Picture this: You've just finished an expensive renovation, but after the first heavy rainstorm, you notice water pooling around your foundation, soil erosion damaging your landscaping, and stains appearing on your exterior walls. This nightmare scenario happens to thousands of homeowners who overlook one of their home's most critical protection systems. Choosing the best gutters for your home isn't just about aesthetics—it's about safeguarding your investment from costly water damage, foundation issues, and structural deterioration. Quality Roof Gutter System Parts play a pivotal role in creating an efficient drainage solution that directs water away from vulnerable areas, protecting your property for decades to come.

Understanding Essential Roof Gutter System Parts and Materials

When selecting gutters for your home, understanding the various Roof Gutter System Parts and materials available is fundamental to making an informed decision. The gutter system comprises several integrated components working together seamlessly, including gutter sections, downspouts, end caps, corner joints, hanging brackets, and connectors. Each component must be manufactured from appropriate materials to ensure long-term performance and durability. Modern Roof Gutter System Parts are engineered to withstand environmental stresses while maintaining optimal water flow efficiency throughout their service life.

-

Aluminum Alloy: The Premium Choice for Modern Homes

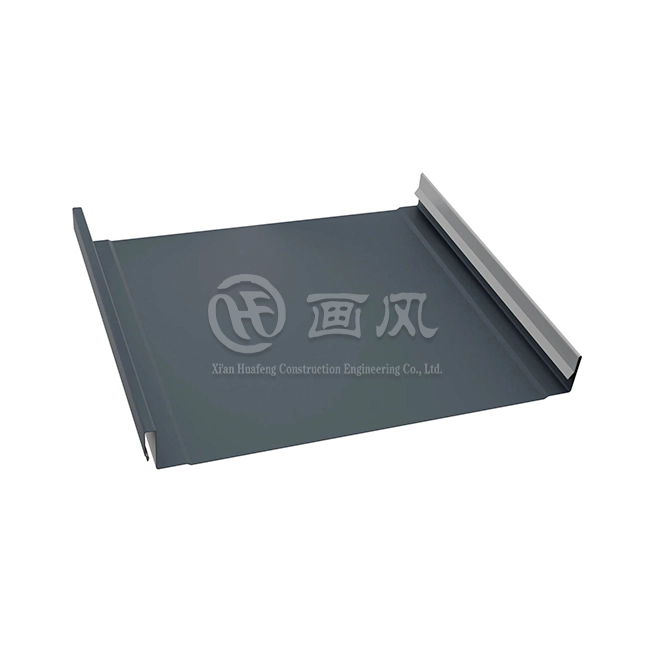

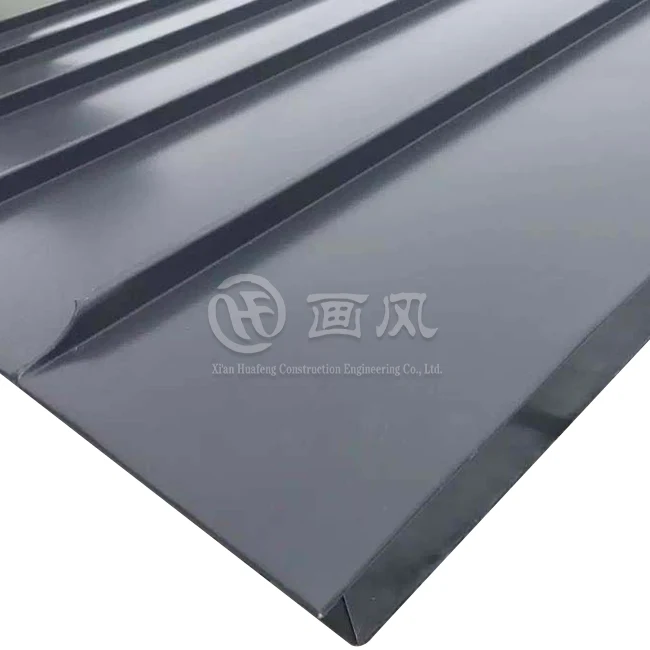

Among all available materials, AA3003 aluminum alloy stands out as the premier choice for residential and commercial gutter applications. This specific aluminum grade offers exceptional corrosion resistance, lightweight handling characteristics, and remarkable durability under diverse weather conditions. Unlike ordinary aluminum, AA3003 contains manganese, which enhances its strength and formability without compromising its rust-resistant properties. Professional manufacturers like Xi'an Huafeng Construction Engineering Co., Ltd. utilize this premium material for their Roof Gutter System Parts, ensuring products that maintain structural integrity even in harsh climates with heavy rainfall, snow loads, or extreme temperature fluctuations. The manufacturing process for quality aluminum Roof Gutter System Parts involves precision roll-forming techniques that create seamless profiles with consistent wall thickness. Typically ranging from 0.7mm to 1.0mm for gutter sections and 0.8mm to 1.0mm for downspouts, these thickness specifications provide the perfect balance between strength and workability. After the forming process, components undergo anodizing treatment followed by electrostatic powder coating, creating a durable surface finish that resists fading, chalking, and environmental degradation. This multi-layer protection system ensures that your gutter installation maintains its appearance and performance throughout its projected 30-year service life.

-

Comprehensive Component Selection for Complete Systems

