Picture this: You've just invested hundreds of thousands into a commercial building or industrial facility, only to discover your roofing system is leaking within five years, causing costly water damage and production downtime. The wrong roofing decision doesn't just affect aesthetics—it impacts your bottom line, maintenance budgets, and long-term operational efficiency. When comparing Ribbed Standing Seam Metal Roofing versus corrugated panels, understanding the fundamental differences in design, performance, and lifecycle costs becomes critical for making an informed investment that protects your assets for decades to come.

Understanding Ribbed Standing Seam Metal Roofing Systems

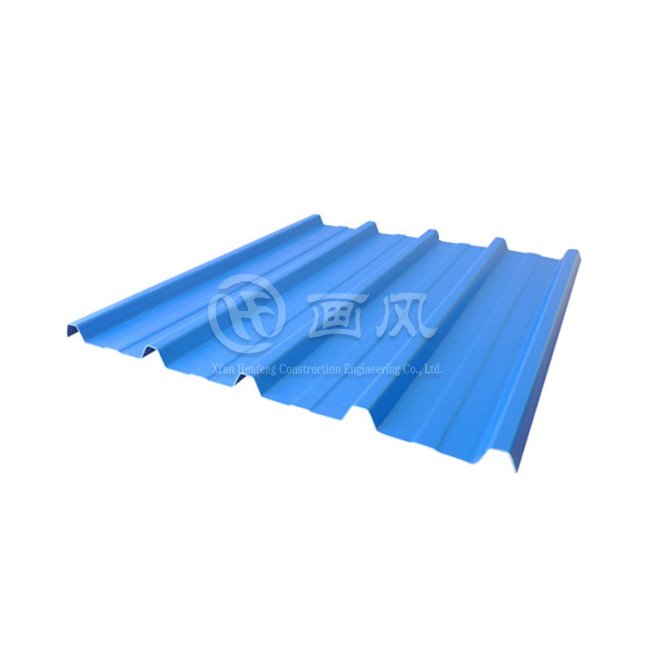

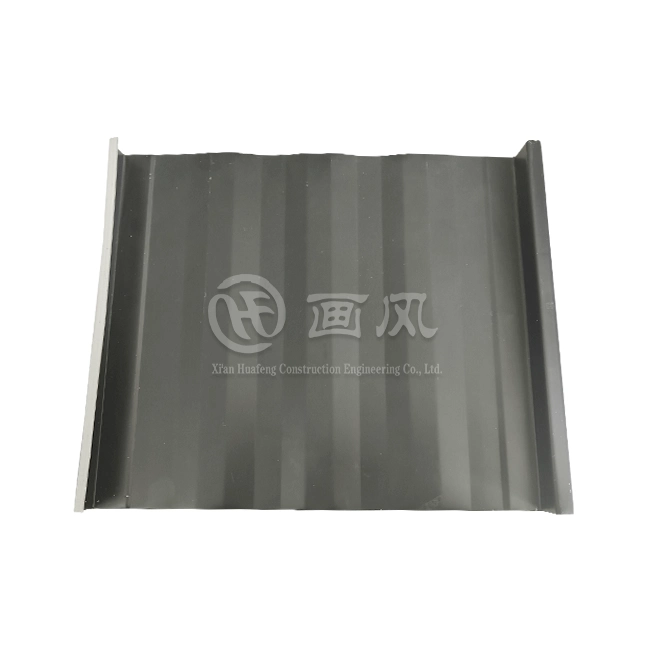

Ribbed Standing Seam Metal Roofing represents the evolution of modern roofing technology, combining structural integrity with sophisticated design elements that address the most challenging weather conditions and architectural requirements. Unlike traditional flat panel systems, this roofing solution incorporates vertical ribs that run the length of each panel, significantly enhancing strength while maintaining the clean, professional appearance that standing seam systems are known for. The raised seams interlock vertically, creating a watertight barrier that eliminates penetration points where moisture could potentially enter the building envelope. The engineering behind Ribbed Standing Seam Metal Roofing involves precision roll-forming technology that creates panels with exact specifications tailored to each project's unique requirements. At Xi'an Huafeng Construction Engineering Co., Ltd., our manufacturing process utilizes state-of-the-art equipment across three factories with seven production lines, ensuring consistent quality and dimensional accuracy. The ribbed profile serves multiple functional purposes: it provides structural stiffening that allows panels to span greater distances between supports, facilitates thermal expansion and contraction without causing oil canning or panel distortion, and enhances drainage efficiency by channeling water away from critical seam areas.

