Picture this: you've invested in a premium metal roofing system with superior weatherproofing and structural integrity, only to watch helplessly as your roof's vibrant color fades into a dull, chalky shadow within just a few years. The disappointment is real, and so are the consequences—not just aesthetically, but financially. Selecting the right color and finish for your Double Lok Roof Panel isn't simply about choosing what looks good today; it's about ensuring your investment maintains its beauty, performance, and value for decades to come. This comprehensive guide demystifies the color and finish options available for Double Lok Roof Panel systems, empowering you to make informed decisions that protect both your building's appearance and your bottom line.

Understanding Double Lok Roof Panel Coating Systems

The performance and longevity of your Double Lok Roof Panel depend heavily on the coating system applied to the metal substrate. Modern metal roofing finishes have evolved significantly, offering building owners unprecedented options for durability, color retention, and weather resistance. At the heart of these advances are two primary coating technologies that dominate the architectural metal market: PVDF and PE coatings. Understanding the fundamental differences between these systems is essential for anyone specifying or purchasing Double Lok Roof Panel products for commercial, industrial, or high-end residential applications.

PVDF Coating: The Premium Choice for Double Lok Roof Panel

PVDF, or polyvinylidene fluoride, represents the gold standard in metal roof coatings and is the preferred finish for Double Lok Roof Panel installations where longevity and appearance retention are critical. This fluoropolymer-based coating system typically contains 70% PVDF resin combined with acrylic components, pigments, and specialized additives. The chemistry behind PVDF's exceptional performance lies in the carbon-fluorine bonds within its molecular structure, which are among the strongest chemical bonds in existence. These powerful bonds provide remarkable resistance to degradation from ultraviolet radiation, chemical exposure, and environmental pollutants. When applied to Double Lok Roof Panel systems, PVDF coatings deliver superior protection against the two primary enemies of painted metal surfaces: chalking and fading. Chalking occurs when UV exposure breaks down paint resins, causing a powdery white residue to form on the surface, while fading results from the degradation of color pigments over time. PVDF-coated Double Lok Roof Panel products resist both phenomena far more effectively than alternative coating systems, maintaining their original appearance for 30 years or more with proper maintenance. The coating's flexibility is another crucial advantage, particularly during the manufacturing and installation of Double Lok Roof Panel systems. The softer, more pliable nature of PVDF coatings allows them to bend and flex without cracking during the roll-forming process and mechanical seaming operations that are integral to Double Lok Roof Panel installation. This flexibility translates to fewer coating failures and maintains the roof's weathertight integrity throughout its service life.

PE Coating: Cost-Effective Solution for Budget-Conscious Projects

PE, or polyester coating, represents a more economical alternative for Double Lok Roof Panel applications where budget constraints are paramount and the expected service life is shorter. Sometimes referred to as SMP (silicone-modified polyester) when enhanced with silicone intermediates, PE coatings offer a middle ground between basic polyester formulations and premium PVDF systems. The primary advantage of PE-coated Double Lok Roof Panel products is their significantly lower initial cost—typically 15-35% less expensive than PVDF-coated panels—making them attractive for projects with tight budgets or shorter anticipated lifespans. PE coatings also exhibit superior hardness compared to PVDF, which translates to better scratch resistance during handling, transportation, and installation of Double Lok Roof Panel systems. This characteristic can be particularly valuable on active construction sites where panels may be subject to rough handling or abrasive conditions. However, the trade-offs become apparent over time. PE-coated Double Lok Roof Panel systems experience more rapid color degradation and chalking when exposed to intense UV radiation and harsh weather conditions. The warranty coverage for PE coatings typically extends to 30 years for film adhesion (resistance to cracking, peeling, and flaking) but only 25-30 years for chalk and fade resistance, with higher acceptable levels of degradation compared to PVDF systems. For this reason, PE coatings are most commonly specified for Double Lok Roof Panel installations on wall systems, industrial buildings, agricultural structures, or projects in moderate climates where extreme UV exposure is limited. When PE coatings are chosen for Double Lok Roof Panel applications, lighter colors and earth tones perform best, as fading is less visually apparent in these hues compared to bright or saturated colors.

