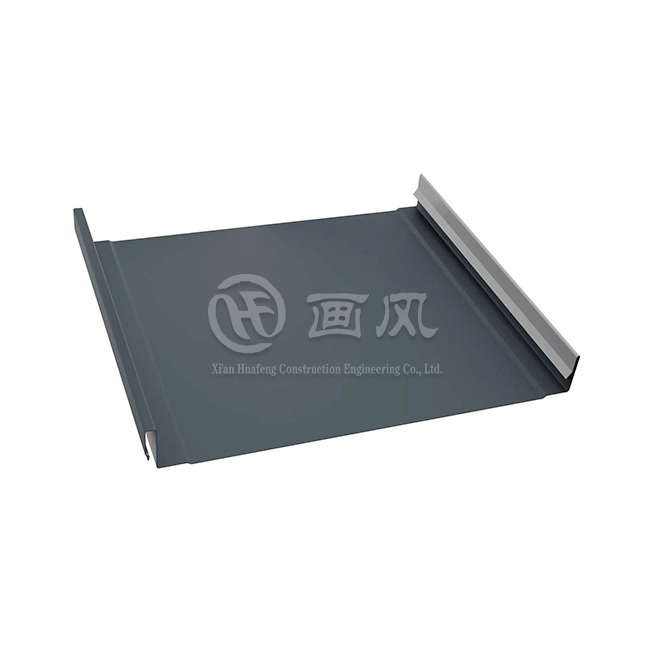

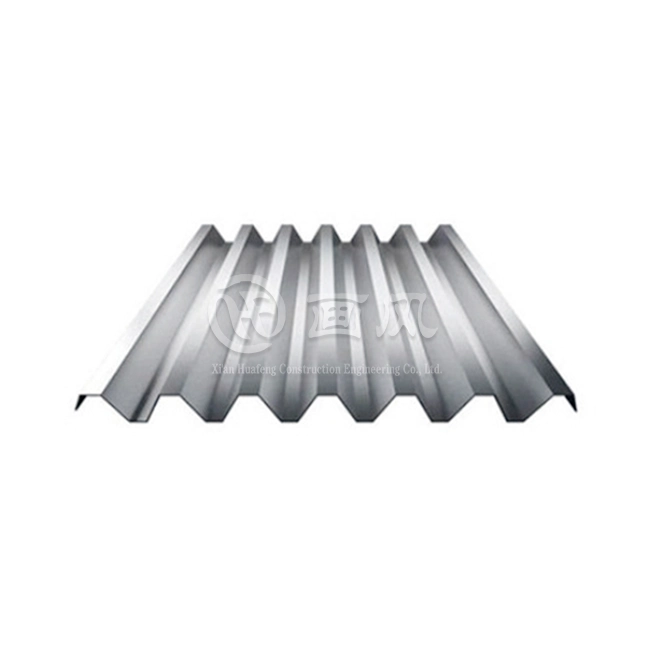

Metal Corrugated Roofing Panel represents one of the most resilient roofing solutions available in today's construction market. The durability of corrugated roofing sheets stems from both their inherent material properties and their distinctive wave-like structural design. Unlike traditional asphalt shingles that typically require replacement every 15 to 25 years, professionally manufactured Metal Corrugated Roofing Panel systems deliver decades of reliable performance with minimal maintenance requirements. The corrugated pattern itself enhances the panel's load-bearing capacity by distributing weight evenly across the surface while simultaneously providing superior water drainage capabilities that prevent moisture accumulation and potential leak points. The manufacturing process plays a critical role in determining the ultimate durability of Metal Corrugated Roofing Panel products. At Xi'an Huafeng Construction Engineering Co., Ltd., our corrugated roofing sheets undergo rigorous quality control measures throughout production. We utilize premium base materials including galvanized steel, aluminum-magnesium-manganese alloys, and specialized coated metals, each selected for specific performance characteristics. Our 7 color coating production lines and advanced roll-forming equipment ensure consistent panel thickness ranging from 0.4mm to 1.2mm, with precision corrugation profiles that maximize structural integrity. The coating systems we apply—including PE, HDP, and PVDF finishes—provide additional protection layers that resist UV degradation, chemical exposure, and atmospheric corrosion, extending the functional lifespan well beyond conventional roofing materials.

