Industrial facilities, commercial warehouses, and agricultural buildings face a common challenge: excessive noise reverberation combined with inadequate airflow that creates uncomfortable working conditions and potential structural moisture problems. Punched or perforated Metal Corrugated Roofing Panel offers an innovative dual-function solution that simultaneously addresses acoustic control and ventilation requirements. These specialized corrugated roofing sheets feature strategically designed perforations that allow sound waves to pass through to absorptive backing materials while facilitating continuous air circulation, making them ideal for environments where noise control and thermal management are critical concerns.

Understanding Perforated Metal Corrugated Roofing Panel Technology

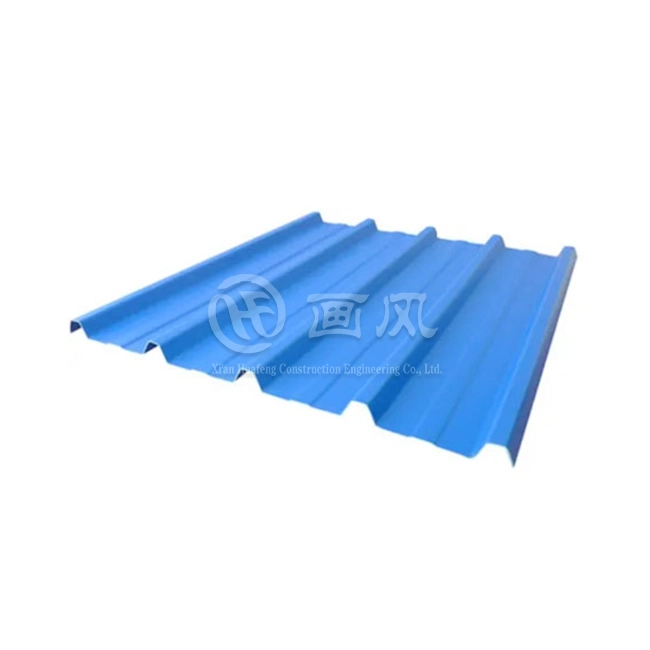

Perforated Metal Corrugated Roofing Panel systems combine the structural advantages of traditional corrugated profiles with the functional benefits of precisely engineered perforation patterns. The corrugated design inherently provides superior strength-to-weight ratios compared to flat panels, while the punched holes create pathways for both acoustic energy absorption and air movement. Manufacturing these panels requires specialized equipment capable of creating uniform perforation patterns before or after the roll-forming process that creates the corrugated profile. At Xi'an Huafeng Construction Engineering Co., Ltd., our advanced production facilities include fully automatic punching production lines integrated with our roll-forming systems, allowing us to produce customized perforated corrugated roofing sheets with hole sizes ranging from 3mm to 25mm in diameter, with various patterns including staggered, straight-line, and decorative configurations. The perforation percentage, typically ranging from 15% to 50% open area, directly influences both acoustic and ventilation performance. Higher perforation percentages allow greater airflow and sound transmission to backing materials, while lower percentages maintain more structural rigidity and weather resistance. Our engineering team works closely with clients to determine the optimal perforation specification based on specific acoustic targets, ventilation requirements, structural loading conditions, and aesthetic preferences. The material selection for perforated Metal Corrugated Roofing Panel is equally important, with options including galvanized steel for cost-effectiveness and corrosion resistance, aluminum for lightweight applications and superior corrosion performance in coastal environments, and color-coated steel with PE, HDP, or PVDF finishes for enhanced aesthetics and additional protective layers.

