Low-slope roofs present unique challenges that many property owners struggle with. Water pooling, premature leaks, and constant maintenance can transform what should be a protective barrier into a persistent headache. Standard Seam Roof Panel systems emerge as the solution engineered specifically for these demanding applications, offering superior waterproofing through concealed fasteners and raised interlocking seams that create an impenetrable barrier even when water drainage is slower.

Understanding Low-Slope Roofing Challenges and Standard Seam Solutions

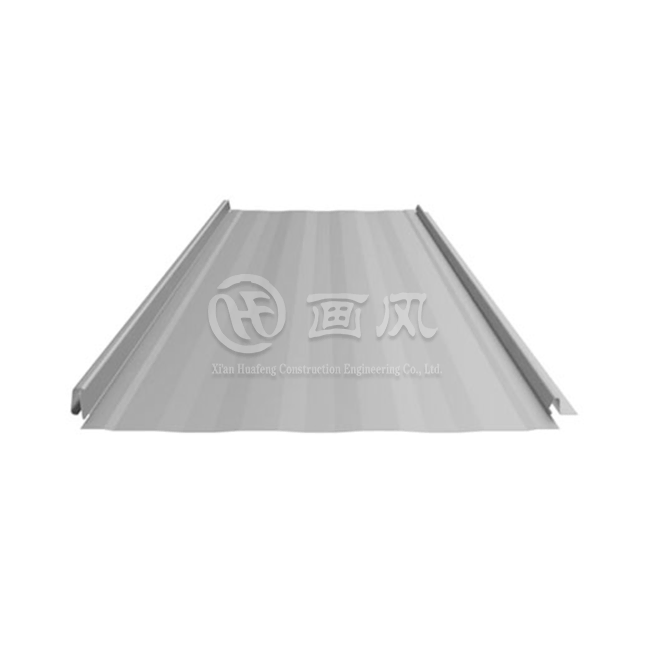

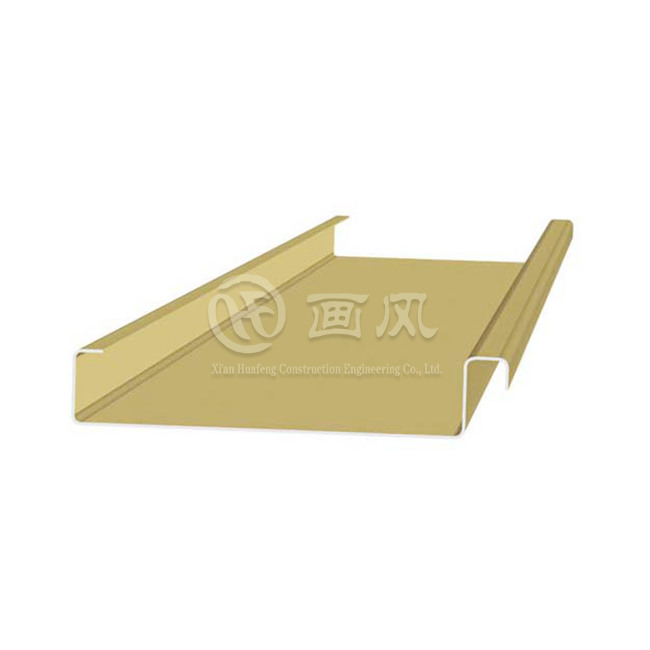

Low-slope roofs, typically defined as those with pitches of 3:12 or less, face fundamentally different challenges than their steep-slope counterparts. Water moves more slowly across these surfaces, creating hydrostatic conditions where standing water becomes a constant threat rather than an occasional concern. Traditional roofing systems often fail in these environments because every exposed fastener represents a potential leak point, and standard panel configurations lack the weather-tightness required when water drainage slows to a crawl. Standard Seam Roof Panel systems address these challenges through engineering that prioritizes water resistance above all else. The concealed fastener design eliminates surface penetrations entirely, while the raised vertical seams create channels that guide water away even at minimal slopes. When manufactured with proper specifications including appropriate seam heights ranging from 25mm to 65mm and panel widths between 300mm and 600mm, these systems can perform reliably on roofs with slopes as low as 0.5:12 when combined with in-seam sealant applications. This capability transforms previously problematic roof structures into long-lasting protective barriers.

