Every contractor knows the frustration of metal roofing systems that promise efficiency but deliver installation headaches, weather-related callbacks, and unhappy clients. Traditional roofing methods often require specialized equipment, extensive labor hours, and still leave you vulnerable to leakage issues that damage your reputation. Snaplok roofing eliminates these pain points by offering a revolutionary snap-together design that transforms how contractors approach metal roofing projects, delivering faster installations, superior weather protection, and long-term reliability that keeps clients satisfied and your business thriving.

Understanding Snaplok Roofing Systems and Their Advantages

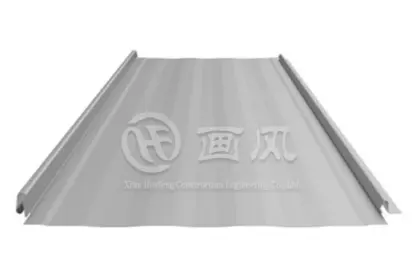

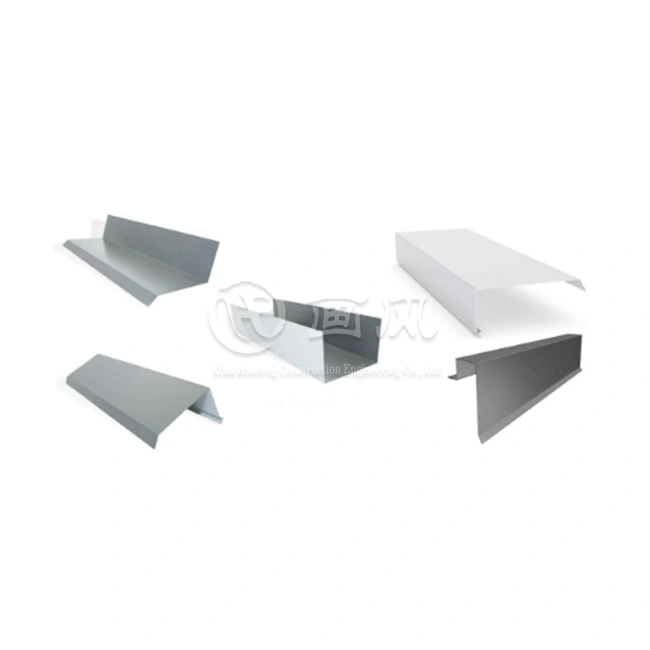

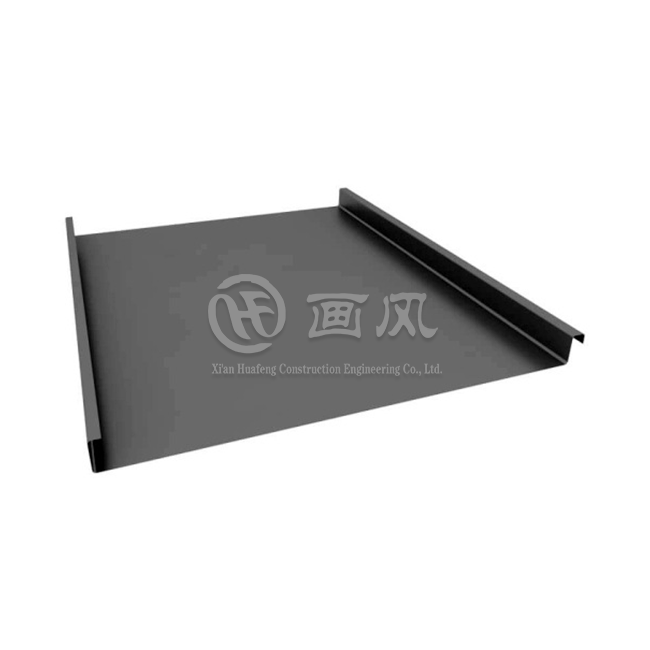

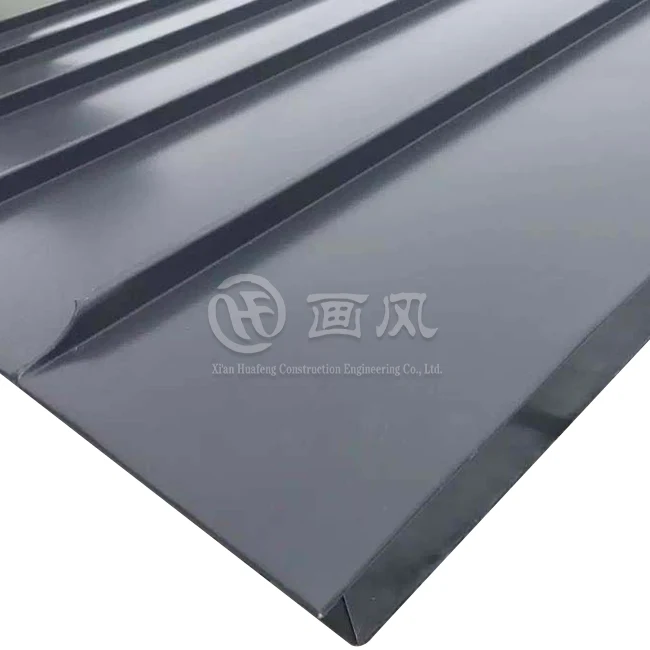

Snaplok roofing represents a significant advancement in metal roofing technology, specifically engineered to address the challenges contractors face daily on job sites. Unlike conventional standing seam systems that require mechanical seaming equipment or exposed fastener panels that compromise weatherproofing, Snaplok roofing utilizes an innovative concealed clip system combined with interlocking panel edges that snap together securely. This design philosophy fundamentally changes the installation process while delivering exceptional structural performance. The system consists of metal panels with factory-formed edges that interlock with adjacent panels through a simple snapping action, secured to the roof deck via hidden clips that allow for thermal expansion and contraction. This engineering approach provides contractors with multiple competitive advantages including reduced labor costs, minimized equipment requirements, and enhanced project timelines without sacrificing quality or durability. The mechanical superiority of Snaplok roofing becomes evident when examining its weather resistance capabilities. The interlocking seam design creates a continuous barrier against water infiltration, with each connection forming a weathertight seal that prevents moisture penetration even under severe weather conditions. This tight mechanical lock edge structure eliminates the need for additional sealants in most applications, reducing material costs and maintenance requirements while ensuring long-term waterproofing performance. Contractors particularly appreciate how snaplock roofing systems handle thermal movement, as the floating clip design accommodates the natural expansion and contraction of metal panels without creating stress points that could compromise the roof's integrity. This feature proves especially valuable in regions experiencing significant temperature fluctuations, where traditional systems often develop issues over time. Furthermore, the concealed fastener approach means no exposed screws that could potentially back out, corrode, or create leak pathways, addressing one of the most common failure points in metal roofing installations.

