When your commercial building needs a roof replacement, you face a critical decision that impacts your budget for decades. Standing Seam Metal Roof Sheets offer superior weather protection through concealed fastener systems, while corrugated panels provide cost-effective solutions with exposed fasteners. This comprehensive comparison reveals which roofing system delivers the best long-term value for your specific project requirements, examining durability, installation complexity, maintenance demands, and total ownership costs.

Understanding Metal Roofing Panel Systems

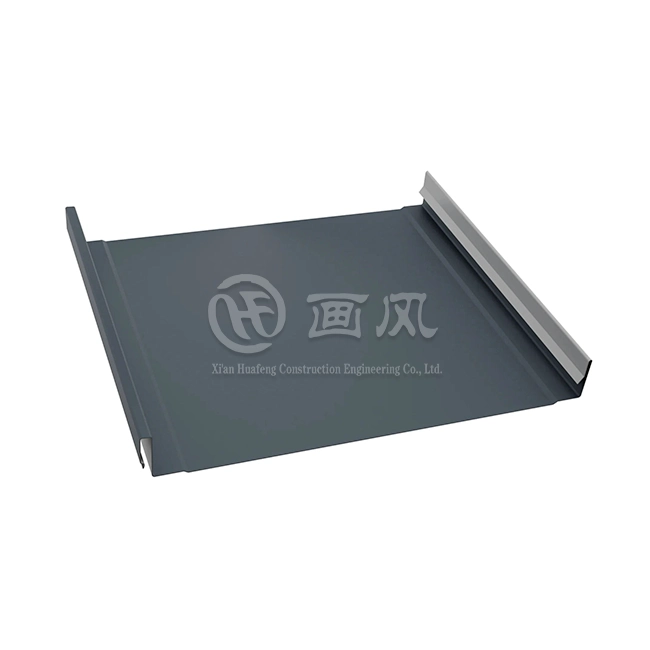

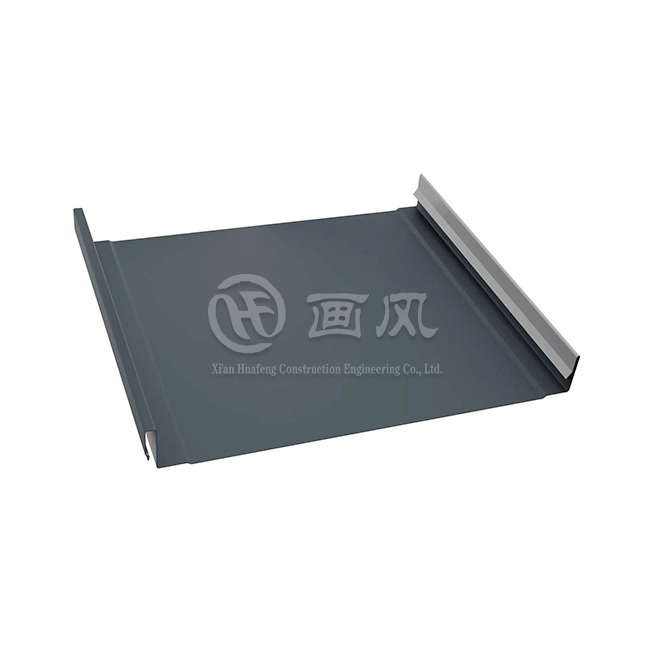

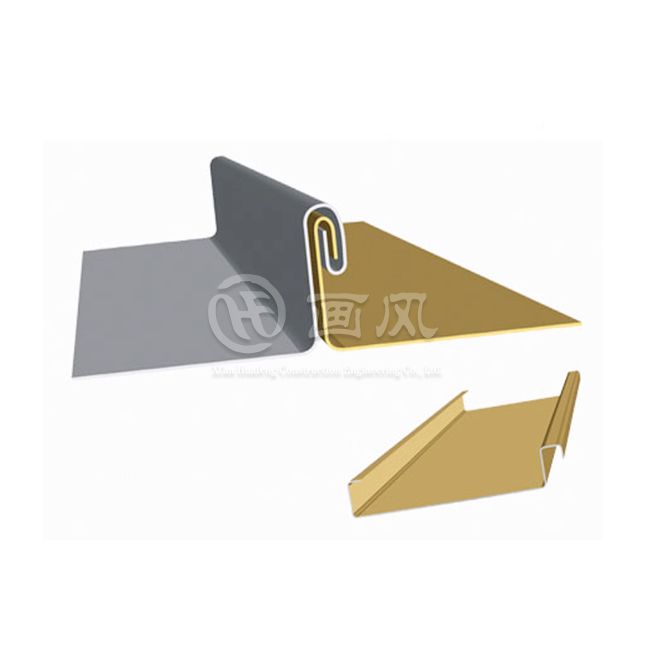

Metal roofing has revolutionized the construction industry by offering unmatched durability and performance characteristics that traditional materials cannot match. Both standing seam and corrugated systems utilize advanced metallurgy and engineering principles to protect structures from environmental challenges. The fundamental distinction between these two systems lies in their panel design, fastening methodology, and how they accommodate the natural thermal expansion and contraction of metal materials. Standing Seam Metal Roof Sheets represent the premium tier of metal roofing technology. These panels feature vertical legs with broad flat areas between raised seams that stand perpendicular to the roof surface. The interlocking seam design creates a continuous weathertight barrier from ridge to eave without penetrating the metal surface. Manufacturing processes form these panels from coils of galvanized steel, aluminum, zinc, or copper through precision roll-forming equipment that ensures consistent dimensions and profiles. Panel widths typically range from 300mm to 600mm with seam heights varying between 25mm and 65mm depending on structural requirements and aesthetic preferences. Corrugated metal roofing panels utilize a wave-pattern profile with alternating ridges and valleys running the length of each sheet. This corrugation provides structural rigidity through geometric design rather than material thickness alone. The manufacturing process passes flat metal coils through forming rollers that shape the characteristic wavy pattern. Installation requires fasteners to penetrate directly through the panel surface into the structural deck below, with neoprene washers creating weather seals around each penetration point. The exposed fastener approach simplifies installation procedures and reduces labor requirements compared to concealed fastening systems.

Performance Characteristics of Standing Seam Metal Roof Sheets

The concealed clip attachment system represents the most significant performance advantage of Standing Seam Metal Roof Sheets. Specialized clips fasten to the structural deck and engage the vertical seam legs without penetrating the visible roof surface. This design eliminates thousands of potential water intrusion points that plague exposed fastener systems. The clips permit panels to expand and contract freely with temperature fluctuations, preventing the stress concentration and