When building or renovating your facility, you're likely facing a critical decision: which roofing material will deliver both performance and value? Many building owners struggle with water infiltration, premature panel failure, and unexpected maintenance costs because they selected the wrong corrugated side panels. The truth is, choosing the best corrugated side panels for your roofline requires understanding material specifications, structural requirements, and long-term performance characteristics. This comprehensive guide will walk you through every essential factor to ensure your investment delivers decades of reliable protection.

Understanding Corrugated Side Panels and Their Applications

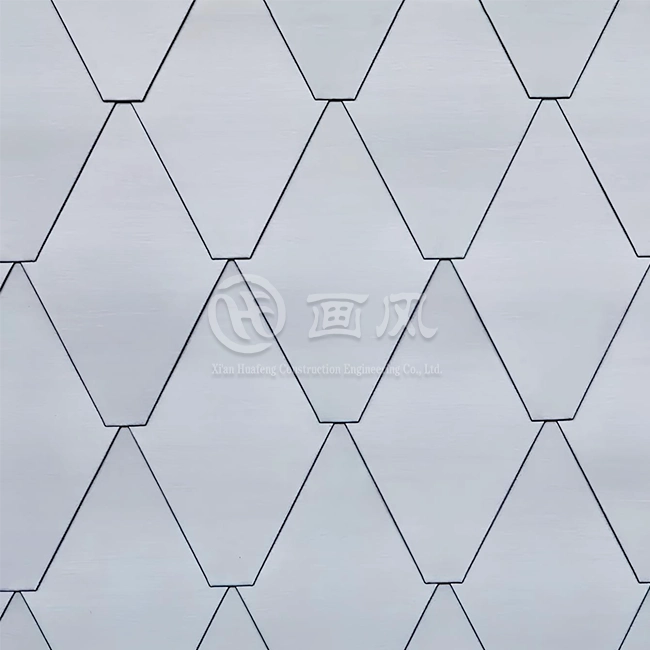

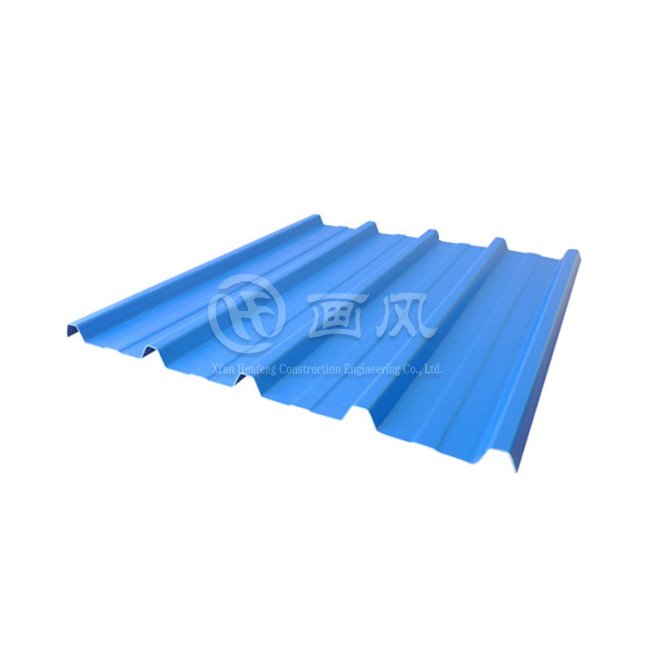

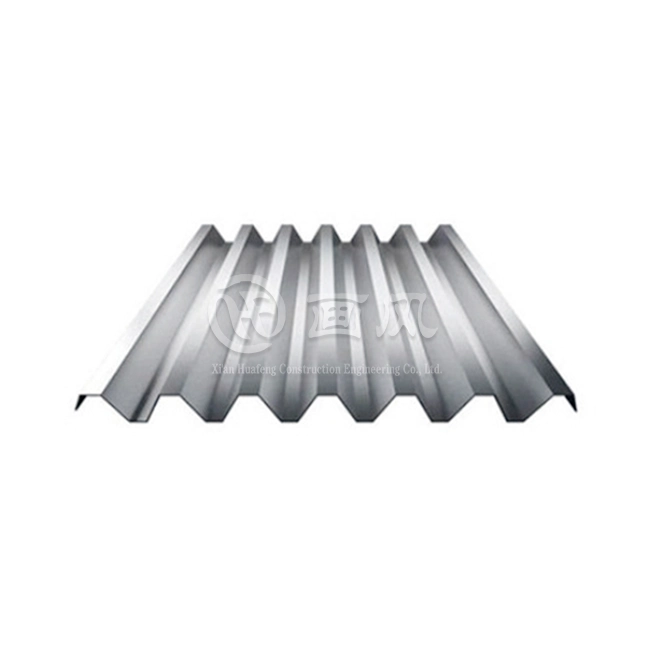

Corrugated side panels represent one of the most versatile and cost-effective building solutions available in modern construction. These metal panels feature a distinctive wavy or "S-shaped" profile created through a roll-forming process that transforms flat metal sheets into structurally reinforced cladding systems. The corrugation design itself serves multiple critical functions beyond aesthetics. The alternating ridges and valleys create exceptional structural rigidity, allowing panels to span greater distances between supports while maintaining strength against wind loads, snow accumulation, and impact forces. This inherent strength-to-weight ratio makes corrugated side panels particularly valuable for industrial warehouses, agricultural buildings, commercial facades, and temporary structures. The manufacturing process begins with high-quality base materials including galvanized steel, aluminum-magnesium-manganese alloys, or specialized coated metals. Through precision roll-forming equipment, these materials are shaped into consistent corrugation patterns with specific depths typically ranging from 10mm to 50mm, though 15mm to 25mm depths are most common for standard applications. The panel width generally spans 600mm to 1200mm, with customizable lengths extending up to 12 meters for large-scale projects. Material thickness varies from 0.3mm to 1.2mm depending on structural requirements and expected service life. Surface finishes include pre-painted options with HDP or PVDF coatings that provide superior weather resistance and color retention, bare metal finishes for specialized applications, and anti-corrosive treatments for harsh environmental conditions.

Key Material Considerations for Roofline Applications

