When architects and builders face challenging facade projects demanding both weatherproof performance and architectural elegance, they often struggle with traditional cladding systems that compromise either aesthetics or durability. Vertical Standing Seam Metal Cladding emerges as the comprehensive solution, combining concealed fastening technology with superior weather resistance in a complete building envelope system. This innovative cladding approach includes precisely engineered metal panels, specialized attachment components, integrated weatherproofing elements, and comprehensive accessory packages that work together to create seamless, long-lasting building facades capable of withstanding extreme environmental conditions while maintaining striking visual appeal.

Understanding Vertical Standing Seam Metal Cladding Systems

Vertical Standing Seam Metal Cladding represents an advanced architectural metal facade system that utilizes vertical mechanical locking technology to join adjacent panels without visible fasteners. This sophisticated building envelope solution transforms how modern structures achieve weather protection, thermal performance, and aesthetic distinction simultaneously. The system comprises multiple integrated components working in harmony to deliver exceptional performance across diverse building applications, from commercial high-rises to industrial facilities and institutional structures. The fundamental architecture of Vertical Standing Seam Metal Cladding centers on precision-rolled metal panels featuring raised seams that interlock along vertical edges. These raised profiles, typically ranging from twenty-five to sixty-five millimeters in height, create distinct shadow lines that add dimensional character to building facades while serving critical functional purposes. The mechanical interlocking mechanism accommodates thermal expansion and contraction through engineered sliding clip systems, preventing material stress and maintaining watertight integrity throughout seasonal temperature variations. This design philosophy addresses one of the most persistent challenges in building envelope construction by allowing materials to move naturally without compromising structural connections or creating leak pathways.

Material selection for Vertical Standing Seam Metal Cladding significantly influences system performance, longevity, and aesthetic outcomes. Premium aluminum alloys such as AA3003, AA3004, and AA5052 offer exceptional corrosion resistance combined with favorable strength-to-weight ratios, making them ideal for coastal environments and humid climates where moisture exposure threatens material integrity. These aluminum grades contain specific alloying elements that enhance workability during panel formation while providing superior resistance to atmospheric corrosion. Alternatively, aluminum-zinc coated steel sheets deliver outstanding structural strength with protective metallic coatings that sacrificially corrode to shield the base steel substrate. High-grade stainless steel options provide unmatched durability for the most demanding applications, while copper and titanium-zinc materials develop distinctive patinas that add unique character as buildings age gracefully. Advanced coating technologies further enhance Vertical Standing Seam Metal Cladding performance by protecting base materials from environmental degradation while providing diverse aesthetic possibilities. Polyvinylidene fluoride coatings, commonly known as PVDF finishes, represent the premium standard for architectural metal cladding applications. These fluoropolymer coatings demonstrate exceptional resistance to ultraviolet radiation, chemical exposure, and atmospheric pollutants, maintaining color stability and gloss retention for decades in harsh outdoor environments. High-performance polyester coatings offer excellent value for projects requiring reliable protection with good color retention at moderate cost levels. These coating systems undergo rigorous testing protocols to verify adhesion strength, impact resistance, salt spray performance, and accelerated weathering characteristics before receiving ISO9001 and ISO14001 certifications that validate their quality and environmental responsibility.

