Picture this winter scenario: after a heavy snowfall, massive sheets of snow and ice suddenly slide off your metal roof, endangering people below, damaging gutters, and creating hazardous icicles. Or worse, ice dams form along your roof edges, causing water to pool and leak into your building, resulting in costly interior damage and mold growth. These common winter challenges affect countless building owners with 1 Inch Standing Seam Metal Roofing systems. This comprehensive guide addresses effective snow and ice solutions specifically designed for 1 Inch Standing Seam Metal Roofing, helping you protect your property, ensure safety, and extend your roof's service life through proper winter management strategies.

Understanding Snow and Ice Challenges on 1 Inch Standing Seam Metal Roofing

Winter weather presents unique challenges for metal roofing systems, and understanding these issues is the first step toward implementing effective solutions. The 1 Inch Standing Seam Metal Roofing system, characterized by its raised vertical ribs measuring approximately 25.4mm in height, offers excellent structural integrity and waterproofing capabilities. However, the smooth metal surface and thermal conductivity properties that make standing seam systems so durable also create specific winter performance considerations that building owners must address proactively. Metal roofing conducts heat more efficiently than traditional asphalt shingles, which affects how snow and ice behave on the roof surface. When interior building heat escapes through inadequate insulation, it warms the metal panels from below. This causes snow to melt on the upper roof sections, creating water that flows downward until it reaches colder roof edges or overhangs where temperatures remain below freezing. The water then refreezes, gradually building up into ice dams that block proper drainage and create standing water behind the barrier. The consequences of unmanaged snow and ice accumulation on 1 Inch Standing Seam Metal Roofing extend beyond mere inconvenience. Ice dams can cause water infiltration beneath the roofing panels, damaging insulation, creating ceiling stains, promoting mold growth, and warping interior structures. The expanding force of freezing ice can separate panel seams, damage trim components, and stress the fastening systems. Additionally, heavy ice buildup in gutters can cause complete gutter failure, leading to fascia damage and requiring expensive repairs. When large volumes of snow suddenly release from the smooth metal surface in dangerous avalanches, they endanger pedestrians, vehicles, landscaping, and ground-level structures positioned near the building perimeter.

Ice Dam Formation and Prevention Strategies

Ice dams represent one of the most significant winter challenges for buildings with 1 Inch Standing Seam Metal Roofing. These ice ridges form through repeated freeze-thaw cycles when heat escaping from the building interior creates uneven roof temperatures. The primary cause stems from inadequate attic insulation combined with poor ventilation, which allows warm air to rise and heat the upper roof deck above freezing temperatures while the overhangs remain cold. Effective ice dam prevention begins with addressing the root thermal issues within the building envelope. Proper attic insulation rated to R-49 value or higher for cold climate regions helps maintain consistent roof temperatures by preventing interior heat from warming the roof deck. Equally important is ensuring adequate attic ventilation through ridge vents, soffit vents, and proper air circulation systems that allow cold outside air to maintain uniform temperatures across the entire roof structure. Sealing air leaks in the ceiling using weather stripping and caulking prevents warm air from bypassing insulation and reaching the roof deck through gaps around fixtures, chimneys, ductwork, and other penetrations. Beyond building envelope improvements, several supplementary solutions enhance ice dam prevention for 1 Inch Standing Seam Metal Roofing systems. Installing heating cables along roof edges and in valleys creates controlled melt pathways that prevent ice accumulation in critical drainage areas. These self-regulating heat trace cables activate when temperatures drop below freezing and automatically adjust their heat output based on ambient conditions, providing energy-efficient ice management. Advanced low-voltage roof de-icing systems specifically designed for standing seam profiles utilize transformers to safely deliver thermal energy through specialized heating elements that clamp directly to the raised seams without penetrating the roof panels or voiding manufacturer warranties.