A complete gutter system requires careful selection of all Roof Gutter System Parts to ensure compatibility and optimal performance. The main gutter sections, available in K-style configurations ranging from 5 inches to 8 inches in width, must be paired with appropriately sized downspouts to handle the calculated water volume from your roof area. Square downspouts come in dimensions of 80x50mm, 80x60mm, 100x80mm, and 120x90mm, while circular options are available in 50mm, 75mm, and 100mm diameters. Professional suppliers provide custom sizing options to accommodate unique architectural requirements or regional rainfall intensities that exceed standard specifications. Supporting components such as mounting brackets, outlet tubes, inside and outside corner pieces, and expansion joints must all be manufactured from compatible materials with matching finish specifications. Quality Roof Gutter System Parts manufacturers maintain strict dimensional tolerances across their entire product range, ensuring that components from different production batches fit together precisely without gaps or misalignments. This attention to manufacturing precision eliminates common installation problems like improper pitch, inadequate sealing, or structural weak points that could lead to premature failure. When sourcing components, verify that all Roof Gutter System Parts comply with international standards including ASTM, DIN, JIS, BS, and GB/T specifications for material composition and performance characteristics.

Climate Considerations and Roof Gutter System Parts Performance

Your geographical location and local climate patterns should significantly influence your selection of Roof Gutter System Parts. Regions experiencing heavy annual rainfall require gutter systems with larger capacity and more frequent downspout placements to prevent overflow during intense storm events. Areas with significant snowfall need components robust enough to support the weight of accumulated ice and snow without sagging or separating from mounting points. Coastal environments demand materials with superior corrosion resistance to withstand salt spray exposure, making premium aluminum alloy Roof Gutter System Parts an ideal choice for these challenging conditions.

-

Sizing Requirements Based on Rainfall Intensity

Proper sizing of Roof Gutter System Parts depends on calculating the maximum water volume your roof will shed during peak rainfall events. A general rule suggests that for every 600 square feet of roof area, you need one square inch of downspout capacity. However, regions with high rainfall intensity may require oversized components to prevent overflow. The K-style gutter profile, with its flat back and decorative ogee front, offers approximately 50% more water-carrying capacity than traditional half-round designs of the same width. This makes K-style Roof Gutter System Parts particularly suitable for areas prone to sudden, intense downpours or homes with large roof catchment areas. Professional gutter designers consider multiple factors when specifying Roof Gutter System Parts dimensions, including roof pitch, surface area, local rainfall data, and the number of roof valleys that concentrate water flow. Steeper roofs accelerate water velocity, requiring larger gutters to capture fast-moving runoff effectively. Manufacturers like Xi'an Huafeng Construction Engineering Co., Ltd. provide technical consultation services to help customers select appropriately sized Roof Gutter System Parts based on their specific project parameters. Their design teams utilize advanced simulation software to model drainage patterns and verify that proposed systems will handle calculated water volumes with adequate safety margins.

