When you're facing roof replacement decisions and staring at quotes that seem to double or even triple traditional roofing costs, the question becomes unavoidable: is investing in a Grey Standing Seam Metal Roof truly worth the substantial financial commitment? With prices ranging from thirty thousand to over fifty thousand dollars for an average residential installation, this decision demands careful consideration of both immediate costs and long-term value. The answer isn't simply yes or no, but rather depends on your specific circumstances, priorities, and understanding of what this premium roofing system actually delivers over its exceptional lifespan.

Understanding the True Value of Grey Standing Seam Metal Roof Systems

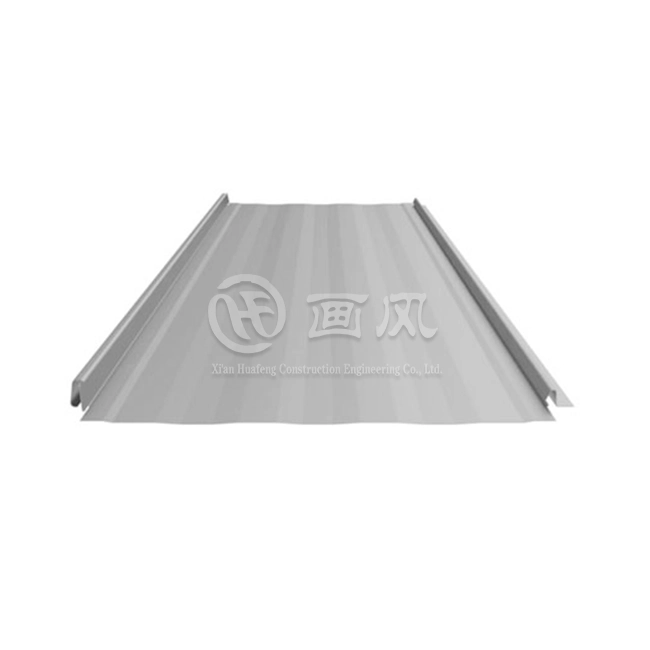

The Grey Standing Seam Metal Roof represents a significant evolution in roofing technology, combining sophisticated engineering with contemporary aesthetics. Unlike traditional roofing materials that require frequent replacement every fifteen to twenty years, this premium system offers decades of reliable protection with minimal maintenance requirements. The distinctive raised interlocking seams that give this roofing style its name aren't merely decorative elements, they serve crucial functional purposes that directly impact the roof's performance and longevity. What distinguishes Grey Standing Seam Metal Roof installations from conventional options is the hidden fastener system that protects critical connection points from weather exposure. Traditional roofing systems expose thousands of penetration points to ultraviolet radiation, moisture infiltration, and temperature fluctuations, creating countless potential failure points that gradually deteriorate over time. By concealing these fasteners beneath protective panels, standing seam systems eliminate this vulnerability entirely, resulting in superior weather resistance and dramatically extended service life that can exceed fifty years when properly installed and maintained. The grey color option offers particular advantages beyond aesthetic appeal. Grey finishes provide excellent heat reflectivity while maintaining a sophisticated, neutral appearance that complements virtually any architectural style from traditional to ultra-modern. This color selection represents the perfect balance between energy efficiency and timeless visual appeal, ensuring your investment remains attractive and functional for decades to come. The matte or gloss grey surfaces available in premium Grey Standing Seam Metal Roof products resist fading even under intense solar exposure, maintaining their original appearance far longer than painted alternatives.

