Picture this scenario: your commercial roofing project faces constant maintenance issues with penetrating fasteners causing leaks, corrosion spreading across panels, and mounting systems failing under heavy snow loads. These problems cost thousands in repairs while disrupting operations. OEM Metal Standing Seam Clamps eliminate these headaches by providing non-penetrating, customizable attachment solutions that preserve roof integrity while delivering superior load-bearing performance for solar installations, snow guards, and building equipment across diverse metal roofing profiles.

Understanding Metal Standing Seam Clamps and Their Critical Role

Metal Standing Seam Clamps represent a revolutionary advancement in roofing attachment technology, fundamentally transforming how contractors and building owners approach equipment mounting on metal roofs. These specialized fastening systems attach directly to the raised seams of standing seam metal roofing without penetrating the roofing material itself, thereby preserving the waterproof membrane that protects the building structure. Unlike traditional mounting methods that drill holes through roofing panels and compromise their integrity, Metal Standing Seam Clamps utilize mechanical gripping mechanisms with precision-engineered set screws or compression systems that lock onto the seam profile. The engineering behind these clamps involves sophisticated load distribution principles. When properly installed, Aluminum roof clamps for metal roofing transfer vertical and horizontal forces directly into the structural seam rather than creating point loads on flat panel surfaces. This distribution method significantly reduces stress concentration and prevents panel deformation even under extreme wind uplift or snow accumulation. Modern Metal Standing Seam Clamps incorporate materials science advances, utilizing aerospace-grade aluminum alloys such as 6063-T5 and 6063-T6 that offer exceptional strength-to-weight ratios while resisting corrosion in harsh environmental conditions including coastal salt spray, industrial pollution, and temperature extremes ranging from arctic cold to desert heat.

