Are you struggling to find a reliable manufacturer for 1 inch standing seam metal roofing that meets both quality standards and project deadlines? Many procurement managers and contractors face challenges with inconsistent panel quality, delayed deliveries, and suppliers who cannot customize products to meet specific architectural requirements. This comprehensive guide addresses these pain points by providing essential insights into sourcing high-quality 1 inch standing seam metal roofing panels from OEM manufacturers, ensuring your commercial or industrial projects achieve superior performance, aesthetic appeal, and long-term durability. Understanding the critical factors in panel selection, manufacturer capabilities, and quality assurance processes will empower you to make informed purchasing decisions that protect your investment and reputation.

Understanding 1 Inch Standing Seam Metal Roofing Systems

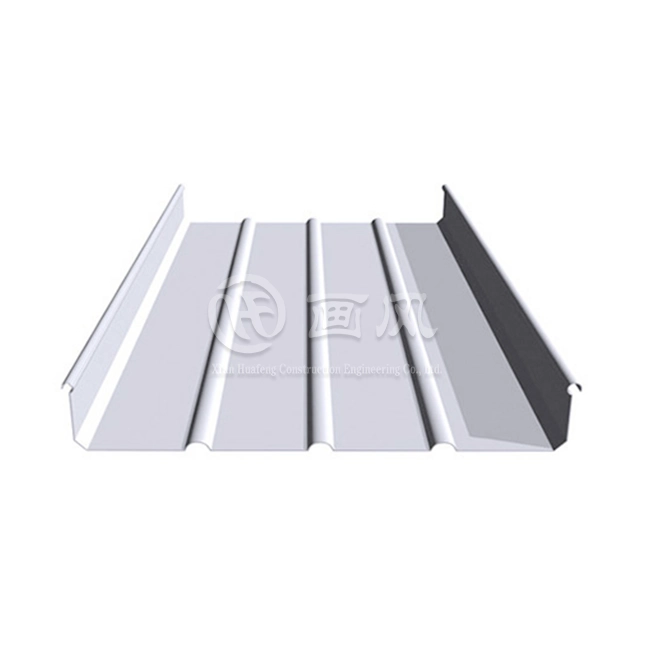

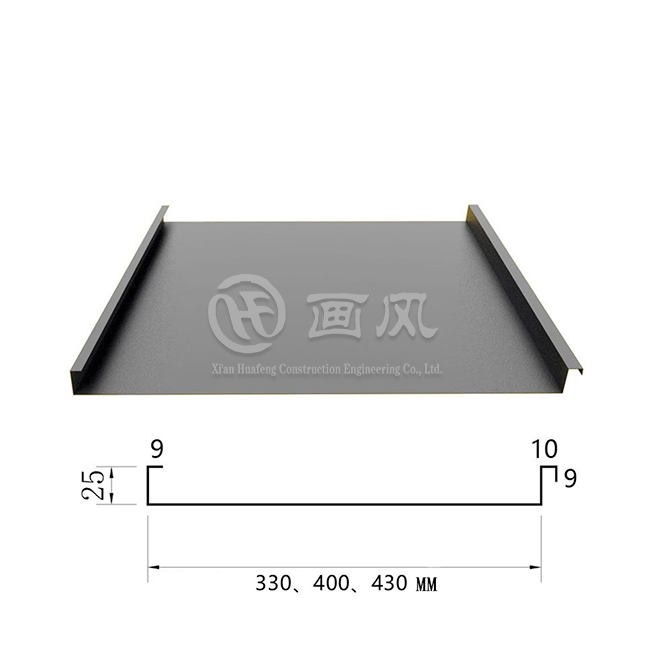

The 1 inch standing seam metal roofing system represents a sophisticated engineering solution that combines structural integrity with aesthetic refinement. The term "1 inch" specifically refers to the height of the standing seam protrusion, measuring approximately 25.4 millimeters, which creates a distinctive vertical profile along the roof surface. This elevated seam design serves multiple critical functions beyond mere appearance. The concealed fastener configuration eliminates exposed screw penetrations that could compromise waterproofing integrity, while the vertical orientation facilitates efficient water drainage and prevents moisture accumulation. Unlike traditional roofing systems where fasteners create potential leak points, 1 inch standing seam metal roofing utilizes hidden clips or fastening flanges that secure panels to the structural substrate without penetrating the weather-exposed surface. The engineering principles behind 1 inch standing seam metal roofing deliver exceptional performance characteristics that address common roofing challenges. The raised seam profile creates a physical barrier that redirects water flow away from panel connections, significantly enhancing leak resistance compared to lower-profile systems. This design proves particularly effective in regions experiencing heavy rainfall, snow accumulation, or wind-driven precipitation. The thermal expansion and contraction properties of metal roofing materials require careful consideration, and the clip-based attachment system allows panels to move naturally without causing buckling, oil canning, or fastener failure. Material thickness typically ranges from 0.5mm to 1.2mm, with aluminum panels commonly specified at 0.7-0.8mm and steel panels at 0.6mm, providing an optimal balance between structural strength, weight considerations, and cost efficiency.

Technical Specifications and Material Selection

When sourcing 1 inch standing seam metal roofing panels from OEM manufacturers, understanding material specifications becomes paramount to project success. Premium manufacturers offer multiple material options including aluminum-magnesium-manganese alloys, galvanized steel, galvalume steel, stainless steel, and titanium-zinc panels, each providing distinct advantages for specific applications. Aluminum-magnesium-manganese alloys deliver superior corrosion resistance and lightweight properties, making them ideal for coastal environments and structures requiring reduced dead loads. Steel-based options