Choosing the wrong wall panel system can cost your project thousands in maintenance, compromise structural integrity, and diminish aesthetic appeal over time. When selecting between Inside Lock Metal Wall Panels and composite panels for your commercial or industrial building, understanding the fundamental differences in performance, durability, and long-term value becomes critical. This comprehensive buyer's guide examines both systems across multiple dimensions, helping you make an informed decision that aligns with your project requirements, budget constraints, and performance expectations for the next three decades.

Understanding Inside Lock Metal Wall Panels Technology

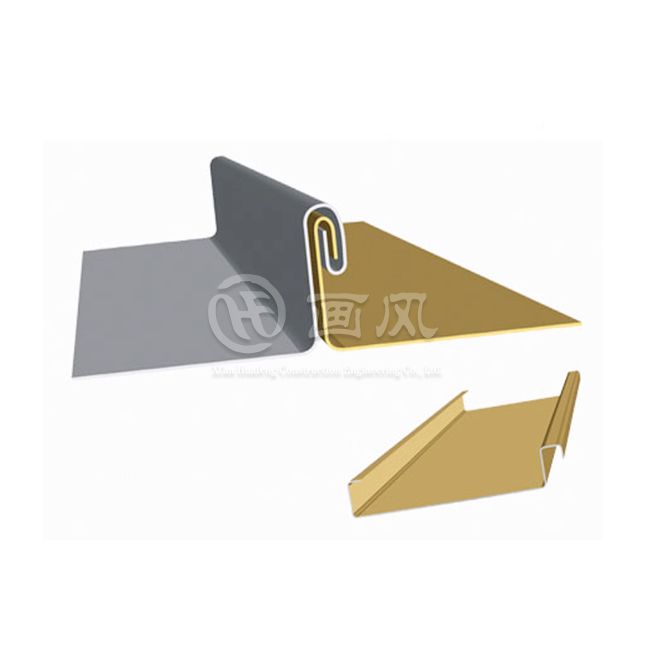

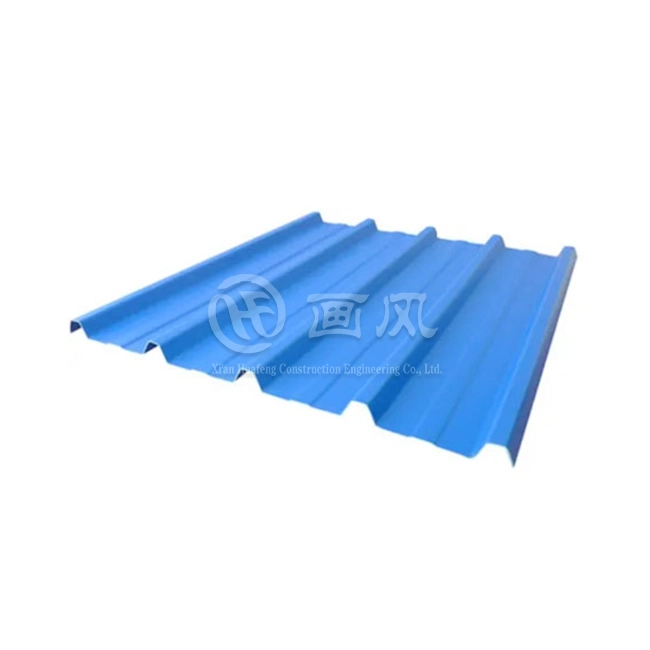

Inside Lock Metal Wall Panels represent an advanced architectural cladding solution that utilizes a concealed fastening mechanism to create seamless, modern building exteriors. Unlike traditional exposed fastener systems, the Inside Lock Metal Wall Panels feature an innovative interlocking design where adjacent panels connect through hidden clips and channels, eliminating visible screws or rivets from the facade. This technology relies on precision-engineered aluminum alloy or galvanized steel base materials, typically ranging from 0.6mm to 1.5mm in thickness, with surface treatments including PVDF coating, powder coating, or anodizing processes that provide exceptional weather resistance. The fundamental advantage of Inside Lock Metal Wall Panels lies in their installation methodology. Each panel features specially designed edges that lock into adjacent panels while being secured to the building substrate through concealed mounting systems. This approach not only enhances visual aesthetics by creating clean, uninterrupted surfaces but also improves weather-tightness by reducing potential water infiltration points. The panels typically come in widths ranging from 300mm to 600mm, with customizable lengths up to 12 meters, allowing for efficient coverage of large building facades with minimal joints. Manufacturing facilities equipped with roll-forming systems and advanced machinery ensure consistent quality across thousands of square meters of production.

