Are you tired of dealing with rotting wood siding, fading vinyl panels, or expensive maintenance costs that drain your renovation budget year after year? Homeowners and contractors seeking aluminum metal siding panels for residential projects in 2026 face a critical decision that will impact their property's appearance, durability, and long-term value for decades to come. This comprehensive guide reveals the best aluminum metal siding panels that combine cutting-edge technology with proven performance, helping you make an informed choice that eliminates common exterior cladding problems while maximizing your investment.

Why Aluminum Metal Siding Panels Dominate Residential Construction in 2026?

The residential construction industry has witnessed a remarkable shift toward aluminum metal siding panels as the preferred exterior cladding solution. Unlike traditional materials that deteriorate over time, aluminum metal siding panels offer unmatched longevity and performance characteristics that make them ideal for modern homebuilding projects. The material's inherent corrosion resistance sets it apart from steel alternatives, particularly in coastal regions where salt air accelerates metal degradation. When aluminum oxidizes, it forms a protective layer of aluminum oxide that actually shields the underlying material from further corrosion, unlike iron oxide rust that continues to expand and flake away, exposing fresh metal to the elements. Residential projects benefit tremendously from the lightweight nature of aluminum metal siding panels, which reduces structural load requirements and simplifies installation processes. The material's flexibility allows for creative architectural designs while maintaining structural integrity across various climate conditions. Modern manufacturing techniques have elevated aluminum metal siding panels to new heights of quality, with advanced coating systems like PE, HDP, and PVDF providing exceptional weather resistance and color retention that outperforms conventional siding materials. These technological improvements ensure that aluminum metal siding panels maintain their aesthetic appeal for thirty years or more, backed by comprehensive manufacturer warranties that give property owners peace of mind.

Superior Performance Characteristics of Modern Aluminum Metal Siding Panels

Today's aluminum metal siding panels incorporate sophisticated engineering that addresses every concern raised by previous generations of exterior cladding materials. The material composition typically utilizes aluminum alloys such as AA3003, AA3004, or AA5052, each formulated to deliver specific performance characteristics suited to residential applications. These alloys provide the perfect balance between formability, strength, and corrosion resistance, ensuring that aluminum metal siding panels can withstand the rigors of installation and decades of environmental exposure without compromising structural integrity or visual appeal. The gauge thickness of aluminum metal siding panels plays a crucial role in determining their durability and acoustic properties. Industry standards for residential facilities typically recommend 26-gauge panels, though premium projects often specify thicker 22 or 24-gauge options for enhanced impact resistance. Thicker aluminum metal siding panels demonstrate superior resistance to hail damage, accidental impacts, and wind-driven debris, making them particularly valuable in regions prone to severe weather events. The investment in heavier gauge materials pays dividends through reduced maintenance requirements and longer service life, ultimately delivering better value than thinner alternatives despite their higher initial cost. Fire safety represents another compelling advantage of aluminum metal siding panels in residential construction. As a non-combustible material, aluminum provides an added layer of protection that vinyl and wood siding simply cannot match. This characteristic becomes increasingly important as wildfire risks expand into previously safe areas and building codes evolve to address fire prevention. Aluminum metal siding panels meet or exceed fire rating requirements for close-proximity builds and commercial projects, giving homeowners and insurance providers confidence in the building's safety profile.