-

Engineering Excellence Behind Standing Seam Technology

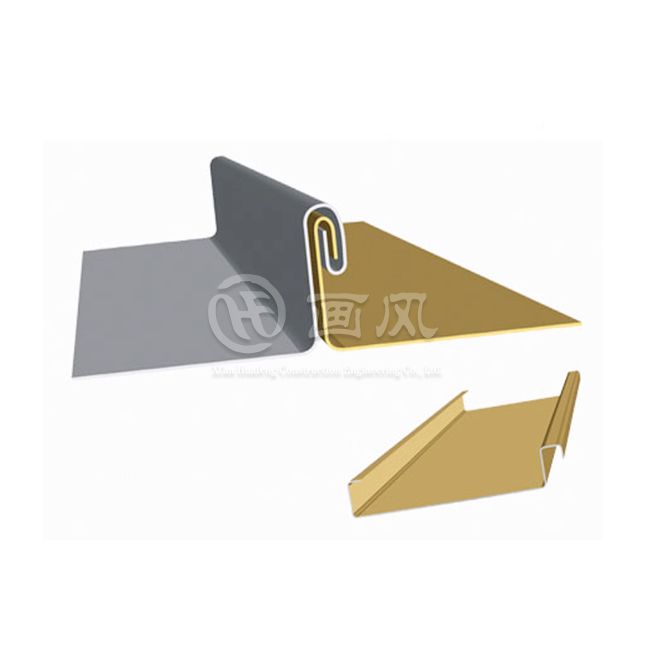

Modern Grey Standing Seam Metal Roof systems incorporate advanced engineering principles that address fundamental challenges inherent in metal roofing applications. Metal naturally expands and contracts with temperature variations, sometimes moving several inches over the length of a standard roof panel. Traditional fastening methods that rigidly secure panels can't accommodate this movement, leading to stress concentrations, fastener failure, and eventually system compromise. Standing seam technology solves this problem through specialized clip systems that allow controlled panel movement while maintaining weathertight integrity. The raised seam height, typically ranging from twenty-five to sixty-five millimeters depending on specific product specifications, creates an effective barrier against water infiltration even under extreme weather conditions. This vertical dimension ensures that water flows off the roof surface rather than pooling or penetrating through seam connections. Combined with precise panel interlocking mechanisms, this design provides exceptional protection against wind-driven rain, heavy snow loads, and other environmental challenges that regularly compromise lesser roofing systems. Premium Grey Standing Seam Metal Roof products manufactured by specialized companies like Xi'an Huafeng Construction Engineering incorporate materials meeting stringent international standards including ASTM, DIN, JIS, BS, and GB/T specifications. These quality standards ensure consistent material properties, reliable performance characteristics, and predictable service life. The typical thickness range of 0.6 to 0.8 millimeters represents optimal balance between structural strength, weight considerations, and manufacturing efficiency, providing robust protection without imposing excessive structural loads on building frameworks.

-

Surface Treatment Technologies and Performance Enhancement

The surface treatment applied to Grey Standing Seam Metal Roof panels significantly impacts both performance and longevity. PVDF (Polyvinylidene Fluoride) and PE (Polyester) coatings represent the industry's premium protective finishes, with PVDF offering superior resistance to ultraviolet degradation, chemical exposure, and color retention. These coating systems bond at molecular level with base metal substrates, creating integrated protective layers that resist chalking, fading, and environmental deterioration for thirty years or more under warranty protection. PVDF coatings specifically demonstrate remarkable durability in harsh environmental conditions, maintaining integrity through repeated thermal cycling, extreme temperature ranges, and prolonged solar exposure. This advanced coating technology explains why premium Grey Standing Seam Metal Roof installations maintain their appearance and protective capabilities decades after installation, while lesser coatings show visible degradation within just a few years. The initial investment in superior surface treatment pays substantial dividends through extended maintenance intervals, preserved aesthetic appeal, and continued weather protection throughout the system's service life.

Cost Analysis and Long-Term Financial Considerations

Understanding the true cost of Grey Standing Seam Metal Roof installation requires looking beyond initial purchase price to comprehensive lifecycle analysis. Standing seam metal roofing typically costs at least thirty thousand to fifty thousand dollars on average homes, representing two to three times the expense of conventional asphalt shingle installation. This substantial price differential creates the primary obstacle for many property owners considering premium roofing options, yet focusing solely on upfront costs ignores crucial long-term financial implications that fundamentally alter the economic equation. Traditional asphalt shingle roofing typically requires complete replacement every fifteen to twenty years, meaning most property owners face multiple roof replacement projects during their occupancy period. Each replacement involves not just material costs but also labor expenses, disposal fees, potential interior damage during installation, and inevitable disruption to daily life. When you calculate cumulative costs over a forty or fifty year period, including multiple replacements of conventional roofing, the lifetime expense often exceeds that of a single Grey Standing Seam Metal Roof installation that lasts the entire duration. Energy efficiency considerations add another dimension to financial analysis. Metal roofing systems with properly selected colors and coatings reflect substantial portions of solar radiation rather than absorbing heat and transmitting it into building interiors. This reflective property, quantified through Solar Reflectance Index measurements, can reduce cooling costs by meaningful percentages in warm climates. Over decades of operation, these accumulated energy savings contribute significantly to offsetting initial installation premiums, particularly in regions with high electricity costs or extended cooling seasons.