-

Material Composition and Performance Characteristics

Inside Lock Metal Wall Panels are manufactured using high-grade aluminum alloys such as AA3003, AA3004, or AA5005, as well as galvanized steel sheets meeting SGCC standards. These base materials undergo rigorous quality control processes, with manufacturers sourcing from established suppliers like Alucosuper, YATAI, and LIDAO for aluminum, or BAOSTEEL and GUANZHOU for steel products. The metal substrate provides inherent advantages including Class A fire resistance according to GB8624 standards, making them suitable for high-rise construction and public buildings where fire safety regulations are stringent. The surface treatment options significantly impact the panel's longevity and appearance. PVDF coating systems offer superior UV resistance and color retention, maintaining aesthetic quality for decades even under harsh environmental conditions. These fluorocarbon coatings typically carry warranties of 30 years or more, reflecting their proven durability in real-world applications. Powder coating alternatives provide environmentally friendly finishes with diverse color options, while anodizing treatments create distinctive metallic textures with excellent wear resistance. Each surface treatment undergoes extensive testing for salt spray resistance, adhesion strength, hardness, impact resistance, film thickness consistency, acid resistance, weather resistance, and color difference measurements to ensure compliance with international standards including ISO9001, ISO14000, and SGS guidelines.

-

Installation Advantages and Project Applications

The concealed fastening system of Inside Lock Metal Wall Panels delivers multiple installation benefits that translate into cost savings and superior performance. Installation teams can achieve faster completion times compared to traditional systems because the interlocking mechanism simplifies alignment and reduces the number of individual fastening points. The hidden clip system also accommodates thermal expansion and contraction of metal panels without compromising structural integrity or creating visible distortions. This feature proves particularly valuable in climates with significant temperature variations throughout the year. Inside Lock Metal Wall Panels find applications across diverse building types, from office towers and convention centers to transportation hubs and cultural institutions. Their lightweight design, typically weighing significantly less than masonry or concrete alternatives, makes them ideal for renovation projects where existing structures have limited load-bearing capacity. The panels can be installed directly over old facades, reducing demolition costs and construction timelines. For new construction, the system accommodates complex geometries including curved surfaces and special-shaped architectural features through custom fabrication capabilities. Notable projects utilizing this technology include major transportation facilities, international exhibition centers, and cultural landmarks, demonstrating the system's versatility and aesthetic appeal.

Composite Panel Systems: Construction and Characteristics

Composite panels, often referred to as sandwich panels or insulated metal panels, consist of multiple layers bonded together to create a single building component. The typical construction includes outer metal skins, usually aluminum or steel, separated by an insulating core material such as polyurethane foam, mineral wool, or polystyrene. This multi-layer structure aims to provide both weather protection and thermal insulation within a single product, potentially simplifying building envelope design. However, the complexity of composite construction introduces considerations regarding long-term durability, fire performance, and environmental impact that buyers must carefully evaluate. The bonding between layers in composite panels represents a critical performance factor. Adhesive systems must maintain integrity across temperature extremes, moisture exposure, and mechanical stresses throughout the panel's service life. Delamination, where layers separate due to adhesive failure, remains a common concern with lower-quality composite products. Additionally, the core materials vary significantly in their fire resistance properties, with some foam-based cores presenting fire safety challenges that have led to regulatory restrictions in certain jurisdictions. Understanding these material characteristics becomes essential when comparing composite panels against metal wall panel alternatives.