The material selection for Ribbed Standing Seam Metal Roofing significantly influences performance characteristics and longevity. Premium options include aluminum alloy grades 3003, 3004, and 5052, which offer exceptional corrosion resistance particularly valuable in coastal or industrial environments with high salt content or chemical exposure. Galvalume steel provides superior weathering performance compared to traditional galvanized steel, with an aluminum-zinc coating that extends service life by preventing rust formation. Stainless steel options in 304 and 316 grades deliver maximum durability for the most demanding applications, while copper and titanium-zinc materials offer unique aesthetic qualities that develop attractive patinas over time while maintaining structural integrity.

Key Technical Specifications and Performance Characteristics

The technical specifications of Ribbed Standing Seam Metal Roofing directly correlate with its exceptional performance in real-world applications. Material thickness ranges from 0.5mm to 1.2mm, with heavier gauges recommended for regions experiencing severe weather events including high winds, heavy snow loads, or frequent hail storms. The standard rib height of 25mm provides optimal structural performance while maintaining a low-profile appearance that complements contemporary architectural designs. This dimension has been engineered to maximize strength-to-weight ratios, ensuring panels can withstand significant stress without requiring excessive material mass that would increase costs and installation complexity. Surface finishing options play a crucial role in both aesthetic appeal and long-term performance of Ribbed Standing Seam Metal Roofing systems. PVDF (Polyvinylidene Fluoride) coatings represent the premium choice, offering superior resistance to fading, chalking, and environmental degradation with proven performance exceeding 30 years in harsh climates. PE (Polyester) finishes provide excellent value for applications where budget considerations are paramount while still delivering reliable protection against weathering. Color customization follows RAL standards and can be matched to any architectural specification, ensuring seamless integration with existing buildings or corporate branding requirements. The reflective properties of properly selected coatings can reduce cooling loads by up to 25%, delivering measurable energy savings throughout the building's operational life.