Core Components Included in Complete Cladding Systems

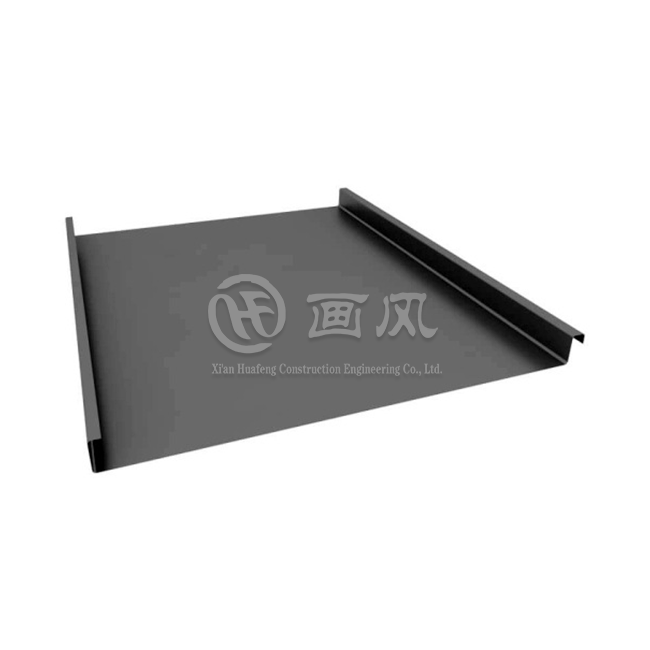

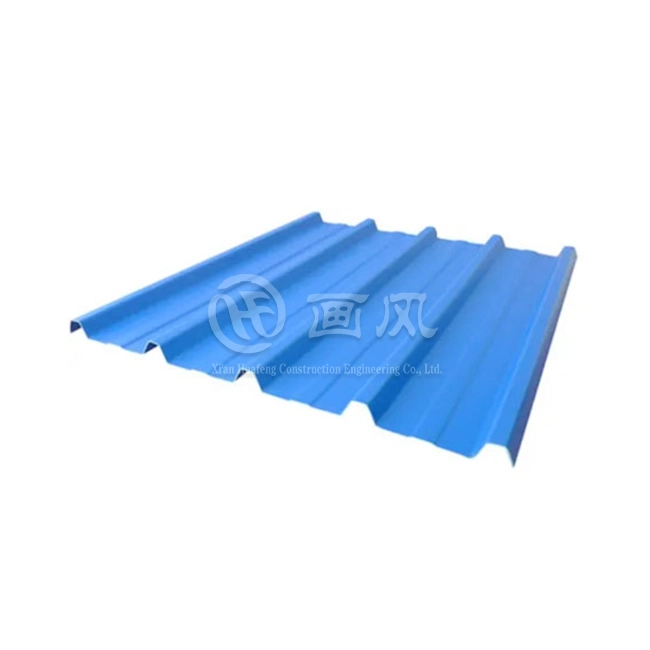

A comprehensive Vertical Standing Seam Metal Cladding system includes numerous precisely engineered components that integrate seamlessly to create complete building envelope solutions. Understanding what elements constitute complete systems helps project stakeholders make informed specification decisions and budget accurately for total installation costs. Professional manufacturers like Xi'an Huafeng Construction Engineering Co., Ltd. provide complete system packages that include all necessary materials, eliminating the coordination challenges and compatibility risks associated with sourcing components from multiple suppliers. The primary panel assemblies form the visible surface of Vertical Standing Seam Metal Cladding systems and receive the most attention during specification development. These panels arrive at construction sites as custom-fabricated units manufactured to exact project dimensions, eliminating field cutting and reducing installation waste. Panel widths typically range from three hundred to six hundred millimeters, with customization capabilities extending from three hundred to eight hundred millimeters to accommodate specific architectural requirements and achieve desired visual proportions. Panel lengths extend up to twelve meters or more as single continuous pieces, minimizing horizontal joints and reducing potential leak points while creating dramatic uninterrupted facade expressions. Thickness specifications vary based on material selection and structural requirements, with aluminum panels typically ranging from 0.7 to 1.5 millimeters and steel panels from 0.4 to 1.2 millimeters, carefully engineered to provide adequate structural rigidity without excessive material weight.

Concealed fastening components represent critical system elements that remain hidden behind finished surfaces yet determine overall performance outcomes. Advanced clip systems manufactured from high-grade stainless steel provide the secure attachment points connecting metal panels to structural substrates. These specialized clips incorporate precise geometries that enable controlled thermal movement while maintaining positive panel retention under wind loading conditions. Fixed clips secure panels at specific locations where movement restriction proves necessary, typically at panel tops or strategic intermediate points. Sliding clips allow controlled horizontal movement as panels expand and contract with temperature changes, preventing material stress and maintaining seam integrity throughout seasonal cycles. Each clip must resist specified pull-out forces, typically fifty decanewtons or greater, verified through rigorous testing protocols that simulate extreme loading scenarios.