Acoustic Performance Characteristics of Punched Corrugated Panels

The acoustic functionality of perforated Metal Corrugated Roofing Panel operates through a combination of sound transmission and resonant absorption principles. When sound waves encounter the perforated metal surface, a portion passes through the holes to interact with sound-absorbing materials installed behind the panel, while the remaining energy is either reflected or absorbed by the metal surface itself. The perforation pattern acts as an acoustic impedance matching layer, allowing sound energy to efficiently transfer from air into the absorptive backing material without excessive reflection. This mechanism is particularly effective for controlling mid to high-frequency noise common in industrial environments, including machinery operation, ventilation systems, and material handling equipment. The corrugated profile itself contributes additional acoustic benefits beyond the perforations. The three-dimensional geometry creates multiple reflection paths that help diffuse sound energy rather than creating strong specular reflections that characterize flat surfaces. This diffusion effect reduces flutter echoes and standing wave patterns that can make spaces feel excessively reverberant and acoustically uncomfortable. When combined with proper backing materials such as mineral wool, fiberglass, or recycled cotton insulation, perforated corrugated roofing sheets can achieve Noise Reduction Coefficients ranging from 0.60 to 0.95, depending on the perforation percentage, hole size, backing material thickness, and air gap depth between the panel and structural substrate.

For optimal acoustic performance, our design team typically recommends installing perforated Metal Corrugated Roofing Panel with a minimum 50mm air cavity between the panel and the roof deck, filled with acoustic insulation material with a density of 48-96 kg/m³. This configuration creates a resonant absorber system that is particularly effective at frequencies between 250Hz and 4000Hz, which encompasses the primary frequency range of human speech and most industrial noise sources. The thickness of our corrugated roofing sheets, available from 0.4mm to 1.2mm, can be selected to balance acoustic performance with structural requirements and cost considerations. Thicker panels generally provide better low-frequency performance due to increased mass, while thinner perforated panels may be sufficient for applications focused primarily on mid and high-frequency control.

Ventilation Applications and Thermal Management Benefits

Beyond acoustic performance, perforated Metal Corrugated Roofing Panel excels in passive ventilation applications that address heat buildup and moisture control challenges common in metal-roofed structures. The perforation pattern allows hot air naturally accumulating at the roof level to escape through the holes, creating a continuous passive ventilation pathway that reduces cooling loads and improves interior comfort conditions. This natural ventilation mechanism operates based on the stack effect principle, where temperature differences between interior and exterior air create pressure differentials that drive airflow through the perforations. The corrugated profile enhances this effect by creating air channels along the panel ribs that facilitate longitudinal airflow toward ridge vents or other exhaust points. In industrial facilities with high internal heat loads from machinery, production processes, or concentrated solar heat gain through the roof, perforated corrugated roofing sheets provide substantial thermal management benefits. Field measurements from similar installations have demonstrated interior temperature reductions of 3-8 degrees Celsius compared to non-ventilated metal roof systems, depending on perforation percentage, climate conditions, and internal heat generation rates. This passive cooling effect translates directly into reduced HVAC energy consumption, improved working conditions for personnel, and decreased thermal stress on temperature-sensitive stored materials or equipment. For agricultural applications such as livestock barns, equipment storage buildings, and produce handling facilities, the ventilation provided by perforated Metal Corrugated Roofing Panel helps maintain appropriate humidity levels and prevents condensation formation that can lead to corrosion, material degradation, and unhealthy environmental conditions.

Design Considerations for Ventilated Roof Systems

Implementing perforated Metal Corrugated Roofing Panel for ventilation applications requires careful consideration of several interrelated design factors. The perforation percentage must balance ventilation effectiveness against weather protection, with typical ventilation applications using 20-35% open area to provide adequate airflow while minimizing rain penetration risk. The corrugation profile dimensions, including wave height and pitch, influence the available ventilation path cross-sectional area and should be coordinated with the overall roof ventilation strategy including intake locations, exhaust provisions, and internal air circulation patterns. Our standard corrugated profiles feature wave heights ranging from 25mm to 50mm with spacing between 60mm and 150mm, providing substantial airflow capacity when combined with appropriate perforation patterns. Weather protection remains a primary concern with any perforated roofing system, requiring attention to perforation hole size, panel orientation, roof slope, and local precipitation patterns. Smaller hole diameters, typically 3-6mm, minimize water infiltration while still providing effective ventilation and acoustic performance. The corrugated profile orientation should align with primary drainage patterns, allowing water to flow efficiently along the panel valleys rather than across perforations where infiltration risk is highest. Our engineering team recommends minimum roof slopes of 10 degrees for perforated corrugated roofing sheets in moderate climate zones, with increased slopes for regions experiencing heavy rainfall or driving rain conditions. Additional weather protection can be achieved through proper flashing details, underlayment systems beneath the perforated panels, and strategic limitation of perforations to specific roof zones rather than full-area coverage.

