Are you frustrated with frequent screen replacements in your screening operations? Punched Plate Screens offer a robust solution to this persistent industrial challenge. These mechanically stamped metal sheets provide exceptional durability and efficiency in material separation, addressing the common pain points of clogging, blinding, and premature wear that plague conventional woven wire screens. Whether you're managing abrasive mining materials, processing aggregates, or requiring architectural solutions, understanding the comprehensive benefits of Punched Plate Screens can transform your operational efficiency and significantly reduce long-term maintenance costs while maximizing throughput in demanding industrial environments.

Understanding Punched Plate Screens Technology

Punched Plate Screens represent a significant advancement in industrial screening technology, manufactured through precision mechanical stamping or plasma cutting processes that create specific patterns of holes, slots, or decorative shapes in solid metal sheets. Unlike traditional woven wire screens where wire diameter determines both thickness and spacing, Punched Plate Screens feature independent variables for plate thickness and hole spacing, enabling engineers to optimize both open area and wear life simultaneously. These screens are typically fabricated from high-grade materials including galvalume plate, aluminum alloy, stainless steel grades 304 and 316, low carbon steel, copper, and specialized wear-resistant alloys, with plate thicknesses ranging from 0.5mm to 12mm depending on application requirements. The manufacturing process begins with selecting premium raw materials that undergo rigorous quality verification, including material certification and third-party testing reports to ensure compliance with international standards. Advanced production facilities utilize precision punching equipment, fully automatic punching production lines, and high-definition plasma cutting tables capable of creating apertures from 0.5mm to 100mm in various geometrical configurations including round, square, rectangular, hexagonal, and octagonal hole patterns. The opening rate can be precisely adjusted between 15% and 80% based on specific application needs, with each configuration engineered to balance material flow efficiency against structural integrity and longevity.

Material Selection and Customization Options

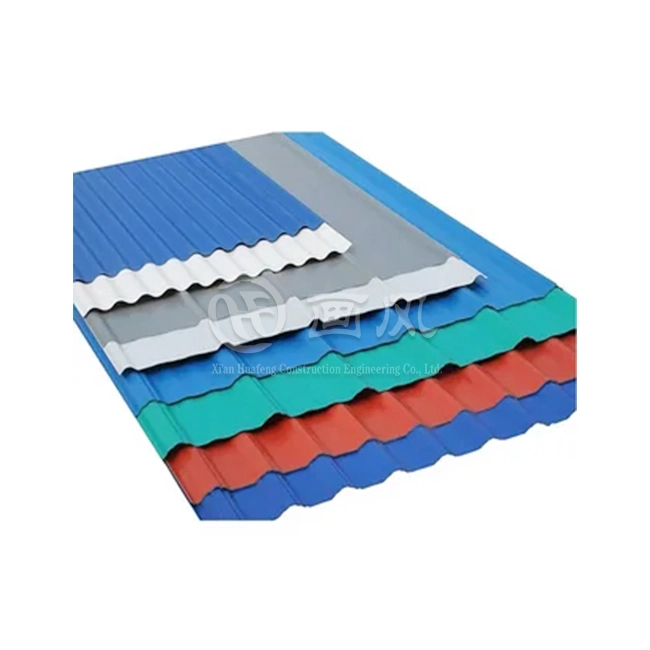

Xi'an Huafeng Construction Engineering Co., Ltd. maintains an extensive material selection brand library featuring premium suppliers including Alucosuper, YATAI, and LIDAO for aluminum alloys in grades 3003, 3004, and 5052, BAOSTEEL, GUANZHOU, and XINYU for steel products encompassing cold rolled sheet, galvanized sheet, galvalume sheet, and color coated sheet, Baosteel and Tsingshan for stainless steel grades 316 and 304, NedZink for titanium zinc plate, and Chinalco for copper grades T2 and TP2. This diverse material portfolio enables precise matching of screen specifications to operational demands, whether requiring corrosion resistance for chemical processing environments, high-temperature stability for metallurgical applications, or maximum abrasion resistance for mining operations. Customization extends beyond material selection to include surface treatment options such as spray painting, galvanizing, polishing, and anodizing, each providing specific rust-proof and corrosion-resistant properties tailored to environmental exposure conditions. Color options span the complete RAL spectrum and other customized colors, allowing Punched Plate Screens to fulfill both functional and aesthetic requirements in architectural applications. Standard sizes commonly range from 1 meter to 2 meters in width with customizable lengths, though specifications can be fully tailored to project requirements, ensuring seamless integration with existing equipment or architectural designs without compromising structural performance or visual impact.

