When project managers face building envelope failures from inadequate cladding systems, the consequences extend far beyond aesthetics to structural damage, costly repairs, and potential safety hazards. Flat Lock Wall Panels have emerged as a critical solution, combining elegant design with rigorously tested performance across wind resistance, water penetration prevention, and fire safety standards. Understanding how these flat lock metal panel systems perform under standardized testing protocols provides architects, engineers, and building owners with the confidence needed to specify these advanced cladding solutions for commercial, industrial, and institutional projects.

Understanding Flat Lock Wall Panel Testing Standards

Modern construction demands building envelope systems that withstand extreme environmental conditions while maintaining structural integrity and occupant safety. Flat Lock Wall Panels must meet stringent industry testing protocols that evaluate their performance across multiple critical parameters. These standardized tests provide quantifiable data that architects and engineers rely upon when specifying exterior cladding systems for projects ranging from commercial office buildings to cultural institutions. The testing methodology for flat lock metal panel systems follows established ASTM protocols that simulate real-world exposure conditions. These comprehensive evaluations assess how panels respond to wind pressure, water infiltration, and fire exposure, providing documented performance characteristics that inform building code compliance and long-term durability projections. Manufacturers like Xi'an Huafeng Construction Engineering Co., Ltd. subject their Flat Lock Wall Panels to these rigorous examinations, ensuring that products meet or exceed industry benchmarks before reaching construction sites.

Key Testing Categories for Metal Wall Cladding

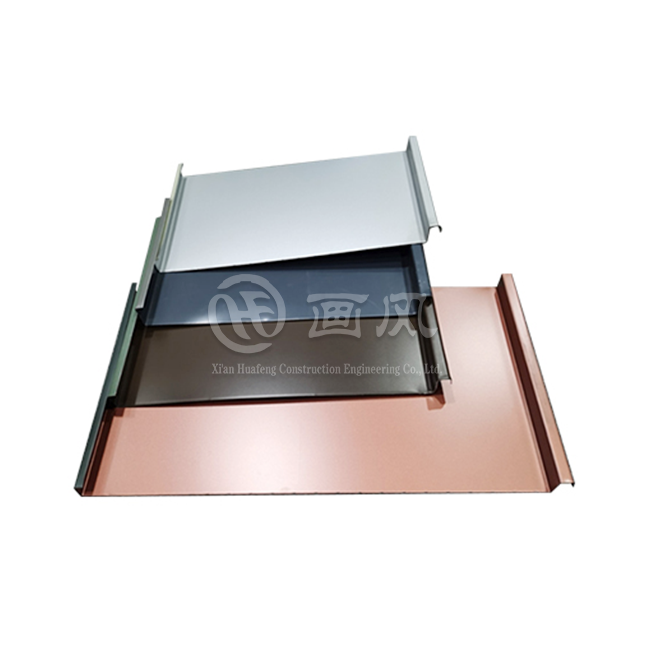

Building envelope testing encompasses three fundamental categories that address the primary threats to wall assembly performance. Wind resistance testing evaluates structural capacity under both positive and negative pressure conditions, simulating hurricane-force winds and pressure differentials. Water penetration testing examines the panel system's ability to prevent moisture infiltration under combined wind and rain conditions. Fire resistance testing determines how assemblies respond to flame exposure, heat transmission, and structural stability during fire events. Each testing category employs specific protocols developed by organizations including ASTM International and the American Architectural Manufacturers Association. These standards provide reproducible test methods that allow for comparison between different cladding systems. For Flat Lock Wall Panels manufactured from materials including titanium zinc, TECU copper, aluminum-magnesium-manganese alloy, and stainless steel, these tests demonstrate the superior performance characteristics that make them suitable for demanding architectural applications.

Wind Resistance Testing of Flat Lock Wall Panels

Wind resistance represents one of the most critical performance parameters for exterior wall cladding systems. The ASTM E330 test method evaluates how flat lock metal panel assemblies withstand both positive and negative wind pressures that occur during severe weather events. This standardized procedure applies uniform static air pressure to panel specimens mounted in laboratory chambers, gradually increasing pressure until structural failure occurs or the panel reaches predetermined performance thresholds. For Flat Lock Wall Panels installed on high-rise buildings or structures in coastal regions, wind resistance testing provides essential data for structural engineering calculations. The testing apparatus applies pressure perpendicular to the panel surface, simulating wind forces that push panels inward or create suction forces pulling panels outward from the building facade. Test results are reported as maximum pressure values in pounds per square foot, indicating the load capacity of the complete assembly including panels, fasteners, and substrate connections.