Comprehensive Snow Retention Systems for 1 Inch Standing Seam Metal Roofing

While preventing ice dams focuses on managing water and ice formation, snow retention systems address the equally critical challenge of controlling snow and ice release from metal roofing surfaces. The inherently smooth and slippery characteristics of 1 Inch Standing Seam Metal Roofing panels create ideal conditions for sudden snow avalanches, particularly when solar radiation or interior heat melts the bottom layer of accumulated snow, creating a lubricated sliding surface. Snow guards and retention systems hold accumulated snow on the roof, allowing it to melt gradually and drain in a controlled manner rather than sliding off in dangerous sheets. Snow guard systems for 1 Inch Standing Seam Metal Roofing typically utilize non-penetrating clamps that attach securely to the raised seams without drilling holes or damaging the protective panel coatings. These heavy-duty brackets accommodate the specific one-inch seam height and feature stainless steel setscrews that create a mechanical interlock with the seam profile, providing exceptional holding strength. Premium snow guard systems designed for harsh alpine conditions can withstand extreme snow loads and remain securely fastened throughout the roof's service life without loosening or causing panel damage. Rail-based snow retention systems represent another effective approach for 1 Inch Standing Seam Metal Roofing applications. These systems feature horizontal pipes or bars mounted on clamp-style brackets positioned across the roof surface at strategic intervals determined by engineering calculations based on roof slope, geographic snow load data, and panel specifications. The continuous rail design distributes snow loads evenly across multiple attachment points, providing superior holding capacity compared to individual pad-style guards. Many advanced systems incorporate color-matched components manufactured from the same materials as the roofing panels, ensuring the snow retention system maintains its appearance throughout decades of service without the finish fading or mismatching.

Professional Engineering and Site-Specific Design

Proper snow retention system design requires professional engineering analysis rather than guesswork or rule-of-thumb estimates. The appropriate quantity, placement pattern, and holding capacity of snow guards depend on multiple site-specific factors including geographic location, historical snowfall data, roof pitch, roof area, valley configurations, and the specific profile characteristics of the 1 Inch Standing Seam Metal Roofing panels. Under-designing a snow retention system creates dangerous conditions where inadequate holding capacity allows snow avalanches, while over-designing wastes resources and creates unnecessary roof loading. Reputable snow retention manufacturers provide engineering calculators and design services that analyze these variables to create optimized system layouts meeting structural safety requirements while minimizing material costs. These engineering assessments consider the tested holding strength of specific clamp designs on the exact panel profile, incorporating safety factors and load distribution principles to ensure reliable performance. For critical applications or complex roof geometries, professional engineers can provide stamped calculations and specifications meeting local building code requirements. The installation quality of snow retention systems directly impacts their effectiveness and longevity. Professional installers experienced with 1 Inch Standing Seam Metal Roofing understand proper clamp positioning, setscrew torque specifications typically around 90 inch-pounds, and the importance of uniform spacing across the roof surface. They ensure clamps seat properly on the seam profiles without damaging panel coatings or creating potential leak points. Quality installations also incorporate ice stopper components where appropriate, preventing snow and ice from sliding between adjacent panels in the gaps between seams.

Advanced Heating Solutions for Active Snow and Ice Management

For buildings in regions experiencing severe winter conditions, passive prevention strategies may require supplementation with active heating systems that aggressively manage snow and ice accumulation. Advanced roof de-icing technologies specifically engineered for standing seam metal roofing provide reliable, energy-efficient solutions that prevent ice dam formation and maintain clear drainage pathways throughout winter weather events. These systems offer particular value for commercial buildings, healthcare facilities, and other structures where winter roof access for manual snow removal presents safety challenges or operational disruptions. Self-regulating heat cable systems represent the most versatile active heating solution for 1 Inch Standing Seam Metal Roofing applications. These specialized cables contain conductive polymers that automatically adjust their heat output in response to ambient temperature and moisture conditions, consuming maximum power only when needed and reducing energy usage during milder conditions. The cables install along roof edges, in valleys, through gutters, and down downspouts, creating complete melt pathways that prevent ice accumulation throughout the drainage system. Installation methods for standing seam profiles utilize non-penetrating clips and brackets that secure the heat cable without damaging the roof panels or compromising waterproofing integrity. Low-voltage roof heating systems offer enhanced safety and performance for larger commercial applications. These sophisticated systems employ transformers that step down standard electrical voltage to 60 volts or less, significantly reducing electrical hazards while maintaining effective de-icing performance. The low-voltage heating elements designed for standing seam roofs feature specialized retention devices that clamp securely to the raised seams, pressing the heating cable directly against the metal panel surface for optimal thermal transfer. This direct contact design conducts heat efficiently into the panel material, creating wide melt pathways along the seams that channel water safely to the roof edges.