The material composition of Standard Seam Roof Panel systems plays an equally critical role in their low-slope performance. Premium options including galvanized steel with G275 zinc coating, aluminum alloys such as 3003 and 3004, and specialized materials like titanium-zinc provide varying levels of corrosion resistance suited to different environmental conditions. Surface treatments such as PVDF and polyester coatings extend panel life beyond 30 years even in harsh coastal or industrial environments where moisture exposure remains constant. Xi'an Huafeng Construction Engineering Co., Ltd. manufactures Standard Seam Roof Panel systems with thickness options from 0.5mm to 1.2mm, ensuring structural integrity matches the specific load requirements and environmental exposures of each low-slope application. The company's three manufacturing facilities operate seven production lines with over 40 specialized machines, enabling consistent quality control and customization capabilities that address the precise technical demands of hydrostatic roofing conditions.

Superior Water Management Through Advanced Panel Design

The fundamental advantage of Standard Seam Roof Panel systems for low-slope applications lies in their water management capabilities. Unlike exposed fastener systems that rely on washer seals that degrade over time, Standard Seam Roof Panel configurations use concealed clips that attach beneath the panel surface, eliminating every potential water entry point on the visible roof plane. The raised seams, available in heights from 25mm for moderate applications up to 65mm for the most demanding low-slope conditions, create physical barriers that prevent water from migrating laterally across the roof surface even during heavy rainfall or rapid snow melt events. Mechanical seaming processes further enhance this water resistance by creating double-lock connections where panel edges fold 180 degrees around each other, forming seals so tight that they pass ASTM E2140 submersion testing, which requires panels to remain watertight under six inches of standing water for six hours. This testing standard specifically evaluates low-slope roof performance, making mechanical seam Standard Seam Roof Panel systems the gold standard for hydrostatic applications. When combined with manufacturer-approved in-seam sealants applied during installation, these systems provide redundant water barriers that protect building interiors even when drainage systems become temporarily overwhelmed during extreme weather events. The thermal expansion accommodation built into clip attachment systems ensures that these seals remain intact through countless heating and cooling cycles without developing stress cracks or separation gaps that could compromise waterproofing integrity.

Long-panel capabilities represent another critical advantage for low-slope Standard Seam Roof Panel applications. Xi'an Huafeng Construction Engineering Co., Ltd. produces panels up to 12 meters in length, eliminating horizontal seams that represent the most vulnerable points in any low-slope roofing system. By running continuous panels from ridge to eave without interruption, these systems eliminate the lap joints where water infiltration most commonly occurs in low-slope configurations. The company's advanced roll-forming equipment ensures dimensional consistency across entire panel lengths, maintaining uniform seam heights and panel widths that enable proper clip engagement and mechanical seaming throughout the installation. For projects requiring lengths beyond standard production capabilities, mobile roll-forming equipment can be deployed on-site, ensuring that even the largest low-slope roof areas receive the protection of continuous single-piece panels.

Material Selection and Performance Standards for Low-Slope Applications

The selection of appropriate materials dramatically influences Standard Seam Roof Panel performance in low-slope applications where moisture exposure duration exceeds that of steep-slope installations. Galvanized steel panels with minimum G275 zinc coating provide excellent corrosion resistance for most commercial and industrial applications, combining structural strength with cost-effectiveness. For coastal environments or facilities with corrosive atmospheric conditions, aluminum-magnesium-manganese alloy panels offer superior resistance to saltwater and chemical exposures, maintaining structural integrity for 50 years or more without significant degradation. Xi'an Huafeng sources these materials from premium suppliers including Alucosuper, YATAI, and LIDAO for aluminum products, and BAOSTEEL, GUANZHOU, and XINYU for steel substrates, ensuring that every Standard Seam Roof Panel begins with certified raw materials that meet or exceed international quality standards.