Dynamic Wind Pressure Performance

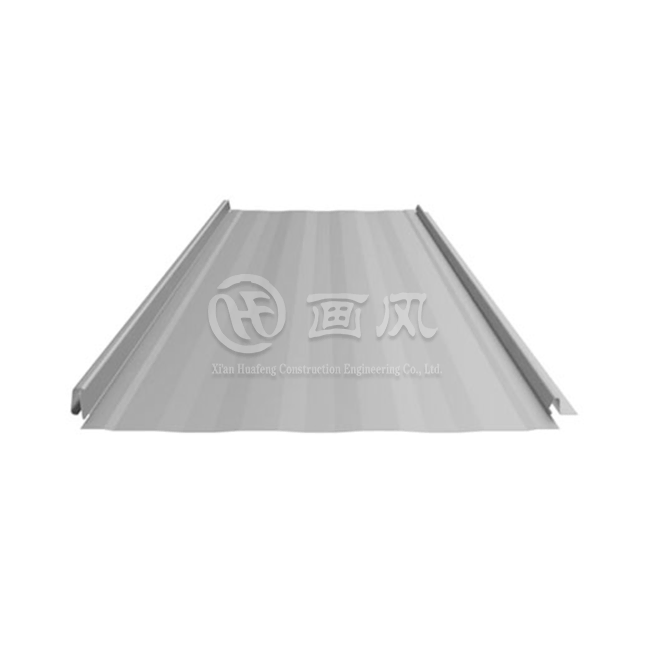

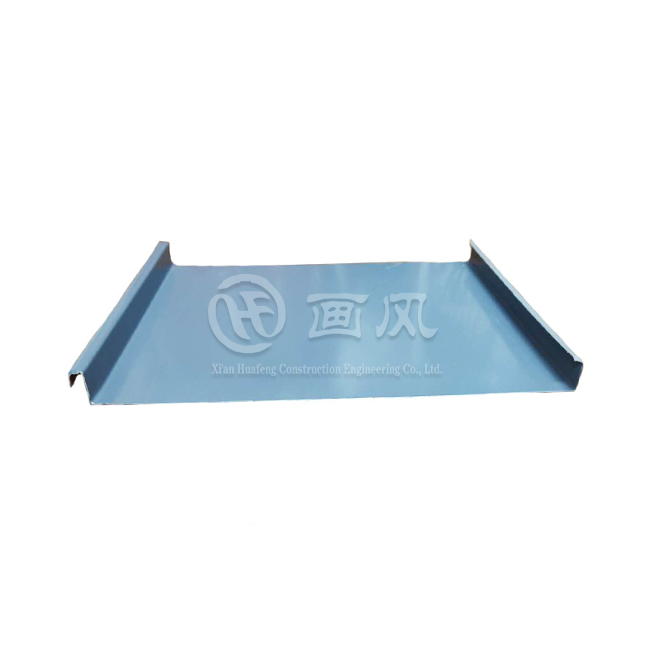

Beyond static pressure testing, advanced evaluation protocols like AAMA 501.1 introduce dynamic pressure cycling that more accurately represents fluctuating wind conditions during storms. This procedure applies alternating positive and negative pressures while simultaneously spraying water onto the panel surface, creating conditions that combine wind-driven rain with pressure differentials. Flat Lock Wall Panels manufactured by Xi'an Huafeng Construction Engineering Co., Ltd. demonstrate exceptional performance in these demanding scenarios, with test results typically exceeding 85 pounds per square foot of negative wind load. The interlocking seam design inherent to flat lock metal panel systems contributes significantly to their wind resistance capabilities. The mechanical connections between adjacent panels create a continuous surface that distributes wind loads across multiple attachment points. When properly installed according to manufacturer specifications, these systems can withstand wind velocities corresponding to Category 3 and Category 4 hurricane conditions. The panels' thickness ranging from 0.4mm to 0.8mm, combined with material properties of aluminum-magnesium-manganese alloys or stainless steel grades 304 and 316, provides the structural rigidity necessary to resist deformation under extreme wind pressures.