Material Composition and Corrosion Resistance

The base metal composition fundamentally determines how Metal Corrugated Roofing Panel performs over its service life. Galvanized steel panels feature a protective zinc coating that acts as a sacrificial barrier, preventing rust formation on the underlying steel substrate even when the surface experiences minor scratches or abrasions. This zinc layer typically ranges from 120 to 275 grams per square meter, with heavier coatings providing enhanced protection in coastal or industrial environments where corrosive elements are more prevalent. Aluminum-based corrugated roofing sheets offer inherent corrosion resistance without requiring protective coatings, making them ideal for marine applications where salt spray would rapidly degrade lesser materials. For projects demanding maximum longevity, aluminum-magnesium-manganese alloys combine lightweight properties with exceptional durability, maintaining structural integrity and aesthetic appeal for 50 years or more under normal environmental conditions. Advanced coating technologies further enhance the corrosion resistance of Metal Corrugated Roofing Panel systems. Polyester (PE) coatings provide economical protection suitable for moderate climate zones, while high-durability polyester (HDP) formulations deliver improved chalk resistance and color retention in more demanding environments. For premium applications requiring maximum weather resistance, PVDF (polyvinylidene fluoride) coatings represent the gold standard, offering superior resistance to UV radiation, acid rain, industrial pollutants, and extreme temperature fluctuations. These fluoropolymer coatings maintain their protective properties and visual appearance for 30 years or more, as evidenced by our company's 30-year warranty coverage on premium corrugated roofing sheets. The molecular structure of PVDF creates an exceptionally stable barrier that resists chalking, fading, and chemical degradation far better than conventional paint systems, ensuring that Metal Corrugated Roofing Panel installations retain their functional and aesthetic qualities throughout their extended service life.

Structural Strength and Load-Bearing Capacity

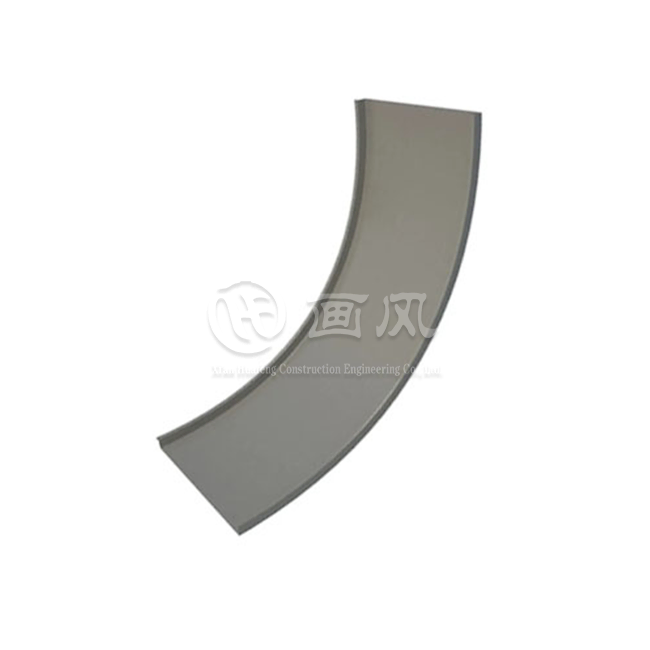

The distinctive corrugated profile that defines Metal Corrugated Roofing Panel provides remarkable structural advantages that directly translate to superior durability and longevity. The wave-like ridges and valleys increase the effective moment of inertia of each panel, enabling thin metal sheets to support substantial loads that would cause flat panels of equivalent thickness to buckle or deflect excessively. Standard corrugation patterns with wave heights ranging from 25mm to 50mm create a three-dimensional geometry that resists bending forces in multiple directions, making corrugated roofing sheets capable of spanning greater distances between structural supports while maintaining adequate safety factors. This inherent strength allows Metal Corrugated Roofing Panel systems to withstand snow accumulation, wind uplift forces, and impact loads from hail or falling debris that would damage or penetrate conventional roofing materials. Panel thickness and gauge significantly influence the load-bearing performance of Metal Corrugated Roofing Panel installations. While 26-gauge (approximately 0.46mm) represents the most common specification for residential and light commercial applications, 24-gauge (approximately 0.61mm) panels provide enhanced strength for structures subjected to higher loads or more severe weather conditions. Our manufacturing capabilities at Xi'an Huafeng allow us to produce corrugated roofing sheets with customized thickness specifications ranging from 0.4mm to 1.2mm, ensuring optimal performance for each project's specific requirements. Thicker panels naturally exhibit greater resistance to denting, perforation, and structural deformation, though they also increase material costs and impose higher dead loads on supporting structures. The corrugation spacing and wave amplitude also affect overall panel stiffness, with tighter corrugation patterns generally providing improved lateral stability while wider spacing facilitates more efficient water drainage. Our engineering team conducts detailed load analysis and structural modeling to specify appropriate Metal Corrugated Roofing Panel configurations that balance durability requirements against economic considerations and architectural design intent.