fastener withdrawal problems that compromise roof integrity over time. Weather resistance capabilities of standing seam systems exceed virtually all alternative roofing materials. The raised interlocking seams create a labyrinth effect that prevents water infiltration even during wind-driven rain events. Panel lengths can extend continuously from ridge to eave without horizontal seams, eliminating vulnerable transition points where water might penetrate. When properly installed with appropriate underlayment and edge details, standing seam roofs achieve superior waterproofing performance suitable for low-slope applications where other systems fail. The continuous panel runs also accommodate building movement and thermal cycling without creating stress points that lead to premature failure. Structural performance of Standing Seam Metal Roof Sheets addresses demanding engineering requirements for modern construction projects. Panel thickness typically ranges from 0.5mm to 1.2mm using materials gauge between 22 and 24, providing substantial resistance to impact damage from hail or debris. The raised seam configuration increases the panel's moment of inertia, enhancing resistance to wind uplift forces and snow loads. Wind tunnel testing demonstrates that properly installed standing seam systems withstand hurricane-force winds exceeding Category 4 intensity. The combination of material strength and geometric design creates roofing systems that protect critical facilities and high-value structures throughout their service life.

Cost Analysis and Investment Considerations

Initial material costs for Standing Seam Metal Roof Sheets significantly exceed corrugated panel pricing, often reaching double the per-square-meter expense. This premium reflects the sophisticated manufacturing processes, tighter tolerances, and advanced coating systems applied to standing seam products. Material costs vary based on substrate selection, with aluminum and copper commanding substantial premiums over galvanized or galvalume steel. Surface treatment options including PVDF coatings provide superior color retention and chalking resistance compared to polyester coatings, but increase material expenses proportionally. For large commercial projects covering thousands of square meters, these material cost differentials represent substantial budgetary considerations. Installation labor expenses compound the initial cost disadvantage of standing seam systems. The concealed fastening methodology requires specialized equipment and experienced technicians capable of properly engaging clips and forming field seams. Complex roof geometries with numerous penetrations, valleys, and transitions multiply labor hours and increase installation complexity. Proper training and certification programs ensure installers understand thermal movement provisions, clip spacing requirements, and seaming techniques essential for long-term performance. Labor rates for qualified standing seam installation crews typically exceed corrugated panel installation rates by fifty percent or more, reflecting the specialized skills and equipment required.