Superior Structural Performance and Durability Benefits

The inherent advantages of Punched Plate Screens stem from their monolithic construction, where holes are created in solid metal sheets rather than assembled from individual wires, resulting in a one-piece design that maintains structural integrity even under severe impact and stress conditions. This fundamental design characteristic delivers exceptional high strength performance through metal sheet stamping, providing superior impact resistance and pressure resistance that makes these screens ideally suited for heavy load environments encountered in mining, quarrying, and aggregate processing operations. The robust construction withstands the continuous bombardment of abrasive materials that would rapidly degrade alternative screening solutions. Punched Plate Screens excel in precise screening applications due to their regular hole shape and uniform distribution across the entire screening surface, ensuring high screening efficiency with consistent particle size separation. The engineered hole patterns eliminate the irregular openings that occur in woven wire screens as wires shift or break, maintaining screening accuracy throughout the product lifecycle. Wear-resistant and durable construction is enhanced through material selection options including high-hardness steel or specialized plating treatments that extend service life significantly, with properly specified Punched Plate Screens demonstrating wear life improvements of six to ten times compared to traditional woven wire screens in abrasive applications.

Operational Advantages in Industrial Applications

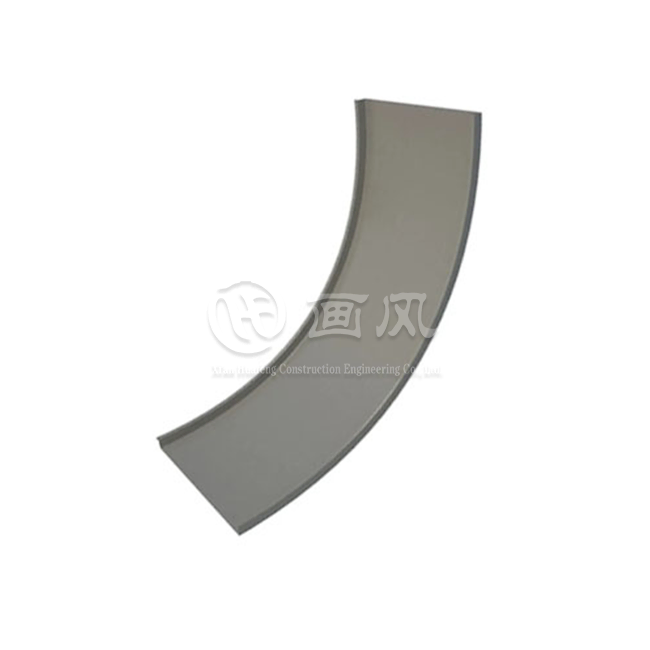

The ventilation and light transmission properties of Punched Plate Screens make them particularly valuable in architectural decoration and building facade applications, where the opening design balances air permeability and light transmittance while maintaining structural support and aesthetic appeal. The smooth surface finish facilitates easy cleaning and maintenance, as the non-porous metal construction resists material buildup and clogging that plague woven wire screens, allowing for efficient high-pressure washing or simple cleaning procedures that minimize downtime and maintenance labor costs while maximizing productive operational time. Field repairability represents another significant advantage of Punched Plate Screens, as damaged sections can be cut out and replaced on-site without requiring complete screen replacement, further extending the economic service life and reducing total cost of ownership. The rigid structure enables formation into various shapes and contours including flat, curved, cylindrical, conical, and U-channel configurations, providing design flexibility for specialized screening equipment and architectural installations. This versatility allows Punched Plate Screens to function effectively in trommel screens, static screeners, mobile screening equipment, and vibrating screen applications across diverse industrial sectors.

Economic and Efficiency Advantages Over Alternative Solutions

When evaluating screening media options, Punched Plate Screens deliver compelling economic advantages through flexible customization capabilities where hole type, arrangement pattern, and material composition can be precisely designed on demand to optimize performance for specific applications. This eliminates the compromises inherent in standardized screening products, ensuring maximum efficiency and longevity for each unique operational requirement. The economical and efficient nature of these screens becomes evident when comparing lifecycle costs, as Punched Plate Screens prove more durable than woven screens while requiring substantially lower maintenance expenditures over their extended service life. The versatility of Punched Plate Screens provides an integrated solution for screening, filtration, decoration, and protection applications, eliminating the need for multiple specialized products and simplifying inventory management while reducing procurement complexity. Industries ranging from mining and construction to food processing and waste management benefit from this multifunctional capability, where a single product category addresses diverse operational needs with consistent quality and reliability. The reduction in common operational problems such as pegging, blinding, and material hangups translates directly into increased throughput and reduced unplanned downtime, improving overall equipment effectiveness and production capacity.