Color Selection Strategies for Double Lok Roof Panel

Choosing the right color for your Double Lok Roof Panel installation involves balancing aesthetic preferences with practical performance considerations. The color selection process should account for architectural design requirements, regional climate conditions, energy efficiency goals, and long-term appearance expectations. Modern manufacturing capabilities enable Double Lok Roof Panel suppliers to offer an extensive palette of colors, but not all colors perform equally well across different coating systems and environmental conditions.

RAL and Pantone Color Matching for Double Lok Roof Panel

Professional Double Lok Roof Panel manufacturers like Xi'an Huafeng Construction Engineering Co., Ltd. offer comprehensive color matching services based on internationally recognized color standards, primarily the RAL and Pantone systems. RAL, developed in Germany, is the most widely used color matching system in the construction industry and provides a standardized reference for paint manufacturers and architects worldwide. When specifying a Double Lok Roof Panel color using RAL codes, you ensure consistent color reproduction regardless of where the panels are manufactured or when they are produced. Popular RAL colors for Double Lok Roof Panel applications include RAL 9002 (Grey White), RAL 7016 (Anthracite Grey), RAL 9006 (White Aluminium), and RAL 8004 (Copper Brown), all of which offer excellent long-term performance when combined with PVDF coatings. The Pantone Matching System provides even more granular color control and is frequently employed for corporate branding applications or architectural projects requiring precise color coordination with other building materials. When ordering Double Lok Roof Panel products in custom Pantone colors, manufacturers typically require a minimum order quantity due to the specialized nature of custom color formulation and coating. Xi'an Huafeng Construction Engineering Co., Ltd. maintains an extensive inventory of standard colors while also providing custom color matching services for projects requiring unique hues, with production capabilities across three factories and seven color coating production lines ensuring consistent color quality and timely delivery for even the most demanding Double Lok Roof Panel specifications.

Climate Considerations for Double Lok Roof Panel Color Selection

The geographic location and microclimate of your project site should significantly influence your Double Lok Roof Panel color selection strategy. In regions characterized by intense solar radiation and high ambient temperatures—such as the Middle East, southern United States, Australia, and tropical zones—lighter colors for Double Lok Roof Panel systems deliver substantial energy efficiency benefits by reflecting rather than absorbing solar heat. Light-colored PVDF-coated Double Lok Roof Panel installations can achieve solar reflectance values exceeding 70%, dramatically reducing heat transfer into the building envelope and lowering cooling costs by up to 40% compared to darker roofing materials. Conversely, in colder climates where heating costs dominate annual energy consumption, darker Double Lok Roof Panel colors can provide passive solar heating benefits during winter months by absorbing and transferring heat into the building. However, climate considerations extend beyond temperature alone. Coastal environments pose unique challenges for Double Lok Roof Panel systems due to salt-laden air and moisture exposure, making PVDF coatings virtually mandatory for long-term performance in these locations. The exceptional chemical resistance of PVDF protects Double Lok Roof Panel surfaces from corrosion even in aggressive marine atmospheres, while PE coatings may degrade more rapidly under these conditions. Industrial areas with high levels of airborne pollutants similarly benefit from PVDF-coated Double Lok Roof Panel installations, as the coating's chemical resistance prevents staining and degradation from acidic deposition and industrial emissions. When selecting colors for Double Lok Roof Panel systems in these challenging environments, medium tones often represent the optimal compromise—dark enough to mask minor dirt accumulation between cleanings, yet light enough to avoid excessive heat absorption and provide good solar reflectance for energy efficiency.

Surface Finishes and Textures for Double Lok Roof Panel

Beyond color selection, the surface finish or texture applied to Double Lok Roof Panel systems significantly impacts both aesthetic appearance and functional performance. Modern coating technology enables manufacturers to produce a diverse range of surface treatments that enhance visual interest, minimize the appearance of minor imperfections, and provide additional performance benefits for specific applications.