Weather Resistance and Environmental Performance

Metal Corrugated Roofing Panel systems demonstrate exceptional resistance to diverse weather conditions that frequently compromise or destroy alternative roofing materials. The impermeable nature of metal prevents water absorption that causes wood to rot, asphalt shingles to deteriorate, and concrete tiles to crack through freeze-thaw cycling. Properly installed corrugated roofing sheets with appropriate overlap configurations and sealed penetrations create a continuous weatherproof barrier that sheds precipitation efficiently while preventing wind-driven rain from infiltrating beneath the roof covering. The corrugated profile's inherent drainage channels direct water flow toward eaves and gutters, minimizing standing water that could accelerate corrosion or create leak pathways. In regions experiencing heavy snowfall, Metal Corrugated Roofing Panel installations facilitate snow shedding through their smooth metallic surfaces and reduced friction coefficients, reducing structural loads and eliminating ice dam formation that plagues textured roofing materials.

Wind resistance represents another critical durability factor where Metal Corrugated Roofing Panel excels compared to many competing roofing systems. The mechanical fastening methods used with corrugated roofing sheets create positive connections that resist uplift forces generated by high winds passing over roof surfaces. When fasteners are properly installed through the panel ridges into structural supports at specified intervals, Metal Corrugated Roofing Panel systems can withstand wind velocities exceeding 150 miles per hour without experiencing panel separation or progressive failure. The corrugated geometry itself provides aerodynamic advantages that reduce pressure differentials across the roof surface, decreasing uplift forces compared to flat or minimally profiled panels. Our installation specifications at Xi'an Huafeng include detailed fastener schedules that account for local wind exposure categories, building height, and roof configuration to ensure that every Metal Corrugated Roofing Panel project delivers reliable performance throughout its design life. We conduct on-site testing after installation completion to verify zero leakage and confirm that all fasteners meet proper torque specifications, providing documentation that installation quality matches our manufacturing standards.

Thermal Performance and Expansion Management

Temperature fluctuations present unique challenges for Metal Corrugated Roofing Panel durability that require careful consideration during both design and installation phases. Metal's high thermal conductivity means that roof surfaces can experience dramatic temperature swings as solar radiation heats panels during daytime hours and radiative cooling reduces temperatures at night. These thermal cycles cause dimensional changes as metal expands when heated and contracts when cooled, with typical coefficients of thermal expansion around 12 to 23 millionths per degree Celsius depending on the specific alloy composition. Over a temperature range of 80°C (from -20°C winter nights to 60°C summer afternoons), a 10-meter-long corrugated roofing sheet could theoretically expand or contract by 10 to 18 millimeters if completely restrained. Proper installation techniques account for this thermal movement by utilizing fastening methods that permit controlled panel movement while maintaining weathertight seals and preventing fastener loosening or material distortion.

The exposed fastener design commonly employed with Metal Corrugated Roofing Panel requires particular attention to thermal expansion management to maintain long-term durability and leak resistance. Fasteners installed through panel ridges must penetrate with sufficient engagement to resist wind uplift while avoiding over-tightening that prevents thermal movement and induces stress concentrations. High-quality fastener assemblies incorporate resilient sealing washers that compress to create weatherproof seals while accommodating minor panel movement without losing effectiveness. Xi'an Huafeng's installation guidance specifies appropriate fastener types, installation torque values, and spacing patterns optimized for different panel configurations and climate conditions. Our technical team provides comprehensive training ensuring that installation crews understand thermal movement principles and implement proper techniques that allow corrugated roofing sheets to expand and contract freely without developing buckles, wrinkles, or fastener withdrawal that could compromise system durability. We also offer advanced coating systems with enhanced emissivity properties that reflect solar radiation more effectively, reducing peak panel temperatures and minimizing thermal stress cycles that can accelerate material fatigue over decades of service.

Maintenance Requirements and Service Life Extension

One of Metal Corrugated Roofing Panel's most compelling durability advantages lies in its minimal maintenance requirements compared to alternative roofing systems. Unlike asphalt shingles that require periodic inspection and replacement of damaged units, or tile roofs that need regular cleaning and broken tile replacement, properly installed corrugated roofing sheets typically require only basic periodic inspections to verify continued performance. The smooth metallic surfaces resist biological growth including moss, algae, and lichen that plague porous roofing materials in humid climates, eliminating the need for chemical treatments or pressure washing that can damage protective coatings. The absence of granular surface treatments means Metal Corrugated Roofing Panel systems don't experience the gradual degradation that occurs as asphalt shingles shed their protective mineral coating, maintaining consistent weather resistance throughout their service life rather than exhibiting progressive deterioration.