-

Temperature Extremes and Material Expansion

Temperature fluctuations cause all materials to expand and contract, a phenomenon that must be accommodated in gutter system design through proper installation techniques and component selection. Quality Roof Gutter System Parts manufactured from AA3003 aluminum alloy exhibit predictable thermal expansion characteristics, allowing experienced installers to incorporate appropriate expansion joints at recommended intervals. In climates with extreme seasonal temperature variations, longer gutter runs require additional expansion provisions to prevent buckling during summer heat or cracking during winter cold. The anodized and powder-coated surface treatment applied to premium Roof Gutter System Parts provides additional protection against thermal stress by creating a flexible finish that moves with the base material. This advanced coating system prevents the surface degradation and paint cracking commonly seen on inferior products after several heating and cooling cycles. When selecting components for installation in harsh climate zones, verify that your supplier provides comprehensive technical data on thermal performance and includes installation guidelines specific to your temperature range. Reputable manufacturers back their Roof Gutter System Parts with extended warranties demonstrating confidence in long-term performance under specified environmental conditions.

Installation Excellence and Long-Term Maintenance

Even the highest quality Roof Gutter System Parts will underperform if improperly installed or inadequately maintained. Professional installation ensures that gutters are pitched correctly for optimal drainage, securely fastened to withstand wind loads, and sealed at all joints to prevent leaks. The recommended slope for gutter runs is approximately one-quarter inch drop per ten feet of length, creating sufficient gravity flow without creating visible sagging or standing water. Experienced installers verify proper pitch throughout the system using precision leveling equipment before final securing of mounting brackets.

-

Professional Installation Standards and Procedures

Working with qualified installers who understand the specific requirements of premium Roof Gutter System Parts guarantees optimal system performance from day one. Professional contractors begin by thoroughly inspecting the fascia board condition and making any necessary repairs before mounting new components. They calculate precise measurements for all gutter sections, accounting for thermal expansion requirements and positioning downspouts at locations that direct water away from foundation walls, landscaping, and walkways. Quality installations incorporate hidden mounting hardware that secures Roof Gutter System Parts firmly to structural framing members rather than relying solely on fascia board strength. Xi'an Huafeng Construction Engineering Co., Ltd. provides comprehensive installation support for their Roof Gutter System Parts, including detailed technical drawings, on-site guidance from experienced technicians, and quality assurance inspections upon project completion. Their installation teams arrive with specialized tools including edge-locking machines for seamless connections, calibrated pitch gauges, and weather-resistant sealants formulated specifically for aluminum components. Following installation, they conduct thorough water testing by simulating rainfall conditions to verify zero leakage at all connection points and confirm that downspouts discharge water sufficiently distant from the building perimeter.

-

Maintenance Protocols for Extended Service Life

Regular maintenance extends the functional life of Roof Gutter System Parts well beyond their warranty period while preventing the water damage that occurs when systems become clogged or damaged. Homeowners should inspect gutters at least twice annually, typically in late spring after tree pollination and in late fall after leaf drop. During inspections, remove accumulated debris from gutter channels and downspout inlets, check for proper drainage pitch, examine mounting brackets for secure attachment, and look for any signs of corrosion or damage requiring professional attention. Premium Roof Gutter System Parts manufactured from AA3003 aluminum alloy require minimal maintenance beyond periodic cleaning due to their corrosion-resistant properties and durable surface finishes. Unlike steel components that rust or vinyl parts that become brittle and crack, properly installed aluminum gutters maintain their structural integrity and appearance with simple routine care. For optimal longevity, consider installing gutter protection systems that prevent debris accumulation while allowing water to flow freely into the channels. Quality manufacturers offer compatible guard systems designed specifically for their Roof Gutter System Parts profiles, ensuring perfect fit and uncompromised water handling capacity.