provide enhanced structural rigidity and impact resistance, suitable for industrial facilities and regions experiencing severe weather conditions. The surface treatment selection significantly impacts long-term performance, with PVDF (polyvinylidene fluoride) coatings offering exceptional color retention and weather resistance for forty years or more, while polyester coatings provide economical protection for applications with shorter design life requirements. Panel width customization typically ranges from 300mm to 600mm, allowing architects and engineers to optimize visual proportions and installation efficiency for specific building geometries. Length customization accommodates virtually any roof configuration, though practical considerations limit individual panel lengths to approximately twelve meters to facilitate transportation and handling. Color selection extends beyond aesthetic preferences to include solar reflectance properties that reduce cooling loads and qualify for energy efficiency incentives. The RAL color system provides standardized color matching across international markets, ensuring consistency when coordinating roofing materials with curtain walls, trim components, and architectural elements. Quality OEM manufacturers maintain extensive color inventories and can produce custom color matches when projects require specific brand coordination or historical restoration accuracy.

Critical Factors in OEM Manufacturer Selection

Selecting the appropriate OEM manufacturer for 1 inch standing seam metal roofing panels requires comprehensive evaluation of production capabilities, quality control systems, and service infrastructure. Manufacturing capacity directly impacts project feasibility, particularly for large-scale commercial developments requiring thousands of square meters of roofing materials within compressed construction schedules. Leading manufacturers operate multiple production facilities with parallel manufacturing lines, providing redundancy that protects against supply chain disruptions and ensures consistent delivery performance. For example, manufacturers with seven color coating production lines, ten longitudinal and transverse shearing lines, and fully automated punching systems can simultaneously process multiple projects while maintaining strict quality standards and dimensional tolerances. This production scale enables monthly output capacities exceeding one thousand tons, sufficient for major institutional, commercial, and industrial projects.

Quality certification demonstrates manufacturer commitment to international standards and provides procurement assurance for projects requiring documented compliance. ISO 9001 certification verifies implementation of comprehensive quality management systems covering material procurement, production processes, inspection procedures, and corrective action protocols. ISO 14001 environmental management certification confirms sustainable manufacturing practices including waste reduction, energy efficiency, and pollution prevention. SGS inspection reports provide independent third-party verification of material properties, dimensional accuracy, and coating performance. ASTM, DIN, JIS, BS, and GB/T standard compliance ensures compatibility with international building codes and engineering specifications. Manufacturers holding these certifications demonstrate institutional maturity and process discipline that translates into consistent product quality and reliable project execution.