Integrated System Design and Control

Maximum effectiveness from roof heating systems requires proper integration with snow retention components and intelligent control systems. Heat cables installed in valleys should always extend through corresponding edge heating systems to ensure meltwater created higher on the roof can flow completely off the structure without refreezing at the eaves. Similarly, snow retention systems and heating cables work synergistically, with guards holding snow in place while heating elements create controlled melt channels through the retained snow mass. Modern heating system controllers enhance performance while minimizing operational costs through intelligent activation strategies. Advanced thermostats with outdoor temperature sensors activate heating systems only when conditions favor ice formation, typically when precipitation occurs with temperatures between 20 and 38 degrees Fahrenheit. Some sophisticated controllers incorporate moisture sensors that detect precipitation events, preventing unnecessary system operation during cold dry periods. Programmable features allow building owners to customize activation parameters based on observed local conditions, optimizing the balance between ice prevention and energy consumption.

Material Specifications and Quality Standards for 1 Inch Standing Seam Metal Roofing

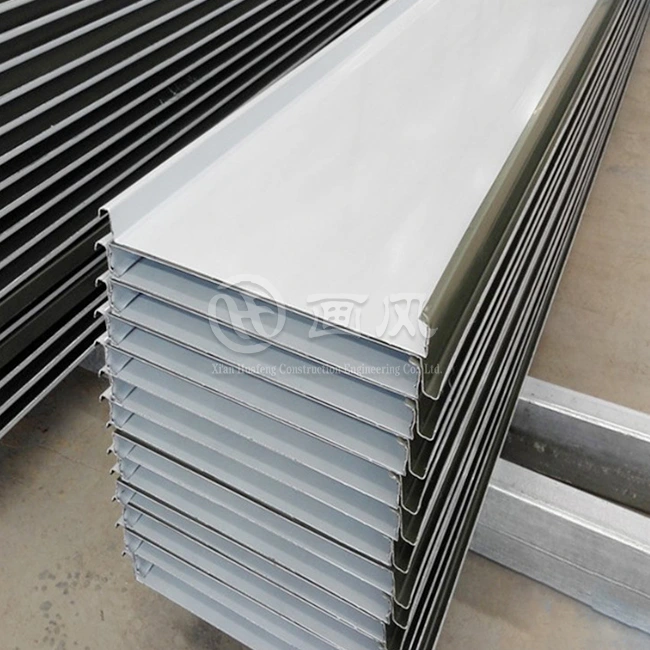

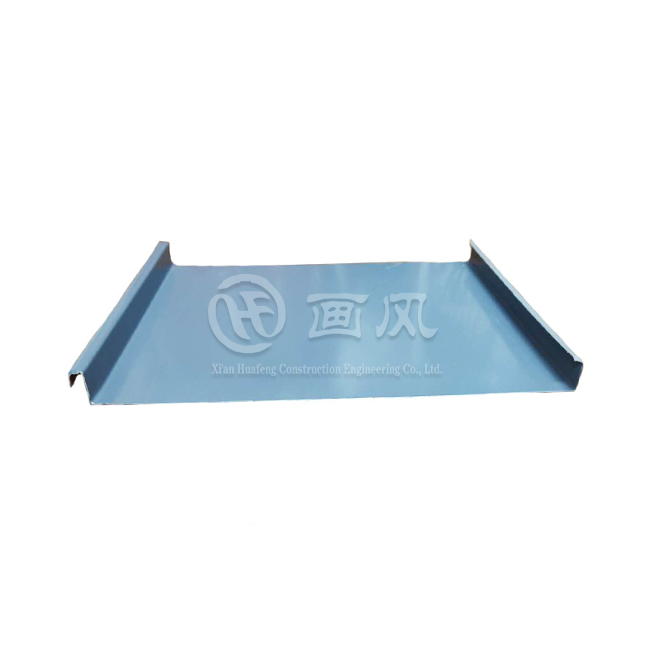

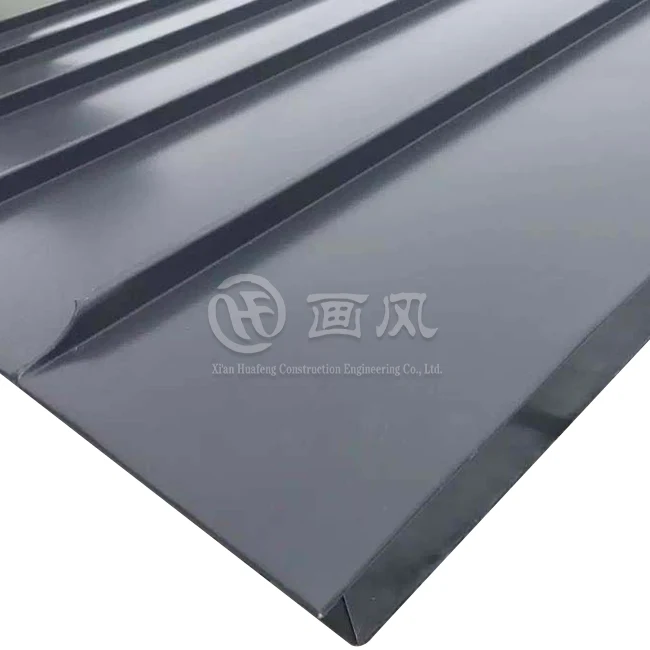

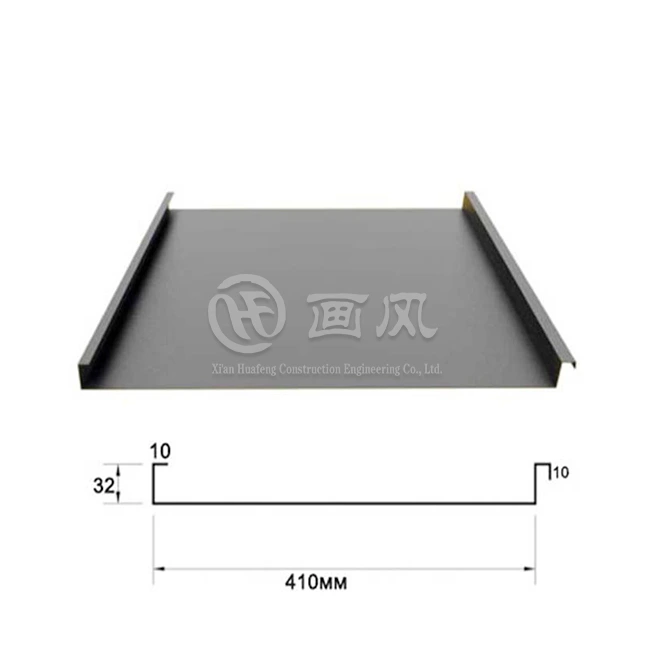

The inherent quality and specifications of the 1 Inch Standing Seam Metal Roofing system directly influence its winter performance characteristics and the effectiveness of supplementary snow and ice management solutions. Xi'an Huafeng Construction Engineering Co., Ltd. manufactures premium 1 