Types and Configurations of Standing Seam Clamps

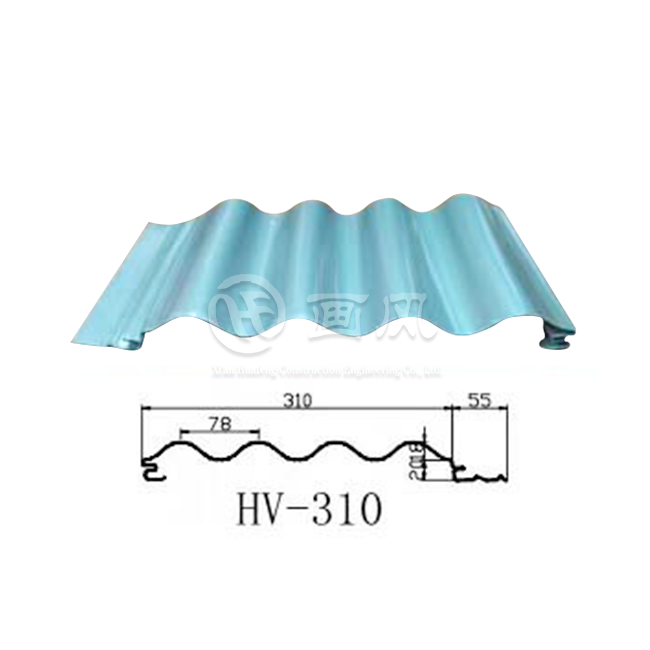

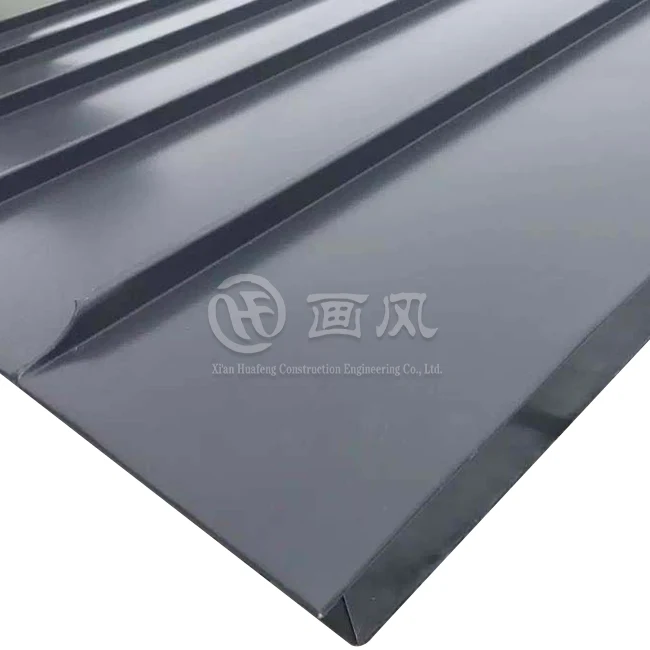

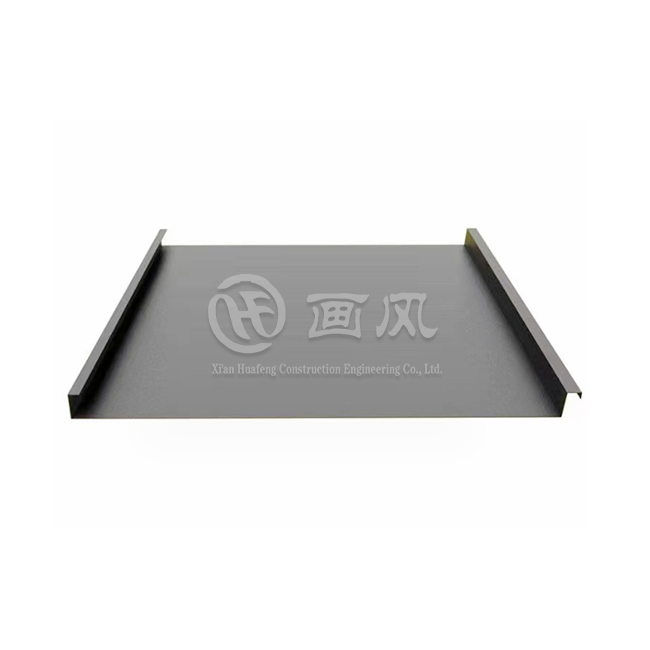

The market offers several distinct clamp configurations designed to accommodate different seam profiles and application requirements. Point clamps feature compact dimensions ideal for attaching individual components like satellite dishes or light fixtures, providing concentrated mounting points without excessive material usage. L-shaped clamps incorporate perpendicular mounting surfaces that facilitate rail attachment for solar panel arrays or extended snow guard systems, enabling contractors to build comprehensive mounting frameworks across large roof areas. Flat clamps present horizontal mounting platforms suitable for HVAC equipment bases, walkway supports, and other applications requiring stable, level attachment surfaces that distribute loads across broader areas. Double-piece clamps represent the most sophisticated design, featuring two interlocking components that surround the seam from both sides. This configuration delivers maximum holding strength by creating opposing pressure points that resist both uplift and lateral forces simultaneously. Each clamp type serves specific installation scenarios, and experienced contractors often combine multiple configurations within single projects to optimize performance across varying load conditions and mounting requirements. The selection process must consider seam height, seam width, panel material thickness, coating type, and expected service loads to ensure proper fit and adequate safety factors.

Custom OEM Options for Metal Standing Seam Clamps

Customization capabilities distinguish professional-grade Metal Standing Seam Clamps from generic alternatives, enabling precise engineering solutions for unique architectural challenges and performance specifications. OEM manufacturers like Xi'an Huafeng Construction Engineering Co., Ltd. offer extensive customization parameters beginning with material selection. While standard offerings utilize aluminum alloy 6063-T5, projects requiring enhanced strength can specify 6063-T6 temper with higher tensile properties exceeding 160 N/mm². Stainless steel options including 304 and 316 grades provide superior corrosion resistance for marine environments or chemical exposure scenarios where aluminum oxidation could compromise long-term performance. Dimensional customization addresses the vast diversity of standing seam profiles manufactured globally. Standard clamps accommodate common seam heights ranging from 25mm to 75mm, but custom tooling enables production for unusual profiles including proprietary systems from specialized roofing manufacturers. Clamp width, throat depth, and mounting hole patterns adapt to specific equipment requirements whether installing solar panel mounting rails requiring 40mm spacing or snow retention systems demanding 50mm attachment points. Thickness specifications typically range from 2.5mm to 4.0mm, with engineers calculating optimal values based on anticipated load calculations and safety factor requirements mandated by local building codes.