Engineering Support and Technical Capabilities

Comprehensive engineering support distinguishes superior OEM manufacturers from commodity suppliers in the 1 inch standing seam metal roofing market. Advanced manufacturers provide structural 3D modeling services that integrate roofing systems into building information modeling platforms, enabling clash detection, load analysis, and coordination with mechanical, electrical, and plumbing systems before fabrication begins. Drainage system simulation identifies potential water accumulation areas and optimizes valley configurations, gutter placements, and downspout locations to prevent overflow conditions. Material specification advisory services help design teams navigate performance trade-offs between aluminum and steel substrates, coating systems, and panel profiles based on project-specific requirements including budget constraints, aesthetic objectives, and maintenance expectations. The drawing deepening process represents a critical value-added service that transforms architectural concepts into fabrication-ready specifications. Professional design departments analyze floor plans, elevations, and node diagrams to identify feasible implementation alternatives and potential constructability challenges. Collaborative communication establishes optimal panel types for specific roof structures, considering slope angles, load-bearing capacity, thermal movement accommodation, and interface conditions with adjacent building systems. One-to-one drawing deepening produces detailed node specifications for eaves, ridges, valleys, penetrations, and transitions, eliminating field coordination issues and reducing installation time. Multiple review cycles with signature confirmation create contractual clarity and protect both manufacturers and contractors from scope disputes and change order conflicts.

Manufacturing Excellence and Quality Assurance

Manufacturing excellence in 1 inch standing seam metal roofing production begins with rigorous material procurement and incoming inspection protocols. Leading manufacturers maintain approved supplier lists for aluminum, steel, stainless steel, titanium-zinc, and copper materials, specifying brand names and material grades that meet or exceed project specifications. For aluminum products, preferred brands include Alucosuper, Yatai, and Lidao in 3003, 3004, and 5052 alloys. Steel products source from Baosteel, Guanzhou, and Xinyu for cold-rolled sheets, galvanized sheets, galvalume sheets, and color-coated sheets. Stainless steel specifications reference Baosteel and Tsingshan for 304 and 316 grades. These brand preferences reflect years of performance validation and quality consistency that protect manufacturers and end users from material failures. Incoming material inspection represents the first critical quality control point in the manufacturing process. Quality assurance departments conduct sampling inspections or full inspections depending on batch sizes and unit values, preventing defective materials from entering production streams. Raw material suppliers provide material certifications and third-party testing reports documenting chemical composition, mechanical properties, and coating characteristics. Inspection protocols encompass appearance verification, dimensional accuracy, salt spray resistance, coating adhesion, hardness testing, impact resistance, film thickness measurement, acid resistance, weather resistance, and color difference evaluation. These comprehensive inspection steps ensure that only materials meeting stringent specifications proceed to production, eliminating the downstream costs and delays associated with material nonconformance.

Production Processing and Finished Product Inspection

Roll-forming systems transform coil stock into precision 1 inch standing seam metal roofing panels through computer-controlled forming sequences that maintain dimensional tolerances and surface finish quality. Real-time quality control monitoring tracks critical parameters including panel width, seam height, edge straightness, and surface planarity throughout production runs. Automated systems detect deviations and trigger corrective adjustments before significant quantities of nonconforming material are produced. Multiple quality checkpoints verify that panels meet dimensional specifications, with particular attention to the one-inch seam height that defines system performance and aesthetic character. Panel flatness and curvature measurements ensure proper fit during installation and minimize oil canning appearance that can diminish visual appeal. Finished product inspection provides final verification before packaging and shipment, protecting manufacturers and customers from field installation problems. Comprehensive inspection steps evaluate product appearance for coating defects, scratches, dents, or contamination that could compromise performance or aesthetics. Dimensional inspection confirms panel width, length, and seam height accuracy within specified tolerances. Flatness measurements across panel widths identify any warping or distortion that could create installation challenges or visual irregularities. Sequential numbering systems applied during production facilitate systematic installation procedures and eliminate field confusion when managing hundreds or thousands of individual panels across large roof areas.

Strategic Packaging and Installation Support

Packaging strategies for 1 inch standing seam metal roofing panels significantly impact installation efficiency and material protection during transportation and storage. Advanced manufacturers divide product packaging into logical sections corresponding to roof plan divisions, creating intuitive organization systems that expedite field operations. Product identification cards affixed to outer packaging include section floor plans and detailed product number lists, enabling installation crews to quickly locate specific panels without unpacking multiple bundles. This systematic approach minimizes handling damage, reduces installation time, and prevents costly errors that occur when panels are installed in incorrect sequences or locations. Packaging materials protect panel surfaces from scratches and contamination while providing sufficient structural support to prevent bending or distortion during shipping and handling operations. On-site construction support and technical guidance distinguish comprehensive OEM manufacturers from simple product suppliers. Pre-construction site consultations establish optimal construction site layouts including material storage areas, processing zones, and waste disposal locations that facilitate efficient workflow and maintain site safety. Product arrival procedures verify shipment accuracy and coordinate material placement based on packaging identification systems and sectioned floor plans. Installation technicians conduct advance site visits to inspect work areas, verify tool completeness including specialized equipment such as edge-locking machines and seaming tools, and confirm that auxiliary materials including clips, structural adhesive, and fasteners are available in sufficient quantities.