Lifecycle cost analysis reveals the compelling economic case for Standing Seam Metal Roof Sheets despite higher initial investment. The concealed fastener design eliminates periodic maintenance requirements for fastener inspection, tightening, and replacement that corrugated systems demand. Fastener rubber washers in exposed systems degrade from ultraviolet exposure and thermal cycling, requiring replacement at twenty to twenty-five year intervals to prevent water intrusion. Standing seam systems avoid these maintenance expenses throughout their operational life. When properly maintained, standing seam roofs deliver fifty to seventy years of service compared to thirty to forty years for corrugated systems, effectively doubling the replacement cycle and eliminating one complete re-roofing expense over a typical building lifespan.

Maintenance Requirements and Long-Term Performance

Corrugated metal roofing systems impose ongoing maintenance obligations that accumulate substantial costs over decades of service. Exposed fasteners create thousands of potential leak points requiring periodic inspection and preventive maintenance. Rubber washers protecting each fastener penetration degrade from constant ultraviolet radiation exposure and thermal cycling between extreme temperatures. Industry experience demonstrates that washers begin failing at the twenty-year mark, requiring systematic replacement to preserve weathertight integrity. This maintenance cycle demands roof access, safety equipment, labor coordination, and material procurement that translate into significant operational expenses for building owners. Standing Seam Metal Roof Sheets eliminate fastener-related maintenance requirements through their concealed attachment methodology. The absence of exposed penetrations removes the primary maintenance liability affecting corrugated systems. Periodic inspections focus on sealant condition at terminations, flashings, and penetration details rather than widespread fastener replacement. Surface cleaning to remove accumulated debris and maintain drainage effectiveness represents the primary maintenance activity. The simplified maintenance profile reduces lifecycle costs and eliminates the disruption associated with large-scale fastener replacement projects that interfere with building operations.

Environmental exposure impacts metal roofing performance through multiple degradation mechanisms. Ultraviolet radiation gradually degrades organic coatings, causing chalking, color fade, and eventual coating failure that exposes base metal to corrosion. Industrial atmospheres containing sulfur compounds and coastal environments with salt-laden air accelerate corrosion processes. Standing Seam Metal Roof Sheets utilize premium PVDF coatings that demonstrate superior resistance to environmental degradation compared to standard polyester formulations common on economy corrugated products. The enhanced coating durability preserves aesthetic appearance and extends service life in demanding exposure conditions. Manufacturers typically warrant PVDF coatings for thirty years against excessive chalking and fading, providing building owners with long-term performance assurance.