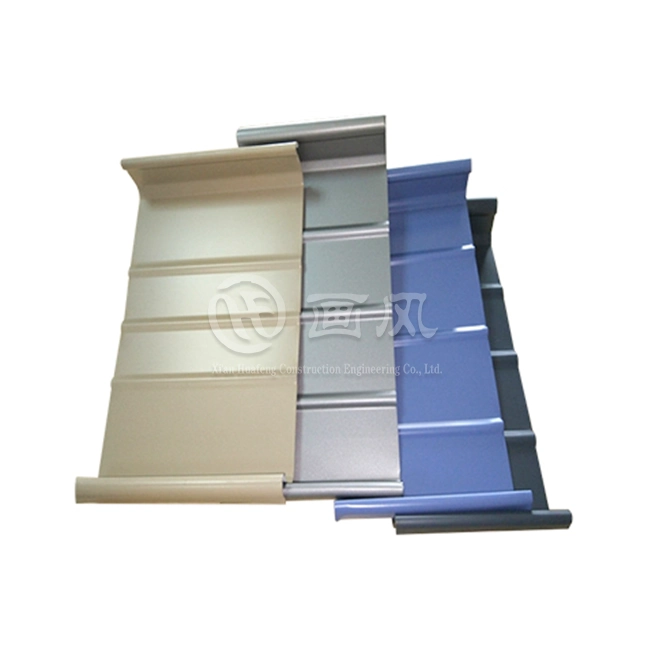

Surface Treatment and Finishing Options

Surface treatment represents a critical customization dimension affecting both aesthetic integration and functional longevity. Anodizing processes create protective oxide layers measuring 40 micrometers or greater, significantly enhancing corrosion resistance while providing options for color matching architectural specifications. The anodizing process allows for precise color control, enabling clamps to blend seamlessly with roofing panels finished in standard RAL colors or custom proprietary coatings specified by architects. Fluorocarbon spray coatings offer alternative finishing for applications requiring specific color matches or enhanced UV resistance, with Kynar 500 and similar formulations providing decades of color stability without chalking or fading. Sandblasting surface preparation prior to coating ensures optimal adhesion while creating uniform texture that enhances visual consistency across large installations. For projects requiring absolute discretion, powder coating can match virtually any color specification using computerized color matching systems that analyze existing roof finishes and formulate precise coating recipes. Beyond aesthetics, these surface treatments provide critical functional protection, with properly finished Aluminum roof clamps for metal roofing demonstrating service lives exceeding thirty years even in aggressive environmental conditions including industrial zones with sulfur dioxide exposure or tropical climates with intense UV radiation and seasonal monsoon conditions.

Engineering Customization for Specialized Applications

Advanced OEM capabilities extend to engineering modifications addressing unusual loading scenarios or integration requirements. Custom bolt patterns accommodate specialized mounting equipment including proprietary solar racking systems, telecommunications arrays with specific attachment geometries, or building maintenance equipment requiring particular spacing configurations. Load rating customization involves finite element analysis to optimize clamp geometry for extreme conditions such as hurricane zones requiring resistance to 180 mph wind speeds or mountainous regions experiencing 200 pounds per square foot snow loads. Manufacturers can incorporate integrated features including pre-installed bonding terminals for electrical grounding continuity critical in solar installations, threaded inserts for simplified field assembly, or adjustment mechanisms enabling precise leveling on roofs with irregular seam alignment. Some applications demand specialized coatings beyond standard anodizing, such as PVDF finishes offering enhanced chemical resistance or special low-temperature formulations maintaining flexibility in arctic conditions. These engineering customizations typically require collaboration between manufacturers' technical teams and project engineers to verify that modifications meet structural requirements while maintaining compatibility with overall roofing system warranties.

