When designing commercial and institutional buildings, architects face mounting pressure from leaking traditional roofs, escalating maintenance costs, and clients demanding sustainable solutions that last decades without constant repairs. The 1 Inch Standing Seam Metal Roofing system addresses these critical pain points by delivering superior waterproofing performance, exceptional structural integrity, and minimal maintenance requirements that conventional roofing materials simply cannot match. This comprehensive guide explores five compelling reasons why architects consistently specify 1 Inch Standing Seam Metal Roofing for projects ranging from transportation hubs to cultural centers, backed by proven engineering principles and real-world project performance data that demonstrate why this roofing solution has become the gold standard for demanding architectural applications.

Superior Water Management and Leak Prevention Performance

The one-inch seam height of 1 Inch Standing Seam Metal Roofing creates a critical vertical barrier that fundamentally transforms how water interacts with the roof surface. Unlike lower profile systems where water can more easily breach seam connections during heavy rainfall or ice dam conditions, the elevated one-inch standing seam forces water to travel significantly higher before it could potentially overflow the seam edge. This design principle becomes especially crucial in regions experiencing severe weather events, where conventional roofing systems frequently fail at connection points and penetrations. Architects who have witnessed costly leak remediation projects understand that the initial investment in proper seam height pays dividends through decades of leak-free performance.

Engineered Waterproofing Through Interlocking Panel Technology

The interlocking panel design inherent to 1 Inch Standing Seam Metal Roofing systems creates multiple lines of defense against water infiltration. Each panel connects through precision-engineered male and female legs that mechanically lock together, forming a continuous barrier that eliminates the reliance on sealants and caulking compounds that degrade over time. The panels are manufactured with tolerances measured in fractions of millimeters, ensuring consistent seam closure across thousands of linear feet of roofing. Xi'an Huafeng Construction Engineering Co., Ltd. produces these systems with material thicknesses ranging from 0.5mm to 1.2mm, allowing architects to specify the optimal gauge for their specific structural requirements and expected loading conditions. The standing seam configuration accommodates thermal expansion and contraction through concealed clip systems that allow the metal to move freely without compromising the weathertight seal, a critical consideration for large-format commercial roofs that can experience temperature differentials exceeding forty degrees Celsius between summer and winter extremes.

Performance Under Extreme Weather Conditions

Buildings in coastal environments, high-altitude locations, and regions prone to severe storms require roofing systems capable of withstanding wind-driven rain, accumulated snow loads, and rapid freeze-thaw cycles. The 1 Inch Standing Seam Metal Roofing specification addresses these challenges through its elevated profile and mechanical seaming technology. During hurricane-force wind events, the concealed fastener system prevents the progressive failure patterns commonly observed in exposed-fastener roofing, where individual screws gradually loosen and allow water infiltration. The one-inch seam height provides sufficient vertical resistance to prevent water from being blown over the seam during extreme weather, while the continuous panel lengths minimize horizontal seams that represent potential weak points. Projects like the Xiongan Station Commercial Body and Xi'an International Convention and Exhibition Center demonstrate this system's capability to protect high-profile structures where roof failure would result in catastrophic damage to interior spaces and building contents.

Long-Term Durability and Minimal Maintenance Requirements

Architects specify 1 Inch Standing Seam Metal Roofing to eliminate the recurring maintenance cycles that plague traditional roofing materials. The system's concealed fastener design represents a fundamental departure from conventional metal roofing approaches that rely on hundreds or thousands of exposed screws penetrating the weatherproof membrane. In a typical exposed-fastener installation, a two-thousand-square-foot roof might contain over two thousand three hundred penetration points, each representing a potential failure location as thermal cycling loosens connections and UV exposure degrades gasket materials. The standing seam approach eliminates this vulnerability entirely, with fasteners located beneath the roofing surface where they remain protected from weather exposure and thermal stress throughout the roof's service life.