Smooth Finish Options for Double Lok Roof Panel

The smooth finish represents the standard surface treatment for Double Lok Roof Panel products and remains the most popular choice across commercial, industrial, and institutional applications. This finish provides a clean, contemporary appearance with consistent gloss levels and excellent color clarity that showcases the vibrant hues available in modern PVDF and PE coating systems. Smooth-finished Double Lok Roof Panel systems offer maximum light reflectance, making them ideal for applications where high solar reflectance and energy efficiency are priorities. The uniform surface also facilitates efficient water runoff, preventing dirt accumulation and reducing maintenance requirements over the roof's service life. When specifying smooth-finished Double Lok Roof Panel products, customers can typically choose between several gloss levels, ranging from high-gloss finishes that provide a mirror-like appearance to low-gloss or satin finishes that minimize glare and create a more subdued aesthetic. Xi'an Huafeng Construction Engineering Co., Ltd. offers smooth-finished Double Lok Roof Panel systems with thickness options ranging from 0.6mm to 1.2mm, providing flexibility to match structural requirements and budget constraints while maintaining consistent surface appearance across the entire installation. The smooth finish works particularly well with lighter colors, where its reflective properties enhance the panel's energy performance, and with darker colors, where the high gloss accentuates the depth and richness of the hue for dramatic architectural effect.

Embossed and Textured Finishes for Double Lok Roof Panel

Embossed and textured finishes represent an increasingly popular alternative for Double Lok Roof Panel installations seeking enhanced visual interest or functional benefits beyond what smooth finishes provide. These specialized surface treatments involve mechanically impressing patterns or textures into the metal substrate before coating application, creating three-dimensional surface variations that interact with light in complex ways. Stucco embossed finishes, which feature a random, slightly rough texture, excel at concealing minor surface imperfections that might be visible on smooth Double Lok Roof Panel products, including the natural waviness known as oil canning that can occur in flat metal panels. This property makes embossed Double Lok Roof Panel systems particularly valuable for large-span applications where panel flatness might otherwise be a concern. The textured surface also reduces glare compared to smooth finishes, creating a more matte appearance that some architects prefer for certain design aesthetics. Ribbed or striated textures add linear visual interest to Double Lok Roof Panel installations, creating shadow lines that enhance the panel's dimensional appearance and architectural presence. These textures can be oriented either parallel or perpendicular to the panel seams, depending on the desired visual effect. From a practical standpoint, textured Double Lok Roof Panel finishes demonstrate superior scratch resistance during handling and installation compared to smooth finishes, as the three-dimensional surface pattern helps mask minor surface damage that would be readily apparent on smooth panels. However, textured finishes are typically only available in specific gauges and with certain coating systems—most commonly 24-gauge steel with SMP/PE coatings—which may limit color options compared to the full palette available for smooth-finished PVDF-coated Double Lok Roof Panel products manufactured by companies like Xi'an Huafeng Construction Engineering Co., Ltd.

Performance Characteristics of Double Lok Roof Panel Coatings

Understanding the technical performance metrics of different coating systems enables informed decision-making when specifying Double Lok Roof Panel products for demanding applications. Performance characteristics extend far beyond simple aesthetics, encompassing measurable properties that directly impact long-term cost of ownership, maintenance requirements, and lifecycle value.

Chalk and Fade Resistance in Double Lok Roof Panel Systems

Chalk and fade resistance represent the most critical performance metrics for Double Lok Roof Panel coatings, as these factors determine how well the roof maintains its original appearance throughout decades of exposure to harsh environmental conditions. Chalking occurs when UV radiation breaks down the resin binders in paint, causing degraded particles to accumulate on the surface as a white, powdery residue. This phenomenon not only compromises appearance but can also accelerate further coating degradation and promote dirt accumulation. PVDF-coated Double Lok Roof Panel systems from quality manufacturers typically carry warranties guaranteeing no more than a minimal chalk rating (measured on a scale of 0-10, with 10 being no chalking) after 30 years of exposure, while PE-coated alternatives may permit higher chalk ratings over shorter warranty periods. Fading, the gradual loss of color intensity and vibrancy, results from the degradation of color pigments within the coating system. The robust carbon-fluorine bonds in PVDF coatings protect pigments from UV damage far more effectively than the weaker bonds in PE systems, enabling PVDF-coated Double Lok Roof Panel installations to maintain their original color for three decades or more. Warranty provisions typically specify acceptable color change measurements using delta E values, which quantify the difference between original and aged colors using standardized colorimetric methods. Premium PVDF warranties for Double Lok Roof Panel products may limit color change to 5 delta E units or less over 30 years, while PE coatings might permit up to 7-8 delta E units over 25 years—a difference that becomes visually apparent when comparing panels installed at different times. For building owners and facility managers, these performance differences translate directly to lifecycle costs, as roofs requiring more frequent repainting or replacement represent substantial ongoing expenses compared to properly specified PVDF-coated Double Lok Roof Panel systems that maintain their appearance for the building's intended service life.