-

Performance Comparison: Durability and Longevity

When evaluating Inside Lock Metal Wall Panels against composite alternatives, durability emerges as a decisive factor for long-term value. Inside Lock Metal Wall Panels constructed from aluminum alloys or galvanized steel with premium surface treatments demonstrate exceptional resistance to corrosion, UV degradation, and physical impacts. The monolithic metal construction eliminates concerns about delamination or core degradation that can affect composite panels over time. Field performance data from installations spanning multiple decades confirms that properly installed metal wall panels with PVDF coatings maintain their structural integrity and aesthetic appearance with minimal maintenance requirements. Composite panels face unique durability challenges related to their multi-layer construction. The organic core materials can absorb moisture if panel edges or penetrations are improperly sealed, leading to reduced thermal performance and potential mold growth. The metal skins may experience localized corrosion at cut edges or fastener penetrations if protective coatings are compromised during installation. Furthermore, the thermal expansion rates of different composite panel components may differ, creating internal stresses that can accelerate deterioration. These factors often result in shorter effective service lives compared to Inside Lock Metal Wall Panels, particularly in harsh environmental conditions involving high humidity, salt exposure, or extreme temperature cycles. The warranty coverage offered by manufacturers provides insight into expected product longevity. Inside Lock Metal Wall Panels from established suppliers typically carry 30-year warranties covering both material performance and finish quality, reflecting confidence in the product's durability. Composite panel warranties often feature more limited coverage periods and may exclude certain failure modes related to core materials or adhesive bonds. Building owners should carefully review warranty terms and consider life-cycle cost implications when comparing initial material costs against long-term maintenance and replacement expenses.

-

Fire Safety and Building Code Compliance

Fire performance represents a critical distinction between Inside Lock Metal Wall Panels and composite panels, particularly for high-rise construction and public buildings. Inside Lock Metal Wall Panels manufactured from aluminum or steel naturally qualify as Class A non-combustible materials, meeting the most stringent fire safety requirements without additional treatments. The metal panels will not contribute fuel to fires, produce toxic smoke, or experience rapid flame spread across building facades. This inherent fire resistance simplifies compliance with building codes and may reduce insurance premiums for commercial properties. Composite panels present more complex fire safety considerations depending on their core materials. Mineral wool cores offer excellent fire resistance, but panels with polyurethane, polystyrene, or polyisocyanurate foam cores require careful evaluation. Some foam-based composite panels have been implicated in rapid fire spread during building fires, leading to tragic outcomes and subsequent regulatory changes in multiple countries. Even when composite panels meet local fire codes at the time of installation, evolving safety standards may render existing facades non-compliant, potentially requiring expensive remediation work. Building owners and developers must thoroughly investigate the fire classification of any composite panel product and verify compliance with current and anticipated future regulations. Testing protocols for fire performance include standardized assessments of flame spread, smoke production, and contribution to fire severity. Inside Lock Metal Wall Panels consistently achieve superior ratings across these parameters. The absence of combustible components eliminates concerns about toxic gas generation during fires, protecting both building occupants and firefighting personnel. For projects where fire safety is paramount, such as hospitals, schools, airports, and residential towers, the proven fire resistance of Inside Lock Metal Wall Panels provides essential peace of mind and regulatory compliance assurance.

Cost Analysis: Initial Investment and Life-Cycle Economics

Initial material and installation costs often dominate procurement decisions, but sophisticated buyers recognize that life-cycle economics provide a more accurate picture of total project value. Inside Lock Metal Wall Panels typically command higher upfront costs compared to basic composite panels, reflecting the precision manufacturing, premium materials, and advanced surface treatments involved. However, this initial investment must be weighed against factors including installation efficiency, maintenance requirements, expected service life, and eventual replacement or renovation costs. Installation labor costs favor Inside Lock Metal Wall Panels due to their concealed fastening system and lightweight construction. Experienced installation teams can achieve high daily coverage rates, reducing overall project duration and associated soft costs. The panels arrive pre-finished and cut to specification, eliminating on-site painting or additional surface preparation. In contrast, composite panels may require more complex detailing at panel joints, penetrations, and building corners to ensure proper sealing and weather protection. Any installation errors that compromise the panel edges or penetrate the core material can lead to performance issues requiring remediation. Maintenance costs diverge significantly over the building's service life. Inside Lock Metal Wall Panels with PVDF coatings require only periodic washing to maintain their appearance, with no repainting or refinishing needed for decades. The concealed fastening system eliminates issues with exposed fastener corrosion or sealant degradation around screw heads. Composite panels may require more frequent inspection and maintenance of panel joints, sealants, and any areas where moisture could infiltrate the core. Panel replacement due to damage or deterioration involves more extensive work, as composite panels cannot be easily removed individually without affecting adjacent panels. When calculating total cost of ownership over a 30-50 year building lifespan, Inside Lock Metal Wall Panels frequently demonstrate superior value despite higher initial investment.