Understanding Aluminum Metal Siding Panel Systems and Installation Methods

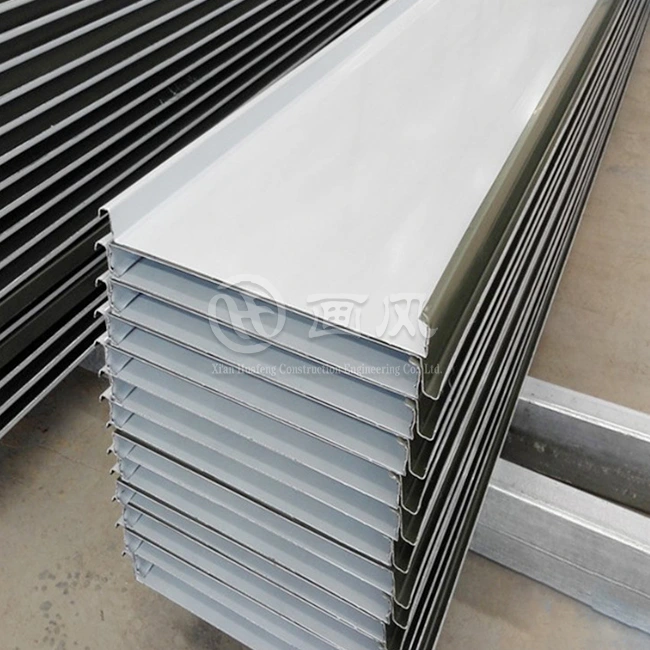

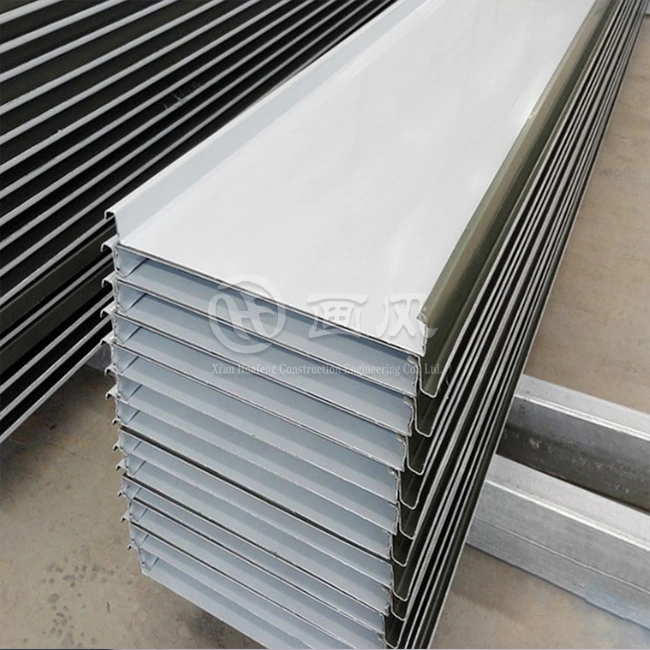

The success of any residential siding project depends heavily on selecting the appropriate panel system and understanding installation requirements. Aluminum metal siding panels are manufactured in two primary configurations: exposed fastener systems and concealed fastener systems. Each approach offers distinct advantages that suit different architectural styles, budget constraints, and performance expectations. Exposed fastener aluminum metal siding panels represent the most economical option, featuring fasteners that penetrate through the panel face and attach directly to the building structure. While the fastener heads remain visible on the finished surface, modern color-matched fasteners minimize their visual impact while providing reliable attachment that can withstand wind loads and thermal movement. Concealed fastener aluminum metal siding panels deliver a premium aesthetic with fasteners hidden within interlocking panel joints or secured through clip systems behind the panel face. This approach creates smooth, uninterrupted surfaces that enhance architectural elegance while providing superior weather protection. The concealed fastener design prevents water infiltration at attachment points, reducing the risk of moisture-related damage and extending the effective service life of the installation. Standing seam aluminum metal siding panels exemplify the concealed fastener approach, offering vertical panel orientations with raised seams that interlock to create weathertight barriers suitable for both walls and roofing applications.