Annual or biannual inspections represent the primary maintenance activity required to maximize Metal Corrugated Roofing Panel longevity. These examinations should focus on verifying fastener tightness, checking for any signs of panel damage or coating deterioration, ensuring that drainage systems remain clear of debris, and confirming that sealants at penetrations and transitions maintain their integrity. Exposed fasteners may require periodic retightening as thermal cycling gradually relaxes initial installation torque, though high-quality fastener assemblies with locking features minimize this requirement. Any damaged coating areas should receive prompt touch-up treatment to prevent corrosion initiation at exposed metal surfaces. Xi'an Huafeng provides detailed maintenance guidelines with every Metal Corrugated Roofing Panel installation, specifying inspection frequencies appropriate for local environmental conditions and offering touch-up coating materials that match original finish systems. Our customer support team remains available throughout the roof's service life to address questions, provide technical guidance, and arrange for professional inspection services when desired. This ongoing commitment to customer success ensures that corrugated roofing sheets continue delivering optimal performance for decades, protecting building contents and maintaining aesthetic appearance that enhances property value.

Cost-Effectiveness and Long-Term Value

When evaluating Metal Corrugated Roofing Panel durability, the relationship between initial investment and lifecycle cost provides critical perspective for informed decision-making. While corrugated roofing sheets may command higher upfront costs than basic asphalt shingles, their extended service life of 40 to 70 years compared to asphalt's 15 to 25-year typical lifespan means that building owners avoid multiple re-roofing expenses over their facility's operational period. A Metal Corrugated Roofing Panel system installed today will likely never require replacement during the working life of most commercial or industrial structures, eliminating the disruption, waste disposal costs, and repeated installation expenses associated with short-lived roofing materials. The minimal maintenance requirements further reduce lifecycle costs, as corrugated roofing sheets don't demand regular treatments, cleaning, or component replacements that consume resources and management attention.

Energy performance considerations add another dimension to Metal Corrugated Roofing Panel's long-term value proposition. Reflective coating systems available on premium corrugated roofing sheets can reduce cooling loads by 10 to 25 percent in warm climates, generating substantial energy cost savings that accumulate over decades of operation. The inherent airspace created by the corrugated profile provides thermal break functionality that reduces conductive heat transfer, while the low thermal mass of metal means roof surfaces cool rapidly after sunset, minimizing nighttime radiant heat transmission into building interiors. Some insurance carriers offer premium discounts for Metal Corrugated Roofing Panel installations due to their superior fire resistance and wind performance compared to combustible or less securely attached roofing systems. Xi'an Huafeng's competitive pricing structure, enabled by our vertically integrated manufacturing operations spanning raw material production through final coating application, delivers exceptional value for Metal Corrugated Roofing Panel projects. Our 1000-ton monthly production capacity and efficient logistics ensure consistent material availability without the premium costs often associated with specialty construction products, making durable metal roofing accessible for projects ranging from modest agricultural structures to major commercial developments.

