Picture this scenario: you've invested heavily in a commercial warehouse or industrial facility, only to watch helplessly as a severe storm tears sections of your roof away, causing devastating water damage to equipment and inventory. This nightmare becomes reality for thousands of building owners annually because their roofing systems lack proper wind resistance engineering. The Snap Clad Standing Seam Roof Panel addresses this critical vulnerability through advanced mechanical interlocking design, concealed fastener systems, and continuous panel construction that creates a unified protective barrier capable of withstanding extreme wind uplift forces that would compromise conventional roofing materials.

Understanding Wind Uplift Forces on Roofing Systems

Wind resistance represents one of the most critical performance factors for any roofing system, particularly in regions prone to severe weather events. When wind flows over a building structure, it creates differential pressure zones that generate powerful uplift forces attempting to literally pull the roof from its substrate. Research has demonstrated that these uplift pressures concentrate most intensely at roof corners, edges, and ridge areas, where wind speeds can accelerate significantly due to aerodynamic effects. The Snap Clad Standing Seam Roof Panel system addresses these challenges through sophisticated engineering that distributes wind loads effectively across the entire roof assembly. The physics of wind uplift involves negative pressure zones forming above the roof surface while positive pressure builds within the building interior. This pressure differential creates suction forces that can exceed several hundred pounds per square foot during severe weather conditions. Traditional roofing systems with exposed fasteners create numerous penetration points where these forces can concentrate, leading to progressive failure as individual fasteners pull through or panels separate. The Snap Clad Standing Seam Roof Panel eliminates this vulnerability by employing concealed clip systems that transfer loads directly to the structural substrate without creating weak points in the weatherproof membrane.

Key Design Features That Enhance Wind Resistance in Snap Clad Standing Seam Roof Panel

Continuous Interlock Seam Technology

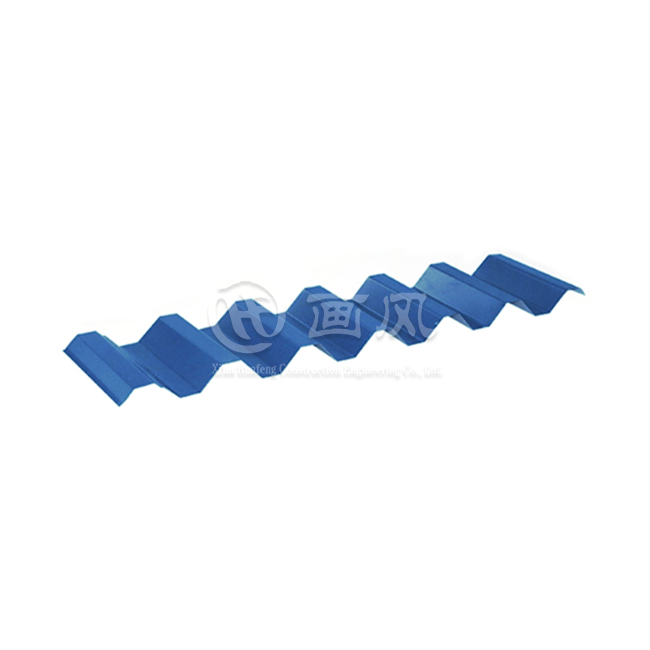

The defining characteristic of the Snap Clad Standing Seam Roof Panel lies in its continuous interlocking seam design that runs the entire length of each panel from eave to ridge. This configuration creates a mechanical connection between adjacent panels that functions like a zipper, distributing wind uplift forces along the entire seam length rather than concentrating stress at isolated fastener points. The interlock features a precise geometric profile that snaps together during installation, creating redundant load paths that maintain structural integrity even if individual clips experience stress. This continuous connection prevents the progressive unzipping failure mode common in other roofing systems where once a single fastener fails, adjacent fasteners experience cascading overload. The seam height specification ranging from 45-50mm provides crucial structural depth that increases the panel's moment of inertia and resistance to deflection under wind loading. When wind pressure attempts to peel back the roof panels, the elevated seam creates a mechanical advantage that directs forces downward into the clip system rather than allowing lateral movement. Xi'an Huafeng Construction Engineering Co., Ltd. manufactures these panels with exacting tolerances to ensure consistent interlock engagement across the entire roof field, eliminating gaps or misalignments that could compromise wind performance.