Panel Profile Options for Distinctive Residential Aesthetics

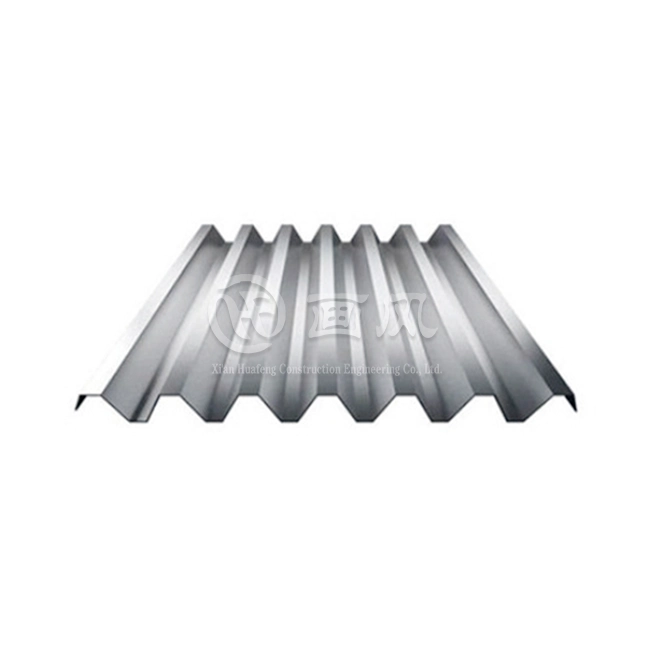

Aluminum metal siding panels are available in numerous profile configurations that enable designers and homeowners to achieve their desired architectural expression. Corrugated profiles provide a classic industrial aesthetic that has found renewed popularity in modern residential design, particularly for barn-style homes and contemporary structures seeking textural contrast. The repeating wave pattern of corrugated aluminum metal siding panels creates visual interest while maintaining the material's inherent strength and rigidity across unsupported spans. Board and batten profiles represent another popular choice for aluminum metal siding panels in residential applications. This traditional design features wide vertical boards alternating with narrow trim strips, creating bold shadow lines that emphasize verticality and provide a farmhouse or barndominium aesthetic. Modern manufacturing processes enable aluminum metal siding panels to faithfully reproduce the dimensional characteristics of wood board and batten siding while eliminating the maintenance burdens associated with natural materials. The panels resist warping, splitting, and insect damage while maintaining consistent appearance for decades. Flat lock panels offer clean, contemporary aesthetics ideal for modernist architecture and commercial-inspired residential designs. These aluminum metal siding panels create geometric grid patterns with subtle reveals that emphasize precision and craftsmanship. The system accommodates large panel sizes while maintaining weathertight performance, making it particularly suitable for projects prioritizing minimalist design principles. Custom metal wall claddings extend the possibilities even further, allowing architects to develop unique panel profiles and attachment systems tailored to specific project requirements, though these specialized solutions typically command premium pricing.

Technical Specifications Critical for Residential Aluminum Metal Siding Panel Selection

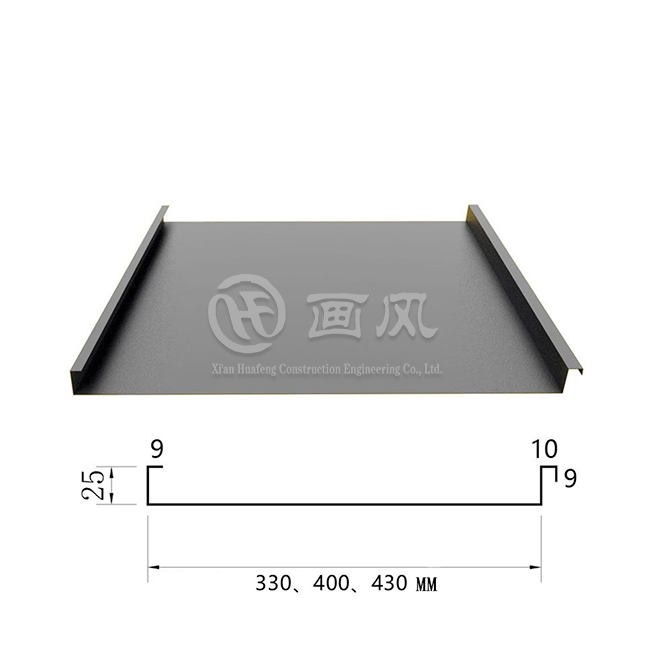

Informed material selection requires understanding the technical specifications that define aluminum metal siding panel performance. Plate width measurements typically range from 400mm to 600mm, affecting both the visual rhythm of the installed system and the efficiency of material coverage. Wider panels reduce the number of seams and joints, accelerating installation while minimizing potential leak points. However, narrower aluminum metal siding panels may better suit certain architectural details or provide more flexibility when navigating complex building geometries. Plate thickness represents a critical specification that directly influences durability, noise transmission, and overall panel behavior. Standard residential aluminum metal siding panels measure between 0.7mm and 1.2mm thick, with heavier gauges providing better resistance to denting and improved acoustic dampening during rain events. The rib height specification, typically ranging from 25mm to 65mm, determines the panel's structural capabilities and wind pressure resistance. Higher ribs create stronger panel sections capable of spanning greater distances between attachment points, reducing installation complexity and costs while maintaining structural performance.