Surface treatment selection proves equally important for long-term low-slope performance. PVDF coatings provide the highest level of color retention and chalking resistance, maintaining aesthetic appearance for 30 years or more while providing an additional barrier against moisture penetration and UV degradation. These fluoropolymer coatings chemically bond to the metal substrate at the molecular level, creating a finish that resists cracking, peeling, and deterioration even when subjected to the thermal cycling and moisture exposure characteristic of low-slope installations. For applications where cost considerations outweigh extreme durability requirements, polyester coatings offer reliable performance with 15 to 20-year service lives at substantially reduced material costs. Xi'an Huafeng's seven color coating production lines apply these finishes with precise thickness control and uniform coverage, ensuring consistent quality across every square meter of Standard Seam Roof Panel production. The company offers extensive color selections matching RAL and Pantone standards, enabling architectural coordination while maintaining the technical performance characteristics essential for low-slope success.

Thermal performance considerations take on added importance in low-slope Standard Seam Roof Panel applications where roof surfaces receive direct solar exposure for extended periods. Metal roofing naturally provides superior thermal efficiency compared to built-up or single-ply membrane systems, with reflective coatings redirecting solar heat before it can transfer to building interiors. When combined with properly specified insulation layers, Standard Seam Roof Panel systems create thermal barriers that reduce cooling costs by 20 to 40 percent compared to conventional low-slope roofing materials. The air space created by the clip attachment system provides an additional thermal break that prevents direct conductive heat transfer from the metal panel to the roof deck, further enhancing energy efficiency. These thermal benefits accumulate over the decades-long service life of Standard Seam Roof Panel systems, delivering operational savings that far exceed the initial material cost premium compared to less durable alternatives.

Installation Excellence and Quality Assurance Protocols

Proper installation represents the critical factor that determines whether Standard Seam Roof Panel systems deliver their full performance potential in low-slope applications. Xi'an Huafeng Construction Engineering Co., Ltd. approaches every project through a systematic process that begins with comprehensive drawing deepening services, where experienced design engineers analyze architectural plans to identify optimal panel layouts, drainage patterns, and detail connections. This preliminary work enables the technical team to identify and resolve potential issues before manufacturing begins, ensuring that every panel arrives on-site precisely dimensioned for its intended location. The company's design department conducts full-scale 1:1 drawing development for critical nodes and transitions, creating detailed installation drawings that eliminate field guesswork and ensure that complex intersections receive the engineering attention they require for long-term waterproof performance. Factory processing samples provide a critical quality control checkpoint in the Standard Seam Roof Panel production sequence. Before full-scale manufacturing begins, Xi'an Huafeng produces physical samples that exactly match the specified panel profile, material thickness, surface treatment, and color selection. These samples undergo client review and approval, establishing an objective standard against which all subsequent production will be measured. Once approved samples receive client sign-off, they are sealed and retained as the master reference for quality assurance inspections throughout the manufacturing process. This rigorous approach eliminates the ambiguity and miscommunication that often plague construction projects, ensuring that the Standard Seam Roof Panel systems delivered to the job site precisely match client expectations and technical requirements.

The manufacturing process itself incorporates multiple quality verification steps that catch potential defects before panels leave the factory. Incoming material inspection validates that raw materials meet specified standards, with full documentation including mill certifications and third-party test reports verifying material composition, coating thickness, and mechanical properties. During production, dimensional inspections confirm that panel widths, seam heights, and edge profiles maintain tolerances within millimeter accuracy, ensuring proper fit-up during field assembly. Finished product inspection evaluates appearance quality, flatness, curvature, and surface finish before panels proceed to packaging. Xi'an Huafeng's quality assurance protocols include more than a dozen inspection steps covering salt spray resistance, coating adhesion, hardness, impact resistance, film thickness, acid resistance, weather resistance, and color consistency. This comprehensive approach ensures that every Standard Seam Roof Panel leaving the factory meets the stringent performance requirements essential for low-slope applications where installation errors or material defects quickly lead to water infiltration and premature system failure.