Corrugated Metal Panels: Traditional Solutions and Limitations

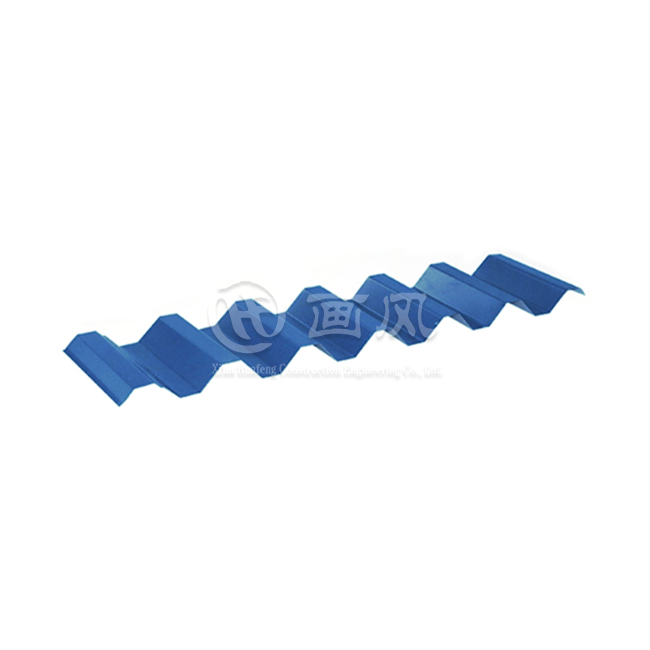

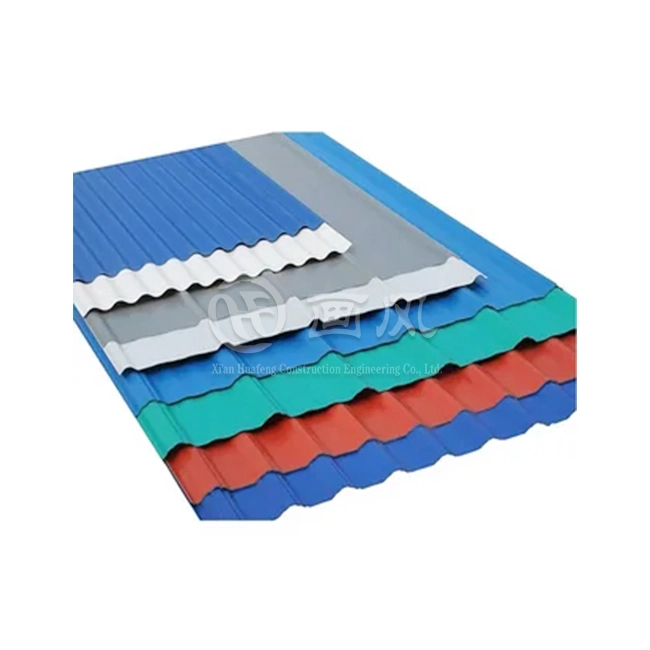

Corrugated metal panels have served the construction industry for over a century, offering a straightforward approach to weather protection with their distinctive wavy profile. The alternating ridges and valleys create a structural pattern that adds stiffness to relatively thin metal sheets, making them an economical choice for agricultural buildings, industrial warehouses, and budget-conscious commercial projects. The exposed fastener system used in corrugated panel installation involves screws driven directly through the panel material into structural supports, with neoprene washers providing a weather seal at each penetration point. While this installation method is simpler and requires less specialized training compared to standing seam systems, it inherently creates hundreds or thousands of potential failure points across the roof surface. The material gauges typically used in corrugated panel manufacturing range from 26 to 29 gauge, resulting in panels that are noticeably thinner and more susceptible to damage from impact, foot traffic, or wind uplift. The lightweight nature of corrugated panels can be advantageous when existing structural capacity is limited, but this same characteristic makes them more vulnerable to denting from hail and more prone to generating noise during rain events. The corrugated profile, while structurally effective in one direction, does not provide the same degree of thermal movement accommodation as Ribbed Standing Seam Metal Roofing systems. As temperatures fluctuate throughout daily and seasonal cycles, corrugated panels experience stress at fastener locations, gradually causing screws to work loose and compromising the weathertight integrity of the installation.

Performance Comparison: Critical Factors for Decision Making

When evaluating Ribbed Standing Seam Metal Roofing against corrugated panels, the fastening system represents perhaps the most significant differentiator in long-term performance. Ribbed standing seam systems utilize concealed clip attachment methods that secure panels to the structural deck without penetrating the weatherproof membrane. These clips accommodate thermal expansion and contraction, allowing panels to move freely as temperatures change while maintaining a secure attachment to the building. In contrast, corrugated panels are mechanically fastened through the face of the material, creating fixed penetration points that must maintain their seal despite the natural movement of metal components. Field experience demonstrates that exposed fastener systems typically require maintenance intervention at the 15 to 20-year mark, when rubber washers begin degrading and fasteners require inspection and potential replacement to prevent leaks. The weather resistance capabilities of Ribbed Standing Seam Metal Roofing substantially exceed those of corrugated systems, particularly in challenging climate conditions. The interlocking raised seams create a continuous barrier that channels water away from vulnerable areas, functioning effectively even on low-slope applications where corrugated panels would be unsuitable. Standing seam profiles can be installed on roofs with slopes as low as 1:12 (some systems even lower with proper underlayment), while corrugated panels require minimum slopes of 3:12 to ensure adequate water drainage and prevent moisture intrusion. Wind uplift resistance testing consistently shows standing seam systems outperforming corrugated installations, with properly designed Ribbed Standing Seam Metal Roofing capable of withstanding hurricane-force winds when engineered and installed according to manufacturer specifications.

Energy efficiency considerations increasingly influence roofing selection decisions as building owners seek to reduce operational expenses and meet sustainability objectives. Ribbed Standing Seam Metal Roofing systems with high-reflectivity PVDF coatings can achieve solar reflectance values exceeding 0.70, meaning they reflect more than 70% of incoming solar radiation back into the atmosphere rather than absorbing it as heat. This performance characteristic translates into measurably lower interior temperatures, reduced air conditioning loads, and improved occupant comfort in naturally ventilated spaces. Corrugated panels can also be finished with reflective coatings, but their wavy profile creates shadow areas that absorb more solar energy compared to the flatter surface of standing seam panels. Additionally, the thermal bridging that occurs at each exposed fastener in corrugated systems creates minor but cumulative heat transfer pathways that slightly diminish overall thermal performance.