Water Penetration Prevention Testing

Water infiltration through building envelopes causes more long-term damage to structures than any other environmental factor. The ASTM E331 standard test method evaluates exterior wall assemblies' resistance to water penetration under uniform static air pressure differences. This protocol simulates wind-driven rain conditions by applying water at 5.0 gallons per square foot per hour to the outdoor face of test specimens while maintaining specified pressure differentials that represent wind forces. During testing, Flat Lock Wall Panels are exposed to water spray for 15-minute intervals at pressures corresponding to wind velocities of 50 mph and 69 mph. Test technicians monitor the interior surface of the assembly, recording any water penetration that reaches beyond the weather-resistive barrier. Successful performance requires zero observable water infiltration during the test duration, demonstrating the assembly's ability to protect interior building components from moisture damage.

Air and Water Infiltration Resistance

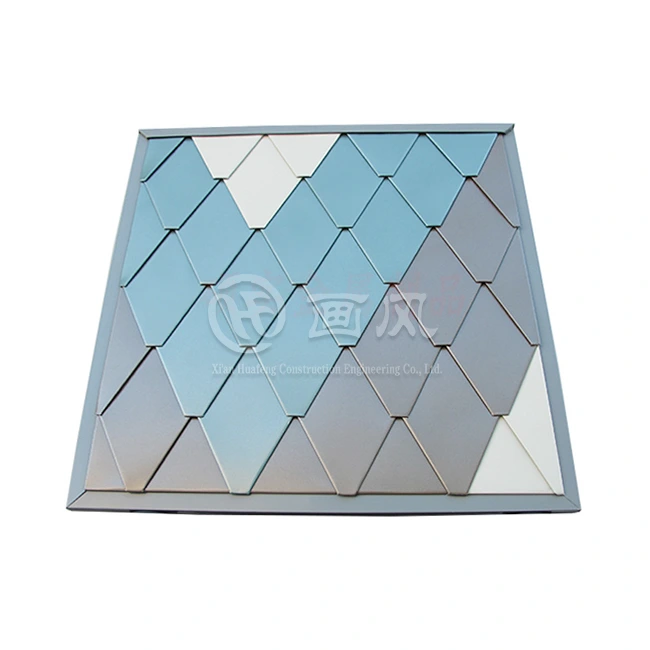

The ASTM E283 standard complements water penetration testing by measuring air leakage rates through wall panel assemblies. This evaluation quantifies how much air passes through the system under specified pressure differences, measured in cubic feet per minute per square foot of wall area. Lower air leakage rates indicate superior assembly quality and contribute to improved building energy efficiency by reducing heating and cooling losses through the building envelope. Flat lock metal panel systems achieve exceptional air and water resistance through their unique installation methodology. The panels' interlocking edges create continuous seams that, when properly formed, eliminate pathways for water and air infiltration. Xi'an Huafeng Construction Engineering Co., Ltd. manufactures Flat Lock Wall Panels with widths ranging from 100mm to 400mm and customizable lengths, allowing for optimized panel layouts that minimize horizontal and vertical joints where leakage typically occurs. The company's precision manufacturing facilities, equipped with advanced roll-forming systems and quality control processes, ensure dimensional accuracy critical for achieving zero-penetration test results.

Field Installation and Real-World Performance

Laboratory test results provide baseline performance data, but field installation quality significantly impacts real-world water resistance. Proper installation requires attention to flashing details at panel terminations, sealant applications at penetrations, and correct formation of panel interlocks. AAMA 509 testing protocols evaluate installed assemblies under field conditions, measuring both water penetration and ventilation characteristics to verify that construction practices maintain the performance levels demonstrated in laboratory environments. The documentation from performance testing guides installation specifications that contractors must follow to achieve warranted results. For projects utilizing Flat Lock Wall Panels from manufacturers meeting ASTM, DIN, JIS, BS, and GB/T standards, installation guidelines specify tolerances for panel alignment, fastener spacing, and joint formation. These precision requirements reflect the engineering analysis behind successful test performance, translating laboratory results into reliable field applications that protect buildings throughout their service life.

