Commercial property owners face a critical dilemma when aging roofs threaten operations with leaks, mounting repair costs, and energy inefficiency that drains budgets year after year. If you're wrestling with frequent maintenance calls, worried about premature roof failure, or seeking a roofing solution that delivers real value without compromise, understanding the strategic advantages of corrugated roofing metal panels becomes essential. This comprehensive guide reveals five transformative benefits that make corrugated metal sheets the intelligent choice for commercial applications, backed by engineering principles, proven performance data, and real-world project success.

Exceptional Durability and Extended Service Life for Commercial Applications

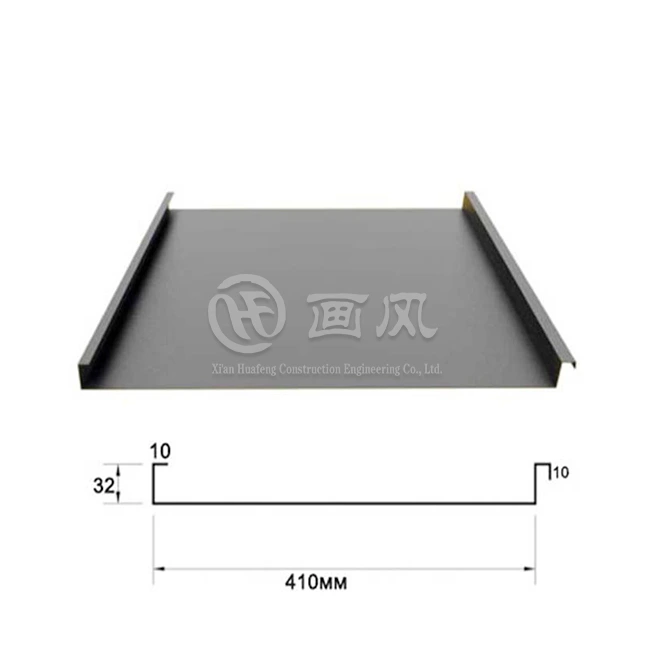

When commercial building owners invest in roofing systems, longevity directly impacts total cost of ownership and operational continuity. Corrugated roofing metal panels deliver exceptional durability through their distinctive wavy surface structure, which fundamentally enhances structural performance compared to flat roofing materials. The corrugated design creates a series of ridges and valleys that increase the panel's moment of inertia, dramatically improving its ability to resist bending forces and distribute loads across the entire surface area. The engineering behind corrugated metal sheets transforms relatively thin materials into remarkably strong structural components. Through the roll-forming manufacturing process, metals that might otherwise lack sufficient rigidity gain impressive load-bearing capacity. This corrugated structure enables the panels to withstand substantial weight from snow accumulation, equipment installations, and maintenance personnel traffic without deformation or failure. Commercial facilities in regions experiencing heavy snowfall particularly benefit from this enhanced structural integrity, as the panels maintain their shape and functionality under conditions that would compromise alternative roofing materials.

Material selection further extends the service life of corrugated roofing metal panels. Xi'an Huafeng Construction Engineering Co., Ltd. manufactures panels from galvanized steel, aluminum-magnesium-manganese alloys, and stainless steel, each offering distinct performance characteristics. Galvanized steel panels feature hot-dip zinc coating that provides sacrificial protection against corrosion, typically delivering fifteen to thirty years of reliable service. Aluminum-magnesium-manganese panels naturally resist oxidation and can exceed thirty years of performance in demanding environments. The thickness range from 0.4mm to 1.2mm allows customization based on specific structural requirements and budget considerations, ensuring each commercial project receives appropriately engineered solutions. Surface treatment technologies multiply the protective capabilities of corrugated metal sheets. PE (polyester), HDP (high-durability polyester), and PVDF (polyvinylidene fluoride) coatings create additional barriers against ultraviolet radiation, acid rain, industrial pollutants, and temperature extremes. PVDF coatings particularly excel in harsh commercial environments, maintaining color stability and surface integrity for decades while resisting chalking, fading, and chemical degradation. This comprehensive protection system ensures that corrugated roofing metal panels maintain both structural performance and aesthetic appeal throughout their extended service life, eliminating the frequent replacement cycles that burden property owners using conventional roofing materials.