Lifecycle Cost Analysis and Return on Investment

Initial installation costs represent only one component of the total economic impact of roofing system selection. While corrugated panels typically cost 40-50% less than Ribbed Standing Seam Metal Roofing in terms of material and installation expenses, this upfront savings must be evaluated against the substantially different maintenance requirements and service life expectations of each system. Corrugated roofing installations generally require their first significant maintenance intervention around year 15 to 20, involving systematic inspection and replacement of degraded fastener washers to prevent leak development. This maintenance activity incurs direct costs for materials and labor, but also generates indirect expenses related to building access, temporary weather protection, and potential business disruption during maintenance operations. Ribbed Standing Seam Metal Roofing systems manufactured to specifications like those from Xi'an Huafeng Construction Engineering Co., Ltd. carry 30-year warranties covering both material performance and weathertight integrity, reflecting the superior longevity and reliability these systems deliver. The concealed fastener design eliminates the periodic maintenance requirements associated with exposed screw systems, and the heavier gauge materials (typically 24-26 gauge versus 26-29 gauge for corrugated) provide enhanced resistance to physical damage that might require panel replacement. Over a 30-year evaluation period, the total cost of ownership for Ribbed Standing Seam Metal Roofing frequently proves competitive with or even favorable compared to corrugated systems when maintenance cycles, repair expenses, and potential business interruption costs are factored into comprehensive financial analysis.

Aesthetic Considerations and Architectural Integration

The visual impact of roofing systems has evolved from a purely functional consideration to an important element of overall architectural expression, particularly for buildings with high visibility or corporate branding requirements. Ribbed Standing Seam Metal Roofing delivers a contemporary, refined appearance characterized by clean lines, consistent panel widths, and the subtle visual interest created by vertical ribs and standing seams. This aesthetic appeals to commercial and institutional clients seeking to project an image of quality, permanence, and attention to detail. The flat areas between ribs provide smooth surfaces that enhance the appearance of metallic finishes or bold colors, while the vertical orientation of all elements creates visual lines that emphasize height and modern design sensibilities. Corrugated panels project a more utilitarian, industrial character that works well for agricultural buildings, manufacturing facilities, and projects where rustic or deliberately unpretentious aesthetics are desired. The wavy profile creates a distinctly different visual texture that reads as more traditional or agricultural in nature, potentially conflicting with contemporary architectural vocabularies. For projects where the roofing system is visible from significant distances or represents a major component of building identity, the aesthetic differences between Ribbed Standing Seam Metal Roofing and corrugated panels can influence client satisfaction and property values beyond purely functional considerations.

Installation Complexity and Project Execution

The installation requirements for Ribbed Standing Seam Metal Roofing demand specialized expertise and equipment that distinguish this system from simpler corrugated panel applications. Proper execution begins with precise substrate preparation ensuring adequate support for clip locations and perfectly aligned attachment points that allow panels to track straight across the roof surface. The concealed clip system requires installers to understand thermal movement calculations, proper clip spacing patterns, and the specific fastening torque requirements that secure panels without over-constraining their ability to expand and contract. Mechanical seaming operations, whether performed with hand seamers or motorized seaming machines, must produce uniform, weathertight seams that meet manufacturer specifications for seam height and interlock engagement. These technical requirements mean that Ribbed Standing Seam Metal Roofing installation typically requires specialized training and experience that not all roofing contractors possess. Xi'an Huafeng Construction Engineering Co., Ltd. addresses this challenge by providing comprehensive installation support, including detailed shop drawings developed through our engineering design process, on-site technical guidance during critical installation phases, and quality assurance verification to ensure proper system performance. Our approach includes analyzing project architectural drawings to identify optimal panel layouts, coordinating with general contractors to establish appropriate construction sequencing, and providing factory-produced samples that serve as quality benchmarks throughout the installation process.

Corrugated panel installation follows more straightforward procedures that require less specialized knowledge and equipment. The exposed fastener approach allows installers to simply drill through panels into structural supports, install screws with sealing washers, and proceed methodically across the roof surface. This simplicity reduces labor costs and makes corrugated systems more accessible for self-installation by building owners with basic construction skills. However, proper corrugated panel installation still requires attention to critical details including fastener spacing, proper alignment to prevent panel buckling, and appropriate overlap treatment at panel ends and ridge conditions. Inadequate installation practices can compromise even the best materials, leading to premature failures that negate any initial cost savings.