Real-World Performance Documentation

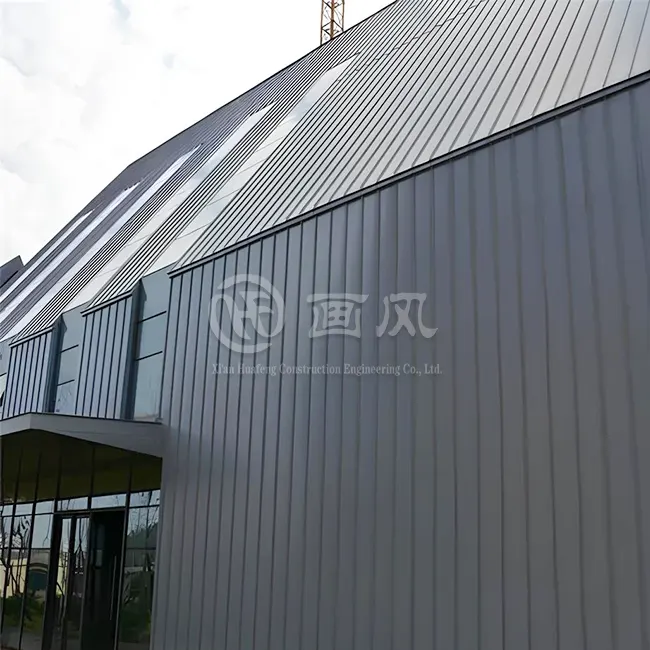

Xi'an Huafeng Construction Engineering Co., Ltd. has successfully installed Metal Corrugated Roofing Panel systems across diverse applications demonstrating the material's exceptional durability under real-world conditions. Our portfolio includes high-profile projects such as the Xiongan Station Commercial Body, where aluminum-magnesium-manganese Metal Corrugated Roofing Panel covers expansive areas subjected to heavy pedestrian traffic, severe weather exposure, and stringent aesthetic requirements. The Xi'an International Convention and Exhibition Center metal roof project showcases how corrugated roofing sheets perform in architecturally demanding applications where durability must coexist with visual impact and complex geometric configurations. These installations undergo regular performance monitoring, confirming that properly specified and professionally installed Metal Corrugated Roofing Panel systems maintain their protective and aesthetic functions year after year with minimal intervention.

Our manufacturing quality assurance program ensures that every corrugated roofing sheet leaving our facilities meets or exceeds international standards including ASTM, DIN, JIS, BS, and GB/T specifications. Raw materials undergo rigorous incoming inspection protocols verifying compliance with supplier certifications and third-party test reports before entering production. We conduct comprehensive quality checks throughout manufacturing including appearance inspection, dimensional verification, salt spray testing, adhesion evaluation, hardness measurement, impact resistance, film thickness assessment, acid resistance, weather resistance simulation, and color consistency analysis. Finished Metal Corrugated Roofing Panel products receive final inspection covering appearance quality, dimensional accuracy, flatness, and curvature before protective packaging and shipment. This multi-stage quality control approach, combined with ISO9001, ISO14001, and SGS certifications, provides assurance that corrugated roofing sheets will deliver the durability and performance that project specifications demand. Our 30-year warranty coverage on premium coating systems reflects confidence in Metal Corrugated Roofing Panel longevity based on decades of field performance data and accelerated testing protocols that simulate extended environmental exposure.

Conclusion

Metal Corrugated Roofing Panel stands as one of the most durable roofing solutions available, offering 40 to 70 years of reliable performance when manufactured to exacting standards and installed by qualified professionals. The combination of corrosion-resistant materials, structural corrugated geometry, advanced coating systems, and minimal maintenance requirements creates exceptional long-term value that far exceeds short-lived alternatives.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. represents your ideal partner for durable Metal Corrugated Roofing Panel solutions backed by comprehensive manufacturing capabilities and proven project execution expertise. As a recognized high-tech enterprise in Shaanxi Province with first-level curtain wall qualifications and third-level steel structure credentials, we deliver complete one-stop services from initial design through final installation. Our 200,000-square-meter raw material production facility in Anhui, complemented by processing plants in Hangzhou and Xi'an, operates 7 color coating production lines and maintains over 40 specialized machines ensuring consistent quality and timely delivery. We hold more than 20 registered patents for roofing systems and maintain ISO9001, ISO14000, and SGS certifications demonstrating our commitment to quality excellence.

As a leading China Metal Corrugated Roofing Panel factory, China Metal Corrugated Roofing Panel supplier, and China Metal Corrugated Roofing Panel manufacturer, we offer High Quality Metal Corrugated Roofing Panel for sale at competitive Metal Corrugated Roofing Panel price points with China Metal Corrugated Roofing Panel wholesale options for large-scale projects. Our engineering team provides design optimization services, raw material quality testing, customized production capabilities, and multiple packaging and transportation solutions tailored to your project requirements. From Fortune 500 companies to specialized industrial applications, our corrugated roofing sheets protect critical assets across residential, commercial, and institutional facilities worldwide. Contact us today at huafeng@hfmetalroof.com to discuss your Metal Corrugated Roofing Panel requirements and discover how our one-stop procurement approach from raw materials through accessories simplifies project execution while ensuring exceptional durability and long-term performance. Save this resource for future reference whenever roofing questions arise.

References

1. Metal Construction Association. "Guide Specification for Standing Seam and Exposed Fastener Metal Roof Panel Systems." Metal Construction Association Technical Standards Committee.

2. American Society for Testing and Materials. "ASTM A653/A653M Standard Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by the Hot-Dip Process." ASTM International.

3. National Roofing Contractors Association. "The NRCA Metal Panel and SPF Roofing Manual." National Roofing Contractors Association Publications.

4. Sheet Metal and Air Conditioning Contractors National Association. "Architectural Sheet Metal Manual." SMACNA Technical Publications.

5. Cool Metal Roofing Coalition. "Metal Roofing Energy Performance and Life Cycle Assessment." Cool Metal Roofing Coalition Research Division.