Every year, thousands of contractors and building owners face costly project delays, leaking roofs, and quality disputes because they chose the wrong Standard Seam Roof Panel supplier. When your project's timeline, budget, and reputation are on the line, selecting a manufacturer with proven capabilities and reliable quality standards becomes critical. This comprehensive guide reveals the essential criteria that distinguish world-class Standard Seam Roof Panel suppliers from mediocre ones, helping you make informed decisions that protect your investment and ensure long-term performance.

Understanding Standard Seam Roof Panel Quality Standards and Specifications

Selecting the right Standard Seam Roof Panel supplier begins with understanding what defines quality in metal roofing systems. Standard seam roofing, also known as standing seam roofing, represents a premium metal roofing solution characterized by vertical panels with raised seams that create a watertight barrier. The quality of these panels directly impacts your project's durability, weather resistance, and lifecycle costs. When evaluating suppliers, the first consideration must be their adherence to international quality standards and their ability to provide comprehensive technical specifications. Quality Standard Seam Roof Panel manufacturers comply with multiple international standards including ASTM A792/A755 for corrosion resistance, ISO 9001 for quality management systems, and EN 10169 for European projects. These certifications are not merely decorative achievements but represent systematic quality control processes that protect your investment. A reputable supplier should readily provide third-party test reports documenting critical performance metrics such as wind uplift resistance per ASTM D3161, fire ratings achieving Class A certification, and coating thickness verification using XRF analyzers to confirm minimum AZ50 standards for Galvalume-coated materials.

Material Composition and Surface Treatment Options

The substrate material and surface treatment significantly determine the Standard Seam Roof Panel's performance and longevity. Professional suppliers offer multiple material options including galvanized steel, aluminum-magnesium-manganese alloys, stainless steel grades 304 and 316, titanium-zinc, and copper, each suited for specific environmental conditions and architectural requirements. The thickness range typically spans from 0.5mm to 1.2mm, with 24-gauge steel being the industry standard for commercial applications requiring 40-plus-year service life expectations. Surface treatment technologies protect the metal substrate from corrosion and UV degradation while providing aesthetic appeal. PVDF (Polyvinylidene Fluoride) coatings offer superior weather resistance and color retention for 30-year warranty periods, making them ideal for high-visibility architectural projects. PE (Polyester) coatings provide cost-effective protection for industrial applications with moderate environmental exposure. Premium suppliers maintain relationships with leading coating manufacturers and can provide detailed technical data sheets documenting adhesion strength, impact resistance, salt spray test results, and accelerated weathering performance that validate their claimed service life warranties.

Specification Ranges and Customization Capabilities

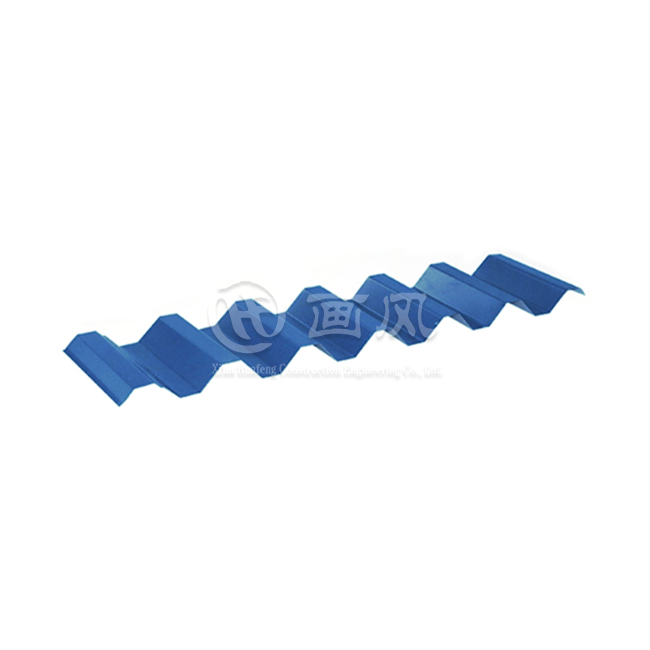

Standard Seam Roof Panel specifications vary significantly based on application requirements and architectural design preferences. Panel specifications typically include seam heights ranging from 25mm to 65mm, with common profiles designated as 25-330/400/430, 32-410, 45-400, and 65-400/430. The seam height selection influences both aesthetic appearance and structural performance, with taller seams providing enhanced water drainage capacity and greater resistance to wind uplift forces. Panel widths generally range from 300mm to 600mm, with customizable lengths up to 12 meters to minimize horizontal joints that could compromise weathertightness. A supplier's customization capabilities reveal their manufacturing sophistication and commitment to meeting specific project requirements. Leading manufacturers operate advanced roll-forming production lines capable of producing panels in precise custom lengths, eliminating field cutting and ensuring optimal fit during installation. They should offer comprehensive color selections spanning RAL and Pantone systems, with the ability to match specific architectural color requirements through custom coating formulations. The best Standard Seam Roof Panel suppliers also provide engineering support for complex geometric requirements including curved panels, transitions between different roof slopes, and integration with solar panel mounting systems.