Material Selection and Sourcing Considerations

The quality and consistency of materials used in metal roofing systems directly impact long-term performance and project success. Xi'an Huafeng Construction Engineering Co., Ltd. maintains rigorous material sourcing standards, working exclusively with established suppliers who provide full material certifications and third-party testing documentation. For aluminum components, we specify products from manufacturers including Alucosuper, YATAI, and LIDAO, using alloy grades appropriate for each application's specific requirements. Steel materials are sourced from premium producers like BAOSTEEL, GUANZHOU, and XINYU, with options ranging from cold-rolled sheet through galvanized, galvalume, and color-coated products. Stainless steel requirements are met through Baosteel and Tsingshan production, titanium-zinc materials specify NedZink products, and copper applications utilize Chinalco T2 and TP2 grades. This comprehensive material selection capability ensures that Ribbed Standing Seam Metal Roofing systems can be optimized for each project's specific environmental conditions, performance requirements, and budget parameters. Our incoming material inspection protocols verify product specifications through more than a dozen testing procedures including appearance inspection, dimensional verification, salt spray testing, adhesion analysis, hardness measurement, impact resistance, film thickness evaluation, acid resistance, weather resistance, and color consistency. These quality assurance measures, conducted at our 200,000 square meter raw material production facility in Anhui and processing plants in Hangzhou and Xi'an, ensure that every panel delivered to project sites meets exacting standards for performance and reliability.

Application-Specific Recommendations and Best Practices

Different building types and usage scenarios present distinct requirements that influence the optimal selection between Ribbed Standing Seam Metal Roofing and corrugated panel systems. For commercial buildings with occupied spaces directly beneath the roof structure, the superior weathertight performance and enhanced acoustic properties of standing seam systems justify the additional investment. Office buildings, retail facilities, hospitality properties, and institutional structures all benefit from the reduced risk of interior damage, improved energy efficiency, and professional aesthetic that Ribbed Standing Seam Metal Roofing provides. The 30-year service life expectation aligns well with commercial property investment horizons and minimizes disruption to business operations over the building's functional lifespan. Industrial facilities present more nuanced evaluation scenarios where either system type might prove appropriate depending on specific circumstances. Manufacturing operations with climate-controlled environments benefit from the thermal performance advantages of Ribbed Standing Seam Metal Roofing, while warehouse and distribution facilities with unconditioned spaces might accept corrugated panel performance characteristics to achieve lower initial costs. Agricultural buildings, equipment storage structures, and similar applications where interior environment control is less critical represent ideal corrugated panel applications, where the system's fundamental weather protection capabilities meet functional requirements at an economical price point.

For projects seeking LEED certification or other sustainability credentials, Ribbed Standing Seam Metal Roofing systems offer documented advantages in materials sourcing, energy performance, and recyclability that contribute to certification point totals. The longer service life reduces the environmental impact of material production and replacement cycles, while high-reflectivity finishes directly support energy reduction targets. Both standing seam and corrugated systems can incorporate recycled content and remain fully recyclable at end of life, but the superior durability of Ribbed Standing Seam Metal Roofing results in fewer replacement cycles and reduced overall environmental footprint when evaluated across complete building lifecycles.

Geographic and Climate Considerations

Regional climate characteristics significantly influence appropriate roofing system selection and specification details. Coastal environments with high salt exposure demand the superior corrosion resistance of aluminum alloy or stainless steel Ribbed Standing Seam Metal Roofing, where the concealed fastener design provides additional protection against galvanic corrosion and electrolytic degradation. The tighter seaming of standing seam panels also provides better resistance against wind-driven rain, a common challenge in coastal regions where conventional wisdom about minimum roof slopes may not adequately prevent moisture intrusion. Hurricane-prone areas require engineered attachment systems capable of resisting extreme wind uplift forces, where properly designed Ribbed Standing Seam Metal Roofing installations can achieve ratings exceeding 150 mph sustained winds. Cold climate applications benefit from the thermal movement accommodation inherent in standing seam clip systems, which allow panels to contract during temperature extremes without generating stress concentrations that lead to fastener withdrawal or panel distortion. The smooth surface profile facilitates snow shedding, though appropriate snow retention systems should be incorporated to prevent dangerous avalanche conditions at building edges. Desert environments with extreme temperature ranges and intense solar exposure favor high-reflectivity PVDF finishes on Ribbed Standing Seam Metal Roofing, where proven fade resistance maintains aesthetic appearance and thermal performance throughout decades of service. The concealed fasteners avoid the thermal cycling stress that gradually loosens exposed screws in corrugated systems subjected to daily temperature swings exceeding 50 degrees Fahrenheit.