Concealed Fastener Clip System Engineering

The concealed fastener approach employed in Snap Clad Standing Seam Roof Panel construction represents a fundamental advancement in wind resistance technology compared to exposed fastener systems. Traditional through-fastened roof panels create thousands of penetrations through the weatherproof barrier, with each screw location representing a potential failure point under uplift loads. The Snap Clad system instead utilizes specially engineered clips that attach to the structural substrate while remaining completely hidden beneath the interlocked panel seams. These clips incorporate features that allow controlled thermal movement while maintaining extraordinary hold-down capacity under wind loading conditions. The clip geometry typically includes a vertical leg that attaches to structural purlins or decking, combined with a horizontal platform that captures the panel seam. During wind events, uplift forces transfer through the panel material into the seam profile, where they engage the clip's horizontal surface and redirect downward into the fasteners securing the clip to the substrate. This load path ensures that wind forces encounter the full holding capacity of multiple fasteners per clip rather than relying on individual screw penetrations through the panel itself. Testing data indicates that properly installed clip systems in Snap Clad Standing Seam Roof Panel assemblies can achieve uplift resistance ratings exceeding 90 pounds per square foot, meeting the most stringent building code requirements for high-wind exposure categories.

The floating clip design further enhances both wind performance and long-term durability by accommodating thermal expansion and contraction without creating stress concentrations. Metal roofing panels experience significant dimensional changes across temperature ranges, with a 60-foot panel potentially expanding or contracting several inches between summer and winter extremes. Fixed fastener systems must resist these movements, creating internal stresses that can lead to fastener loosening, panel distortion, or connection failure. The Snap Clad Standing Seam Roof Panel clip system allows panels to move freely in their longitudinal direction while maintaining consistent uplift resistance, ensuring that thermal cycling does not degrade wind performance over the roof's service life.

Material Selection and Panel Profile Optimization

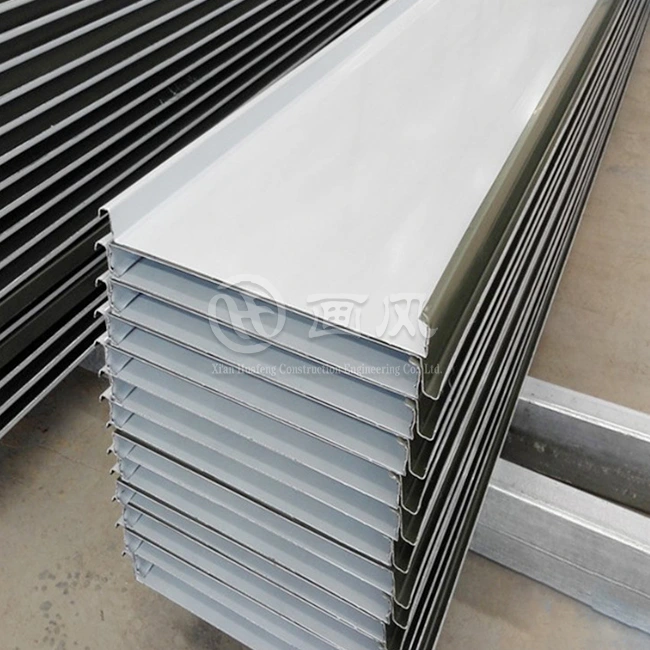

Xi'an Huafeng Construction Engineering Co., Ltd. offers Snap Clad Standing Seam Roof Panel systems in multiple material specifications including aluminum alloy grades 3003, 3004, and 5052, galvanized and galvalume steel, stainless steel grades 316 and 304, copper, and titanium-zinc alloys. Each material option provides distinct advantages for wind resistance applications based on its strength-to-weight ratio, stiffness properties, and corrosion resistance characteristics. Aluminum alloys deliver exceptional performance in coastal high-wind environments where salt spray would rapidly degrade ferrous materials, while their low density reduces dead loads on the structural system. Steel options provide superior rigidity and dent resistance in applications where impact loads from wind-borne debris represent a concern. The panel thickness specifications ranging from 0.5-1.2mm allow engineers to optimize the roof system for specific wind exposure classifications. Thicker gauge materials increase panel stiffness and reduce deflection under wind loading, though they also increase material costs and structural loading. Advanced engineering calculations consider factors including panel span between supports, expected wind pressures based on building location and geometry, and required safety factors to determine the minimum thickness necessary for code compliance. For extreme wind exposure applications, Xi'an Huafeng Construction Engineering Co., Ltd. recommends 1.0mm or greater thickness combined with reduced clip spacing to maximize uplift resistance capacity.

Surface coating selection also impacts wind performance through its effect on panel rigidity and resistance to environmental degradation. The PVDF (polyvinylidene fluoride) coating option provides superior weather resistance and maintains material properties over decades of exposure to UV radiation, temperature cycling, and moisture. This long-term stability ensures that the Snap Clad Standing Seam Roof Panel maintains its design wind resistance capacity throughout its service life rather than experiencing gradual degradation that could lead to premature failure during severe weather events.