Application-Specific Performance Benefits

In mining operations, Punched Plate Screens handle the most demanding conditions including screening and sorting of ore, gravel, and minerals where abrasive materials would rapidly destroy conventional screening media. The heavy-duty construction withstands high impact forces from large rocks while maintaining precise size separation essential for mineral processing efficiency. Construction and quarrying applications similarly benefit from the ability to separate aggregates such as sand, gravel, stone, and rock during production processes, with Punched Plate Screens installed in vibrating screens providing reliable sizing and grading performance in harsh environmental conditions that include dust, moisture, and temperature extremes. Food processing industries utilize Punched Plate Screens for sieving and sorting food products including grains, cereals, and vegetables, where the smooth, cleanable surface meets stringent hygiene requirements while effectively removing impurities and foreign particles. The customizable hole patterns accommodate various product sizes and flow characteristics, optimizing processing efficiency while maintaining food safety standards. Agricultural applications benefit from similar advantages in seed cleaning, grain sorting, and produce grading operations where consistent hole sizing ensures accurate classification and minimal product damage during handling.

Architectural and decorative applications leverage the aesthetic versatility of Punched Plate Screens, where customizable hole patterns, shapes, and surface treatments create visually striking building facades, interior partitions, sunshade systems, and acoustic panels that combine functional performance with artistic expression. The material options including aluminum alloy, stainless steel, and color-coated steel provide designers with extensive creative flexibility while ensuring long-term durability and minimal maintenance requirements in exterior exposure conditions. Petrochemical, chemical processing, and environmental applications utilize Punched Plate Screens for screening and filtering operations where chemical resistance, temperature stability, and cleanability are paramount considerations.

Manufacturing Excellence and Quality Assurance

Xi'an Huafeng Construction Engineering Co., Ltd. operates advanced manufacturing facilities including a raw material production plant covering 200,000 square meters in Anhui province, supplemented by two specialized plate and accessories processing plants strategically located in Hangzhou and Xi'an. This comprehensive infrastructure encompasses seven color coating production lines, one laminating production line, ten longitudinal and transverse shearing production lines, fully automatic punching production lines, and more than forty units of shearing machines, presses, bending machines, and auxiliary equipment. The scale and sophistication of these production capabilities ensure consistent quality, rapid turnaround times, and the ability to handle projects ranging from small custom orders to large-scale industrial installations. Quality control processes begin with rigorous incoming material inspection procedures that include both full inspection for small quantities and high unit price materials, and statistical sampling for large quantities or frequently ordered materials, preventing defective raw materials from entering the production workflow. Inspection protocols encompass more than a dozen verification steps including product appearance inspection, dimensional verification, salt spray testing, adhesion testing, hardness measurement, impact resistance evaluation, film thickness verification, acid resistance assessment, weather resistance testing, and color difference analysis. These comprehensive quality assurance measures ensure that every Punched Plate Screen meets or exceeds specified performance requirements before shipping to customers.

Engineering Support and Technical Services

The technical capabilities of Xi'an Huafeng Construction Engineering Co., Ltd. extend beyond manufacturing to encompass comprehensive engineering support throughout the project lifecycle. The design department conducts detailed project drawing deepening services, analyzing architectural engineering drawings to develop optimized solutions based on floor plans, elevations, and node diagrams. This process includes communicating with customers to determine the most appropriate panel types for specific roof or screening structures, conducting one-to-one drawing deepening of nodes in different project areas, and providing multiple rounds of review and confirmation before finalizing signed technical drawings. Factory processing sample production provides customers with physical verification of specifications including board type, material, thickness, surface treatment method, and color before committing to full-scale production. After customer confirmation of sample parameters, the approved sample is sealed and maintained as the standard for subsequent product processing, production, and acceptance procedures, ensuring perfect consistency between expectations and delivered products. Processing drawing deepening services break down detailed technical drawings into specific manufacturing instructions that guide production department operations, with each unit numbered sequentially according to project specifications and quantities to prevent confusion during processing, quality inspection, packaging, and on-site installation phases.