Coating Systems That Extend Aluminum Metal Siding Panel Longevity

The coating applied to aluminum metal siding panels fundamentally determines their long-term appearance retention and environmental resistance. Polyester coatings offer economical protection suitable for moderate climates, providing good color stability and reasonable durability at accessible price points. High durability polyester coatings represent the mid-tier option, incorporating enhanced resin formulations that deliver improved chalk resistance and color retention compared to standard polyester systems. These coatings suit most residential applications where longevity expectations align with thirty-year warranty periods. Polyvinylidene fluoride coatings, commonly known by the trademark PVDF or Kynar, represent the premium tier of aluminum metal siding panel protection. These fluoropolymer-based systems demonstrate exceptional resistance to ultraviolet degradation, chemical exposure, and environmental pollutants that degrade lesser coatings. PVDF-coated aluminum metal siding panels maintain their original color and gloss characteristics for decades, even in harsh industrial or coastal environments. The investment in PVDF coatings proves particularly worthwhile for prominent architectural elements where appearance preservation justifies the premium cost. Quality coating application requires sophisticated manufacturing processes that ensure uniform coverage and proper adhesion. Reputable manufacturers employ multi-coat systems beginning with chemical pretreatment that promotes coating adhesion, followed by primer layers and finish coats applied through precisely controlled spray or coil coating processes. The coating is then baked at specific temperatures to achieve full cure, creating durable finishes that resist cracking, peeling, and delamination throughout the panel's service life. Xi'an Huafeng Construction Engineering Co., Ltd. operates seven color coating production lines that implement these rigorous quality standards, ensuring every aluminum metal siding panel meets international certification requirements including ISO9001, ISO14000:14001, and SGS guidelines.

Customization Capabilities That Distinguish Premium Aluminum Metal Siding Panels

The ability to customize aluminum metal siding panels represents a significant advantage for residential projects seeking distinctive architectural character. Color selection extends far beyond basic hues, with manufacturers offering comprehensive palettes that include trending tones, classic favorites, and custom color matching services. The 2026 design landscape emphasizes sophisticated neutrals and deep earth tones that complement natural surroundings while providing timeless appeal that transcends temporary trends. Advanced coating technologies enable aluminum metal siding panels to faithfully reproduce wood grain textures, brick patterns, or stone appearances, delivering the aesthetic benefits of traditional materials without their maintenance requirements or durability limitations. Pattern customization allows designers to specify unique panel configurations that create signature visual effects aligned with project branding or architectural themes. Standing seam profiles can be manufactured with various seam heights and spacing dimensions, while corrugated patterns can be modified to emphasize or minimize their textural impact. Board and batten aluminum metal siding panels accommodate different board widths and batten spacing to achieve proportions that harmonize with building scale and surrounding context. These customization options ensure that aluminum metal siding panels contribute meaningfully to architectural expression rather than imposing generic appearances that diminish design intent.

Design Integration and Architectural Compatibility

Successful aluminum metal siding panel integration requires consideration of how the material interacts with other building elements and systems. Trim details, corner treatments, and transition conditions demand careful planning to maintain weathertight integrity while achieving clean visual connections. Quality manufacturers provide comprehensive accessory systems including J-channels, corner posts, starter strips, and finishing trim pieces specifically engineered to work with their aluminum metal siding panels. These coordinated components eliminate the improvisation that often compromises installation quality when mixing products from different sources. Window and door openings require particular attention when designing aluminum metal siding panel installations. Proper flashing details must integrate with the panel system to direct water away from vulnerable penetrations while accommodating thermal movement that occurs as materials expand and contract with temperature fluctuations. Modern installation practices emphasize back-dam flashing techniques and continuous drainage plane management that prevents water infiltration regardless of wind-driven rain conditions. These sophisticated approaches transform aluminum metal siding panels from simple cladding materials into comprehensive building envelope systems that protect structural elements and interior spaces from moisture damage.