Technical Specifications and Material Options for Professional Applications

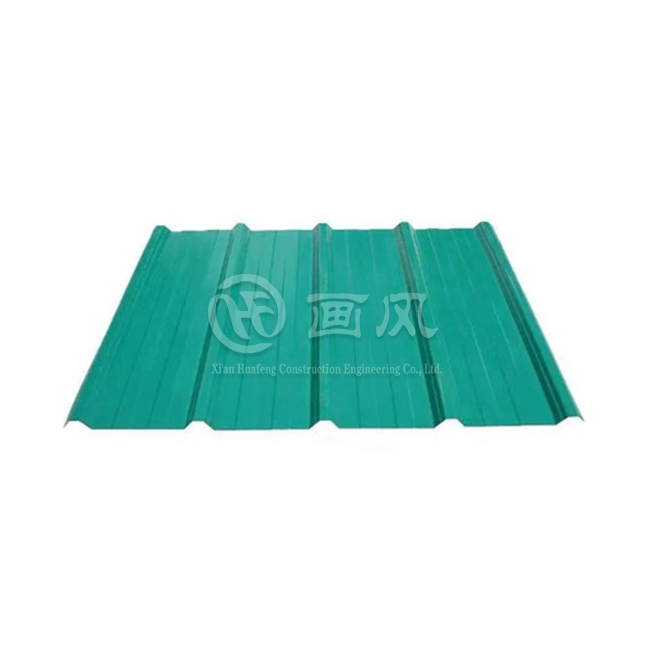

Understanding the technical specifications of Snaplok roofing enables contractors to make informed decisions that align with project requirements and client expectations. Modern snaplok roofing panels are manufactured using premium base materials including aluminum alloy grades 3003, 3004, and 5052, galvanized steel with AZ150 or G550 coating, stainless steel grades 304 and 316 for coastal applications, and specialized materials like titanium-zinc and copper for architectural projects demanding distinctive aesthetics. Material thickness typically ranges from 0.4mm to 1.2mm, with 0.5mm to 0.7mm being the most common specifications for residential and light commercial applications, providing an optimal balance between structural performance, weight, and cost-effectiveness. Panel widths generally span 300mm to 600mm in coverage width, with customizable lengths up to 12 meters depending on transportation constraints and project requirements, allowing contractors to minimize seams and reduce installation time on large-span applications. Surface treatment options significantly impact both the appearance and longevity of Snaplok roofing installations. PVDF coatings represent the premium choice, offering exceptional UV resistance, color retention, and weather durability with expected service lives extending 30 to 50 years under normal exposure conditions. Polyester coatings provide a cost-effective alternative suitable for less demanding applications, while specialized finishes including embossed textures and bare metal options cater to specific architectural visions. Color selection extends across the full RAL and Pantone spectrum, enabling contractors to match any design specification while maintaining the technical performance characteristics that make snaplock roofing the preferred choice for quality-conscious projects. The fire rating classification of Class A non-combustible material meets stringent building code requirements, while the system's ability to perform on roof slopes as low as 1:12 (approximately 5 degrees) expands application possibilities compared to many competing systems that require steeper pitches for proper water drainage.

Installation Efficiency and Labor Advantages

The installation process for Snaplok roofing delivers tangible efficiency gains that directly impact project profitability and timeline management. Traditional standing seam systems often require specialized mechanical seaming equipment operated by trained technicians, creating equipment rental costs and limiting the number of installers who can work simultaneously. In contrast, snaplok roofing panels install using basic hand tools and hidden clips, enabling contractors to deploy larger crews without investing in expensive machinery or extensive specialized training. The snap-together connection mechanism reduces installation time by over 50% compared to conventional metal roofing systems, as installers simply position each panel, verify alignment, and apply pressure to engage the interlocking seam without the time-consuming process of operating seaming equipment along every panel joint. This efficiency translates to reduced labor hours, lower project costs, and faster project completion, allowing contractors to take on more work and improve profit margins while maintaining high quality standards. The ergonomic advantages of Snaplok roofing installation should not be underestimated when considering total project efficiency. The lightweight nature of metal panels, typically weighing only one-tenth that of traditional ceramic tiles, reduces physical strain on installers and minimizes structural load requirements on the building. This weight advantage proves particularly valuable during retrofit projects where existing structures may have limited load capacity, potentially eliminating the need for structural reinforcement that would otherwise add significant cost and complexity to the project. The concealed clip system also provides installers with clear visual feedback during installation, as properly engaged connections produce a distinct snapping sensation and uniform appearance, reducing the likelihood of installation errors that might not become apparent until after project completion. Additionally, the systematic numbering and sectional packaging approach employed by quality manufacturers ensures installers can quickly locate the correct panels for each roof section, minimizing confusion on complex projects and preventing costly mistakes that could delay completion.

Durability and Long-Term Performance Benefits

Long-term performance characteristics distinguish Snaplok roofing as a premium solution that delivers value far beyond the initial installation. The corrosion-resistant base materials combined with advanced coating systems create roofing panels capable of withstanding decades of exposure to harsh environmental conditions without significant degradation. Aluminum alloy panels, particularly those using 3004 or 5052 alloys, naturally resist corrosion without requiring additional protective coatings, making them ideal for coastal environments where salt air would rapidly damage inferior materials. Galvanized and galvalume steel options provide excellent corrosion protection through sacrificial zinc layers that protect the underlying steel even if the surface coating becomes compromised, while PVDF topcoats add an additional barrier against UV radiation, acid rain, and atmospheric pollutants that could otherwise accelerate material deterioration. The thermal performance of snaplock roofing systems contributes significantly to building energy efficiency and occupant comfort. High-reflectivity surface finishes can reflect 25% to 67% of solar radiation, substantially reducing heat absorption compared to traditional roofing materials and lowering cooling costs during warm months. This characteristic proves especially valuable for commercial and industrial buildings with large roof areas where heat gain through the roof assembly can significantly impact HVAC system operating costs. The low-maintenance requirements of Snaplok roofing further enhance its long-term value proposition, as the mold-resistant and rust-proof characteristics of properly installed systems typically require only periodic rainwater washing to maintain appearance and performance. Unlike organic roofing materials that may require periodic treatments or replacements of individual components, quality metal roofing installations often require minimal intervention throughout their service life, reducing total ownership costs and eliminating the disruption associated with frequent maintenance activities.