-

Return on Investment and Property Value Enhancement

Standing seam metal roofing increases property values, though the exact appreciation varies based on local real estate market dynamics and buyer preferences. The dramatic improvement in curb appeal created by Grey Standing Seam Metal Roof installations particularly appeals to buyers seeking contemporary aesthetics or concerned about long-term maintenance obligations. Properties with premium roofing systems often command price premiums and sell more quickly than comparable homes with conventional roofing, particularly in markets where buyers understand and appreciate quality construction. Beyond direct property value increases, Grey Standing Seam Metal Roof systems deliver value through insurance considerations and risk reduction. Many insurance providers offer premium discounts for metal roofing due to superior fire resistance, wind performance, and hail durability compared to conventional materials. These ongoing insurance savings, combined with elimination of periodic replacement costs, dramatically improve the financial profile of premium roofing investments when evaluated over appropriate timeframes.

Durability, Longevity, and Performance Under Extreme Conditions

Standing seam metal roofs last thirty to fifty years with proper installation and periodic maintenance, with premium materials like copper, stainless steel, and zinc extending well beyond fifty years of service. This exceptional longevity stems from fundamental material properties and sophisticated system design that addresses common failure modes affecting lesser roofing options. Grey Standing Seam Metal Roof installations demonstrate particular resilience in challenging environments where temperature extremes, severe weather events, and environmental exposure accelerate deterioration of conventional materials. The inherent properties of metal roofing materials provide natural resistance to numerous destructive forces. Unlike organic materials that support biological growth or gradually deteriorate through natural decomposition processes, metal panels resist rot, mold, mildew, and insect damage that plague wood-based products. The non-combustible nature of metal provides Class A fire resistance, the highest rating achievable, offering critical protection in wildfire-prone regions or urban areas where fire spread between structures presents significant risk. Wind resistance represents another critical performance advantage. Standing seam metal roofing withstands winds up to 140 mph when properly installed, far exceeding capabilities of conventional shingle systems that begin losing individual components at much lower wind speeds. This superior wind resistance proves particularly valuable in hurricane-prone coastal regions, tornado-vulnerable interior areas, and any location experiencing severe thunderstorm activity. The mechanical interlocking of Grey Standing Seam Metal Roof panels creates continuous structural connection across entire roof surfaces, distributing wind loads effectively and preventing progressive failure that compromises lesser systems.

-

Weather Resistance and Environmental Performance

Heavy precipitation presents challenges for any roofing system, but Grey Standing Seam Metal Roof installations handle water management with exceptional effectiveness. The raised seam design creates natural drainage channels that efficiently direct water off roof surfaces, while hidden fastener systems eliminate thousands of potential penetration points where moisture might infiltrate. This combination proves particularly valuable in regions experiencing intense rainfall, rapid snow accumulation, or freeze-thaw cycling that stresses conventional roofing materials. The thermal expansion characteristics of metal require careful design consideration, but standing seam technology specifically addresses this challenge through clip-based attachment systems allowing controlled panel movement. As panels expand in summer heat or contract during winter cold, they slide freely along their attachment points without creating stress concentrations that would eventually cause fastener failure or panel distortion. This engineered flexibility prevents the warping, buckling, and structural compromise that affects rigidly-fastened metal roofing alternatives, ensuring Grey Standing Seam Metal Roof systems maintain their weathertight integrity throughout countless thermal cycles.

Aesthetic Excellence and Architectural Integration

The visual impact of Grey Standing Seam Metal Roof installations extends far beyond simple weather protection, transforming building appearance through clean lines, contemporary styling, and sophisticated color selection. The vertical panel orientation creates strong directional emphasis that draws the eye along roof slopes, adding visual interest and architectural sophistication to structures ranging from modest residential homes to expansive commercial facilities. Grey color options provide neutral backdrop that harmonizes with virtually any exterior material palette while maintaining distinctive character that sets premium installations apart from conventional alternatives. The concealed fastener design eliminates visual clutter created by exposed screw heads typical of lower-cost metal roofing options. This smooth, uninterrupted surface appearance contributes to the refined aesthetic that makes standing seam systems preferred choices for high-end residential construction, contemporary architectural designs, and projects where visual excellence ranks equally with functional performance. The matte or gloss finish options available in premium Grey Standing Seam Metal Roof products allow precise matching to design intentions, whether seeking understated elegance or bold visual statement. Architectural versatility represents another significant advantage of standing seam technology. These systems adapt readily to complex roof geometries, integrating seamlessly with valleys, ridges, dormers, and other architectural features that challenge conventional roofing materials. Professional installers can create custom flashings, transitions, and trim details that maintain weathertight integrity while achieving sophisticated appearances appropriate to any architectural style. This adaptability makes Grey Standing Seam Metal Roof systems equally suitable for traditional residential applications, cutting-edge contemporary designs, and specialized commercial or industrial facilities.