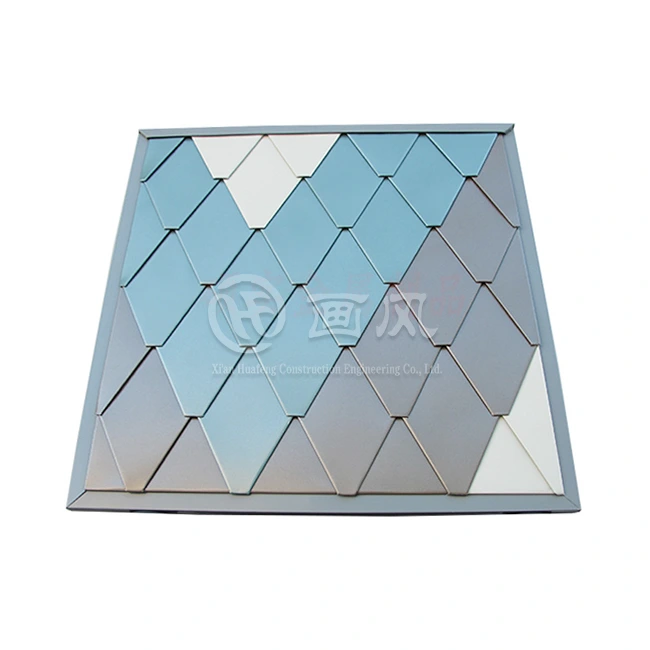

Aesthetic Flexibility and Architectural Expression

Modern architecture demands building envelope systems that support creative design visions while delivering reliable performance. Inside Lock Metal Wall Panels excel in providing aesthetic flexibility through their concealed fastening approach, which creates seamless facades with clean geometric lines. The hidden joint system allows architects to emphasize horizontal or vertical panel orientations, create bold color contrasts, or incorporate subtle texture variations without visual interruption from fasteners. Panel widths ranging from 300mm to 600mm enable designers to establish distinctive rhythms and proportions that define building character. Surface finish options expand the aesthetic palette available for Inside Lock Metal Wall Panels. PVDF coating technology delivers vibrant, long-lasting colors including metallic effects, while powder coating systems offer matte, satin, or glossy finishes in virtually unlimited color specifications. Anodized finishes provide sophisticated metallic appearances with depth and luster that complement contemporary architectural styles. The ability to combine different finishes, colors, and panel widths within a single facade creates opportunities for dynamic visual compositions that respond to program requirements, solar orientation, or urban context. Composite panels offer their own aesthetic characteristics, though typically with less refinement in surface finish quality compared to premium metal wall panels. The embossed textures sometimes applied to composite panel faces aim to simulate natural materials but may appear artificial compared to authentic metal finishes. The visible joint details required for composite panel systems can interrupt the facade composition, particularly in installations requiring dense patterns of fasteners for structural or wind load requirements. For projects where architectural distinction and enduring visual quality are priorities, Inside Lock Metal Wall Panels provide superior options for creative expression.

Environmental Sustainability and Green Building Credentials

Sustainability considerations increasingly influence material selection decisions as building owners seek to minimize environmental impacts and achieve green building certifications. Inside Lock Metal Wall Panels offer significant sustainability advantages beginning with their material composition. Aluminum and steel are among the most recycled materials globally, with well-established collection and processing infrastructure. At the end of the building's service life, Inside Lock Metal Wall Panels can be completely recycled without quality degradation, supporting circular economy principles. The recycled content in new panel production often exceeds 50%, reducing embodied carbon compared to virgin material production. The manufacturing process for Inside Lock Metal Wall Panels at facilities like Xi'an Huafeng Construction Engineering Co., Ltd. incorporates environmental management systems certified to ISO14000 standards. Energy-efficient production equipment, waste minimization protocols, and water recycling systems reduce the environmental footprint of panel fabrication. The lightweight nature of metal panels also decreases transportation energy consumption during project delivery, particularly relevant for large-scale installations requiring thousands of square meters of cladding material. Composite panels present more complex sustainability challenges depending on their core materials. Foam-based cores derived from petrochemicals carry higher embodied energy and may release volatile organic compounds during manufacturing. Recycling composite panels proves difficult due to the bonded multi-layer construction, with many products ending up in landfills at building demolition. Mineral wool core composites offer better recyclability but represent only a portion of the composite panel market. For projects pursuing LEED certification or other green building standards, the recyclability, recycled content, and environmental product declarations associated with Inside Lock Metal Wall Panels provide valuable sustainability credits.