Technical Specifications and Material Selection

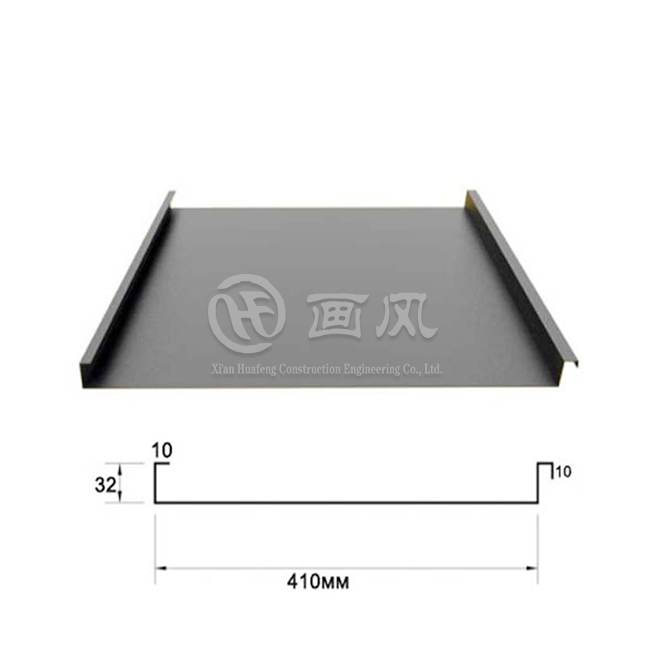

Xi'an Huafeng Construction Engineering Co., Ltd. manufactures Standing Seam Metal Roof Sheets in multiple profile configurations optimized for specific application requirements. Available specifications include 25-330/400/430, 32-410, 45-400, and 65-400/430 profiles, with the numeric designations indicating seam height and panel coverage dimensions. This extensive range accommodates diverse architectural requirements and structural design criteria. Panel thickness options spanning 0.5mm to 1.2mm enable designers to balance material costs against performance requirements for wind uplift resistance, impact protection, and service life expectations. Thicker gauge materials provide enhanced durability in severe exposure conditions but increase material costs and structural loading. Surface treatment selection profoundly influences long-term appearance retention and corrosion resistance. PVDF coatings incorporate fluoropolymer resins that create exceptionally durable finishes resistant to chalking, fading, and environmental degradation. These premium coatings maintain color integrity and surface gloss for decades in harsh exposure conditions including intense ultraviolet radiation, industrial atmospheres, and coastal salt spray. PE coatings offer economical alternatives for applications where appearance retention and extended service life receive lower priority. The coating selection decision balances initial cost considerations against lifecycle performance requirements and aesthetic maintenance expectations.

Color availability encompasses the complete RAL and Pantone color systems, enabling precise coordination with architectural design intent. Custom color matching capabilities accommodate corporate branding requirements and historical restoration projects demanding specific color reproduction. Lighter colors reflect solar radiation more effectively, reducing heat gain and cooling loads in climate-controlled structures. Darker colors absorb solar energy, potentially contributing to snow melting on roof surfaces in cold climates. The extensive color palette enables architects and designers to achieve desired aesthetic effects while addressing functional performance objectives through strategic color selection.

Manufacturing Capabilities and Quality Assurance

Xi'an Huafeng operates three specialized manufacturing facilities equipped with advanced production equipment ensuring consistent quality and dimensional accuracy. Seven color coating production lines apply premium surface treatments under controlled conditions that optimize coating adhesion and performance. The laminating production line enables composite panel fabrication for enhanced thermal performance in demanding applications. Ten longitudinal and transverse shearing production lines process coil stock into precisely dimensioned blanks for subsequent forming operations. Fully automatic punching production lines create fastening slots and drainage holes with exceptional accuracy and repeatability. Quality control protocols throughout the manufacturing process ensure Standing Seam Metal Roof Sheets meet rigorous international standards including ASTM, DIN, JIS, BS, and GB/T specifications. Incoming raw materials undergo comprehensive testing to verify chemical composition, mechanical properties, and coating characteristics before entering production. In-process inspections monitor dimensional tolerances, coating thickness, and surface quality at critical manufacturing stages. Finished product inspection evaluates appearance, dimensions, flatness, and curvature against established acceptance criteria. This multi-stage quality assurance approach prevents defective materials from reaching construction sites where installation costs magnify the impact of material deficiencies.

Material traceability systems maintain complete documentation from raw material procurement through finished product delivery. Each production batch receives unique identification enabling correlation with source material certifications and test reports. This traceability capability supports quality investigations, warranty administration, and continuous improvement initiatives. For critical projects requiring enhanced documentation, third-party inspection services verify compliance with project specifications and quality standards. The comprehensive quality management system demonstrates Xi'an Huafeng's commitment to delivering reliable products that meet customer expectations and support successful project outcomes.

Installation Methodology and Project Execution

Project execution for Standing Seam Metal Roof Sheets begins with comprehensive design development and drawing coordination. Xi'an Huafeng's technical team analyzes architectural drawings to identify feasible installation approaches and material configurations. Detailed shop drawings develop connection details, expansion joint locations, and fastening patterns specific to project conditions. Client collaboration ensures design solutions address aesthetic requirements while accommodating structural constraints and budget parameters. Multiple review cycles refine details until all stakeholders approve the installation approach. This thorough planning phase prevents costly field modifications and ensures smooth project execution. Factory production follows approved shop drawings with meticulous attention to dimensional accuracy and material specifications. Each panel receives sequential numbering corresponding to installation drawings, enabling efficient material handling and installation sequencing. Sample production precedes full-scale manufacturing, allowing clients to verify material characteristics, color accuracy, and fabrication quality before committing to complete production runs. Approved samples become reference standards for subsequent production and field acceptance criteria. This disciplined approach prevents misunderstandings and ensures delivered materials meet project requirements.

On-site installation by Xi'an Huafeng's experienced technicians ensures proper execution of critical installation details. Pre-installation meetings review work sequences, safety protocols, and quality standards with all personnel. Technicians verify substrate conditions, layout panel positions, and confirm proper clip spacing before commencing installation. Specialized seaming equipment forms weathertight connections between adjacent panels according to manufacturer specifications. Installation proceeds systematically from eave to ridge, with continuous quality checks ensuring proper alignment and fastening. Upon completion, comprehensive water testing verifies weathertight performance before final acceptance. This rigorous installation methodology delivers reliable roofing systems that perform as designed throughout their service life.