Comprehensive Installation and Project Management Services

Xi'an Huafeng Construction Engineering Co., Ltd. provides seamless installation services backed by extensive engineering experience in both design and construction phases, ensuring that Punched Plate Screens are installed correctly to deliver optimal performance throughout their service life. On-site construction or guidance services begin with consultation based on actual site conditions to confirm specific construction layouts including product storage locations, accessory organization areas, and on-site processing zones. Product arrival and warehousing procedures verify data accuracy and arrange materials in correct locations based on packaging identification cards, sectioned floor plans, and product number lists, facilitating efficient installation progression. Installation technicians conduct advance site visits one day prior to installation commencement, inspecting work areas and verifying that all tools including pliers, edge-locking machines, and hammers, plus auxiliary materials such as rivets, structural adhesive, screws, and other accessories are complete and properly maintained. Technical briefing meetings thoroughly review work details and safety precautions before installation begins, ensuring all personnel understand procedures and responsibilities. Upon installation completion, comprehensive on-site testing confirms zero leakage and proper function, followed by customer review of the installation interface, formal acceptance procedures with signature confirmation, and guidance for ongoing maintenance or arrangement of regular maintenance personnel.

Project Portfolio and Industry Recognition

The extensive project portfolio of Xi'an Huafeng Construction Engineering Co., Ltd. demonstrates proven expertise across diverse applications including the Xiongan Station Commercial Body Aluminum Magnesium Manganese Metal Roof project, Xi'an International Convention and Exhibition Center Metal Roof Project, the Metal Roof Project at Xi'an Station East Auxiliary Building, South Hall 2-2 of Jinghe New City International Culture and Art Center, Liyuanping Highway Station Metal Roof Project, Weihua Cadre College Teaching Building and Office Building Aluminum Magnesium Manganese Metal Roof Wall, Hangzhou Sanpu Drainage Pump Station Aluminum Magnesium Manganese Metal Roof Wall, Archaeological Museum design deepening project, and Inner Mongolia Tongliao Art Museum Metal Roof Wall installation. The company holds more than 20 registered patent certificates for roofing systems along with various trademarks and computer software certificates, demonstrating continuous innovation and technical leadership in metal building systems. International certifications including CE certification, ISO9001 quality management certification, ISO14000:14001 environmental management certification, and SGS verification confirm adherence to the highest quality requirements and environmental standards. Recognition as a high-tech enterprise in Shaanxi Province in 2020, combined with first-level qualification for building curtain walls and third-level qualification for building steel structures, validates the technical competence and industry standing of Xi'an Huafeng Construction Engineering Co., Ltd. Successful collaboration with Fortune 500 companies further demonstrates the capability to meet the exacting standards of global industrial leaders.

Conclusion

Punched Plate Screens deliver exceptional value through superior durability, operational efficiency, and versatile applications across industrial and architectural sectors. The combination of advanced manufacturing capabilities, rigorous quality control, comprehensive engineering support, and proven project experience positions these screening solutions as the optimal choice for demanding applications requiring long-term reliability and performance excellence.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

As a leading China Punched Plate Screens factory, China Punched Plate Screens supplier, and trusted China Punched Plate Screens manufacturer, Xi'an Huafeng Construction Engineering Co., Ltd. offers China Punched Plate Screens wholesale solutions with competitive Punched Plate Screens price points. Our High Quality Punched Plate Screens for sale integrate green sustainable development principles with cutting-edge technology. With engineering design excellence, construction expertise, seven raw material production lines, over 20 plate production machines, more than 20 patent certificates, CE certification, ISO certification, and SGS certification, we deliver one-stop procurement from raw materials to accessories. Contact us today at huafeng@hfmetalroof.com to discuss your project requirements and discover how our customized solutions can optimize your operations.

References

1. "Perforated Metal Screens: Design and Performance Characteristics" by Thompson, R.J. and Mitchell, D.L., Materials Science and Engineering Journal

2. "Industrial Screening Technology: Comparative Analysis of Wire Mesh and Punched Plate Systems" by Anderson, P.K., Mining Engineering International

3. "Durability Assessment of Perforated Plate Screens in Abrasive Environments" by Chen, W. and Zhang, H., Journal of Materials Processing Technology

4. "Architectural Applications of Perforated Metal Systems" by Williams, S.M., International Journal of Architectural Engineering

5. "Optimization of Hole Patterns in Perforated Plates for Screening Applications" by Kumar, A. and Patel, R., Industrial Engineering Research