At Xi'an Huafeng Construction Engineering Co., Ltd., our comprehensive design services include computational fluid dynamics analysis for complex ventilation requirements, thermal modeling to predict cooling performance, and detailed weather infiltration risk assessments. Our experienced design department conducts 1:1 drawing development for all project-specific conditions, ensuring proper integration of perforated Metal Corrugated Roofing Panel with overall building envelope systems, structural support requirements, and architectural aesthetic intentions. We utilize advanced 3D modeling and load analysis capabilities to verify that perforated panels meet structural performance requirements including wind uplift resistance, snow loading capacity, and seismic design criteria while maintaining the desired acoustic and ventilation functionality.

Manufacturing Excellence and Quality Assurance

Producing high-performance perforated Metal Corrugated Roofing Panel demands sophisticated manufacturing capabilities and rigorous quality control processes. Our production methodology integrates several specialized processes including precision metal punching, roll-forming or press-brake forming, surface treatment application, and comprehensive quality inspection protocols. The punching operation, which creates the perforation pattern, must be executed with high accuracy to ensure uniform hole geometry, consistent spacing, and minimal burr formation that could compromise aesthetic appearance or create safety hazards during handling and installation. Our fully automatic punching production lines utilize CNC-controlled technology that achieves hole positioning tolerances of ±0.1mm and produces clean-edged perforations that require no secondary deburring operations for most applications. Following perforation, the flat sheets undergo roll-forming to create the corrugated profile, a process requiring careful coordination between perforation pattern and corrugation geometry to avoid distortion or cracking at perforation sites. Our seven color coating production lines apply protective and decorative finishes including polyester, high-durability polyester, and PVDF coatings in thicknesses ranging from 18-35 microns, providing corrosion protection, UV resistance, and color stability exceeding 30 years under normal environmental exposure. Material selection draws from our established supplier network including premium brands such as Baosteel, Guangzhou, and Xinyu for steel products, Alucosuper, YATAI, and LIDAO for aluminum alloys, and Chinalco for copper materials when specified. All incoming raw materials undergo comprehensive testing including thickness verification, coating weight measurement, tensile strength evaluation, and chemical composition analysis to ensure compliance with international standards including ASTM, DIN, JIS, BS, and GB/T specifications.