Weather Resistance and Environmental Performance

Commercial facilities require roofing systems capable of withstanding diverse weather challenges while maintaining protective integrity. Corrugated roofing metal panels excel in this demanding role through multiple performance mechanisms. The wavy profile naturally channels water away from the roof surface, preventing ponding that accelerates material degradation and increases leak potential. This self-draining geometry proves particularly valuable for low-slope commercial applications where water accumulation poses persistent challenges for traditional roofing systems. The corrugated groove design facilitates rapid water evacuation during rain events, reducing stress on roofing membranes and minimizing opportunities for water infiltration through fasteners or panel joints. When properly installed with appropriate butyl sealants at panel laps and proper flashing around penetrations, corrugated metal sheets create weather-tight assemblies that protect valuable building contents and mechanical systems from moisture damage. Xi'an Huafeng's manufacturing process ensures precise panel dimensions and consistent corrugation profiles, enabling tight overlaps that enhance weather resistance without requiring excessive sealant application. Wind resistance represents another critical performance factor for commercial roofing systems. The corrugated structure inherently resists wind uplift forces more effectively than flat panels, as the ridges and valleys create mechanical interlocking when panels overlap. The exposed fastener installation method, when executed according to manufacturer specifications, provides secure attachment to structural substrates. Fasteners placed in the crests of corrugations avoid creating water collection points while ensuring adequate withdrawal resistance against wind suction forces. Commercial buildings in hurricane-prone regions or areas experiencing frequent severe storms benefit substantially from this enhanced wind performance.

Cost-Effectiveness and Superior Return on Investment

Budget considerations drive many commercial roofing decisions, making cost-effectiveness a paramount concern for facility managers and property owners. Corrugated roofing metal panels deliver exceptional value through multiple economic mechanisms that extend far beyond initial material costs. The lightweight nature of corrugated metal sheets significantly reduces transportation expenses compared to heavier roofing materials, allowing efficient shipping from manufacturing facilities to project sites. Xi'an Huafeng operates three factories with seven production lines and more than forty specialized machines, enabling economies of scale that translate into competitive pricing for bulk orders while maintaining stringent quality standards. Installation efficiency provides substantial cost advantages. The corrugated panels' prefabricated nature eliminates time-consuming on-site fabrication, while their modular design enables rapid coverage of large roof areas. Professional installation crews can complete commercial roofing projects significantly faster with corrugated metal sheets compared to built-up roofing systems or complex membrane applications. This accelerated installation timeline reduces labor costs, minimizes building downtime, and allows earlier occupancy or reopening of commercial facilities. The exposed fastener system, though requiring proper technique, remains straightforward for experienced contractors, avoiding the specialized equipment requirements and training needed for more complex roofing profiles.

Long-term maintenance costs represent a frequently overlooked component of total ownership expenses. Corrugated roofing metal panels require minimal maintenance compared to alternative commercial roofing systems. The panels naturally resist common roofing problems including organic growth, insect damage, and material deterioration from ultraviolet exposure. Periodic inspections to verify fastener tightness and sealant integrity constitute the primary maintenance requirement, representing minimal expense compared to the frequent repairs, coating reapplications, and partial replacements demanded by many conventional roofing systems. This reduced maintenance burden directly improves operational budgets and frees facility management resources for other priorities. The thirty-year warranty provided by Xi'an Huafeng demonstrates confidence in product longevity and provides property owners with valuable financial protection. This extended warranty coverage reduces risk exposure and supports accurate long-term financial planning for commercial real estate portfolios. When amortized over the full service life, the cost per year of corrugated roofing metal panels frequently undercuts alternatives that appear less expensive initially but require replacement multiple times over the same period.

Energy Efficiency and Operational Cost Reduction

Rising energy costs make building efficiency increasingly important for commercial property economics. Corrugated roofing metal panels contribute to reduced energy consumption through multiple thermal management mechanisms. Metal roofing naturally reflects solar radiation rather than absorbing it like dark asphalt or conventional built-up roofing systems. This inherent reflectivity reduces heat transfer into building interiors, lessening the burden on air conditioning systems during warm months. The temperature reduction can be substantial in hot climates, directly translating into lower electricity consumption and reduced utility expenses. Specialized cool-roof coatings further enhance the thermal performance of corrugated metal sheets. These highly reflective finishes maximize solar reflectance while increasing thermal emissivity, allowing the roof surface to reject absorbed heat more effectively. Commercial buildings utilizing cool-roof technology on corrugated roofing metal panels can experience roof surface temperature reductions of twenty to thirty degrees Celsius compared to uncoated alternatives, dramatically decreasing cooling loads. Many jurisdictions now provide incentives, tax credits, or expedited permitting for energy-efficient roofing systems, potentially offsetting material and installation costs.