Evaluating Manufacturing Capabilities and Production Infrastructure

Manufacturing capability assessment separates reliable Standard Seam Roof Panel suppliers from opportunistic traders who lack actual production assets. When sourcing panels for critical projects, understanding a supplier's production infrastructure, quality control systems, and supply chain integration becomes essential for ensuring consistent product quality and reliable delivery schedules. Comprehensive evaluation of manufacturing capabilities protects against common sourcing problems including specification inconsistencies, delayed deliveries, and quality variations between production batches.

Factory Scale and Equipment Technology Assessment

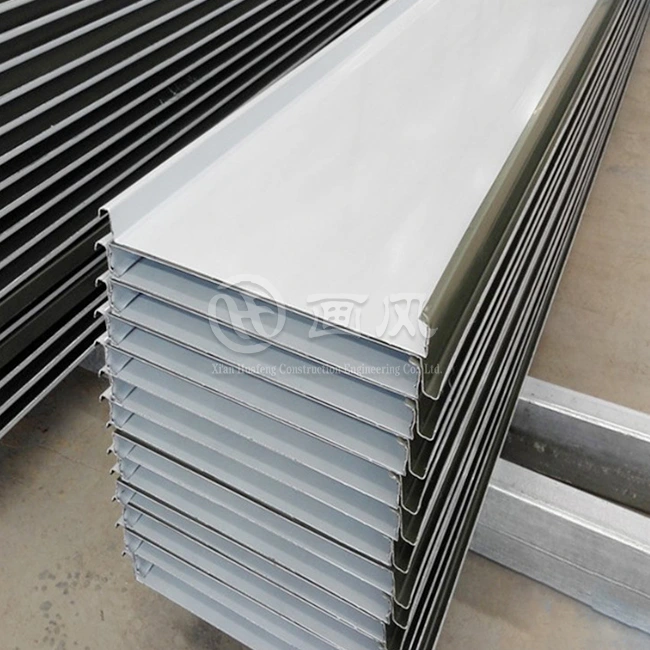

Production capacity and equipment sophistication directly impact a supplier's ability to handle large-scale projects while maintaining quality consistency. Leading Standard Seam Roof Panel manufacturers operate multiple production facilities with combined monthly capacities exceeding 1000 tons, supported by advanced roll-forming systems, automated punching lines, and precision cutting equipment. Xi'an Huafeng Construction Engineering exemplifies this manufacturing excellence with three factories, seven color coating production lines, one laminating production line, and ten longitudinal and transverse shearing production lines, plus more than forty specialized machines including shearing machines, presses, and bending equipment covering 200,000 square meters in Anhui province. The technological sophistication of production equipment determines dimensional accuracy, surface finish quality, and production efficiency. Modern CNC-controlled roll-forming systems ensure consistent seam height and panel width tolerances within ±0.5mm, critical for proper panel interlocking and weather seal performance. Automated punching systems create fastening holes with precise spacing and clean edges that prevent stress concentration points and premature panel failure. Quality-focused suppliers invest in real-time monitoring systems that track coating thickness, panel dimensions, and surface defects throughout production, enabling immediate corrective actions that maintain specification compliance.

Quality Control Systems and Material Traceability

Comprehensive quality control distinguishes professional Standard Seam Roof Panel manufacturers from volume-oriented producers. Effective quality systems begin with rigorous incoming material inspection protocols that verify raw material specifications before production commencement. Suppliers should require material certifications and third-party testing reports from their steel coil, aluminum sheet, and coating suppliers, conducting verification testing using methods including product appearance inspection, dimensional measurement, salt spray testing, adhesion evaluation, hardness testing, impact resistance, film thickness measurement, acid resistance, weather resistance assessment, and color difference analysis. Production quality control extends beyond basic inspections to include comprehensive process monitoring and finished product verification. Leading manufacturers implement in-process quality checkpoints that verify panel dimensions, seam formation quality, coating integrity, and surface finish at multiple production stages. Finished product inspection protocols should include flatness measurement, curvature verification, seam lock functionality testing, and visual inspection for surface defects before packaging. The best suppliers maintain complete material traceability systems that link each panel batch to specific raw material lots and production dates, enabling rapid problem resolution and warranty claim processing.