Aesthetic Integration with Architectural Design

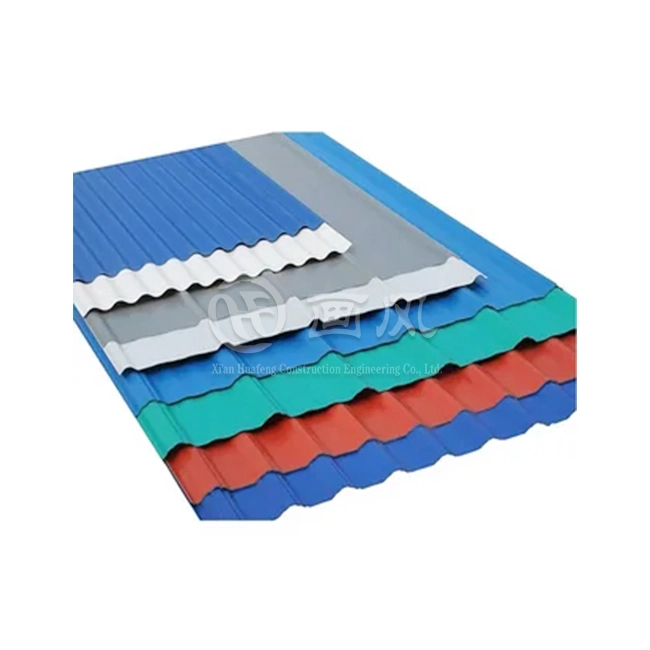

Modern Roof Gutter System Parts serve dual purposes, providing essential water management while contributing to your home's curb appeal and architectural character. Today's manufacturers offer extensive color selections that coordinate with popular exterior finishes, allowing seamless integration with your home's design palette. Standard color options for premium aluminum Roof Gutter System Parts include white, light gray, milky white, dark gray, black, brown, and bronze, with custom color matching available for specialized architectural applications or historic restoration projects.

-

Color Selection and Visual Impact

The color of your Roof Gutter System Parts significantly influences your home's overall appearance, either blending discreetly with fascia and soffit or creating intentional visual contrast as a design element. For traditional homes, selecting gutter colors that match trim work creates a cohesive, understated look that emphasizes architectural details without drawing attention to utilitarian components. Contemporary designs may incorporate contrasting gutter colors that complement exterior cladding materials or repeat accent colors used elsewhere on the facade, creating visual continuity across the entire building envelope. Quality powder-coat finishes applied to premium Roof Gutter System Parts maintain their color integrity throughout decades of sun exposure, eliminating the fading and chalking that plague inferior products. The electrostatic application process used by reputable manufacturers ensures complete, uniform coverage of all surfaces, including hard-to-reach corners and seams where conventional paint application might leave vulnerable bare spots. When specifying Roof Gutter System Parts colors for your project, request physical samples rather than relying solely on digital representations, as actual appearance can vary depending on surface texture, lighting conditions, and surrounding materials.

-

Architectural Style Compatibility

Different architectural styles call for specific profiles and configurations of Roof Gutter System Parts to maintain period authenticity or design coherence. Victorian and Colonial Revival homes often look best with half-round gutter profiles that echo the curved forms found in other architectural elements. Mid-century modern and contemporary structures typically pair well with clean-lined K-style Roof Gutter System Parts that complement the angular geometry and horizontal emphasis characteristic of these design periods. Mediterranean and Spanish Colonial styles may incorporate decorative conductor heads and ornamental downspout straps that transform functional drainage components into attractive design features. Professional architects and designers understand how proper selection of Roof Gutter System Parts enhances rather than detracts from intended architectural expression. When planning renovations or new construction, consult with experienced professionals who can recommend component profiles, sizes, and finishes that support your overall design vision while meeting functional performance requirements. Manufacturers like Xi'an Huafeng Construction Engineering Co., Ltd. work collaboratively with design teams to develop customized Roof Gutter System Parts solutions that address both aesthetic preferences and technical specifications, ensuring that completed installations achieve the perfect balance between form and function.

Quality Assurance and Certification Standards

Reputable manufacturers of Roof Gutter System Parts maintain rigorous quality control systems throughout their production processes, from raw material inspection through final product testing and packaging. International quality standards including ISO9001 for quality management systems and ISO14000:14001 for environmental management provide frameworks ensuring consistent product quality and sustainable manufacturing practices. Products bearing these certifications have undergone thorough auditing by independent third-party organizations verifying compliance with specified requirements.