-

Color Selection and Long-Term Appearance Retention

Grey represents particularly popular color choice for standing seam installations, offering timeless appeal that transcends temporary design trends. Unlike bold colors that may fall out of fashion or clash with future landscaping changes, grey tones provide enduring aesthetic foundation that complements evolving tastes and surrounding environmental changes. The neutral character of grey finishes allows architectural features, landscaping elements, and other design components to take visual precedence while the roof provides sophisticated backdrop rather than competing for attention. Superior coating technologies employed in premium Grey Standing Seam Metal Roof products ensure color consistency and appearance retention far exceeding capabilities of conventional roofing materials. While asphalt shingles typically show significant fading, granule loss, and color inconsistency within just ten to fifteen years, PVDF-coated metal panels maintain their original appearance for thirty years or more under warranty protection. This sustained aesthetic quality means your roof looks substantially identical to installation day even after decades of service, preserving property appearance and value throughout the system's extended lifespan.

Installation Complexity and Professional Requirements

The sophisticated engineering of Grey Standing Seam Metal Roof systems demands corresponding installation expertise to achieve optimal performance. Unlike conventional roofing materials that forgive minor installation variations, standing seam technology requires precise panel alignment, correct clip placement, proper seam formation, and careful attention to thermal expansion allowances. Improper installation can lead to leaks, aesthetic issues, and structural damage, making contractor selection critically important to project success and long-term satisfaction. Qualified installation professionals understand the specific requirements of standing seam systems, including substrate preparation, underlayment selection, panel handling procedures, and seam formation techniques. They possess specialized equipment necessary for accurate seam creation, whether using mechanical seaming machines for field-locked systems or implementing proper snap-lock assembly procedures for factory-formed panel edges. This technical expertise ensures weather-tight installation that performs reliably throughout decades of service while maintaining the aesthetic excellence that makes standing seam systems attractive. The installation process typically begins with thorough substrate inspection and preparation, ensuring proper ventilation, adequate structural support, and appropriate underlayment application. Professional installers then carefully measure and cut panels to precise dimensions, accounting for thermal expansion requirements and creating proper clearances at all termination points. Sequential panel installation proceeds with meticulous attention to alignment and fastener placement, followed by seam formation using appropriate mechanical equipment or manual assembly techniques depending on specific system requirements.

-

Quality Assurance and Installation Verification

Reputable manufacturers like Xi'an Huafeng Construction Engineering Co., Ltd. provide comprehensive installation guidelines, technical support, and quality verification protocols ensuring consistent results across diverse project applications. Their experienced technical support teams offer design guidance, specification assistance, and on-site consultation services that help installers navigate complex details and challenging conditions. This manufacturer involvement significantly reduces installation risks while ensuring that completed projects meet performance expectations and warranty requirements. Post-installation testing represents crucial final step verifying system integrity before project completion. Professional installers conduct thorough inspections checking seam formation, fastener engagement, flashing integration, and overall weather-tightness. Many perform water testing on completed installations, deliberately flooding roof sections to verify that no leaks develop under realistic conditions. This quality verification provides confidence that your Grey Standing Seam Metal Roof investment will deliver promised performance throughout its extended service life.

Maintenance Requirements and Operational Considerations

Standing seam roofing requires less maintenance than other metal roofing types due to concealed fasteners, though regular inspections remain important for identifying potential issues before they develop into significant problems. The hidden fastener design eliminates the primary maintenance concern affecting exposed-fastener systems, where ultraviolet exposure gradually degrades rubber washers, allowing water infiltration and requiring periodic fastener replacement. This fundamental advantage means Grey Standing Seam Metal Roof systems typically need only annual visual inspections and occasional cleaning to maintain optimal performance. Recommended maintenance activities include removing accumulated debris from roof surfaces, checking drainage systems for blockages, inspecting flashing details at penetrations and transitions, and verifying that panel attachments remain secure. These straightforward tasks require minimal time and expense compared to maintenance demands of conventional roofing materials, which often need moss treatment, granule loss assessment, damaged shingle replacement, and other regular interventions. The minimal maintenance profile of standing seam systems contributes significantly to their favorable lifecycle economics. Environmental conditions influence specific maintenance needs. Installations in areas with significant tree coverage may require more frequent cleaning to prevent organic debris accumulation, while coastal locations benefit from occasional washing to remove salt deposits that could eventually promote corrosion. Industrial environments with airborne contaminants might warrant periodic inspection of coating integrity, though premium PVDF finishes demonstrate remarkable resistance to chemical exposure. These modest maintenance requirements pale compared to ongoing attention demanded by conventional roofing materials, particularly in challenging environments.