Installation Excellence and Performance Verification

Technical briefing meetings prior to installation commencement thoroughly review work details, safety protocols, and quality expectations with all project stakeholders. Detailed installation drawings provide panel-specific guidance for each roof section, eliminating ambiguity and ensuring consistent execution across entire roof areas. On-site installation supervision by manufacturer representatives ensures proper panel placement, seam engagement, clip installation, and detail work at critical interface conditions. This hands-on technical support prevents common installation errors that can compromise system performance or void manufacturer warranties. Installation quality directly impacts long-term roof performance, making skilled technical guidance a critical value proposition from quality OEM manufacturers. Upon installation completion, comprehensive performance testing verifies system integrity before final acceptance. Water testing protocols confirm zero leakage at panel seams, penetration details, and interface conditions with adjacent building elements. These field tests provide immediate feedback on installation quality and allow corrective action before protective scaffolding or access equipment is removed. Customer acceptance procedures include detailed interface reviews where clients examine completed work and confirm compliance with contract specifications and quality expectations. Signature confirmation documents acceptance and triggers warranty activation. Ongoing maintenance guidance ensures that building owners and facility managers understand proper care procedures that preserve system performance and appearance throughout the design life.

Conclusion

Sourcing high-quality 1 inch standing seam metal roofing panels from experienced OEM manufacturers requires careful evaluation of technical capabilities, quality systems, and comprehensive service offerings that extend beyond simple product supply to encompass engineering support, manufacturing excellence, and installation guidance.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a premier China 1 inch standing seam metal roofing factory, China 1 inch standing seam metal roofing supplier, and China 1 inch standing seam metal roofing manufacturer, offering comprehensive solutions from design through installation. Established in 2018 and recognized as a high-tech enterprise in Shaanxi Province, our company brings extensive engineering design experience, advanced engineering construction capabilities, and proven project execution across major commercial and institutional projects including Xiongan Station, Xi'an International Convention and Exhibition Center, and Inner Mongolia Tongliao Art Museum. Our three state-of-the-art factories house seven raw material production lines and more than twenty plate production machines, supporting monthly production capacities exceeding one thousand tons with delivery timeframes of fifteen to twenty days. Quality certifications including ISO 9001, ISO 14001, SGS verification, and more than twenty registered patents demonstrate our commitment to manufacturing excellence and product innovation. We offer high quality 1 inch standing seam metal roofing with competitive 1 inch standing seam metal roofing prices, customized solutions tailored to your specific project requirements, and one-stop procurement from raw materials to accessories including comprehensive technical support throughout project lifecycles. Our 1 inch standing seam metal roofing for sale includes extensive material options with PVDF and PE surface treatments, thickness ranges from 0.5mm to 1.2mm, RAL and customized color selections, thirty-year warranty coverage, and minimum order quantities of just five hundred square meters or one ton. Contact our technical team at huafeng@hfmetalroof.com to discuss your project requirements and discover why leading contractors, architects, and building owners throughout China and internationally choose Huafeng as their trusted wholesale partner for premium standing seam metal roofing systems that deliver exceptional performance, aesthetic appeal, and long-term value.

References

1. Metal Construction Association, "Standing Seam Metal Roof Systems: Design and Installation Guidelines," Technical Bulletin Series, 2023

2. Smith, Robert J. and Williams, Patricia M., "Advanced Metal Roofing Technologies: Materials, Performance, and Sustainability," Journal of Building Engineering, Volume 45, 2024

3. American Society for Testing and Materials (ASTM), "Standard Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by the Hot-Dip Process," ASTM A653/A653M, 2023

4. National Roofing Contractors Association, "The NRCA Metal Panel and Standing Seam Roof Systems Manual," Fifth Edition, 2024

5. Chen, David L., "Quality Control in Metal Building Component Manufacturing: Best Practices and International Standards," International Journal of Construction Materials, Volume 12, Issue 3, 2024