Three-Decade Performance Warranty Backed by Manufacturing Excellence

Xi'an Huafeng Construction Engineering Co., Ltd. offers a thirty-year warranty on 1 Inch Standing Seam Metal Roofing installations, reflecting the confidence that comes from manufacturing excellence and rigorous quality control protocols. This warranty coverage extends beyond simple material defects to encompass weathertight performance, ensuring that architects can specify these systems with full confidence in long-term protection. The company's manufacturing facilities in Anhui, Hangzhou, and Xi'an operate seven color coating production lines, one laminating production line, and ten longitudinal and transverse shearing production lines, supported by more than forty specialized machines for cutting, pressing, and forming operations. Every panel undergoes comprehensive inspection protocols including surface treatment verification, dimensional accuracy checks, salt spray testing for corrosion resistance, adhesion testing, hardness evaluation, impact resistance assessment, film thickness measurement, acid resistance verification, weather resistance testing, and color consistency validation. These rigorous quality control measures ensure that every panel leaving the factory meets international standards including ASTM, DIN, JIS, BS, and GB/T specifications.

Material Selection for Extended Service Life

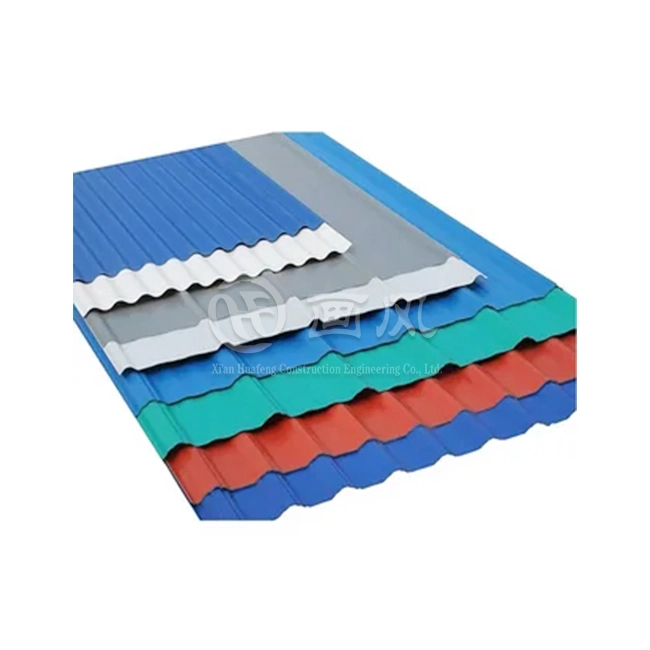

The longevity of 1 Inch Standing Seam Metal Roofing depends critically on substrate material selection and surface treatment specification. Architects working with Xi'an Huafeng can specify aluminum-magnesium-manganese alloys in grades 3003, 3004, and 5052, which offer exceptional corrosion resistance and favorable strength-to-weight ratios for structural applications. Steel substrates from premium manufacturers including BAOSTEEL, GUANZHOU, and XINYU provide options ranging from cold-rolled sheet to galvanized, galvalume, and color-coated products suitable for varying environmental exposures. Stainless steel options in grades 316 and 304 from Baosteel and Tsingshan offer maximum corrosion resistance for the most demanding coastal and industrial environments. Surface treatments applied through PVDF or PE coating processes provide the final protective barrier, with PVDF coatings delivering superior UV resistance and color retention over decades of continuous exposure. The availability of RAL color system options and custom color matching allows architects to achieve precise aesthetic objectives while maintaining the functional performance characteristics essential for long-term building protection.