Weather and Chemical Resistance of Double Lok Roof Panel Finishes

The ability of Double Lok Roof Panel coatings to withstand diverse environmental challenges determines their suitability for specific applications and geographic locations. Weather resistance encompasses protection against multiple degradation mechanisms, including UV radiation, thermal cycling, moisture intrusion, and mechanical stresses from wind-driven rain and hail. PVDF coatings' molecular structure provides exceptional resistance to all these factors, maintaining adhesion to the metal substrate and physical integrity even after decades of exposure to harsh conditions. This durability proves particularly valuable for Double Lok Roof Panel installations in regions experiencing extreme weather, including intense solar radiation, heavy precipitation, severe temperature fluctuations, and violent storms. The coating's flexibility enables it to expand and contract with the metal substrate through countless thermal cycles without cracking or delaminating—a critical property for mechanically seamed Double Lok Roof Panel systems where coating failure at the seams could compromise the roof's weathertight performance. Chemical resistance becomes especially important for Double Lok Roof Panel applications in coastal environments, industrial zones, and urban areas with high atmospheric pollution levels. The fluoropolymer chemistry of PVDF coatings provides remarkable resistance to acids, alkalis, solvents, and salt spray, protecting both the coating itself and the underlying metal substrate from corrosion. This property enables PVDF-coated Double Lok Roof Panel systems to perform reliably in environments that would rapidly degrade PE-coated alternatives, including seaside locations where salt-laden air would otherwise attack the coating and substrate, industrial facilities where chemical emissions might deposit acidic or alkaline compounds on the roof surface, and urban environments where atmospheric pollutants and acid rain pose ongoing challenges. Xi'an Huafeng Construction Engineering Co., Ltd. manufactures Double Lok Roof Panel products using premium materials including aluminum-magnesium-manganese alloys, galvalume steel, and stainless steel substrates, each offering distinct corrosion resistance characteristics that, when combined with appropriate PVDF coatings, deliver unmatched longevity even in the most aggressive environments.

Practical Considerations for Double Lok Roof Panel Color Selection

Beyond technical performance metrics and aesthetic preferences, several practical factors should inform your Double Lok Roof Panel color and finish selection process. These considerations help ensure your choice delivers optimal value throughout the roof's service life while meeting budgetary constraints and project requirements.

Matching and Touch-Up for Double Lok Roof Panel Installations

Color consistency represents a significant concern for large Double Lok Roof Panel installations or phased construction projects where panels may be manufactured and installed at different times. Even when using standardized RAL or Pantone color specifications, minor variations can occur due to differences in coating batches, substrate materials, or manufacturing conditions. Reputable Double Lok Roof Panel manufacturers like Xi'an Huafeng Construction Engineering Co., Ltd. implement rigorous quality control procedures to minimize color variation, including computerized color matching systems, controlled application processes across their seven color coating production lines, and batch testing to verify color consistency. When specifying Double Lok Roof Panel products for projects requiring multiple shipments or future expansion capability, architects and specifiers should request sealed color samples from the manufacturer that represent the exact coating batch to be used for production. These physical samples become the contractual standard against which all delivered panels are evaluated, ensuring visual consistency across the entire installation. Touch-up requirements present another practical consideration, particularly for Double Lok Roof Panel projects where field modifications or damage repair may necessitate on-site coating application. PVDF coatings cannot be accurately reproduced using field-applied touch-up paints, as the specialized resin chemistry and high-temperature curing required for factory-applied PVDF coatings cannot be replicated on-site. Touch-up paints formulated for PVDF-coated Double Lok Roof Panel systems provide adequate corrosion protection and reasonable color matching for small repairs but will not perfectly replicate the appearance or performance of the original factory coating. For this reason, careful handling during transportation and installation of Double Lok Roof Panel products remains essential to minimize coating damage and reduce the need for field touch-up work.