-

Long-Term Performance Monitoring

Establishing regular inspection schedules ensures early detection of any developing issues while they remain minor and inexpensive to address. Many property owners combine roof inspections with seasonal gutter cleaning or other routine maintenance activities, creating efficient workflows that address multiple systems during single service visits. Professional roofing contractors offer maintenance programs providing scheduled inspections, detailed condition reports, and recommended interventions, giving property owners peace of mind that their Grey Standing Seam Metal Roof investment receives appropriate ongoing attention. Documentation of maintenance activities, inspection findings, and any repairs performed creates valuable records supporting warranty claims and demonstrating proper system care should property sale occur. This documentation proves particularly valuable for commercial properties where building condition reports factor significantly into transaction valuations and buyer confidence. Systematic maintenance tracking also helps identify any patterns suggesting manufacturing defects, installation issues, or environmental factors requiring attention, enabling proactive responses that prevent minor concerns from escalating into costly problems.

Conclusion

The question of whether Grey Standing Seam Metal Roof systems justify their substantial initial investment ultimately depends on individual priorities, financial capacity, and long-term ownership intentions. For property owners seeking lifetime roofing solutions, minimal maintenance obligations, superior weather protection, and contemporary aesthetic excellence, standing seam technology delivers exceptional value despite premium pricing. The combination of decades-long service life, energy efficiency benefits, enhanced property values, and negligible maintenance requirements creates compelling financial justification when evaluated over appropriate timeframes, particularly for those planning extended property occupancy.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as your premier China Grey Standing Seam Metal Roof manufacturer, offering unparalleled expertise in metal roofing system design, production, and installation. Established in 2018 and recognized as a high-tech enterprise in Shaanxi Province, Huafeng operates three state-of-the-art factories with seven color coating production lines and over forty specialized machines, ensuring production capacity exceeding one thousand tons monthly. Our comprehensive facilities include a two-hundred-thousand square meter raw material production plant in Anhui, plus dedicated processing plants in Hangzhou and Xi'an, providing complete vertical integration from raw materials through finished installations.

As a leading China Grey Standing Seam Metal Roof supplier and China Grey Standing Seam Metal Roof wholesale provider, we maintain rigorous quality standards validated through ISO9001, ISO14000:14001, and SGS certifications, backed by more than twenty registered patents for roofing systems. Our products meet international standards including ASTM, DIN, JIS, BS, and GB/T specifications, with every Grey Standing Seam Metal Roof for sale carrying comprehensive thirty-year warranties. We offer High Quality Grey Standing Seam Metal Roof solutions with competitive Grey Standing Seam Metal Roof price structures, customized to your specific project requirements from initial design through final installation and ongoing maintenance support.

Our one-stop service model encompasses structural 3D modeling, load analysis, drainage system simulation, precision manufacturing with real-time quality control, and seamless on-site installation management. Major projects including Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, and Inner Mongolia Tongliao Art Museum demonstrate our capability handling complex, high-profile installations. For inquiries about our China Grey Standing Seam Metal Roof factory capabilities, customized solutions, or project quotations, contact our experienced team at huafeng@hfmetalroof.com to discover how Huafeng's engineering excellence can transform your roofing vision into lasting reality.

References

1. Bill Ragan Roofing. "What are the Pros and Cons of a Standing Seam Metal Roof?" Roofing industry analysis examining durability, cost factors, and performance characteristics of standing seam systems.

2. Sheffield Metals International. "11 Reasons You Shouldn't Buy a Standing Seam Metal Roof." Comprehensive evaluation of standing seam limitations, cost considerations, and alternative metal roofing options.

3. Western States Metal Roofing. "10 Benefits Of A Standing Seam Metal Roof." Technical assessment of fire resistance, concealed fastener advantages, and long-term performance characteristics.

4. Able Roofing. "The Pros and Cons of Standing Seam Metal Roofing." Professional contractor perspective on installation requirements, durability benefits, and maintenance considerations for standing seam systems.

_1757558889992.webp)