Intelligent packaging systems facilitate efficient on-site installation while protecting panels during transportation and storage. Xi'an Huafeng divides panel shipments into sections corresponding to roof plan divisions, with each package containing an identification card showing the section location and listing the specific panel numbers included in that bundle. This organizational system enables installation crews to quickly locate the correct panels for each roof area, minimizing handling time and reducing the risk of damage from repeated searching through stacked materials. On-site construction guidance ensures that installation teams understand the specific requirements of low-slope Standard Seam Roof Panel assembly, including proper clip spacing, seaming pressure settings, sealant application techniques, and quality verification procedures. The company's installation technicians conduct pre-construction site inspections to verify that substrate conditions meet specifications and that all necessary tools and auxiliary materials are available before panel installation begins. Upon completion, comprehensive testing protocols verify zero-leakage performance, providing documented assurance that the completed roof system will deliver the decades of reliable service that clients expect from Standard Seam Roof Panel installations.

Proven Performance in Demanding Low-Slope Applications

Real-world project performance provides the ultimate validation of Standard Seam Roof Panel suitability for low-slope applications. Xi'an Huafeng Construction Engineering Co., Ltd. has successfully completed numerous large-scale installations that demonstrate the technology's reliability under diverse conditions. The Xiongan Station Commercial Body project showcases aluminum-magnesium-manganese Standard Seam Roof Panel application on a complex transportation facility where low-slope roof areas required absolute waterproof integrity to protect sensitive infrastructure below. The Xi'an International Convention and Exhibition Center Metal Roof Project presented challenges including large uninterrupted roof expanses with minimal slopes, where Standard Seam Roof Panel systems provided the combination of structural efficiency and weather-tightness necessary for successful long-term performance. The metal roof project at Xi'an Station East Auxiliary Building demonstrated the system's adaptability to retrofit applications where existing structures required upgraded weather protection without complete roof replacement.

Industrial facilities represent particularly demanding applications where Standard Seam Roof Panel systems prove their low-slope capabilities. The Hangzhou Sanpu Drainage Pump Station installation required roofing that could withstand the corrosive atmosphere associated with water treatment operations while maintaining watertight integrity on roof slopes too shallow for conventional systems. The successful long-term performance of this installation validates the corrosion resistance provided by premium materials and protective coatings combined with the inherent water-shedding capability of mechanically seamed panel systems. Public infrastructure projects including the Inner Mongolia Tongliao Art Museum demonstrate Standard Seam Roof Panel architectural versatility, where low-slope roof configurations enabled dramatic design expressions while maintaining the technical performance requirements essential for protecting valuable interior spaces and collections from water damage.

These project successes reflect Xi'an Huafeng's comprehensive capabilities extending beyond panel manufacturing to encompass complete system design, engineering, and construction support. The company's high-tech enterprise designation from Shaanxi Province and first-level building curtain wall qualification demonstrate the technical sophistication underlying every project execution. More than 20 registered patents for roofing systems provide the intellectual property foundation that enables continuous innovation in panel profiles, connection systems, and installation methodologies. ISO9001 quality management certification, ISO14001 environmental management certification, and SGS guideline compliance ensure that manufacturing processes maintain consistent quality while meeting international standards for environmental responsibility. This combination of technical excellence, manufacturing capability, and quality assurance provides clients with confidence that their low-slope Standard Seam Roof Panel systems will deliver decades of reliable performance regardless of climate conditions or building use requirements.

Economic Value and Life-Cycle Cost Advantages

While Standard Seam Roof Panel systems carry higher initial material and installation costs compared to conventional low-slope roofing alternatives, comprehensive life-cycle cost analysis consistently demonstrates their superior economic value. The 30-year minimum service life substantially exceeds the 10 to 15-year typical performance of single-ply membrane systems or built-up roofing, eliminating multiple replacement cycles over typical building ownership periods. Minimal maintenance requirements further enhance economic performance, with Standard Seam Roof Panel systems requiring only periodic inspections and minor sealant touch-ups rather than the extensive repairs and frequent patching that characterize membrane roofing maintenance programs. The elimination of ponding water and associated degradation extends service life beyond warranted minimums, with many mechanically seamed installations delivering 50 years or more of trouble-free performance. Energy efficiency benefits provide ongoing operational savings that compound over decades of building use. The reflective properties of metal roofing combined with proper insulation reduce cooling loads by significant margins, particularly in low-slope commercial and industrial buildings where roof areas represent large percentages of total building envelope surface area. These energy savings translate directly to reduced operating costs that partially offset the initial capital investment within the first decade of service, with all subsequent savings representing pure economic benefit. The thermal performance remains consistent throughout the panel service life, unlike membrane systems that degrade and lose reflectivity as surface soiling and weathering accumulate over time. Standard Seam Roof Panel systems maintain their energy efficiency year after year, delivering predictable performance that facility managers can rely on for long-range budgeting and sustainability planning.