Cost Considerations for Double Lok Roof Panel Coating Options

Budget realities significantly influence coating selection decisions for Double Lok Roof Panel projects, as the premium cost of PVDF coatings may represent a substantial portion of the total material expense. When evaluating coating options, building owners and developers should conduct lifecycle cost analyses that account for initial material costs, expected service life, maintenance requirements, and eventual replacement costs rather than focusing solely on upfront pricing. While PVDF-coated Double Lok Roof Panel systems typically cost 15-35% more initially than PE-coated alternatives, the extended service life (40-50 years versus 25-35 years) and minimal maintenance requirements of PVDF systems often result in lower total cost of ownership over the building's lifetime. For projects with constrained initial budgets, PE-coated Double Lok Roof Panel systems represent a viable alternative, particularly when specified in lighter colors with good fade resistance or for wall applications with reduced UV exposure. Xi'an Huafeng Construction Engineering Co., Ltd. offers flexible pricing structures with bulk order discounts and competitive rates enabled by their efficient manufacturing operations across three factories with a combined production capacity exceeding 1,000 tons monthly. The company's minimum order quantity of 500 square meters or 1 ton makes Double Lok Roof Panel systems accessible even for smaller commercial and industrial projects, while their 15-20 day delivery time ensures project schedules remain on track without the premium pricing often associated with rush orders. For developers and contractors seeking to maximize value, partnering with an experienced manufacturer offering both PVDF and PE coating options enables informed decision-making based on specific project requirements rather than being limited to a single coating system regardless of application suitability.

Conclusion

Selecting the appropriate color and finish for your Double Lok Roof Panel system requires careful consideration of multiple factors including coating technology, color permanence, climate conditions, aesthetic preferences, and lifecycle costs. PVDF coatings offer superior long-term performance and appearance retention, making them the preferred choice for demanding applications where durability and color stability are paramount, while PE coatings provide cost-effective alternatives for budget-conscious projects with shorter expected service lives or reduced environmental exposure. Understanding these distinctions empowers building owners, architects, and contractors to specify Double Lok Roof Panel systems that deliver optimal value throughout their decades-long service life while meeting both functional requirements and design objectives.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