Comprehensive Quality Control and Testing Protocols

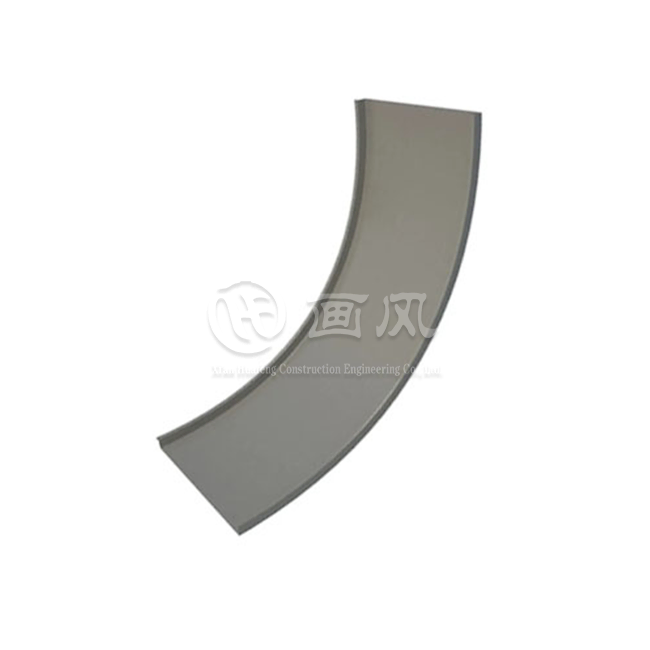

Quality assurance for perforated corrugated roofing sheets encompasses multiple inspection stages from raw material receipt through final product packaging. Our incoming material inspection process includes more than a dozen verification steps covering product appearance, dimensional accuracy, salt spray resistance, coating adhesion, hardness, impact resistance, film thickness, acid resistance, weather resistance, and color consistency. These rigorous incoming checks prevent defective materials from entering production, ensuring that every perforated Metal Corrugated Roofing Panel begins with premium quality substrate material. During production, real-time quality monitoring systems track perforation accuracy, corrugation profile dimensions, coating application uniformity, and surface finish quality, with automated rejection of any products falling outside specified tolerances. Finished product inspection procedures verify dimensional accuracy including overall length and width measurements, corrugation wave height and spacing, perforation hole diameter and pattern alignment, panel flatness within acceptable tolerances, and curvature consistency for panels intended for curved roof applications. Mechanical property testing confirms that the forming processes have not compromised material strength, ductility, or coating integrity through bend tests, tensile evaluations, and coating adhesion verification. For projects requiring specific acoustic or ventilation performance levels, we conduct laboratory testing to measure actual Noise Reduction Coefficients, sound transmission loss values, and airflow resistance characteristics, providing documented performance data that validates design assumptions and contractual requirements.

Our three manufacturing facilities, including our 200,000 square meter raw material production plant in Anhui and processing plants in Hangzhou and Xi'an, collectively house more than 40 specialized machines including shearing equipment, press brakes, bending machines, and roll-forming systems. This distributed manufacturing capacity provides redundancy ensuring continuous production capability and allows optimization of logistics by producing panels close to project locations, reducing transportation costs and delivery times. Our monthly supply capacity exceeds 1000 tons of finished corrugated roofing sheets, with the flexibility to accommodate both large-scale commercial projects and smaller specialized applications. Standard delivery timeframes range from 15-20 days from order confirmation, with expedited production available for urgent project requirements.

Installation Best Practices and Technical Support

Successful implementation of perforated Metal Corrugated Roofing Panel systems requires proper installation techniques that preserve the acoustic and ventilation performance characteristics while ensuring weather-tight integrity and structural adequacy. Our comprehensive installation support begins with pre-construction planning including site layout confirmation, material staging area identification, and construction sequencing coordination with other building trades. Installation technicians receive detailed shop drawings showing panel layout, fastener locations, flashing details, and interface conditions with adjacent roof components. For complex projects, our technical staff conducts on-site guidance visits, arriving at least one day prior to installation commencement to verify substrate preparation, review safety protocols, and confirm availability of all required tools including edge-locking machines, fastening equipment, and cutting tools. The installation process for perforated corrugated roofing sheets follows similar procedures to standard metal roofing with additional considerations for maintaining perforation pattern alignment and preventing damage to the acoustic backing materials during handling. Panels should be installed progressing from eave to ridge with appropriate end and side laps as specified in project documents, typically 150-200mm for side laps and 200-300mm for end laps depending on roof slope and local building code requirements. Fastener selection and spacing must account for the reduced effective panel width created by perforations, potentially requiring closer fastener spacing or larger diameter fasteners compared to solid panels to achieve equivalent wind uplift resistance. We recommend using neoprene or EPDM washered fasteners that provide weather sealing at penetration points while allowing slight thermal movement of the panels.

Long-Term Performance and Maintenance Requirements

Perforated Metal Corrugated Roofing Panel systems require minimal ongoing maintenance when properly specified and installed, though periodic inspections help ensure continued performance throughout the expected 30-year service life. Recommended maintenance protocols include annual visual inspections to identify any coating damage, fastener back-out, panel distortion, or debris accumulation in perforation holes that could impair ventilation or acoustic function. Any identified coating damage should be promptly repaired using compatible touch-up paint to prevent corrosion initiation at exposed substrate areas. Fastener tightness should be verified and any loose fasteners re-tightened to manufacturer specifications, maintaining proper compression of sealing washers. For applications where acoustic backing materials are exposed to interior moisture from humidity or condensation, periodic inspection of backing material condition helps identify potential degradation before performance impacts become significant. Fiberglass and mineral wool materials generally resist moisture-related degradation, though prolonged saturation can reduce acoustic effectiveness and potentially lead to compression or sagging that creates air gaps reducing system performance. Modern encapsulated backing materials with vapor-barrier facings largely eliminate these concerns while maintaining superior acoustic performance. Our technical support team provides customized maintenance guidance based on specific project conditions, environmental exposure, and performance requirements, helping building owners maximize the return on their investment in perforated Metal Corrugated Roofing Panel systems.