Design Flexibility and Aesthetic Versatility

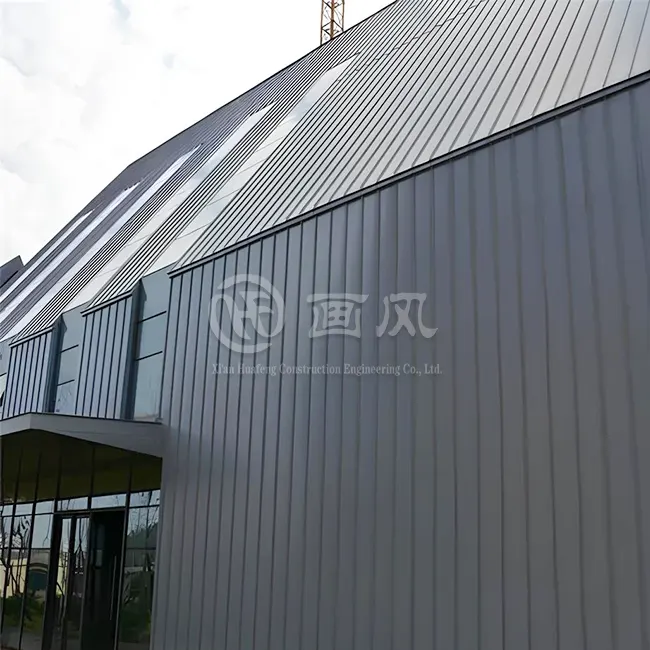

The 1 Inch Standing Seam Metal Roofing system provides architects with exceptional design freedom to realize complex geometric concepts while maintaining weathertight integrity. Panel widths customizable from 300mm to 600mm allow for proportional relationships that complement building scale and architectural rhythm. Custom panel lengths up to twelve meters enable continuous runs from eave to ridge on many building configurations, eliminating horizontal seams that can disrupt visual continuity and introduce potential leak paths. The material's formability supports curved applications, complex hip and valley configurations, and transitions between roof planes that would be problematic or impossible with rigid roofing materials. This geometric adaptability has made 1 Inch Standing Seam Metal Roofing the preferred specification for landmark projects including the Inner Mongolia Tongliao Art Museum, where roof forms integral to the building's architectural identity demanded a roofing system capable of following complex geometries without compromising performance.

Achieving Architectural Vision Through Material Properties

Contemporary architectural practice increasingly emphasizes buildings as complete design statements where every material selection contributes to the overall aesthetic impact. The clean lines and vertical emphasis of 1 Inch Standing Seam Metal Roofing align perfectly with modernist design principles while remaining compatible with traditional building forms. The one-inch seam height creates shadow lines that add depth and visual interest to large roof surfaces, preventing the flat appearance that can make buildings feel visually heavy or monotonous. Color selection through the RAL system provides architects with a comprehensive palette enabling precise color matching to other building elements or creation of deliberate contrasts that establish visual hierarchy. The availability of specialized finishes including matte, satin, and high-gloss options allows further refinement of the building's appearance under varying lighting conditions. Projects like the Jinghe New City International Culture and Art Center South Hall demonstrate how thoughtful specification of 1 Inch Standing Seam Metal Roofing can enhance architectural expression while delivering the practical performance required for major institutional buildings.

Integration with Building Envelope Systems

Successful architectural projects require seamless integration between roofing, wall cladding, and building envelope components. The 1 Inch Standing Seam Metal Roofing system facilitates this integration through compatible trim profiles, flexible flashing details, and coordination with adjacent materials. Xi'an Huafeng's comprehensive product line includes standing seam metal wall sheets that match roofing profiles, enabling continuous material expression from roof to wall planes. This design continuity proves particularly valuable for buildings with complex roof-wall transitions, canopies, or architectural features where visual consistency across different building planes enhances the design concept. The company's design services include structural 3D modeling, load analysis, and drainage system simulation, allowing architects to verify that aesthetic intentions can be achieved while meeting structural and performance requirements. Project drawing deepening services ensure that conceptual designs translate accurately into buildable construction details, with one-to-one scale node development for critical connection points, transitions, and penetrations throughout the building envelope.

Sustainable Building Performance and Environmental Responsibility

Architects increasingly face mandates to design buildings that minimize environmental impact throughout their lifecycle, from material extraction through end-of-life disposal. The 1 Inch Standing Seam Metal Roofing system addresses these sustainability requirements through multiple pathways. Metal roofing materials offer complete recyclability at end of service life, with aluminum and steel retaining their material properties through unlimited recycling cycles. The extended service life of standing seam systems, potentially exceeding fifty years with proper maintenance, dramatically reduces the environmental burden associated with frequent roof replacements. Material efficiency during manufacturing and installation minimizes waste, with precise fabrication techniques ensuring that material consumption closely matches actual roof coverage requirements. The inherent reflectivity of metal surfaces, particularly when specified with high-solar-reflectance coatings, reduces cooling loads in warm climates by reflecting solar radiation rather than absorbing it into building thermal mass.