Technical Specifications and Quality Assurance

Procurement decisions require careful evaluation of technical specifications to ensure products meet project performance requirements. Inside Lock Metal Wall Panels from reputable manufacturers like Xi'an Huafeng Construction Engineering Co., Ltd. provide detailed specifications covering material composition, dimensional tolerances, surface finish properties, structural capacity, and thermal performance. Base materials conform to international standards including ASTM, DIN, JIS, BS, and GB/T specifications, with third-party certification verifying compliance. The company's quality management system ensures consistent production across 7 coating lines and 10 cutting lines, with capacity exceeding 1000 tons monthly. Quality assurance protocols for Inside Lock Metal Wall Panels encompass incoming raw material inspection, in-process production monitoring, and finished product verification. Material suppliers provide certification and test reports confirming alloy composition, coating thickness, and mechanical properties. Production facilities conduct comprehensive testing including appearance inspection, dimensional accuracy verification, salt spray testing, adhesion strength measurement, hardness evaluation, impact resistance, film thickness confirmation, acid resistance, weathering resistance, and color difference assessment. These rigorous quality controls ensure every panel meets specification requirements before shipment to project sites.

Composite panel specifications require equally careful scrutiny, particularly regarding core material properties, adhesive bond strength, and fire performance characteristics. Buyers should request complete technical documentation including fire test reports, thermal performance data, structural load ratings, and environmental exposure testing results. The quality of composite panels varies significantly across manufacturers, with premium products incorporating superior core materials and advanced bonding systems that justify their higher costs. For critical applications, specifying composite panels with mineral wool cores and proven fire performance provides greater assurance, though at price points comparable to Inside Lock Metal Wall Panels.

Conclusion

Selecting between Inside Lock Metal Wall Panels and composite panels demands careful consideration of performance, durability, fire safety, life-cycle costs, aesthetics, and sustainability factors. Inside Lock Metal Wall Panels deliver superior longevity, fire resistance, aesthetic refinement, and environmental responsibility that justify their position as the premium choice for discerning building owners and architects seeking exceptional value over the building's entire service life.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in 2018 in Shaanxi Province, stands as a leading China Inside Lock Metal Wall Panels manufacturer and China Inside Lock Metal Wall Panels supplier, delivering High Quality Inside Lock Metal Wall Panels for sale at competitive Inside Lock Metal Wall Panels price points. As a trusted China Inside Lock Metal Wall Panels factory and China Inside Lock Metal Wall Panels wholesale provider, we combine advanced manufacturing capabilities—including 3 factories, 7 production lines, and more than 40 specialized machines—with over 20 patented technologies and comprehensive certifications from CE, ISO9001, ISO14000, and SGS. Our one-stop service spans custom design optimization, precision manufacturing using premium brands like BAOSTEEL and Alucosuper, rigorous quality testing, and professional installation support. With successful projects including Xiongan Station, Xi'an International Convention Center, and Inner Mongolia Tongliao Art Museum, we deliver tailored solutions for industrial, commercial, and public buildings worldwide. Contact us today at huafeng@hfmetalroof.com for customized Inside Lock Metal Wall Panels solutions that elevate your project's performance and value.

References

1. Smith, J. & Thompson, R. "Comparative Analysis of Metal Wall Panel Systems in Commercial Construction." Journal of Architectural Engineering Technology, 2023.

2. Anderson, M. "Fire Safety Performance of Contemporary Building Facade Systems." International Building Safety Council, 2024.

3. Chen, L. & Wang, Y. "Life Cycle Assessment of Metal and Composite Cladding Systems." Sustainable Construction Materials Review, 2023.

4. Williams, D. "Durability and Maintenance Considerations for Modern Building Envelopes." Building Science Institute Technical Report, 2024.