Inch Standing Seam Metal Roofing systems engineered to meet demanding performance requirements while providing exceptional longevity. Our panels feature material thickness ranging from 0.5mm to 1.2mm, with common specifications utilizing 0.7-0.8mm aluminum alloys or 0.6mm steel substrates, providing optimal structural strength while maintaining workability during fabrication and installation processes. The standing seam height of precisely 25.4mm creates the characteristic one-inch raised profile that defines this roofing system. This vertical seam design provides multiple performance advantages including enhanced structural rigidity, improved water shedding capabilities, thermal movement accommodation through concealed fastening systems, and compatibility with non-penetrating accessory mounting solutions. Panel widths typically range from 300mm to 600mm depending on project requirements and architectural design preferences, while custom panel lengths up to 12 meters accommodate most building dimensions without requiring horizontal seams that could compromise waterproofing integrity. Surface treatment specifications significantly impact the roof's long-term durability, color retention, and resistance to environmental degradation. Premium PVDF fluoropolymer coatings provide superior protection against UV radiation, chemical exposure, and mechanical abrasion compared to standard polyester coatings. These advanced finish systems maintain their appearance throughout decades of service, resisting the chalking and fading that afflicts inferior coating technologies. The extensive RAL color system offers virtually unlimited color matching capabilities, allowing architects to achieve precise design visions while ensuring snow retention components can be powder-coated to match the roof finish perfectly.