Fire Resistance and Safety Testing

Fire safety represents the most critical life-safety consideration in building envelope design. The ASTM E119 standard test method evaluates how wall assemblies contain fire, prevent flame spread, and maintain structural integrity during fire exposure. This comprehensive evaluation subjects full-scale wall specimens to controlled fire conditions following a standard time-temperature curve that reaches approximately 1,700°F within the first hour of exposure. During fire testing of assemblies incorporating flat lock metal panel systems, multiple criteria determine pass/fail outcomes. The assembly must prevent flame penetration through joints or seams, limit temperature rise on the unexposed surface to specified thresholds, and maintain structural stability without collapse. For loadbearing wall assemblies, the system must continue supporting applied loads throughout the test duration. Test results establish fire-resistance ratings expressed in time increments of 30 minutes, 1 hour, 2 hours, or longer depending on assembly performance.

Material Fire Performance Characteristics

The inherent fire resistance of materials used in Flat Lock Wall Panels contributes to overall assembly performance. Metals including aluminum-magnesium-manganese alloys, stainless steel, titanium zinc, and copper are non-combustible materials that neither ignite nor contribute fuel to fire development. These materials maintain dimensional stability at elevated temperatures, resisting warping or melting that could compromise assembly integrity. When combined with appropriate substrate materials and insulation systems, flat lock metal panel assemblies can achieve fire-resistance ratings suitable for Type I and Type II construction classifications under the International Building Code. Surface coatings applied to Flat Lock Wall Panels, including PVDF and PE finishes, undergo separate evaluation for flame spread and smoke development characteristics per ASTM E84 testing protocols. High-quality architectural coatings demonstrate Class A flame spread ratings, indicating the lowest fire hazard classification for interior finish materials. This performance characteristic becomes particularly important for panel installations in occupied spaces or on interior walls where fire safety codes impose strict limitations on combustible finishes.

Comprehensive Fire Safety Engineering

Modern building codes require consideration of fire safety throughout the entire wall assembly, not just individual components. Fire-resistive assemblies must address thermal barriers that prevent excessive heat transmission to combustible materials within wall cavities. For exterior wall applications, Flat Lock Wall Panels serve as non-combustible cladding that provides the first line of defense against external fire exposure, preventing flames from entering the building through the facade. Xi'an Huafeng Construction Engineering Co., Ltd. provides comprehensive documentation supporting fire-safe applications of their Flat Lock Wall Panels, including material certifications, test reports, and installation details that address fire-stopping requirements at wall penetrations and horizontal floor intersections. The company's products meet requirements specified in ISO 9001 and ISO 14001 standards, ensuring consistent quality management practices that support reliable fire safety performance. With a service life exceeding 30 years under warranty, these systems provide long-term fire protection that remains effective throughout building occupancy.

Integrated Testing for Complete System Validation

While individual test protocols evaluate specific performance parameters, real-world building envelopes must simultaneously resist all environmental threats. Integrated testing approaches combine wind, water, and structural loading to validate complete system performance under realistic exposure conditions. These comprehensive evaluations reveal how assemblies respond when multiple stressors act concurrently, identifying potential vulnerabilities that single-parameter testing might miss. Advanced testing facilities conduct sequential exposure tests that apply wind pressure, water spray, and thermal cycling in programmed sequences mimicking seasonal weather patterns and daily temperature fluctuations. Flat lock metal panel systems demonstrate particular advantages during these multi-parameter evaluations, as their mechanical interlocking seams accommodate thermal expansion and contraction without compromising water resistance or wind load capacity. The flexibility designed into these systems allows panels to move independently while maintaining continuous weather protection.

Manufacturing Quality and Test Reliability

Test results only translate to reliable field performance when manufacturing processes maintain consistent quality throughout production. Xi'an Huafeng Construction Engineering Co., Ltd. operates three factories with seven production lines and more than 40 advanced machines dedicated to flat lock metal panel manufacturing. This extensive infrastructure supports monthly production capacity exceeding 1,000 tons while maintaining the dimensional precision and material consistency required for reproducible test performance. The company's quality control procedures include incoming material inspection with requirements for material certifications and third-party test reports from suppliers. Premium material brands including Alucosuper, YATAI, and LIDAO aluminum alloys, BAOSTEEL and GUANZHOU steel products, and Baosteel and Tsingshan stainless steel ensure that base materials meet performance specifications. Production processes incorporate real-time quality control checkpoints evaluating appearance, dimensions, flatness, and coating integrity before panels proceed to packaging and shipment.