Selecting appropriate base materials for corrugated side panels directly impacts both initial project costs and long-term performance. Galvanized steel panels offer excellent strength and corrosion resistance through a protective zinc coating applied via hot-dip galvanizing processes. This coating acts as a sacrificial barrier, corroding preferentially to protect the underlying steel substrate. For coastal environments or industrial facilities with aggressive atmospheric conditions, aluminum-magnesium-manganese alloys provide superior corrosion resistance while maintaining favorable strength characteristics. These alloys naturally form a protective oxide layer that self-repairs minor scratches and continues protecting the base material throughout its service life. Coated steel products represent the intersection of performance and aesthetics. Premium coating systems like PVDF (polyvinylidene fluoride) deliver exceptional UV resistance, chemical stability, and color retention even after decades of exposure. These molecular-level coatings maintain their integrity through extreme temperature fluctuations and resist chalking, fading, and degradation from atmospheric pollutants. High-durability polyester (HDP) coatings offer a more economical alternative while still providing good weather protection and color stability for most commercial and industrial applications. The coating selection should align with your project's expected service life, environmental exposure level, and maintenance capabilities.

Critical Factors When Selecting Corrugated Side Panels

Panel Thickness and Gauge Requirements

Understanding metal gauge specifications is fundamental to selecting corrugated side panels that will perform reliably throughout their service life. The gauge system operates inversely to thickness—higher gauge numbers indicate thinner material. Corrugated side panels typically range from 26 gauge (approximately 0.5mm thick) to 20 gauge (approximately 0.9mm thick), with commercial and industrial applications commonly specifying 24 to 26 gauge materials. Thicker panels naturally provide greater resistance to impact damage, higher wind load capacity, and improved sound attenuation properties. For roofline applications in regions experiencing severe weather conditions including hail, heavy snow loads, or sustained high winds, specifying thicker gauge materials becomes essential for preventing panel deformation and maintaining weathertight integrity. The corrugation depth works synergistically with material thickness to determine overall panel strength. Deeper corrugations create more pronounced stiffening ribs that dramatically increase the panel's moment of inertia—its resistance to bending under load. A 7/8" corrugated panel manufactured from 24-gauge steel will significantly outperform a 1/2" corrugated panel of the same gauge because the deeper profile creates greater structural efficiency.