Conclusion

The comparison between Ribbed Standing Seam Metal Roofing and corrugated panels reveals fundamental differences in design philosophy, performance capabilities, and lifecycle value. While corrugated systems offer lower initial costs and simpler installation procedures, Ribbed Standing Seam Metal Roofing delivers superior weather resistance, enhanced durability, reduced maintenance requirements, and professional aesthetics that justify the additional investment for commercial, institutional, and high-performance applications. The decision ultimately depends on specific project requirements, budget parameters, and long-term ownership objectives.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a China Ribbed Standing Seam Metal Roofing manufacturer with comprehensive capabilities spanning design, production, and construction services. Established in 2018 and recognized as a high-tech enterprise in Shaanxi Province in 2020, our company maintains first-level qualifications for building curtain walls and third-level qualifications for building steel structures. As a leading China Ribbed Standing Seam Metal Roofing supplier, we operate a raw material production plant covering 200,000 square meters in Anhui, complemented by processing facilities in Hangzhou and Xi'an equipped with seven color coating production lines, one laminating line, ten longitudinal and transverse shearing lines, fully automatic punching systems, and more than 40 specialized machines.

Our position as a premier China Ribbed Standing Seam Metal Roofing factory enables us to deliver customized solutions that address each project's unique requirements. We offer Ribbed Standing Seam Metal Roofing for sale with specifications including 0.5-1.2mm thickness, 25mm rib height, and materials ranging from aluminum alloy through steel, stainless steel, copper, and titanium-zinc, all backed by a 30-year warranty. As a trusted China Ribbed Standing Seam Metal Roofing wholesale provider, we maintain 1000-ton monthly supply capacity with competitive Ribbed Standing Seam Metal Roofing price structures and 500㎡/1T minimum order quantities. Our High Quality Ribbed Standing Seam Metal Roofing products comply with ASTM, DIN, JIS, BS, and GB/T standards, supported by ISO9001, ISO14000:14001, and SGS certifications alongside more than 20 registered patents.

We deliver one-stop solutions encompassing structural 3D modeling, load analysis, drainage system simulation, and material specification advisory services. Our engineering team provides project drawing deepening, factory processing samples, and production-ready processing drawings that ensure seamless installation. Through rigorous material procurement standards partnering with industry-leading suppliers, comprehensive incoming material inspection protocols, and systematic quality control throughout manufacturing, we guarantee consistent excellence. Our installation support includes on-site construction guidance, technical briefing meetings, safety compliance documentation, and post-installation acceptance verification. Successfully completed projects include Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, and Inner Mongolia Tongliao Art Museum, demonstrating our capability to execute complex, high-profile installations.

Contact us at huafeng@hfmetalroof.com to discuss your Ribbed Standing Seam Metal Roofing requirements and discover how our engineering expertise, manufacturing excellence, and comprehensive service approach can optimize your project outcomes. Bookmark this resource for future reference as you evaluate roofing solutions that protect your investment while delivering decades of reliable performance.

References

1 .Metal Construction Association. "Design Guide for Standing Seam Metal Roof Systems." Technical Publication Series, 2022.

2. Smith, J.R. and Johnson, T.K. "Comparative Performance Analysis of Metal Roofing Systems in Commercial Applications." Journal of Building Performance, Vol. 28, No. 3, 2023, pp. 145-162.

3. National Roofing Contractors Association. "Metal Roofing Best Practices Manual: Installation Standards and Quality Guidelines." 8th Edition, 2024.

4. Chen, L. and Williams, D.M. "Lifecycle Cost Assessment of Metal Roofing Systems: Standing Seam versus Exposed Fastener Panels." Construction Economics Review, Vol. 41, 2023, pp. 78-94.

5. American Society of Civil Engineers. "Wind Load Design Requirements for Metal Roofing Components." ASCE Standard 7-22 Commentary, 2022.