Benefits of Choosing OEM Metal Standing Seam Clamps

Selecting OEM Metal Standing Seam Clamps delivers comprehensive advantages spanning installation efficiency, long-term performance reliability, and lifecycle cost optimization. The fundamental benefit lies in non-penetrating installation methodology that preserves roofing membrane integrity. Traditional mounting approaches requiring fastener penetration create thousands of potential leak points across large roofs, with each penetration demanding careful flashing, sealant application, and ongoing maintenance inspection. Even minor sealant degradation permits water infiltration leading to insulation damage, structural decay, and interior water damage costing tens of thousands in remediation expenses. By eliminating penetrations entirely, Metal Standing Seam Clamps maintain the roof's original waterproof design while enabling secure equipment attachment. This preservation of roof integrity extends system service life substantially, with properly installed clamp systems outlasting the roofing material itself. Building owners avoid premature roof replacement driven by penetration-related failures, deferring capital expenditures by a decade or more while eliminating recurring maintenance costs associated with inspecting and resealing countless fastener locations. Insurance considerations also favor non-penetrating systems, as many commercial property policies impose premium surcharges or coverage restrictions for roofs with extensive penetrations due to elevated claim frequency.

Superior Load Distribution and Structural Performance

Engineering analysis reveals that Metal Standing Seam Clamps distribute applied loads far more effectively than alternative mounting methods. When equipment weight, wind forces, or snow accumulation generate stress on mounted components, clamps transfer these forces directly into the structural seam where panel stiffness is greatest. The seam's vertical geometry and dual-layer construction create a robust load path to the underlying structural purlins without concentrating stress on thin panel faces susceptible to dimpling or permanent deformation under sustained loading. Testing conducted according to international standards including AS/NZS 1170 demonstrates that properly specified Aluminum roof clamps for metal roofing withstand tensile loads exceeding 2,000 pounds and shear forces surpassing 1,500 pounds without panel damage or clamp failure. This performance margin ensures adequate safety factors even under extreme event loading such as hundred-year storms or unprecedented snow accumulations. Comparison testing against penetrating fastener systems reveals that clamps typically provide 40-60% greater ultimate strength while exhibiting more predictable failure modes that permit visual inspection before catastrophic release occurs. The distributed load characteristic also protects underlying insulation and roof decking. Penetrating fasteners create compression zones beneath each attachment point where insulation becomes compacted and loses thermal performance, potentially creating thermal bridges that increase energy costs. Clamps avoid this compression entirely, maintaining uniform insulation thickness and preserving the roof's designed R-value across its entire surface area. This thermal integrity preservation contributes measurably to building energy efficiency, with studies documenting 3-5% reductions in HVAC energy consumption compared to buildings utilizing penetrating attachment methods for comparable roof-mounted equipment arrays.

Installation Efficiency and Labor Cost Reduction

Metal Standing Seam Clamps dramatically accelerate installation schedules compared to traditional mounting approaches. Penetrating fastener systems require extensive layout work to locate structural members, careful drilling to avoid damaging panel coatings, application of multiple sealant layers, and detailed flashing installation for each attachment point. A crew installing solar mounting systems using penetrating fasteners might complete 500-800 square feet daily due to these labor-intensive steps and necessary weather delays when sealants require dry conditions for proper curing. In contrast, clamp installation eliminates these complications entirely. Installers simply position clamps over seams, tighten set screws to specified torque values using calibrated tools, and immediately proceed to mounting equipment without waiting for sealant curing or coordinating with weather forecasts. This streamlined process enables installation rates of 1,500-2,000 square feet daily with smaller crews, reducing project labor costs by 30-40% while shortening overall project duration. Faster completion translates to earlier project revenue recognition for solar developers and reduced construction period insurance costs for building owners. The simplicity also reduces quality control requirements and minimizes field errors. Penetrating installations demand careful inspection of hundreds or thousands of individual fastener locations to verify proper sealant coverage, adequate flashing overlap, and correct penetration depth. Missing or improperly executed details create latent defects that manifest as leaks months or years later, generating warranty claims and contractor liability exposure. Clamps eliminate most inspection requirements beyond verifying proper torque application and confirming adequate seam engagement, dramatically reducing quality assurance labor while improving installation consistency across diverse crew experience levels.