Corrugation Pattern and Structural Performance

The specific corrugation pattern selected for your roofline installation affects both aesthetic presentation and structural capability. Standard corrugation depths include 1/2" (approximately 13mm), 3/4" (approximately 19mm), and 7/8" (approximately 22mm) profiles. Industry experience demonstrates that 7/8" corrugated side panels offer superior overall performance for most commercial and industrial applications. These deeper profiles provide enhanced spanning capability, allowing greater distances between structural purlins while maintaining adequate deflection control under design loads. The 7/8" corrugation pattern also facilitates more efficient water management. The pronounced valleys create clear drainage paths that channel rainwater and melted snow away from fastener penetrations, reducing the risk of moisture infiltration through exposed fastener systems. Additionally, the regular spacing of corrugations—typically 2.67 inches between peaks—creates a rhythmic visual pattern that integrates well with modern architectural design while maintaining the functional character expected in industrial and agricultural structures. When comparing corrugation options, consider that panels with deeper profiles generally require less material overlap during installation, potentially reducing overall material costs despite higher per-panel pricing.

Weather Resistance and Coating Systems

The coating system applied to corrugated side panels fundamentally determines their ability to resist environmental degradation and maintain appearance throughout their service life. PVDF coating systems represent the premium choice for demanding applications where color retention, chalk resistance, and long-term weathering performance are priorities. These fluoropolymer-based coatings maintain their protective qualities and aesthetic appearance for 30 years or more, making them ideal for high-visibility architectural applications and facilities in harsh coastal or industrial environments where atmospheric pollutants accelerate degradation. High-durability polyester coatings provide an economical alternative that still delivers good performance for many commercial and agricultural applications. While HDP coatings may experience some fading and chalking after 15 to 20 years of exposure, they maintain adequate protection against corrosion and continue to provide serviceable performance well beyond their warranty period. The coating selection should consider not only initial project budget but also the facility's expected operational lifespan and the importance of maintaining exterior appearance over time. Facilities planning for multi-decade service lives or those with prominent public visibility benefit from investing in premium coating systems, while structures with shorter operational timelines or industrial settings where aesthetics are secondary may find HDP coatings entirely adequate.

Installation Requirements and Fastening Systems

Exposed Fastener Methodology

Corrugated side panels typically utilize exposed fastener installation systems where specialized screws penetrate the panel profile to secure it directly to the structural substrate. This installation approach offers several advantages including lower material costs, faster installation rates, and compatibility with a wider range of structural configurations. However, proper fastener selection and installation technique are critical to preventing water infiltration and maintaining long-term weathertight integrity. For roofline applications, fasteners should be placed in the high point of corrugations rather than the valleys. This positioning keeps the fastener penetration elevated above the natural water drainage path, significantly reducing the likelihood of moisture infiltration around fastener holes. Each fastener should include a sealing washer—typically EPDM rubber—that compresses during installation to create a weathertight seal between the screw head and the panel surface. Proper installation torque is essential: over-tightening compresses the sealing washer excessively and can dimple the panel surface, while under-tightening fails to create adequate compression for a reliable seal.

Panel Overlap and Side Lap Considerations

Understanding panel overlap requirements is essential for accurate material estimation and ensuring weathertight installation. Corrugated side panels require lateral overlap where adjacent panels meet, typically spanning one or two corrugations depending on the application. For roofline installations, a two-corrugation side lap is standard practice to provide adequate weather protection. This overlap pattern means that a panel with a nominal 39-inch width will yield only 34.67 inches of effective coverage, requiring approximately 12 percent additional material compared to the nominal panel width. The side lap overlap must be sealed with butyl sealant tape or similar weatherproofing compound to prevent wind-driven rain from penetrating between overlapping panels. The sealant should be applied in a continuous bead along the full length of the overlap area before the adjacent panel is positioned and fastened. This creates a compressed seal that accommodates minor panel movement from thermal expansion while maintaining weathertight integrity. At endlaps where panels meet end-to-end along the roofline slope, a minimum 6-inch overlap is required, with 8 to 12 inches recommended for low-slope applications or regions with severe weather exposure.