Testing Standards and Performance Verification for Wind Resistance

ASTM E1592 Wind Uplift Testing Methodology

The industry-recognized standard for evaluating metal roof system wind resistance, ASTM E1592 provides a comprehensive test methodology that subjects full-scale roof assemblies to simulated wind uplift pressures in laboratory conditions. This test protocol employs a pressure chamber that creates uniform static pressure differential across a specimen assembly, typically measuring 12 feet by 24 feet and incorporating actual structural substrates, insulation layers, underlayment materials, roof panels, and all connection hardware exactly as specified for field installation. The test procedure incrementally increases uplift pressure while monitoring for signs of distress including seam separation, clip disengagement, fastener pullout, or panel deflection beyond acceptable limits. Snap Clad Standing Seam Roof Panel systems undergo rigorous ASTM E1592 testing to document their ultimate uplift capacity and establish design pressure ratings for engineering calculations. The test continues until the assembly experiences defined failure modes, with the ultimate pressure recorded as the maximum loading achieved. Building codes typically require design pressures calculated as 50% of the ultimate test pressure, incorporating a 2:1 safety factor to account for variability in materials, installation quality, and actual wind loading patterns. Test reports provide detailed documentation of failure mechanisms, allowing engineers to understand how the system responds under extreme loading and identify potential areas for optimization through modified clip spacing, increased material thickness, or enhanced fastener schedules.

UL 580 Classification System

Underwriters Laboratories Standard 580 provides an alternative wind resistance rating system widely referenced in building specifications and insurance requirements. This test method evaluates roof assemblies under simulated wind conditions using a standardized pressure chamber configuration. Results classify systems into uplift resistance categories designated as Class 15, 30, 60, or 90, with the number indicating the pressure in pounds per square foot that the assembly withstood for one minute without failure. Snap Clad Standing Seam Roof Panel installations routinely achieve UL 90 classifications when properly engineered and installed, demonstrating their suitability for the most demanding wind exposure categories including coastal high-hazard areas. The UL testing protocol examines multiple potential failure modes including progressive seam separation, fastener withdrawal, substrate failure, and panel distortion. Achieving higher classification levels requires attention to every system component, from the structural deck and its attachment to the building frame, through the insulation and vapor barrier layers, to the final roof panel and trim installations. Xi'an Huafeng Construction Engineering Co., Ltd. provides comprehensive installation specifications developed from extensive UL testing programs, ensuring that field installations replicate the laboratory configurations that achieved certified performance ratings.

Installation Factors That Maximize Wind Resistance Performance

Substrate Preparation and Clip Spacing Optimization

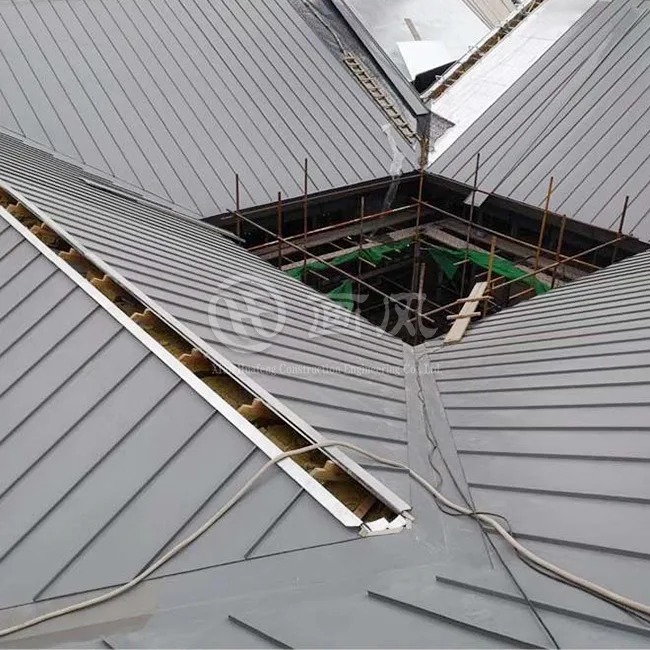

Even the most advanced Snap Clad Standing Seam Roof Panel design cannot achieve its rated wind resistance capacity without proper substrate conditions and strategic clip placement. The structural deck must provide adequate bearing surface and fastener holding capacity to resist the concentrated loads transferred through each clip attachment. Minimum substrate specifications typically require 5/8-inch exterior-grade plywood, minimum 18-gauge steel decking, or equivalent rigid board insulation systems approved by the panel manufacturer. Substrate materials must meet minimum density and compression strength requirements to prevent crushing or fastener pullout under uplift loading conditions. Clip spacing represents the most critical variable in optimizing wind resistance for specific building geometries and exposure classifications. Standard clip spacing might employ 24-inch on-center placement for interior roof zones experiencing moderate wind pressures, but engineering calculations often require reduced spacing approaching 12 inches or less in high-stress areas including roof corners, edges, and ridges. Advanced engineering analysis using computational fluid dynamics can identify precise pressure distribution patterns for complex building geometries, allowing strategic clip placement that delivers required resistance capacity while minimizing material costs. Xi'an Huafeng Construction Engineering Co., Ltd.'s technical team provides customized clip spacing layouts for each project based on detailed wind engineering calculations that account for building height, roof slope, geographic location, terrain exposure, and nearby structures that influence wind flow patterns.