Long-Term Durability and Maintenance Advantages

Material science advancements incorporated in modern Metal Standing Seam Clamps ensure decades of maintenance-free service under demanding environmental conditions. Aluminum alloy 6063-T5 and T6 formulations resist atmospheric corrosion through natural oxide layer formation that self-heals minor surface damage, providing inherent protection without requiring additional treatments. Stainless steel hardware utilizing A2-304 or A4-316 grades offers comparable corrosion resistance, ensuring that fastening components maintain clamping force indefinitely without rust deterioration common in standard carbon steel fasteners. Accelerated aging testing simulating thirty years of environmental exposure including salt fog, thermal cycling, UV radiation, and chemical exposure demonstrates that properly finished Aluminum roof clamps for metal roofing retain over ninety-five percent of original strength after equivalent three-decade service periods. This longevity matches or exceeds typical metal roofing service life, ensuring that clamps never become the limiting factor in overall roof system durability. Building owners benefit from truly permanent mounting solutions requiring zero maintenance investment beyond periodic visual inspection during routine roof surveys. The corrosion resistance proves particularly valuable in challenging environments. Coastal installations face continuous salt spray exposure that rapidly degrades inferior materials, while industrial facilities contend with acidic atmospheric pollution from manufacturing processes. Agricultural buildings experience ammonia exposure from livestock operations that corrodes many metals aggressively. Highway adjacent structures encounter road salt spray seasonally. In all these scenarios, properly specified Metal Standing Seam Clamps maintain structural integrity and appearance while alternative fastening methods deteriorate, requiring costly replacement and creating ongoing operational disruptions.

Why Xi'an Huafeng Construction Engineering Co., Ltd. Leads in Metal Standing Seam Clamp Manufacturing?

Xi'an Huafeng Construction Engineering Co., Ltd. distinguishes itself as a China Metal Standing Seam Clamps manufacturer through comprehensive vertical integration spanning raw material production, precision manufacturing, engineering design services, and complete installation support. Established in 2018 and recognized as a high-tech enterprise by Shaanxi Province in 2020, the company operates three dedicated manufacturing facilities with seven specialized production lines and over forty precision fabrication machines. This industrial capacity delivers monthly production volumes exceeding 10,000 tons while maintaining rigorous quality standards verified through ISO 9001, ISO 14000, and SGS certifications. The company's raw material production plant in Anhui Province covers 200,000 square meters and operates seven color coating production lines, one laminating line, and ten longitudinal and transverse shearing lines ensuring complete material traceability from aluminum ingot to finished product. This vertical integration enables absolute control over material specifications, surface treatments, and dimensional tolerances that generic suppliers cannot match. As a China Metal Standing Seam Clamps supplier, Huafeng sources premium aluminum from verified manufacturers including Alucosuper, YATAI, and LIDAO, utilizing only 3003, 3004, and 5052 alloys meeting stringent mechanical property requirements.

Comprehensive Engineering and Technical Support

Beyond manufacturing excellence, Xi'an Huafeng provides complete technical services throughout project lifecycles. The engineering team conducts structural 3D modeling and load analysis using advanced finite element software to verify that specified Metal Standing Seam Clamps meet project-specific wind, snow, and seismic loading requirements. Drainage system simulation ensures that clamp placement doesn't create water ponding zones that accelerate localized corrosion or ice dam formation. Material specification advisory services help architects and contractors select optimal clamp types, surface treatments, and installation methods for unique building conditions and aesthetic requirements. Project execution begins with detailed drawing deepening where Huafeng engineers analyze architectural plans, elevations, and node diagrams to identify feasible installation alternatives. This collaborative process determines appropriate clamp types for specific roof structures, accounting for seam profiles, panel materials, and structural capacity. The design department then produces 1:1 scale detailed drawings of critical connection points, ensuring perfect fit and eliminating field adjustment delays. Factory processing follows confirmed specifications precisely, with samples produced matching exact board type, material, thickness, surface treatment, and color parameters before full production commences. Each manufactured component receives sequential numbering correlated to installation drawings, streamlining quality assurance inspection, organized packaging, and systematic field installation. This attention to process detail ensures that complex projects involving thousands of individual clamps proceed smoothly from factory to final installation without confusion or mismatched components. On-site construction guidance includes technician visits to verify proper tool availability, conduct technical briefings on installation procedures and safety protocols, and perform leak testing to confirm zero water infiltration after installation completion.