The thermal mass characteristics of metal roofing also influence building performance. Unlike heavy masonry roofing materials that absorb and slowly release heat, corrugated metal sheets respond quickly to temperature changes. This rapid thermal response prevents prolonged heat retention after sunset, allowing buildings to cool more efficiently during evening hours. The effect proves particularly valuable for commercial facilities operating primarily during daytime hours, as the building envelope dissipates accumulated heat before the next business day. Proper insulation integration maximizes the energy performance of corrugated roofing metal panels. The air space created by the corrugated profile itself provides modest insulation value, while rigid insulation boards or spray foam applications between the panels and the roof deck create comprehensive thermal barriers. Xi'an Huafeng's design engineering services help optimize insulation strategies for specific climate zones and building uses, ensuring that corrugated metal roofing systems deliver maximum energy savings while meeting local building code requirements.

Versatile Customization and Aesthetic Flexibility

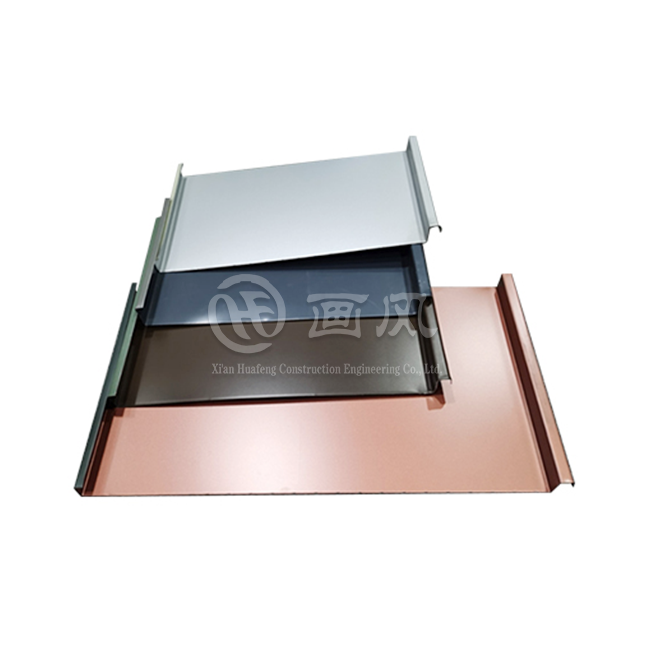

Commercial architecture demands roofing solutions that satisfy functional requirements without compromising design intent. Corrugated roofing metal panels provide remarkable versatility for diverse architectural visions while maintaining superior performance characteristics. The ability to customize dimensions represents a fundamental advantage—panels can be manufactured in lengths from one to thirteen meters according to project specifications, minimizing waste and reducing the number of transverse seams that require weatherproofing. This customization capability proves invaluable for complex roof geometries or buildings with unique dimensional requirements that standardized materials cannot accommodate efficiently. Color and finish options enable precise coordination with overall building aesthetics. Xi'an Huafeng offers comprehensive color customization through advanced coating technologies, allowing commercial property owners to select hues that complement corporate branding, blend with surrounding environments, or create distinctive architectural statements. The coating systems utilize pigments that maintain color stability throughout the service life, preventing the fading and chalking that compromise the appearance of lesser-quality coated metals. Pattern customization extends beyond simple color selection, encompassing embossed textures and specialty finishes that add visual depth and architectural interest to what might otherwise appear as utilitarian roofing surfaces.

Material selection provides additional customization opportunities. Different base metals offer distinct aesthetic characteristics alongside their performance attributes. Aluminum-magnesium-manganese panels present a contemporary appearance while delivering exceptional corrosion resistance for coastal commercial properties. Stainless steel options provide premium aesthetics with mirror-like finishes suitable for high-profile commercial developments where appearance significantly influences property value. Galvanized steel remains popular for industrial applications where durability and cost-effectiveness outweigh aesthetic refinement. This material diversity ensures appropriate solutions exist for virtually any commercial roofing application.

Applications Across Commercial Building Types

The versatility of corrugated metal sheets extends to their suitability for diverse commercial building types and applications. Industrial warehouses benefit from the panels' ability to span substantial distances between structural supports, reducing required substrate density and overall structural costs. Manufacturing facilities appreciate the fire resistance classification of metal roofing, which supports risk management objectives and may reduce insurance premiums. Distribution centers capitalize on the rapid installation timeline to minimize construction-related operational disruptions. Retail developments increasingly specify corrugated roofing metal panels for their contemporary aesthetic appeal and long-term value proposition. Shopping centers, big-box retailers, and strip mall developments benefit from minimal maintenance requirements that reduce lifecycle costs while maintaining attractive appearances that support customer engagement. The material's resistance to impact damage from hail or debris proves particularly valuable for retail properties in severe weather regions, protecting inventory and avoiding costly business interruptions from roof failures. Office complexes and commercial mixed-use developments utilize corrugated roofing metal panels to achieve LEED certification goals and demonstrate environmental responsibility. The high recycled content of steel and aluminum panels contributes toward materials credits, while their energy performance supports building efficiency objectives. At end-of-life, the panels remain fully recyclable, supporting circular economy principles increasingly important to corporate sustainability programs and tenant attraction strategies.