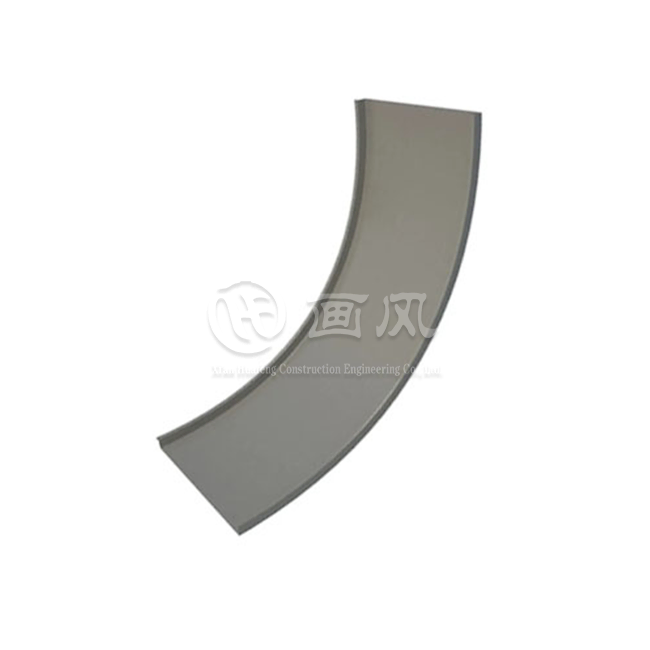

Comprehensive flashing assemblies provide critical transitions at building corners, openings, terminations, and penetrations where standard panel installations require specialized treatment. Corner flashings create weathertight conditions at inside and outside corners where two facade planes intersect, maintaining water integrity while accommodating differential movement between perpendicular surfaces. Window and door perimeter flashings integrate cladding systems with fenestration assemblies, creating continuous weather barriers that prevent moisture infiltration at these vulnerable junctions. Base flashings establish proper water management at facade bottoms, incorporating weep systems that evacuate incidental moisture while preventing capillary action that might draw water upward into wall assemblies. Ridge and parapet cap flashings protect exposed horizontal edges from direct weather exposure while accommodating thermal movement and maintaining aesthetic continuity. Specialized trim components complete system installations by providing finished appearances at terminations, transitions, and decorative applications. Starter strips establish the initial installation reference line and provide secure attachment for the first panel course. Closure strips seal panel ends at horizontal terminations, preventing moisture entry while maintaining proper ventilation characteristics. Expansion joint covers accommodate building movement at structural control joints without compromising weather protection or visual continuity. Color-matched fasteners, sealants, and touch-up materials ensure that all visible elements maintain consistent appearances that meet architectural specifications. Professional manufacturers maintain extensive inventories of compatible accessories, enabling rapid project supply without delays that might impact construction schedules.

Manufacturing Process and Quality Control Integration

The production of Vertical Standing Seam Metal Cladding involves sophisticated manufacturing processes that transform raw materials into precision-engineered building components. Understanding these manufacturing operations provides insight into the quality standards and capabilities that distinguish professional suppliers from commodity producers. Xi'an Huafeng Construction Engineering Co., Ltd. operates advanced manufacturing facilities spanning over two hundred thousand square meters, housing state-of-the-art equipment that enables consistent quality output and rapid project fulfillment. Material procurement begins with stringent supplier qualification protocols that verify raw material sources meet specified quality standards. The purchasing department maintains approved supplier registries documenting material certifications, test reports, and quality management system verifications from established brands including Alucosuper, YATAI, and LIDAO for aluminum alloys, BAOSTEEL and XINYU for steel products, and specialized suppliers for stainless steel, titanium-zinc, and copper materials. Each incoming material shipment undergoes comprehensive inspection procedures including visual examination, dimensional verification, and mechanical property testing. Laboratory analysis confirms chemical composition, coating thickness, adhesion strength, hardness values, and corrosion resistance characteristics match specification requirements. This rigorous incoming inspection prevents defective materials from entering production streams where they might compromise finished product quality.