-

Material Testing and Performance Verification

Before Roof Gutter System Parts enter production, manufacturers conduct comprehensive material testing to verify that aluminum alloy compositions meet specified grades and that all physical properties fall within acceptable ranges. Testing protocols examine tensile strength, yield strength, elongation characteristics, and hardness values, comparing results against established standards like ASTM B209 for aluminum sheet and plate. Surface coating systems undergo separate evaluation including salt spray resistance testing per ASTM B117, adhesion testing per ASTM D3359, and accelerated weathering exposure to simulate years of outdoor service in condensed timeframes. Quality-focused manufacturers like Xi'an Huafeng Construction Engineering Co., Ltd. maintain fully equipped testing laboratories staffed by certified technicians who perform ongoing quality verification throughout production. Their comprehensive testing regimen includes dimensional accuracy checks on formed profiles, coating thickness measurements using calibrated gauges, color consistency evaluation using spectrophotometric analysis, and destructive testing of sample assemblies to verify connection strength and joint integrity. This multi-layered quality assurance approach ensures that every Roof Gutter System Parts component leaving their facilities meets or exceeds published performance specifications.

-

Certifications and Compliance Documentation

When sourcing Roof Gutter System Parts for significant projects, request complete certification packages documenting material compliance, manufacturing quality systems, and product performance testing results. Reputable suppliers readily provide test reports from independent laboratories confirming that their aluminum alloy compositions meet grade specifications and that finished products achieve required performance benchmarks. SGS certification, recognized globally as a mark of quality and compliance, provides additional confidence that Roof Gutter System Parts have undergone rigorous evaluation by one of the world's most respected inspection and verification organizations. Professional contractors and architects specify certified Roof Gutter System Parts to protect their clients' interests and ensure compliance with building codes and project specifications. Insurance companies may require documentation proving that building components meet minimum quality standards as a condition of coverage. Property owners benefit from the peace of mind that comes with knowing their gutter system incorporates components that have been independently verified to perform as claimed. Always retain certification documents and warranty information in your property records for future reference during renovations, insurance claims, or property transfers.

Conclusion

Selecting appropriate gutters requires balancing performance requirements, aesthetic preferences, climate considerations, and budget constraints. Quality Roof Gutter System Parts manufactured from premium materials like AA3003 aluminum alloy offer the optimal combination of durability, low maintenance, and long-term value for protecting your property investment.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in 2018 and recognized as a high-tech enterprise in Shaanxi Province, specializes in comprehensive metal roofing and building envelope solutions. With three manufacturing facilities spanning 200,000 square meters in Anhui, Hangzhou, and Xi'an, the company operates seven color coating production lines and maintains over 40 specialized machines for producing premium Roof Gutter System Parts. Their product portfolio includes standing seam metal roofing panels, aluminum-magnesium-manganese plates, titanium-zinc plates, and complete gutter system solutions serving industrial, commercial, and public building sectors globally.

The company's integrated approach encompasses design optimization, precision manufacturing, and seamless installation services backed by ISO9001 and ISO14000:14001 certifications. Their engineering team provides structural 3D modeling, load analysis, and drainage system simulation to ensure optimal system performance. As a China Roof Gutter System Parts factory, China Roof Gutter System Parts supplier, and China Roof Gutter System Parts manufacturer offering China Roof Gutter System Parts wholesale, they deliver Roof Gutter System Parts for sale at competitive Roof Gutter System Parts prices without compromising quality standards. Every High Quality Roof Gutter System Parts component includes a 30-year warranty and complies with ASTM, DIN, JIS, BS, and GB/T international standards.

Partner with Xi'an Huafeng Construction Engineering Co., Ltd. for your next project and experience the difference that comes from working with an industry leader committed to excellence. Their experienced team provides free samples, customized solutions, and responsive technical support throughout your project lifecycle. With proven expertise delivering major installations including Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, and Inner Mongolia Tongliao Art Museum, they bring unmatched capabilities to projects of any scale. Contact their team today at huafeng@hfmetalroof.com to discuss your specific requirements and discover how their comprehensive solutions can protect your property for decades to come.

References

1. Anderson, M. & Thompson, R. (2023). Residential Gutter Systems: Design, Materials, and Installation Best Practices. Journal of Building Envelope Design.

2. Chen, L., Wang, H., & Zhang, Y. (2024). Performance Evaluation of Aluminum Alloy Building Components in Variable Climate Conditions. International Journal of Construction Materials.

3. Martinez, J. (2022). Water Management Systems for Modern Architecture: A Comprehensive Guide to Drainage Solutions. Architectural Engineering Press.

4. Peterson, K. & Davidson, S. (2023). Sustainable Building Envelope Systems: Material Selection and Life-Cycle Analysis. Green Building Research Institute.