Supply Chain Integration and Material Sourcing Strategy

Material sourcing strategy significantly impacts both product quality and supply reliability. Premium Standard Seam Roof Panel suppliers maintain strategic partnerships with internationally recognized material manufacturers rather than sourcing from commodity spot markets. For example, aluminum should come from established brands like Alucosuper, YATAI, or LIDAO in grades 3003, 3004, or 5052. Steel substrates should originate from major producers like BAOSTEEL, GUANZHOU, or XINYU, offering cold rolled sheet, galvanized sheet, galvalume sheet, and color coated sheet options. Stainless steel components should be sourced from quality manufacturers like Baosteel or Tsingshan in grades 316 or 304. This strategic approach to material sourcing provides multiple advantages beyond quality assurance. Established supplier relationships enable better pricing stability during raw material market fluctuations, protecting your project from unexpected cost escalations. Long-term partnerships facilitate better technical support, allowing manufacturers to optimize coating formulations and substrate specifications for specific environmental conditions or performance requirements. Integrated supply chains also reduce lead times by maintaining strategic raw material inventories, enabling faster response to urgent project requirements while maintaining consistent product quality.

Assessing Technical Support and Engineering Services

Technical support capabilities distinguish full-service Standard Seam Roof Panel suppliers from simple product vendors. Comprehensive engineering support adds significant value to complex roofing projects by optimizing system design, preventing installation problems, and ensuring long-term performance. When evaluating potential suppliers, their ability to provide custom design services, installation guidance, and ongoing technical consultation should weigh heavily in the selection decision, particularly for projects involving challenging architectural features, stringent performance requirements, or integration with other building systems.

Design Optimization and Engineering Calculation Services

Professional Standard Seam Roof Panel suppliers offer comprehensive design support that optimizes system performance while controlling project costs. This begins with detailed structural analysis including 3D modeling capabilities that visualize panel layout, seam orientation, and transition details before manufacturing commencement. Advanced suppliers provide load analysis services that verify panel profiles and attachment systems can withstand specified wind uplift forces, snow loads, and seismic requirements per applicable building codes. Drainage system simulation capabilities ensure proper water management by analyzing roof slopes, valley configurations, and outlet locations to prevent ponding and premature system failure. Material specification advisory services help clients select optimal substrate materials, coating systems, and panel profiles based on specific environmental conditions, architectural requirements, and budget constraints. This consultative approach considers factors including coastal salt exposure, industrial pollution levels, temperature extremes, UV radiation intensity, and aesthetic design objectives. Suppliers should provide detailed project drawing deepening services that analyze architectural engineering drawings, propose feasible alternatives for different roof structures, and develop detailed node drawings showing panel connections, penetrations, edge conditions, and transition details. This engineering investment prevents costly field modifications and ensures proper system performance.

Installation Support and Technical Training Programs

Proper installation critically impacts Standard Seam Roof Panel system performance, making installation support a valuable supplier service. Leading manufacturers provide comprehensive installation guidance beginning with on-site construction consultation that reviews actual site conditions, confirms construction sequencing, and establishes material storage and processing areas. They should supply detailed installation drawings with product identification cards showing sectioned floor plans and numbered panel lists that facilitate organized material handling and prevent installation errors. Technical training programs offered by quality-focused suppliers ensure installation teams understand proper procedures for panel handling, seam engagement, fastener installation, and weather seal application. On-site technical supervision during critical installation phases provides real-time guidance for complex details including curved sections, valley formations, ridge caps, and penetration flashing. Post-installation testing protocols should include comprehensive leak testing using water spray or pressure testing methods to verify system weather-tightness before project acceptance. Suppliers offering these comprehensive support services demonstrate confidence in their products and commitment to successful project outcomes.

Verifying Certifications, Patents, and Industry Recognition

Certifications and intellectual property holdings provide objective evidence of a Standard Seam Roof Panel supplier's technical capabilities and market position. When selecting manufacturers for important projects, verification of quality certifications, patent portfolios, and industry recognition helps identify suppliers with genuine expertise and innovation capacity. These credentials also provide assurance of regulatory compliance and liability protection that become important considerations for projects requiring performance warranties or facing stringent building code requirements.