Quality Standards and Performance Certifications

International Compliance Requirements

Corrugated side panels for commercial and industrial applications must comply with relevant international standards that govern material quality, manufacturing tolerances, and performance characteristics. ASTM (American Society for Testing and Materials) standards provide comprehensive specifications for steel sheet products, coating systems, and weathering performance. DIN (Deutsches Institut für Normung) standards offer European benchmarks for material properties and testing protocols. JIS (Japanese Industrial Standards) and GB/T (Chinese National Standards) provide additional frameworks for quality verification and manufacturing consistency. When evaluating corrugated side panels suppliers, verification of compliance with these international standards provides assurance that materials meet minimum quality thresholds for chemical composition, mechanical properties, coating thickness, and corrosion resistance. Reputable manufacturers maintain detailed material certifications and provide third-party test reports confirming compliance with specified standards. These certifications become particularly important for projects requiring building permit approval, insurance qualification, or adherence to specific architectural specifications that reference international standards.

Quality Control and Manufacturing Consistency

Manufacturing facilities employing comprehensive quality control systems deliver more consistent panel quality and reduce the risk of premature failures from material defects or processing irregularities. Advanced manufacturing operations incorporate multiple quality checkpoints throughout the production process, including incoming material inspection to verify supplier-provided specifications, in-process monitoring to maintain dimensional tolerances and coating quality, and finished product inspection before packaging and shipment. Incoming material inspection protocols should include verification of base metal gauge thickness, coating weight measurements, hardness testing, and chemical composition analysis where appropriate. Third-party material certifications from steel suppliers provide traceability to specific production runs and verify compliance with ordered specifications. In-process quality control monitors critical parameters including corrugation depth consistency, panel width accuracy, and coating application uniformity. Finished product inspection examines panel appearance for surface defects, verifies dimensional accuracy, and confirms proper packaging to prevent transit damage.

Customization Options for Specific Project Requirements

Color Selection and Architectural Integration

Modern corrugated side panels are available in extensive color palettes that allow architectural integration with existing structures or creation of distinctive visual identities for new facilities. Standard color collections typically include neutral tones like white, gray, and beige that complement traditional industrial and commercial architecture, along with earth tones, blues, greens, and accent colors for more dynamic presentations. Custom color matching services can replicate specific colors from architectural samples, corporate branding standards, or regional aesthetic preferences. Beyond basic color selection, panel finish options influence both appearance and performance. Matte finishes provide subdued, non-reflective surfaces that minimize glare and create more understated presentations suitable for facilities seeking to blend with surrounding environments. Glossy finishes deliver more vibrant color presentation and slightly enhanced cleanability but may show surface scratches more readily. Textured finishes add visual depth and can help mask minor surface imperfections that develop during normal service life.

Dimensional Customization for Complex Rooflines

Standard corrugated side panels are manufactured in fixed widths but can be cut to custom lengths to accommodate specific roofline configurations and minimize waste. For projects with complex roof geometries including multiple slopes, valleys, ridges, and transitions, custom panel lengths reduce the number of end laps required and improve weather tightness while potentially reducing installation labor. Panel lengths extending up to 12 meters can be manufactured and transported, though longer panels require careful handling during installation to prevent damage and maintain proper alignment. Width customization within the range of 600mm to 1200mm allows optimization for specific structural layouts and purlin spacing. Narrower panels may be specified for areas with limited access or complex geometries where maneuverability is restricted, while wider panels maximize coverage efficiency for large, open expanses of roofline. Corrugation depth can also be customized within manufacturing capabilities to meet specific structural requirements or achieve desired aesthetic effects, though standard profiles typically provide adequate performance for most applications.