Advanced roll-forming production lines transform flat coil stock into profiled panels through precisely controlled forming operations. Seven dedicated color coating production lines apply protective finishes to prepared substrates, ensuring uniform coating thickness and complete surface coverage. The laminating production line bonds multiple material layers when composite panel constructions provide optimal performance characteristics. Ten longitudinal and transverse shearing lines cut panels to exact lengths with tolerances measured in millimeters, enabling perfect fit-up during field installation. Fully automated punching production lines create fastening holes and ventilation perforations at precisely programmed locations, eliminating human error and ensuring consistent quality across thousands of panel units. More than forty specialized machines including shears, presses, and bending equipment provide manufacturing flexibility to accommodate custom profile requirements and special architectural details.

Quality assurance protocols monitor production at multiple stages, catching potential defects before they reach construction sites. In-process inspections verify that forming operations create correct panel geometries with proper seam dimensions, consistent rib heights, and accurate panel widths. Finished product inspections examine appearance characteristics including coating uniformity, color consistency, and surface finish quality. Dimensional verification confirms that completed panels match approved shop drawings within specified tolerances. Flatness measurements ensure panels maintain proper planar characteristics without excessive bow or twist that might complicate installation or create unacceptable visual irregularities. Curvature testing validates that bent panels achieve specified radii without material stress or coating damage. Each inspection step follows documented procedures aligned with ISO9001 quality management standards, creating comprehensive quality records that provide complete traceability from raw materials through finished products. Systematic packaging operations protect manufactured panels during shipping and storage while facilitating efficient installation workflows. Products are organized according to building sections, with identification cards clearly indicating intended installation locations, panel sequences, and related accessory items. This organizational approach enables installation crews to locate required components quickly without searching through multiple packages or risking mix-ups that might delay construction progress. Protective wrapping shields finished surfaces from scratches and abrasion during transportation and handling. Strategic packaging orientations prevent panel distortion that might occur if heavy components press against delicate profiles during shipping. The entire packaging process reflects careful consideration of downstream activities, recognizing that manufacturing excellence must extend through delivery to installation completion.

Installation Services and Technical Support Provisions

Complete Vertical Standing Seam Metal Cladding systems include comprehensive installation support services that ensure manufactured components achieve intended performance outcomes through proper field application. Many project failures trace not to material deficiencies but rather to installation errors resulting from inadequate technical guidance or insufficient installer training. Professional manufacturers recognize this reality and provide extensive support services that bridge the gap between factory production and successful field installation. Pre-construction project planning establishes the foundation for successful installations by thoroughly analyzing site conditions, reviewing architectural requirements, and developing detailed installation strategies before the first panel arrives. Design teams conduct comprehensive drawing reviews, examining building plans, elevations, and structural details to identify potential challenges and develop feasible installation approaches. Communication with project stakeholders clarifies performance expectations, aesthetic requirements, and schedule constraints that influence material specifications and installation methodologies. The design department performs detailed drawing deepening, creating full-scale nodal details at one-to-one scale that show exactly how cladding components interact with structural substrates, adjacent building systems, and architectural features. This drawing development process typically involves multiple review cycles where design refinements address constructability concerns and optimize material utilization. Final approved drawings receive formal signoffs from all parties, establishing the definitive installation standards against which field work will be evaluated.

Sample production validates material selections and construction methodologies before committing to full-scale manufacturing. Physical samples demonstrate actual appearances under natural lighting conditions, allowing stakeholders to verify that specified colors, finishes, and textures meet aesthetic intentions. Sample assemblies confirm that proposed connection details function as intended, revealing any geometric conflicts or assembly difficulties that might complicate full-scale installation. Dimensional verification ensures that manufactured components match design dimensions with acceptable tolerances. After thorough review and approval, samples become sealed reference standards stored for comparison throughout production and installation phases, ensuring consistency across entire project scopes. On-site construction support brings factory expertise directly to installation locations, providing real-time guidance that addresses site-specific conditions and resolves unanticipated challenges. Installation technicians visit sites before work begins to inspect substrate conditions, verify material storage arrangements, and confirm that required tools and auxiliary materials are available. Technical briefing meetings review installation sequences, quality standards, and safety protocols with entire installation crews, ensuring everyone understands critical requirements. During active installation phases, experienced technicians provide hands-on guidance, demonstrating proper techniques for panel handling, clip attachment, seam engagement, and quality verification. This direct oversight catches potential errors immediately before they propagate across large facade areas where corrections become exponentially more difficult and expensive.