Essential Quality and Environmental Certifications

ISO 9001 certification represents the foundation quality management standard that all serious Standard Seam Roof Panel manufacturers should maintain. This certification verifies that suppliers operate documented quality management systems including process controls, measurement procedures, corrective action protocols, and continuous improvement mechanisms. ISO 14001 environmental management certification demonstrates commitment to sustainable manufacturing practices including waste reduction, energy efficiency, and pollution prevention that increasingly matter to environmentally conscious project owners and green building certification programs like LEED. Product-specific certifications validate performance claims and regulatory compliance. SGS certification provides independent verification of material properties, coating performance, and dimensional accuracy through third-party testing. For international projects, CE marking confirms compliance with European safety, health, and environmental protection standards. Fire resistance certifications documenting Class A ratings verify that Standard Seam Roof Panel systems meet the highest fire safety standards, critical for insurance requirements and building code compliance. Weather-tightness warranty programs, often spanning 20 to 30 years, demonstrate manufacturer confidence in their product quality and willingness to stand behind performance claims with financial guarantees.

Patent Portfolio and Innovation Capacity

Patent holdings reveal a supplier's investment in research and development and their capacity for innovation in Standard Seam Roof Panel technology. Manufacturers holding more than 20 registered patents for roofing systems, connection details, installation tools, and manufacturing processes demonstrate ongoing commitment to technical advancement rather than simple commodity production. Patent portfolios covering seam locking mechanisms, thermal expansion accommodation systems, fastening clip designs, and panel profile geometries indicate sophisticated engineering capabilities that translate into superior product performance and easier installation procedures. Computer software certificates for design optimization tools, structural analysis programs, and manufacturing control systems further demonstrate technical sophistication. These digital capabilities enable precise customization of panel specifications to meet specific project requirements while ensuring manufacturing accuracy and quality consistency. Trademark registrations protecting product names and brand identities indicate established market presence and commitment to brand reputation protection through consistent quality delivery. When evaluating Standard Seam Roof Panel suppliers, those investing in intellectual property development typically offer more innovative solutions and superior technical support compared to manufacturers simply copying existing designs.

Comparing Pricing Structure, Lead Times, and Commercial Terms

Commercial terms significantly impact project economics and risk management, making thorough evaluation of pricing structures, delivery capabilities, and contractual conditions essential when selecting Standard Seam Roof Panel suppliers. While unit pricing obviously matters, comprehensive cost analysis must include factors like minimum order quantities, payment terms, warranty provisions, and technical support inclusions that substantially affect total project costs and risk exposure. Understanding these commercial dimensions helps identify suppliers offering genuine value rather than simply the lowest quoted prices.

Transparent Pricing Models and Cost Components

Standard Seam Roof Panel pricing varies based on material selection, panel specifications, coating systems, order quantities, and customization requirements. Premium materials like aluminum-magnesium-manganese alloys, titanium-zinc, or stainless steel command higher prices than standard galvanized steel, reflecting their superior corrosion resistance and extended service life. PVDF coating systems cost more than polyester coatings but deliver better color retention and weather resistance justifying their premium for high-visibility architectural applications. Understanding these cost drivers enables informed value comparisons between supplier quotations rather than simple price-per-square-meter comparisons. Minimum order quantities significantly impact unit economics, with typical thresholds around 500 square meters or one ton for custom specifications. Suppliers offering lower minimums provide flexibility for smaller projects or sampling requirements but may charge premium pricing to offset setup costs. Bulk order discounts reward larger commitments, with meaningful price reductions typically available for quantities exceeding 5000 square meters or monthly supply contracts. The best pricing structures transparently itemize costs for base panels, accessories like fastening clips and sealants, custom colors, special packaging requirements, and engineering services, enabling accurate project budgeting and preventing unexpected cost additions during order processing.

Delivery Capabilities and Lead Time Management

Lead time performance directly impacts project scheduling and carrying costs for construction projects. Standard Seam Roof Panel delivery timeframes typically range from 15 to 30 days depending on specification complexity, order quantity, and production queue depth. Suppliers maintaining strategic raw material inventories and flexible production scheduling can offer faster turnaround for standard specifications while custom profiles requiring special tooling or unique coating formulations may require extended lead times. On-time delivery rates exceeding 90% indicate reliable supply chain management and production planning capabilities that minimize project delays. Production capacity matters significantly for large projects or those requiring accelerated delivery schedules. Manufacturers like Xi'an Huafeng Construction Engineering with monthly capacity exceeding 1000 tons across multiple production facilities can accommodate substantial order volumes without compromising quality or delivery commitments. Geographic distribution of manufacturing facilities also impacts delivery logistics, with coastal locations facilitating international shipping while inland facilities may offer advantages for domestic market service. Packaging methods affect transportation safety and material handling efficiency, with suppliers using secure packaging methods and working with trusted logistics partners providing better protection against transit damage and more reliable delivery execution.