Energy Performance Through Reflective Technology

Building energy consumption represents one of the most significant environmental impacts over a structure's operational lifetime. The surface treatments available for 1 Inch Standing Seam Metal Roofing play a crucial role in moderating heat gain through the roof assembly. PVDF coatings can be formulated to achieve high solar reflectance values, meeting or exceeding requirements for cool roof programs and green building certification systems. By reflecting solar radiation, these coatings reduce roof surface temperatures by twenty to thirty degrees Celsius compared to darker, low-reflectance materials. This temperature reduction translates directly into decreased air conditioning loads, particularly in commercial buildings with large roof areas relative to their floor area. The reduced thermal stress on the roof assembly also extends material service life by minimizing thermal cycling damage. Xi'an Huafeng's commitment to green sustainable development extends throughout their operations, from material selection through manufacturing processes designed to minimize environmental impact. Their ISO14000:14001 certification demonstrates systematic management of environmental aspects, ensuring that product manufacturing aligns with international environmental management standards.

Material Lifecycle and Resource Efficiency

The concept of embodied energy, representing the total energy consumed in material extraction, processing, transportation, and installation, provides important context for evaluating roofing material sustainability. While metal production requires significant initial energy input, the extended service life of 1 Inch Standing Seam Metal Roofing systems distributes this embodied energy over decades of use. When a metal roof reaches end of service life, the material retains substantial value as recycled feedstock for new metal production. Aluminum recycling, for example, requires only five percent of the energy needed for primary aluminum production from bauxite ore. Steel recycling similarly offers dramatic energy savings compared to primary steel production. This recyclability ensures that material value continues beyond a single-use cycle, reducing long-term resource consumption. Xi'an Huafeng's raw material sourcing from established manufacturers including Alucosuper, YATAI, and LIDAO for aluminum products and BAOSTEEL, GUANZHOU, and XINYU for steel products ensures traceability and quality verification throughout the supply chain. The company's incoming material inspection protocols, including verification of material certifications and third-party testing reports, provide assurance that specified materials meet performance and sustainability criteria.

Proven Performance Through Major Project Implementations

The specification of 1 Inch Standing Seam Metal Roofing for high-profile projects provides architects with confidence in system performance under real-world conditions. Xi'an Huafeng Construction Engineering Co., Ltd. has successfully completed installations at landmarks including the Xiongan Station Commercial Body, where the roof system protects a major transportation facility serving thousands of daily passengers. The Xi'an International Convention and Exhibition Center project demonstrates the system's capability to cover large column-free spans typical of exhibition spaces while maintaining weathertight integrity. The metal roof project at Xi'an Station East Auxiliary Building showcases integration with existing infrastructure and coordination with multiple building systems. These projects represent diverse applications, from the Liyuanping Highway Station Metal Roof Project serving transportation infrastructure to the Weihua Cadre College Teaching Building and Office Building installation protecting educational facilities. The Hangzhou Sanpu Drainage Pump Station installation demonstrates the system's suitability for critical infrastructure where roof failure would compromise essential municipal services.

Comprehensive Project Support From Design Through Installation

Xi'an Huafeng's one-stop solution approach provides architects with seamless support throughout project execution. The design phase includes analysis of project drawings, communication with clients to determine optimal panel types for specific roof structures, and detailed node development at one-to-one scale for critical connections. Factory processing of samples ensures that material parameters including board type, material grade, thickness, surface treatment, and color match project specifications before full production begins. The samples undergo customer confirmation and sealing to establish standards for production and acceptance procedures. Processing drawings break down detailed designs into shop fabrication documents, with sequential numbering systems ensuring that manufacturing, inspection, packaging, and site installation proceed systematically without confusion. On-site construction support includes consultation on construction site layout, product warehousing based on sectioned floor plans and product identification systems, and installation guidance from experienced technicians. The completion process includes comprehensive testing to verify zero-leakage performance, customer review of installation quality, formal acceptance procedures with signature confirmation, and guidance for ongoing maintenance to protect the long-term investment in building protection.