Supplier Selection and Partnership Considerations

Manufacturing Capability and Production Capacity

When selecting a corrugated side panels supplier, evaluating their manufacturing infrastructure and production capacity ensures they can deliver materials on the timeline and scale required for your project. Established manufacturers operating multiple production facilities with advanced roll-forming equipment, automated quality control systems, and substantial material inventory can accommodate large-scale projects and tight construction schedules more reliably than smaller operations with limited equipment and capacity. Production capacity measured in monthly tonnage provides insight into a supplier's ability to fulfill substantial orders without compromising delivery timelines. Suppliers with capacity exceeding 1000 tons per month can typically accommodate major commercial and industrial projects while maintaining reasonable lead times. Multiple production lines—ideally seven or more—provide operational redundancy that protects project schedules from disruption if equipment requires maintenance or repair. Advanced manufacturing facilities also maintain substantial raw material inventory allowing them to respond quickly to order placement rather than waiting for steel mill deliveries.

Technical Support and Engineering Services

Comprehensive technical support differentiates premium corrugated side panels suppliers from commodity material distributors. Manufacturers offering engineering design assistance, load calculation verification, and specification development add substantial value beyond basic material supply. Design optimization services review architectural drawings and structural requirements to recommend appropriate panel profiles, gauges, and fastening patterns that meet performance requirements while potentially reducing material costs or simplifying installation. Project-specific drawing development services create detailed installation drawings showing panel layout, fastener locations, trim details, and flashing configurations tailored to your specific building geometry. These detailed drawings reduce field coordination requirements, minimize installation errors, and ensure weather-tight system integration. Some suppliers provide on-site technical support during critical installation phases, offering guidance to installation crews and verifying that panels are being installed according to manufacturer specifications and industry best practices.

Conclusion

Selecting the best corrugated side panels for your roofline requires balancing structural performance, weather resistance, aesthetic preferences, and budget constraints. By carefully evaluating material specifications, coating systems, manufacturing quality, and supplier capabilities, you can specify panels that deliver reliable protection and maintain their appearance throughout decades of service.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a leading China corrugated side panels manufacturer offering comprehensive metal roofing solutions since 2018. As a high-tech enterprise recognized by Shaanxi Province with first-level building curtain wall qualifications and third-level steel structure qualifications, Huafeng operates three advanced factories with seven production lines and more than 40 specialized machines ensuring consistent quality and rapid delivery. Our corrugated side panels for sale feature premium materials, HDP and PVDF coating systems, customizable dimensions from 600-1200mm width and 0.3-1.2mm thickness, all backed by a comprehensive 30-year warranty. As a trusted China corrugated side panels supplier and China corrugated side panels wholesale partner, we provide high quality corrugated side panels with MOQ of 500㎡, delivery within 15-20 days, and full compliance with ASTM, DIN, JIS, BS, and GB/T standards. Our corrugated side panels price remains competitive while maintaining superior quality, and our one-stop service encompasses design optimization, precision manufacturing with raw material traceability, and seamless installation support. Experience partnering with a China corrugated side panels factory that has successfully delivered projects for Xiongan Station, Xi'an International Convention Center, and numerous other prestigious facilities. Contact us at huafeng@hfmetalroof.com for customized solutions tailored to your roofline requirements.

References

1. Western States Metal Roofing. "Corrugated Metal Roofing Guide: Installation, Costs, and Comparisons." Technical Documentation Series.

2. Smith, Robert J. and Johnson, Michael K. "Metal Building Systems: Design and Installation Standards for Commercial Construction." American Institute of Steel Construction.

3. National Roofing Contractors Association. "Metal Panel Roof Systems Design Manual." NRCA Technical Publications.

4. Anderson, David L. "Weather-Resistant Building Envelope Systems: Performance Requirements and Selection Criteria." Journal of Building Enclosure Design, Volume 15, Issue 3.

5. International Building Code Council. "Structural Requirements for Metal Panel Roof and Wall Systems." IBC Compliance Guidelines.

_1757558889992.webp)