Warranty Terms and After-Sales Support Provisions

Warranty provisions reflect manufacturer confidence in product quality and willingness to stand behind performance claims. Premium Standard Seam Roof Panel systems should include comprehensive warranties spanning 30 years or more, covering both material defects and performance characteristics like coating adhesion, color retention, and weather-tightness. Warranty terms should clearly specify coverage scope, exclusions for improper installation or maintenance, and claim procedures that provide practical recourse if problems arise. Weather-tightness warranties offering 20-year leak-free guarantees demonstrate particular confidence in system design and manufacturing quality. After-sales support capabilities distinguish suppliers committed to long-term customer relationships from transaction-oriented vendors. Quality-focused manufacturers provide regular maintenance guidance helping building owners optimize system performance and maximize service life through proper cleaning procedures, fastener inspection protocols, and coating maintenance recommendations. They should offer readily accessible technical support for addressing field problems, warranty claim processing, and questions about system modifications or repairs. Suppliers maintaining service networks with trained installation consultants and technical representatives provide valuable resources for troubleshooting problems and ensuring proper system performance throughout the warranty period.

Conclusion

Choosing the best Standard Seam Roof Panel supplier requires comprehensive evaluation of manufacturing capabilities, quality systems, technical support, certifications, and commercial terms that extend far beyond simple price comparisons. Successful supplier selection balances immediate project requirements with long-term performance expectations, risk management considerations, and total lifecycle costs. By systematically assessing suppliers against the criteria outlined in this guide, you can identify manufacturing partners capable of delivering quality products, reliable service, and ongoing support that protect your investment and ensure project success.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a China Standard Seam Roof Panel factory, China Standard Seam Roof Panel supplier, and China Standard Seam Roof Panel manufacturer offering comprehensive metal roofing solutions. Established in 2018 in Shaanxi Province and recognized as a high-tech enterprise in 2020, we hold first-level building curtain wall qualifications and third-level building steel structure qualifications. Our production infrastructure spans a 200,000 square meter raw material plant in Anhui plus two processing facilities in Hangzhou and Xi'an, operating seven color coating lines, one laminating line, ten shearing lines, and more than forty specialized machines ensuring 1000-ton monthly capacity.

Our Standard Seam Roof Panel for sale includes specifications 25-330/400/430, 32-410, 45-400, and 65-400/430 with thickness range 0.5-1.2mm, PVDF/PE surface treatments, and extensive RAL/Pantone color options meeting ASTM, DIN, JIS, BS, and GB/T standards. We maintain strategic material sourcing partnerships with premium brands including Alucosuper, YATAI, LIDAO for aluminum, BAOSTEEL, GUANZHOU, XINYU for steel, and Baosteel, Tsingshan for stainless steel. With more than 20 registered patents and ISO9001, ISO14001, SGS certifications, we deliver High Quality Standard Seam Roof Panel backed by 30-year warranties and competitive Standard Seam Roof Panel price. Our one-stop service encompasses custom engineering design with 3D modeling, precision manufacturing with real-time quality control, and seamless installation with on-site technical support for projects including Xiongan Station, Xi'an International Convention Center, and Inner Mongolia Tongliao Art Museum. China Standard Seam Roof Panel wholesale opportunities available with 500 square meter minimum orders and 15-20 day delivery. Contact our team at huafeng@hfmetalroof.com to discuss your project requirements and discover how our engineering expertise, manufacturing excellence, and comprehensive service support can deliver superior roofing solutions for your next project.

References

1. Metal Construction Association. "Guidelines for Specification and Installation of Architectural Standing Seam Metal Roof Systems." Technical Bulletin Series, 2024.

2. Zhang, W., Chen, L., and Wang, H. "Performance Evaluation of Metal Roofing Systems in Commercial Applications: A Comparative Study of Standing Seam Technologies." Journal of Building Construction and Planning Research, Volume 11, 2023.

3. National Roofing Contractors Association. "The NRCA Metal Panel and SPF Roof Systems Manual." NRCA Technical Publications, 2024 Edition.

4. American Society for Testing and Materials. "Standard Specification for Steel Sheet, 55% Aluminum-Zinc Alloy-Coated by the Hot-Dip Process." ASTM A792/A792M-23, 2023.

5. Thompson, R. and Martinez, J. "Supplier Selection Criteria for Construction Materials: A Multi-Criteria Decision Analysis Framework." Construction Management and Economics, Volume 42, Issue 3, 2024.