Quality Assurance Through Certification and Testing

Xi'an Huafeng Construction Engineering Co., Ltd. holds more than twenty registered patents for roofing systems, demonstrating ongoing innovation in product development and installation methodologies. The company's recognition as a high-tech enterprise in Shaanxi Province in 2020 reflects their commitment to technological advancement in metal roofing systems. First-level qualification for building curtain walls and third-level qualification for building steel structures provide evidence of technical capability and regulatory compliance. Quality management systems certified to ISO9001 standards ensure consistent processes throughout design, manufacturing, and installation operations. Environmental management certification to ISO14000:14001 demonstrates systematic attention to environmental impacts. SGS certification provides third-party verification of product quality and manufacturing processes. These certifications and qualifications give architects confidence that specifications will be executed according to international standards and best practices. The combination of manufacturing capability, with facilities covering two hundred thousand square meters in Anhui and processing plants in Hangzhou and Xi'an, ensures reliable production capacity to support major projects with demanding schedules and quality requirements.

Conclusion

Architects specify 1 Inch Standing Seam Metal Roofing because it delivers uncompromising performance across all critical evaluation criteria: superior waterproofing through elevated seam design, exceptional durability with minimal maintenance requirements, design flexibility enabling complex architectural expressions, sustainable performance reducing environmental impact, and proven reliability through successful major project implementations. This roofing system represents a comprehensive solution addressing the technical, aesthetic, and sustainability imperatives that define contemporary architectural practice.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a premier China 1 Inch Standing Seam Metal Roofing manufacturer, factory, and supplier, delivering exceptional value through comprehensive capabilities spanning design, production, and construction services. Established in Shaanxi Province in 2018 and recognized as a high-tech enterprise in 2020, we maintain first-level building curtain wall qualifications and third-level building steel structure qualifications, ensuring regulatory compliance and technical excellence across all project engagements. Our manufacturing infrastructure includes a two-hundred-thousand-square-meter raw material production facility in Anhui and dedicated plate and accessories processing plants in Hangzhou and Xi'an, operating seven color coating production lines, one laminating production line, ten longitudinal and transverse shearing production lines, and more than forty specialized machines supporting precision fabrication operations.

When you choose Xi'an Huafeng as your China 1 Inch Standing Seam Metal Roofing wholesale partner, you gain access to High Quality 1 Inch Standing Seam Metal Roofing backed by thirty-year warranties, competitive 1 Inch Standing Seam Metal Roofing price structures reflecting our efficient manufacturing operations, and 1 Inch Standing Seam Metal Roofing for sale with minimum order quantities of just five hundred square meters or one ton, making premium roofing systems accessible for projects of all scales. Our commitment to green sustainable development, integration of architecture with technology and aesthetics, and dedication to creating added value for global customers positions us as your ideal partner for demanding architectural projects requiring proven performance and reliable project execution. Contact our team at huafeng@hfmetalroof.com to discuss your project requirements, request technical specifications, and discover how our one-stop solution approach from raw materials to accessories can streamline your procurement process while delivering superior building protection that enhances architectural vision and ensures decades of trouble-free performance.

References

1. Sheffield Metals International, Inc. "Standing Seam Metal Roofing Systems: Design Considerations and Performance Standards." Sheffield Technical Manual.

2. National Roofing Contractors Association. "Structural and Architectural Metal Panel Roof Systems: Installation Guidelines and Minimum Slope Requirements." NRCA Roofing Manual.

3. American Architectural Manufacturers Association. "Metal Roof Panel Systems: Material Specifications, Testing Protocols, and Performance Criteria." AAMA Standards Documentation.

4. International Code Council. "Metal Roof Panel and Metal Roof Shingle Requirements." International Building Code Chapter 15: Roof Assemblies and Rooftop Structures.

5. Copper Development Association. "Standing Seam Roofing: Technical Design Details and Installation Methods for Architectural Applications." CDA Architectural Handbook.