Sustainable Construction and Environmental Responsibility

Environmental considerations increasingly influence commercial construction decisions as organizations pursue sustainability goals and respond to stakeholder expectations. Corrugated roofing metal panels align exceptionally well with green building objectives through multiple mechanisms. The recyclability of metal roofing materials represents perhaps the most significant environmental advantage—steel and aluminum panels maintain material value throughout their service life and can be recycled indefinitely without quality degradation. This closed-loop material flow dramatically reduces environmental impact compared to roofing systems destined for landfills at end-of-life. The manufacturing process for corrugated metal sheets increasingly incorporates recycled content. Steel panels routinely contain twenty-five to ninety-five percent recycled material, with the percentage varying based on steel grade and manufacturing source. Aluminum panels similarly utilize substantial recycled content, reducing the energy-intensive primary aluminum production required. Xi'an Huafeng's commitment to green sustainable development extends throughout operations, from material procurement through manufacturing processes designed to minimize waste and energy consumption. This comprehensive environmental approach resonates with commercial property owners seeking to reduce their operations' carbon footprint. The extended service life of corrugated roofing metal panels itself constitutes an environmental benefit. By eliminating frequent replacement cycles required by shorter-lived roofing systems, metal panels reduce the cumulative resource consumption, manufacturing energy, transportation emissions, and installation waste associated with multiple roof replacements over equivalent time periods. A single corrugated metal roof installation serving thirty years displaces potentially two to three installations of conventional materials, delivering substantial environmental benefits through material conservation alone.

Integration with Renewable Energy Systems

Modern commercial properties increasingly incorporate renewable energy generation capabilities, with rooftop photovoltaic arrays representing the most common implementation. Corrugated roofing metal panels provide excellent substrates for solar panel mounting systems. The structural strength of the corrugated profile supports equipment loads without requiring roof reinforcement, while the metal substrate facilitates secure attachment methods. The long service life expectancy of quality corrugated metal roofing aligns well with solar system design life, avoiding scenarios where roofing replacement necessitates costly solar array removal and reinstallation. The reflective properties of metal roofing complement solar energy systems by reducing building cooling loads, allowing smaller, less expensive photovoltaic arrays to meet facility energy requirements. This synergistic relationship optimizes overall building energy performance and accelerates return on investment for renewable energy installations. Some advanced systems integrate solar photovoltaic cells directly into metal roofing panels, creating building-integrated photovoltaic solutions that eliminate separate mounting structures while maintaining weather protection and energy generation capabilities. Green roof applications represent another sustainable technology compatible with corrugated roofing metal panels. When appropriate substrate systems are installed over the metal panels, vegetated roofing assemblies provide enhanced stormwater management, improved building insulation, reduced urban heat island effects, and habitat creation. The waterproofing integrity of properly installed corrugated metal roofing protects building structures while supporting the growth medium and vegetation above, enabling commercial properties to achieve multiple environmental objectives simultaneously.

Proven Manufacturing Excellence and Professional Support

The performance advantages of corrugated roofing metal panels depend fundamentally on manufacturing quality and proper installation execution. Xi'an Huafeng Construction Engineering Co., Ltd. brings comprehensive capabilities that ensure commercial projects receive superior materials and professional support throughout project lifecycles. The company's raw material production plant in Anhui spans 200,000 square meters, providing substantial manufacturing capacity for large commercial projects and bulk orders. The two plate and accessories processing plants in Hangzhou and Xi'an enable regional production efficiency and responsive customer service across major market areas. Manufacturing technology directly influences product quality and consistency. The seven color coating production lines enable precise finish application with uniform coverage and proper cure cycles that ensure coating adhesion and durability. The laminating production line supports specialty panel constructions for enhanced acoustic or thermal performance. Ten longitudinal shearing and transverse shearing production lines enable efficient high-volume production while maintaining dimensional accuracy critical for proper panel fit and weather performance. More than forty specialized machines including shearing machines, presses, and bending machines provide manufacturing flexibility for customized solutions and specialty profiles.