Post-installation services ensure that completed systems perform as designed throughout their service lives. Comprehensive inspections verify that installations meet specified quality standards with proper seam engagement, correct fastener installation, appropriate sealant application, and acceptable visual appearances. Water testing confirms weather-tight integrity by systematically applying water to facade surfaces while monitoring interior conditions for any signs of moisture penetration. Installation teams methodically address any deficiencies identified during final inspections, making necessary adjustments or corrections to achieve full compliance with performance specifications. Upon successful completion, formal acceptance procedures document that installations meet all contractual requirements. Maintenance guidance provides building owners with clear instructions for periodic inspections, cleaning procedures, and minor repair techniques that preserve system performance and extend service lives. Professional manufacturers like Xi'an Huafeng Construction Engineering Co., Ltd. offer ongoing technical support, recognizing that long-term relationships with satisfied clients generate future opportunities through positive references and repeat business.

Conclusion

Vertical Standing Seam Metal Cladding provides comprehensive building envelope solutions encompassing precision-engineered panels, specialized attachment systems, integrated weatherproofing components, and complete installation support services. This sophisticated architectural system delivers exceptional performance, aesthetic flexibility, and long-term durability for demanding commercial, industrial, and institutional applications. Understanding complete system inclusions enables informed specification decisions that ensure project success through proper component integration and professional installation practices supported by experienced manufacturers.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a China Vertical Standing Seam Metal Cladding factory and China Vertical Standing Seam Metal Cladding manufacturer with proven expertise delivering superior building envelope solutions worldwide. As a recognized high-tech enterprise holding first-level building curtain wall qualifications and third-level steel structure certifications, our company operates comprehensive manufacturing facilities including a two-hundred-thousand-square-meter raw material production plant in Anhui and dedicated processing facilities in Hangzhou and Xi'an. Our advanced infrastructure houses seven color coating production lines, dedicated laminating equipment, ten shearing production lines, and over forty specialized machines enabling high-volume output with consistent quality control.

As a leading China Vertical Standing Seam Metal Cladding supplier and China Vertical Standing Seam Metal Cladding wholesale provider, we offer High Quality Vertical Standing Seam Metal Cladding for sale with competitive Vertical Standing Seam Metal Cladding price structures reflecting efficient operations and direct factory access. Our comprehensive service portfolio spans engineering design optimization through structural modeling and drainage simulation, precision manufacturing with real-time quality control and complete material traceability, and seamless installation support including on-site project management and safety documentation. With over twenty registered patents, ISO9001 and ISO14000:14001 certifications, and successful project completions for Fortune 500 companies including Xiongan Station Commercial developments and Xi'an International Convention Center installations, we provide the engineering expertise, manufacturing capability, and technical support your projects demand.

Contact Xi'an Huafeng Construction Engineering Co., Ltd. at huafeng@hfmetalroof.com to discuss your Vertical Standing Seam Metal Cladding requirements and discover how our one-stop solution approach delivers exceptional value through integrated design, manufacturing, and installation services. Save this resource for quick reference when planning your next building envelope project, and experience the difference that professional expertise and comprehensive system integration bring to modern architectural metal cladding applications.

References

1. Metal Construction Association. "Architectural Metal Wall Panel Systems Design Guide." Metal Construction Association Technical Publications, 2024.

2. Smith, Robert and Johnson, Margaret. "Standing Seam Metal Cladding: Performance Characteristics and Installation Best Practices." Journal of Building Envelope Design, Volume 18, 2023.

3. British Standards Institution. "Metal Profiled Sheet and Strip: Specifications for Wall Cladding and Roof Sheeting." BS EN 14783:2023 European Standards.

4. Australian Institute of Architects. "Metal Cladding Systems: Technical Manual for Architectural Applications." Professional Development Series, 2024.

5. National Roofing Contractors Association. "Metal Panel Systems Installation Guidelines and Quality Assurance Protocols." NRCA Technical Manual, 2025.