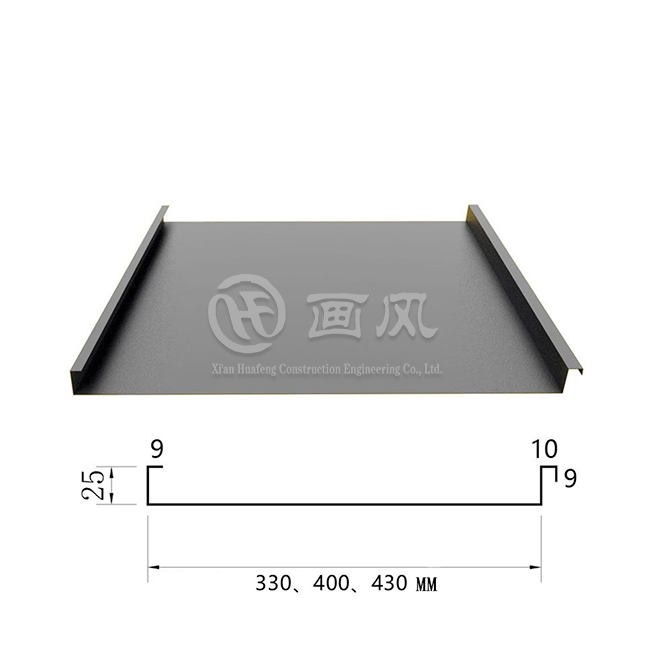

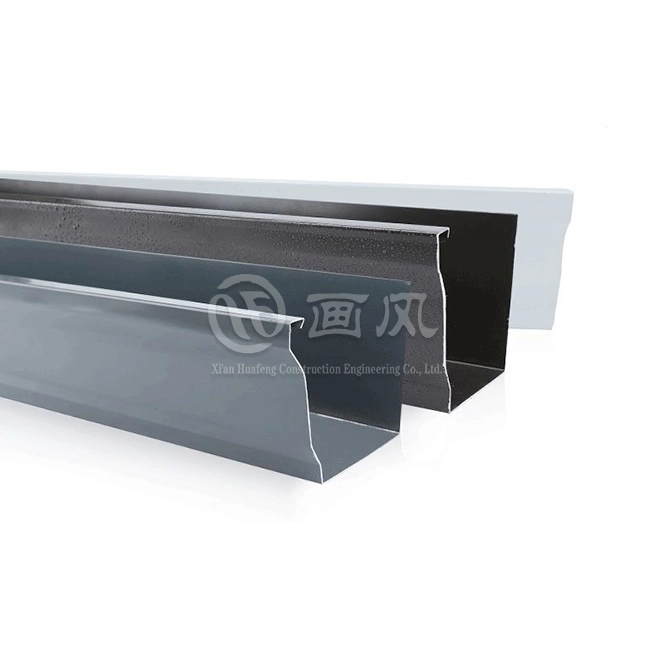

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a premier China Double Lok Roof Panel manufacturer and China Double Lok Roof Panel supplier specializing in high-performance metal roofing systems for commercial, industrial, and institutional applications worldwide. Established in 2018 in Shaanxi Province, China, our company has rapidly emerged as a trusted China Double Lok Roof Panel factory, recognized as a high-tech enterprise with first-level qualifications for building curtain walls and third-level qualifications for building steel structures. Our comprehensive manufacturing infrastructure includes a 200,000-square-meter raw material production facility in Anhui plus two specialized processing plants in Hangzhou and Xi'an, equipped with seven color coating production lines, one laminating production line, ten longitudinal and transverse shearing lines, and more than 40 precision manufacturing machines ensuring consistent quality for every Double Lok Roof Panel for sale.

Our commitment to excellence extends beyond manufacturing to encompass complete design, engineering, and installation services that transform your vision into reality. From initial structural 3D modeling and drainage system simulation through precision manufacturing with real-time quality control to seamless on-site installation and post-project maintenance, we deliver integrated solutions that eliminate coordination challenges and ensure optimal performance. Our High Quality Double Lok Roof Panel products meet the most stringent international standards including ASTM, DIN, JIS, BS, and GB/T specifications, backed by comprehensive ISO9001, ISO14001, and SGS certifications plus more than 20 registered patents protecting our innovative roofing technologies. With a 30-year warranty on our Double Lok Roof Panel systems, thickness options from 0.6mm to 1.2mm, PVDF/PE surface treatments, and the full spectrum of RAL and Pantone colors, we provide the flexibility and reliability your project demands at competitive Double Lok Roof Panel price points.

Our engineering team brings decades of combined experience designing and optimizing metal roof systems for challenging applications including airports, stadiums, exhibition centers, commercial complexes, industrial facilities, and transportation hubs. We've successfully completed prestigious projects throughout China and internationally, including the Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, Xi'an Station East Auxiliary Building, and Inner Mongolia Tongliao Art Museum—each showcasing our technical expertise and commitment to architectural excellence. Whether you need wholesale quantities for large-scale developments or customized solutions for unique architectural requirements, Xi'an Huafeng Construction Engineering Co., Ltd. delivers responsive service, technical support, and manufacturing excellence that sets new standards in the metal roofing industry.

Ready to specify China Double Lok Roof Panel wholesale solutions that combine superior performance with exceptional value? Contact our technical sales team today at huafeng@hfmetalroof.com to discuss your project requirements, request detailed specifications and samples, or schedule a consultation with our engineering staff. Save this guide to your resources for easy reference when evaluating color and finish options for your next metal roofing project—your future self will thank you when your building's roof still looks pristine decades from now while competitors' installations show obvious signs of degradation and require costly replacement.

References

1. Metal Building Manufacturers Association. "Design Guide for Standing Seam Metal Roof Systems." MBMA Engineering Committee.

2. American Society for Testing and Materials. "Standard Practice for Determining Color Change Resistance of Paints and Coatings to Ultraviolet Radiation." ASTM D4956-19.

3. Cool Roof Rating Council. "Product Rating Program Manual." CRRC Technical Committee.

4. National Roofing Contractors Association. "The NRCA Metal Panel and SPF Roof Systems Manual." NRCA Technical Operations Department.

5. International Building Code. "Chapter 15: Roof Assemblies and Rooftop Structures." International Code Council.