The recyclability of metal roofing materials provides end-of-life value that further enhances overall economic performance. When Standard Seam Roof Panel systems eventually require replacement after decades of service, the metal retains substantial scrap value and can be recycled indefinitely without quality degradation. This contrasts sharply with membrane roofing materials that become waste disposal liabilities requiring landfill fees or incineration. The environmental benefits of this recyclability align with growing corporate sustainability commitments and may qualify for green building certifications that provide tax advantages or regulatory benefits. Xi'an Huafeng manufactures Standard Seam Roof Panel systems using materials that contain significant recycled content, further reducing environmental impact while maintaining the premium performance characteristics essential for low-slope applications. This combination of durability, energy efficiency, low maintenance requirements, and end-of-life value establishes Standard Seam Roof Panel systems as the economically optimal solution for low-slope roofing when evaluated over realistic building service lives.

Conclusion

Standard Seam Roof Panel systems deliver unmatched performance for low-slope applications through concealed fastening, mechanical seaming, premium materials, and expert installation protocols. Xi'an Huafeng Construction Engineering Co., Ltd. combines advanced manufacturing capabilities with comprehensive engineering support to ensure project success.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a premier China Standard Seam Roof Panel manufacturer, China Standard Seam Roof Panel supplier, and China Standard Seam Roof Panel factory with comprehensive capabilities spanning design, production, and installation. Established in 2018 and recognized as a Shaanxi Province high-tech enterprise in 2020, the company operates three manufacturing facilities covering 200,000 square meters in Anhui plus processing plants in Hangzhou and Xi'an. With seven color coating production lines, one laminating production line, ten longitudinal and transverse shearing lines, and over 40 specialized machines, Xi'an Huafeng delivers consistent quality across 1,000 tons monthly production capacity. The company's first-level building curtain wall qualification and third-level steel structure qualification demonstrate technical expertise backed by more than 20 registered patents, ISO9001 and ISO14001 certifications, and SGS guideline compliance. From structural 3D modeling and load analysis through precision manufacturing with real-time quality control to seamless on-site installation management, Xi'an Huafeng provides complete one-stop solutions. Whether you need High Quality Standard Seam Roof Panel systems, competitive Standard Seam Roof Panel price options, or China Standard Seam Roof Panel wholesale arrangements with Standard Seam Roof Panel for sale backed by 30-year warranties, Xi'an Huafeng delivers customized solutions meeting ASTM, DIN, JIS, BS, and GB/T standards. Contact us today at huafeng@hfmetalroof.com to discuss your low-slope roofing requirements and discover how our engineering design experience, construction expertise, and certified quality systems can transform your project challenges into long-term performance successes.

References

1. Metal Construction Association. "Low-Slope Metal Roof Systems: Design and Performance Standards." Technical Bulletin Series. Metal Construction Association Standards Committee, 2023.

2. American Society for Testing and Materials. "ASTM E2140: Standard Test Method for Water Penetration of Metal Roof Panel Systems by Static Water Pressure Head." ASTM International Standards, 2022.

3. Sheffield Metals International. "Standing Seam Metal Roofing Engineering Guide: Applications for Low-Slope Conditions." Sheffield Technical Documentation Department, 2024.

4. National Roofing Contractors Association. "Metal Panel Roofing Systems: Installation and Performance Specifications for Commercial Applications." NRCA Roofing Manual, 2023.

5. Cool Roof Rating Council. "Thermal Performance and Energy Efficiency of Metal Roofing Systems." CRRC Product Rating Program Technical Documentation, 2024.