Certification and Standards Compliance

Independent certification bodies verify that manufacturing facilities and products meet established industry standards. Xi'an Huafeng Construction Engineering Co., Ltd. holds ISO 9001 quality management certification, ISO 14001 environmental management certification, and SGS testing verification. These credentials demonstrate systematic approaches to quality assurance that maintain consistency between laboratory test specimens and production panels delivered to construction sites. The company's recognition as a high-tech enterprise in Shaanxi Province with first-level curtain wall qualifications and third-level steel structure qualifications further validates technical capabilities. Product certifications include compliance with multiple international standards: ASTM standards used throughout North America, DIN standards governing European construction practices, JIS standards for Asian markets, and GB/T Chinese national standards. This multi-standard compliance enables specification of Flat Lock Wall Panels on projects with diverse regulatory requirements, providing architects and engineers with confidence that products meet or exceed applicable building codes regardless of project location.

Conclusion

Flat Lock Wall Panels deliver proven performance across wind resistance, water penetration prevention, and fire safety testing, making them reliable choices for demanding architectural applications where building envelope integrity directly impacts occupant safety and long-term structural protection.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

As a China Flat Lock Wall Panels factory and leading China Flat Lock Wall Panels supplier, Xi'an Huafeng Construction Engineering Co., Ltd. stands as a China Flat Lock Wall Panels manufacturer offering China Flat Lock Wall Panels wholesale with competitive Flat Lock Wall Panels price while delivering High Quality Flat Lock Wall Panels with Flat Lock Wall Panels for sale through comprehensive one-stop solutions. Established in 2018 and recognized as a high-tech enterprise in Shaanxi Province, we specialize in design, production, sales, and construction of metal roofing systems and building curtain wall systems. Our three factories spanning 200,000 square meters in Anhui with processing plants in Hangzhou and Xi'an feature seven color coating production lines, one laminating line, ten longitudinal and transverse shearing lines, and fully automatic punching systems ensuring precision manufacturing. With first-level curtain wall qualifications, third-level steel structure certifications, over 20 registered patents, and ISO9001, ISO14000:14001, and SGS certifications, we deliver customized solutions from raw material procurement through final installation. Our engineering services include structural 3D modeling, load analysis, drainage simulation, comprehensive quality inspection with salt spray, adhesion, hardness, and weather resistance testing, plus on-site construction guidance ensuring zero-leakage performance. Successfully completed projects including Xiongan Station, Xi'an International Convention and Exhibition Center, and Inner Mongolia Tongliao Art Museum demonstrate our capability to deliver excellence on landmark buildings. Contact us at huafeng@hfmetalroof.com to discuss your project requirements and receive expert consultation on High Quality Flat Lock Wall Panels solutions tailored to your specifications, complete with free samples, 15-20 day delivery, and 30-year warranty coverage.

References

1. American Society for Testing and Materials. "Standard Test Method for Water Penetration of Exterior Windows, Skylights, Doors, and Curtain Walls by Uniform Static Air Pressure Difference (ASTM E331)." ASTM International Committee E06 on Performance of Buildings.

2. American Society for Testing and Materials. "Standard Test Methods for Fire Tests of Building Construction and Materials (ASTM E119)." ASTM International Committee E05 on Fire Standards.

3. American Society for Testing and Materials. "Standard Test Method for Structural Performance of Exterior Windows, Doors, Skylights and Curtain Walls by Uniform Static Air Pressure Difference (ASTM E330)." ASTM International Committee E06.

4. American Architectural Manufacturers Association. "Quality Assurance and Diagnostic Water Leakage Field Check of Installed Storefronts, Curtain Walls, and Sloped Glazing Systems (AAMA 511)." AAMA Standards Development.

5. International Code Council. "International Building Code Requirements for Exterior Wall Assemblies." ICC Building Codes and Standards Committee.