Quality Control During Field Installation

Wind resistance performance depends critically on installation workmanship quality, as even minor deviations from specified procedures can significantly compromise system capacity. Proper seam engagement requires careful alignment of adjacent panels during the interlocking process, ensuring that the male and female seam profiles fully engage along the entire panel length without gaps or partial connections. Installation crews must verify seam engagement visually and through tactile confirmation, checking that the snap-lock mechanism has positively engaged at regular intervals. Incomplete seam interlocking creates stress concentrations where wind forces can initiate progressive unzipping failures. Fastener installation quality equally impacts ultimate wind resistance, with proper fastener type, size, embedment depth, and torque application all affecting holding capacity. The Snap Clad Standing Seam Roof Panel system specifications from Xi'an Huafeng Construction Engineering Co., Ltd. provide detailed fastener schedules identifying approved fastener products, minimum embedment lengths for different substrate types, and torque ranges that ensure adequate clamping force without crushing substrates or distorting clips. Field inspection protocols should verify that installers follow these specifications consistently across the entire roof area, with particular attention to high-stress zones where a single incorrectly installed fastener could precipitate system failure during severe weather events.

Conclusion

The Snap Clad Standing Seam Roof Panel delivers superior wind resistance through integrated engineering of continuous interlocking seams, concealed clip systems, optimized material specifications, and rigorous performance testing validated through industry-standard protocols. This comprehensive approach addresses the fundamental mechanisms of wind-induced roof failure, creating robust assemblies capable of protecting structures throughout their service life.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in 2018 in Shaanxi Province, China, stands as a premier manufacturer and supplier of advanced metal roofing systems, specializing in the design, production, and installation of building envelope solutions. Recognized as a high-tech enterprise in Shaanxi Province in 2020, the company holds first-level qualifications for building curtain walls and third-level qualifications for building steel structures, demonstrating its technical expertise and quality management capabilities. Our manufacturing infrastructure encompasses a 200,000 square meter raw material production facility in Anhui, complemented by processing plants in Hangzhou and Xi'an, housing 7 color coating production lines, 1 laminating line, 10 longitudinal and transverse shearing lines, fully automatic punching systems, and more than 40 specialized machines.

As a leading China Snap Clad Standing Seam Roof Panel factory, China Snap Clad Standing Seam Roof Panel supplier, and China Snap Clad Standing Seam Roof Panel manufacturer, we provide comprehensive solutions from initial design consultation through final installation and maintenance. Our expertise extends to structural 3D modeling, load analysis, drainage system simulation, and material specification advisory services. We offer China Snap Clad Standing Seam Roof Panel wholesale options with customizable specifications including thickness from 0.5-1.2mm, seam heights of 45-50mm, and extensive color selections meeting RAL standards. Our High Quality Snap Clad Standing Seam Roof Panel products feature PVDF and PE finishes, carry 30-year warranties, and comply with international standards including ASTM, DIN, JIS, BS, and GB/T. With more than 20 registered patents, ISO9001 and ISO14001 certifications, and proven performance in prestigious projects including Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, and Inner Mongolia Tongliao Art Museum, we deliver proven reliability for commercial, industrial, and institutional applications. Our competitive Snap Clad Standing Seam Roof Panel price, combined with Snap Clad Standing Seam Roof Panel for sale options featuring 15-20 day delivery times and 1000 ton monthly supply capacity, makes us your ideal partner for metal roofing excellence. Contact our engineering team at huafeng@hfmetalroof.com to discuss your project requirements and discover how our one-stop service approach delivers superior value from raw materials to installed performance.

References

1. Morrison, M.J., Henderson, D.J., and Kopp, G.A. "Performance of Metal Roofing to Realistic Wind Loads and Comparison with Current Test Standards." Insurance Institute for Business & Home Safety.

2. Zhao, Rui, Wu, Libo, Zhao, Huijun, Wang, Yihao, and He, Yifan. "Study on the Reliability of Wind-Uplifted Resistance of Different Types of Standing Seam Metal Roof Systems." Buildings Journal, Volume 15, Issue 21, 2025.

3. American Society for Testing and Materials. "ASTM E1592 Standard Test Method for Structural Performance of Sheet Metal Roof and Siding Systems by Uniform Static Air Pressure Difference." ASTM International.

4. Underwriters Laboratories. "UL 580 Tests for Uplift Resistance of Roof Assemblies." Underwriters Laboratories Standard.

5. Factory Mutual Global. "FM 4471 Approval Standard for Class 1 Panel Roofs." FM Approvals LLC.