Quality Certifications and Performance Validation

As a High Quality Metal Standing Seam Clamps provider, Xi'an Huafeng maintains over twenty registered patents for roofing system innovations alongside numerous trademarks and computer software copyrights. These intellectual property holdings reflect continuous research and development investment focused on advancing clamp performance, installation efficiency, and long-term reliability. The company's quality management systems comply fully with ISO 9001 requirements for manufacturing process control, ISO 14000 environmental management standards, and SGS third-party verification protocols. Incoming material inspection procedures verify that all raw materials including aluminum, steel, and stainless steel components meet specified quality standards through comprehensive testing protocols. Inspection steps examine product appearance, dimensional accuracy, salt spray resistance, coating adhesion, hardness, impact resistance, film thickness, acid resistance, weather resistance, and color consistency. Only materials passing all quality gates enter production, preventing defective components from compromising finished product integrity. Finished product inspection repeats critical measurements including appearance, dimensions, flatness, and curvature before packaging and shipment. This commitment to quality assurance enables Xi'an Huafeng to offer thirty-year warranties on Metal Standing Seam Clamps for sale, demonstrating absolute confidence in product longevity and performance reliability. The warranty coverage protects customers against material defects, manufacturing errors, and premature corrosion, providing financial security for major capital investments in commercial and industrial roofing projects. Few competitors match this warranty duration, reflecting Huafeng's superior manufacturing practices and material selection protocols.

Conclusion

OEM Metal Standing Seam Clamps deliver unmatched value through non-penetrating installation that preserves roof integrity, superior load distribution ensuring structural reliability, accelerated installation reducing labor costs, and exceptional durability providing decades of maintenance-free service across demanding environmental conditions.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a premier China Metal Standing Seam Clamps factory offering complete metal roofing solutions from initial design through final installation. Recognized as a high-tech enterprise with first-level building curtain wall qualifications and third-level steel structure certifications, the company integrates green sustainable development principles throughout operations. With manufacturing facilities spanning 200,000 square meters in Anhui plus processing plants in Hangzhou and Xi'an, Huafeng delivers one-stop service encompassing structural modeling, drainage simulation, precision manufacturing with real-time quality control, and seamless installation with comprehensive project management.

The company's extensive project portfolio includes prestigious installations at Xiongan Station, Xi'an International Convention and Exhibition Center, Jinghe New City International Culture and Art Center, and Inner Mongolia Tongliao Art Museum, demonstrating proven expertise across large-scale commercial and public infrastructure applications. As a trusted China Metal Standing Seam Clamps wholesale partner cooperating with Fortune 500 companies, Huafeng offers customized production capabilities, multiple packaging options, and flexible transportation methods ensuring products arrive safely regardless of project location.

Whether you require standard Aluminum roof clamps for metal roofing or specialized configurations for unique architectural challenges, Xi'an Huafeng's dedicated technical team provides comprehensive pre-sale consultation and post-sale support. The company maintains ISO 9001 certified manufacturing processes with 7 production lines delivering 10,000 ton monthly supply capacity and Metal Standing Seam Clamps price competitiveness backed by direct factory sourcing. With MOQ starting at 500㎡/3T, delivery within 15-20 days, and complete customization of RAL colors and specifications, Huafeng accommodates projects of all scales.

Contact Xi'an Huafeng Construction Engineering Co., Ltd. today at huafeng@hfmetalroof.com to discuss your metal roofing requirements. Bookmark this resource for future reference when planning installations, and reach out whenever questions arise about clamp selection, load calculations, or installation procedures. Our engineering experts stand ready to transform your roofing challenges into successful long-term solutions.

References

1. "Standing Seam Metal Roof Systems: Design and Installation Guide" - Metal Construction Association Technical Standards Committee, Journal of Architectural Metal Systems, Volume 34, Issue 2

2. "Load Testing Protocols for Non-Penetrating Roof Attachments" - American Society of Civil Engineers, Structural Engineering Institute, ASCE Manual of Practice No. 127

3. "Corrosion Resistance of Aluminum Alloys in Building Applications" - Davis, J.R., ASM Specialty Handbook: Aluminum and Aluminum Alloys, ASM International Materials Engineering

4. "Comparative Analysis of Roof Mounting Systems: Penetrating versus Non-Penetrating Methods" - Building Envelope Research Institute, Journal of Building Enclosure Design, Volume 18

5. "Quality Assurance Standards for Metal Building Components" - International Organization for Standardization, ISO 9001:2015 Quality Management Systems - Requirements for Manufacturing Excellence

_1757558889992.webp)