Manufacturing Excellence and Quality Assurance

Xi'an Huafeng Construction Engineering Co., Ltd. operates three state-of-the-art manufacturing facilities equipped with seven color coating production lines, one laminating production line, ten longitudinal and transverse shearing production lines, fully automatic punching systems, and more than 40 specialized machines including shearing equipment, presses, and precision bending machinery. This extensive production capacity enables monthly output exceeding 1000 tons while maintaining rigorous quality standards throughout every manufacturing stage. Our comprehensive quality control program begins with incoming material inspection, where all raw materials undergo verification against supplier certifications and third-party testing reports. Premium material brands including Alucosuper, YATAI, and LIDAO aluminum alloys in 3003, 3004, and 5052 specifications, along with BAOSTEEL, GUANZHOU, and XINYU steel products ensure consistent substrate performance. Each material batch undergoes extensive testing including appearance inspection, dimensional verification, salt spray resistance, coating adhesion, hardness, impact resistance, film thickness measurement, acid resistance, weather resistance, and color consistency evaluation. Finished product inspection maintains these quality standards through final verification of appearance quality, dimensional accuracy, flatness tolerances, and curvature specifications before products receive approval for packaging and shipment. Our systematic approach to quality assurance has earned recognition including designation as a high-tech enterprise in Shaanxi Province, first-level qualification for building curtain walls, third-level qualification for building steel structures, and certifications including ISO9001, ISO14000:14001, and SGS compliance verification.

Professional Installation and Long-Term Performance

Even the highest quality 1 Inch Standing Seam Metal Roofing panels and premium snow management accessories deliver optimal performance only when installed according to proper specifications by experienced professionals. Xi'an Huafeng Construction Engineering Co., Ltd. provides comprehensive one-stop services encompassing design optimization, manufacturing, and construction support, ensuring every project achieves maximum performance throughout its service life. Our technical team conducts detailed project drawing analysis, identifying feasible alternatives and optimal solutions based on architectural requirements, structural constraints, and site-specific conditions. Our design department performs detailed 1:1 scale drawing development for all project components, creating comprehensive shop drawings that specify exact panel dimensions, accessory locations, fastening details, and assembly sequences. This thorough engineering process eliminates field confusion and ensures efficient installation while maintaining complete waterproofing integrity. Before production begins, we manufacture physical samples matching confirmed specifications for board profile, material composition, thickness, surface treatment, and color selection. These sealed samples serve as quality reference standards throughout production and provide acceptance criteria for final inspection. The installation phase incorporates professional project management, on-site technical guidance, and safety compliance documentation to ensure successful project completion. Our experienced installation technicians visit construction sites in advance to verify work area conditions, confirm tool readiness, and ensure all auxiliary materials including rivets, structural adhesive, screws, and accessories are available before work begins. Technical briefing meetings thoroughly review installation procedures and safety protocols with all personnel. Upon completion, comprehensive testing verifies zero leakage performance, and formal acceptance procedures with customer sign-off confirm project requirements have been met.

Maintenance and Service Life Optimization

Proper maintenance practices extend the service life of 1 Inch Standing Seam Metal Roofing systems while ensuring continued effectiveness of snow and ice management components. Regular inspections identify potential issues before they develop into serious problems, examining panel conditions, fastener tightness, sealant integrity, accessory attachment security, and gutter performance. These proactive assessments help building owners address minor concerns promptly rather than facing expensive emergency repairs during winter weather events. Snow retention systems require periodic inspection to verify clamp setscrew torque remains within specifications and confirm no panel movement or damage has occurred. Heating cable systems benefit from pre-season testing to ensure electrical connections remain secure, sensors function properly, and the cables show no physical damage from thermal cycling or environmental exposure. Gutter systems should be cleaned before winter to ensure unrestricted drainage capacity, and any damaged sections should be repaired or replaced to prevent ice dam formation. Xi'an Huafeng Construction Engineering Co., Ltd. backs our 1 Inch Standing Seam Metal Roofing systems with comprehensive 30-year warranties covering material performance, coating integrity, and structural adequacy. This industry-leading warranty coverage reflects our confidence in the exceptional quality and longevity of our products, manufactured according to international standards including ASTM, DIN, JIS, BS, and GB/T specifications. Our commitment to customer success extends throughout the entire project lifecycle, from initial design consultation through decades of reliable service.