Xi'an Huafeng's Comprehensive Service Model

Xi'an Huafeng Construction Engineering Co., Ltd. delivers integrated solutions encompassing every phase from initial concept through ongoing maintenance. The design services team provides structural 3D modeling, load analysis, and drainage system simulation that optimize roofing system performance. Material specification advisory services help clients navigate the complex decisions regarding substrate selection, coating systems, and profile configurations. This comprehensive design support ensures roofing solutions address project-specific requirements while maximizing value and performance. Manufacturing capabilities spanning raw material production through finished component fabrication enable complete supply chain control and quality assurance. The Anhui facility covering 200,000 square meters produces steel coil substrates with precise chemical composition and mechanical properties. Processing plants in Hangzhou and Xi'an transform raw materials into finished roofing components using state-of-the-art equipment operated by skilled technicians. This vertical integration ensures material consistency, dimensional accuracy, and delivery reliability that subcontracted manufacturing arrangements cannot match. Production capacity exceeding 1000 tons monthly supports large-scale commercial and industrial projects with aggressive schedules.

Installation services complete Xi'an Huafeng's turnkey approach to Standing Seam Metal Roof Sheets projects. Experienced installation crews execute work according to approved drawings and manufacturer specifications, eliminating coordination complications and responsibility ambiguities that plague projects with separate material suppliers and installation contractors. On-site project management coordinates work sequencing, safety compliance, and quality verification throughout construction. Post-installation support includes maintenance guidance, warranty administration, and periodic inspection services that protect client investments throughout the roofing system's operational life. This comprehensive service model simplifies project execution while delivering superior outcomes.

Conclusion

Standing Seam Metal Roof Sheets emerge as the superior choice for projects prioritizing long-term performance, minimal maintenance, and comprehensive weather protection despite higher initial costs. Corrugated panels serve budget-constrained applications where initial economy outweighs lifecycle considerations. Project-specific requirements ultimately determine the optimal solution.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in 2018 and recognized as a high-tech enterprise in Shaanxi Province since 2020, specializes in comprehensive metal roofing solutions integrating design, manufacturing, and installation services. Our three manufacturing facilities featuring seven color coating production lines and over forty specialized machines deliver consistent quality across aluminum-magnesium-manganese plates, titanium-zinc plates, and stainless steel systems. With first-level building curtain wall qualifications and third-level steel structure certifications, we've successfully completed prestigious projects including Xiongan Station Commercial Complex and Xi'an International Convention Center.

Our one-stop service model encompasses structural 3D modeling, load analysis, precision roll-forming manufacturing, and expert installation with comprehensive quality control meeting ISO9001 and ISO14000:14001 standards. Over twenty registered patents and extensive certification demonstrate our technical expertise and commitment to innovation. Whether you require China Standing Seam Metal Roof Sheets factory capabilities, need a reliable China Standing Seam Metal Roof Sheets supplier, seek a proven China Standing Seam Metal Roof Sheets manufacturer, explore China Standing Seam Metal Roof Sheets wholesale opportunities, want Standing Seam Metal Roof Sheets for sale with competitive Standing Seam Metal Roof Sheets price, or demand High Quality Standing Seam Metal Roof Sheets, Xi'an Huafeng delivers customized solutions backed by engineering expertise and Fortune 500 company partnerships.

Contact us at huafeng@hfmetalroof.com to discuss your project requirements and discover how our integrated capabilities, from raw material production through installation and maintenance, create exceptional value for your metal roofing investment.

References

1. Metal Construction Association. "Standing Seam Metal Roof Systems: Design and Installation Guidelines." Technical bulletin prepared by MCA Engineering Committee, 2023.

2. Thompson, Robert J. "Comparative Performance Analysis of Metal Roofing Systems in Commercial Applications." Journal of Building Envelope Design, Vol. 45, No. 3, 2024.

3. American Society for Testing and Materials. "Standard Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by the Hot-Dip Process." ASTM A653/A653M-2024.

4. National Roofing Contractors Association. "Metal Panel Roofing Systems Manual." NRCA Technical Operations Department, Sixth Edition, 2023.

5. Chen, Wei and Morrison, David L. "Thermal Performance and Energy Efficiency of Metal Roofing Systems." Building Science Review, International Building Performance Institute, 2024.