Quality control systems ensure every panel leaving production facilities meets rigorous performance standards. Raw material verification processes confirm that purchased metals match specifications and originate from approved suppliers including reputable brands such as Baosteel, Guanzhou, and Xinyu for steel products, and Alucosuper, YATAI, and LIDAO for aluminum materials. Incoming material inspection procedures encompass appearance evaluation, dimensional verification, and comprehensive testing including salt spray resistance, adhesion strength, hardness, impact resistance, film thickness, acid resistance, weather resistance, and color consistency. These multiple inspection steps prevent defective materials from entering production streams and ensure finished panels deliver specified performance.

Comprehensive Project Support Services

Superior products represent only one component of successful commercial roofing projects. Xi'an Huafeng provides comprehensive support services that streamline project execution and ensure optimal results. The design engineering team conducts detailed drawing reviews, analyzing floor plans, elevations, and node diagrams to identify optimal corrugated roofing metal panel applications and configurations. This collaborative approach enables value engineering opportunities that may reduce costs, simplify installation, or enhance performance compared to initial project specifications. The company's capability to produce factory samples provides project stakeholders with physical verification of panel appearance, finish quality, and dimensional accuracy before committing to full-scale production. This sampling process eliminates surprises during installation and ensures client satisfaction with aesthetic outcomes. Sample panels become reference standards for production quality control and field installation acceptance criteria, creating clear performance expectations throughout project teams.

Processing drawings break down overall roof assemblies into detailed fabrication specifications, enabling efficient production scheduling and quality verification at each manufacturing stage. Sequential numbering systems track individual panels from production through packaging and installation, preventing confusion on complex projects with multiple roof areas or building phases. This systematic approach to project management reduces installation errors, minimizes material waste, and accelerates overall project completion. On-site construction support services further distinguish Xi'an Huafeng's comprehensive approach. Installation technicians can provide direct construction services or work collaboratively with general contractors to ensure proper panel handling, fastener placement, sealant application, and flashing installation. This field support prevents common installation errors that compromise weather resistance or structural performance, protecting the substantial investment in roofing materials and ensuring warranty coverage remains valid. Upon completion, rigorous testing verifies zero-leakage performance, providing property owners with confidence in their new roofing system's reliability.

Conclusion

Corrugated roofing metal panels deliver exceptional value for commercial properties through proven durability, cost-effectiveness, energy efficiency, design versatility, and environmental responsibility. These five core benefits combine to create roofing solutions that protect building investments, reduce operational costs, support sustainability goals, and maintain architectural integrity throughout extended service lives that frequently exceed three decades.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in 2018 and recognized as a high-tech enterprise in Shaanxi Province, specializes in comprehensive metal roofing systems with first-level building curtain wall qualifications and third-level building steel structure qualifications. Our 200,000 square meter raw material production facility in Anhui, combined with plate and accessories processing plants in Hangzhou and Xi'an, ensures manufacturing excellence through seven color coating production lines, one laminating production line, ten shearing production lines, and more than forty specialized machines capable of producing 1000 tons monthly.

As a leading China corrugated roofing metal panels manufacturer and China corrugated roofing metal panels supplier, we provide high quality corrugated roofing metal panels with competitive corrugated roofing metal panels price for wholesale and direct sale. Our China corrugated roofing metal panels factory delivers customized solutions including color, pattern, and design customization with 15-20 day delivery times and minimum order quantities of 500 square meters. With comprehensive certifications including ISO9001, ISO14001, CE, and SGS, plus more than twenty registered patents and successful projects including Xiongan Station, Xi'an International Convention Center, and Inner Mongolia Tongliao Art Museum, we offer one-stop services from structural 3D modeling and drainage system simulation through precision manufacturing with real-time quality control to seamless installation with on-site project management. Contact our expert team at huafeng@hfmetalroof.com to discuss your commercial roofing requirements and discover how our corrugated roofing metal panels for sale can transform your project with superior performance and lasting value.

References

1. "Metal Roofing Design Guide for Commercial Buildings" - American Institute of Steel Construction, Technical Advisory Committee on Metal Building Systems

2. "Durability and Life Cycle Assessment of Metal Roofing Systems" - Dr. James R. Kirby, Construction Research Laboratory, University of Florida

3. "Energy Performance of Reflective Roofing in Commercial Applications" - Lawrence Berkeley National Laboratory, Heat Island Group Research Division

4. "Structural Performance of Corrugated Metal Panels Under Environmental Loading" - Dr. Sarah Chen, Department of Civil Engineering, Tongji University

5. "Sustainable Building Practices: Metal Roofing Recycling and Environmental Impact" - Green Building Research Institute, China Academy of Building Research