Project Success Stories and Application Examples

Xi'an Huafeng Construction Engineering Co., Ltd. has successfully implemented Metal Corrugated Roofing Panel solutions across diverse project types demonstrating our technical capabilities and commitment to client satisfaction. Our portfolio includes high-profile installations such as the Xiongan Station Commercial Body featuring aluminum-magnesium-manganese metal roofing, the Xi'an International Convention and Exhibition Center Metal Roof Project, and the Metal Roof Project at Xi'an Station East Auxiliary Building. These demanding applications required coordination with multiple stakeholders, adherence to stringent quality requirements, and delivery of complex roof geometries within compressed construction schedules. Additional notable projects include the South Hall 2-2 of Jinghe New City International Culture and Art Center, Liyuanping Highway Station Metal Roof Project, and various educational facility installations including the Weihua Cadre College Teaching Building and Office Building featuring aluminum-magnesium-manganese metal roof wall systems. Each project benefited from our comprehensive one-stop solution approach encompassing initial design consultation, detailed engineering development, precision manufacturing, quality-controlled production, and expert installation support or guidance. Our design team's capabilities in structural 3D modeling, load analysis, drainage system simulation, and material specification advisory ensure that every project receives optimized solutions addressing the specific performance requirements, budget constraints, and aesthetic objectives. The combination of our three state-of-the-art factories, seven production lines, and more than 40 advanced machines enables us to deliver consistent quality across projects of all scales, from small specialized applications to large commercial and institutional developments requiring hundreds of tons of roofing materials.

Conclusion

Perforated Metal Corrugated Roofing Panel technology represents an advanced building envelope solution that simultaneously addresses acoustic control and passive ventilation requirements while maintaining the structural performance, durability, and aesthetic qualities expected from premium metal roofing systems, making these specialized corrugated roofing sheets particularly valuable for industrial, commercial, and institutional applications where environmental quality directly impacts operational efficiency and occupant comfort.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

As a leading China Metal Corrugated Roofing Panel manufacturer, China Metal Corrugated Roofing Panel supplier, and China Metal Corrugated Roofing Panel factory, Xi'an Huafeng Construction Engineering Co., Ltd. delivers exceptional value through our integrated capabilities spanning design optimization, precision manufacturing, and comprehensive installation support. Established in 2018 and recognized as a high-tech enterprise with first-level qualification for building curtain walls and third-level qualification for building steel structures, our company brings proven expertise and quality commitment to every project. We offer competitive Metal Corrugated Roofing Panel price points supported by flexible minimum order quantities of 500㎡, customized solutions for color, pattern, and design specifications, and reliable 15-20 day delivery schedules. Our High Quality Metal Corrugated Roofing Panel products feature premium materials sourced from industry-leading suppliers, advanced surface treatments including PE, HDP, and PVDF coatings, and comprehensive quality certifications including ISO9001, ISO14001, CE, and SGS standards. For China Metal Corrugated Roofing Panel wholesale inquiries or to discuss Metal Corrugated Roofing Panel for sale opportunities for your upcoming projects, contact our experienced team at huafeng@hfmetalroof.com to discover how our one-stop service approach can deliver superior results for your building envelope requirements.

References

1. Smith, R.J. and Johnson, M.K. "Acoustic Performance of Perforated Metal Building Panels in Industrial Applications," Journal of Architectural Engineering, American Society of Civil Engineers.

2. Chen, W. and Liu, X. "Natural Ventilation Strategies for Metal Roof Systems in Commercial Buildings," Building and Environment Journal, Elsevier.

3. Anderson, P.L. "Corrugated Metal Panel Systems: Design, Performance and Installation Standards," Metal Construction Association Technical Guidelines.

4. Williams, T.R. and Brown, S.D. "Sound Absorption Characteristics of Perforated Metal Panels with Fibrous Backing Materials," Applied Acoustics International Journal.

5. Zhang, Y. and Wang, H. "Thermal Performance and Energy Efficiency of Ventilated Metal Roofing in Hot Climate Zones," Energy and Buildings Research Institute Publications.