Conclusion

Effective snow and ice management for 1 Inch Standing Seam Metal Roofing requires comprehensive understanding of winter weather challenges, proper system design incorporating both passive and active solutions, premium quality materials manufactured to rigorous specifications, and professional installation practices. Building owners who implement appropriate snow retention systems, address ice dam formation through proper insulation and ventilation, and consider supplementary heating solutions where warranted can enjoy safe, reliable roof performance throughout even the harshest winter conditions while protecting their property investment and ensuring occupant safety.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in 2018 in Shaanxi Province, China, specializes in comprehensive metal roofing solutions including design, production, sales, and construction services for metal roof systems, building curtain wall systems, and steel structure enclosure systems. Recognized as a high-tech enterprise in Shaanxi Province in 2020, we hold first-level qualification for building curtain walls and third-level qualification for building steel structures, demonstrating our technical capabilities and industry expertise.

Our manufacturing infrastructure includes a 200,000 square meter raw material production plant in Anhui plus two specialized plate and accessories processing facilities located in Hangzhou and Xi'an. This comprehensive production capability encompasses seven color coating production lines, one laminating production line, ten longitudinal and transverse shearing production lines, fully automatic punching production lines, and more than 40 specialized machines providing complete in-house manufacturing control. Our product portfolio includes standing seam metal roofing panels, aluminum-magnesium-manganese plates, titanium-zinc plates, standing seam metal wall sheets, corrugated roofing and wall sheets, flat lock panels, roofing system accessories, and color aluminum and steel coils suitable for industrial, commercial, and public building applications.

As a leading China 1 Inch Standing Seam Metal Roofing manufacturer, China 1 Inch Standing Seam Metal Roofing supplier, and China 1 Inch Standing Seam Metal Roofing factory, we integrate green sustainable development concepts throughout our operations. We maintain over 20 registered patents for roofing systems, various trademarks, and computer software certificates, all supported by rigorous quality control systems meeting ISO9001, ISO14000:14001, and SGS certification standards. Our extensive engineering experience, advanced production capabilities, quality certifications, and ability to provide customized solutions make us the ideal partner for your High Quality 1 Inch Standing Seam Metal Roofing projects.

Whether you need 1 Inch Standing Seam Metal Roofing for sale, competitive 1 Inch Standing Seam Metal Roofing price quotations, or China 1 Inch Standing Seam Metal Roofing wholesale opportunities, our team provides responsive support from initial consultation through project completion and beyond. We offer minimum order quantities of 500 square meters or 1 ton with delivery timeframes of 15-20 days, supported by one-stop procurement services covering everything from raw materials to complete accessory packages. Our mission focuses on developing metal roofing solutions that add production capacity benefits, solve idle building roof waste, and contribute lasting beauty to architectural designs. Contact Xi'an Huafeng Construction Engineering Co., Ltd. today at huafeng@hfmetalroof.com to discuss your project requirements and discover how our comprehensive expertise in 1 Inch Standing Seam Metal Roofing systems can deliver superior winter performance, exceptional longevity, and outstanding value for your building. Save this article for future reference whenever you need guidance on snow and ice solutions for your metal roofing projects.

References

1. Metal Roofing Alliance. "Snow Retention Systems: Engineering and Design Guidelines for Standing Seam Metal Roofs." Technical Bulletin Series on Metal Roofing Performance. Metal Roofing Alliance Standards Committee.

2. Johnson, Robert K., and Patricia M. Chen. "Ice Dam Formation and Prevention Strategies for Metal Roofing Systems in Cold Climates." Journal of Building Physics and Environmental Performance, Volume 48, Issue 3.

3. American Society of Civil Engineers. "Snow Load Design Requirements for Metal Building Structures." ASCE Standards and Guidelines for Structural Engineering Practice. ASCE Structural Engineering Institute.

4. Thompson, David L. "Heat Transfer Characteristics and Thermal Performance of Standing Seam Metal Roofing Assemblies." Building Science Research Series. National Institute of Building Sciences.

5. International Code Council. "Metal Roof Assembly Design and Installation Requirements." International Building Code Commentary and Application Guide. ICC Code Development Committee.

_1757558889992.webp)