Application Versatility Across Building Types

The versatility of Snaplok roofing enables contractors to apply this system across diverse building types and architectural styles, expanding market opportunities and service offerings. Commercial buildings including shopping centers, warehouses, airports, and athletic facilities benefit from the large-span capability and rapid installation characteristics of snaplok roofing, as these projects often demand extensive roof coverage completed within tight timelines to avoid disrupting business operations. The clean, modern aesthetic of standing seam profiles complements contemporary architectural designs while providing the structural performance necessary to meet stringent commercial building codes and warranty requirements. Industrial facilities present unique challenges including exposure to corrosive atmospheres, high thermal loads, and rigorous safety standards that make Snaplok roofing an ideal solution, particularly when specified with appropriate material grades and coating systems designed for harsh environments. Residential applications represent a growing market segment for quality Snaplok roofing systems, as homeowners increasingly recognize the long-term value and aesthetic appeal of metal roofing. Modern villas, custom homes, and architectural residences particularly benefit from the sleek appearance and design flexibility of snaplock roofing, which can accommodate complex roof geometries including valleys, hips, and dormers while maintaining weathertight integrity. The compatibility with solar panel installations adds further appeal for environmentally conscious homeowners seeking to maximize energy independence, as the concealed clip system provides secure mounting points without compromising roof waterproofing. Public facilities including schools, hospitals, and government buildings often specify metal roofing systems based on lifecycle cost analysis and sustainability considerations, areas where Snaplok roofing excels through extended service life, minimal maintenance requirements, and complete recyclability at end of service life. Special applications including agricultural buildings, greenhouse structures, and coastal properties requiring enhanced corrosion resistance demonstrate the adaptability of properly specified snaplok roofing systems to meet demanding performance requirements across virtually any building type.

Conclusion

Snaplok roofing delivers unmatched value for contractors seeking efficient installation, superior weather protection, and long-term reliability that satisfies demanding clients while improving project profitability through reduced labor and equipment costs.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Partner with Xi'an Huafeng Construction Engineering Co., Ltd., a leading China Snaplok Roofing factory, China Snaplok Roofing supplier, and China Snaplok Roofing manufacturer offering premium Snaplok Roofing for sale at competitive Snaplok Roofing price points. Our China Snaplok Roofing wholesale program provides High Quality Snaplok Roofing backed by ISO9001, ISO14001, and SGS certifications, over 20 registered patents, and proven collaboration with Fortune 500 companies. Our three state-of-the-art facilities featuring 7 raw material production lines and more than 40 advanced machines ensure consistent quality and 15-20 day delivery for orders meeting our 500㎡ MOQ. We offer comprehensive one-stop solutions from custom design optimization and precision manufacturing to seamless on-site installation guidance, with material options including aluminum alloy, steel, stainless steel, copper, and titanium-zinc in thicknesses from 0.4-1.2mm with PVDF/PE finishes and 30-year warranty coverage. Our engineering expertise enables us to provide structural 3D modeling, load analysis, and drainage system simulation tailored to your project requirements, while our rigorous quality control includes material traceability, incoming inspection, and finished product verification ensuring every panel meets ASTM, DIN, JIS, BS, and GB/T standards. Contact our team at huafeng@hfmetalroof.com today to discuss your Snaplok roofing needs and discover how our factory-direct pricing, technical support, and proven track record on major projects including Xiongan Station, Xi'an International Convention Center, and Inner Mongolia Tongliao Art Museum can elevate your next construction project.

References

1. Metal Roofing Alliance. "Standing Seam Metal Roofing Systems: Design and Performance Guidelines." Metal Construction Association.

2. Canadian Sheet Steel Building Institute. "Installation Standards for Concealed Fastener Metal Roofing Panels." CSSBI Publication S8-2008.

3. National Roofing Contractors Association. "Metal Panel Systems: Installation and Weatherproofing Best Practices." NRCA Technical Manual.

4. American Society for Testing and Materials. "Standard Specification for Steel Sheet, Zinc-Coated (Galvanized) by the Hot-Dip Process." ASTM A653/A653M.