Manufacturing Excellence and Quality Control in Aluminum Metal Siding Panel Production

The quality of aluminum metal siding panels depends fundamentally on manufacturing processes and quality control protocols implemented by producers. Leading manufacturers maintain extensive facilities equipped with roll-forming systems capable of producing panels in continuous lengths exceeding twelve meters, minimizing field joints that represent potential weak points in the building envelope. Real-time quality control systems monitor panel dimensions, coating thickness, and surface characteristics throughout production, automatically flagging deviations that require correction before materials reach job sites. Raw material traceability ensures that every component in aluminum metal siding panels meets specified standards and originates from approved sources. Premium manufacturers maintain supplier qualification programs that verify metal composition, coating materials, and fastener components before accepting them for production use. This rigorous approach to material procurement prevents substandard inputs from compromising finished product quality, protecting both manufacturer reputation and customer satisfaction. Xi'an Huafeng Construction Engineering Co., Ltd. sources aluminum alloys exclusively from established brands including Alucosuper, YATAI, and LIDAO, ensuring consistent material properties across all production runs.

Inspection Protocols That Guarantee Performance

Comprehensive inspection procedures validate that finished aluminum metal siding panels meet all specified requirements before shipment to construction sites. Incoming material inspection verifies raw material quality through testing protocols that assess appearance, dimensional accuracy, coating adhesion, and corrosion resistance. These evaluations include salt spray testing, hardness measurements, impact resistance verification, and film thickness analysis that confirm materials will perform as expected in field conditions. Full inspection approaches apply to high-value or critical materials, while statistical sampling methods efficiently assess large-volume commodity inputs without compromising quality assurance objectives. Production and processing inspections monitor panel fabrication quality throughout manufacturing operations, catching potential issues before they multiply across multiple units. Operators verify that forming operations produce panels with correct profiles, accurate dimensions, and proper edge conditions. Coating inspections ensure uniform coverage without defects such as pinholes, scratches, or contamination that could compromise long-term durability. Finished product inspection represents the final quality gate, examining appearance characteristics, dimensional accuracy, flatness, and curvature to verify conformance with project specifications. Only aluminum metal siding panels that pass these rigorous evaluations receive approval for packaging and shipment to customers.

Project Execution Strategies for Aluminum Metal Siding Panel Installation

Successful aluminum metal siding panel projects require careful planning that begins long before materials arrive at the construction site. Design development should include comprehensive drawing packages that specify panel types, dimensions, colors, and trim details for every building elevation and condition. These documents provide the foundation for accurate material ordering, efficient fabrication, and successful field installation. Leading manufacturers offer design support services that include structural 3D modeling, load analysis, and drainage system simulation to validate that specified aluminum metal siding panel systems will perform as intended under actual service conditions. Factory sample production provides critical verification before committing to full-scale fabrication. Physical samples demonstrate panel profile, material finish, color accuracy, and assembly details that help stakeholders visualize finished appearance and confirm that selections meet project requirements. Sample sealing ceremonies formalize approval, establishing these specimens as quality standards against which production materials and installed work will be judged. This disciplined approach prevents costly changes and rework while ensuring consistent outcomes that satisfy all project participants.

On-Site Installation Management

Professional installation management ensures that aluminum metal siding panels achieve their designed performance and appearance potential. Pre-installation planning addresses logistics including material storage, staging areas, equipment access, and workflow sequencing that enables efficient progress while protecting materials from damage. Product arrival and warehousing procedures verify shipment accuracy, checking received materials against packing lists and organizing panels according to installation sequence. Proper material handling prevents denting, scratching, or coating damage that would require replacement and cause schedule delays. Installation technician preparation ensures field crews possess the knowledge, skills, and tools necessary for quality workmanship. Pre-installation site visits allow technicians to assess actual conditions, verify substrate readiness, and identify potential challenges requiring resolution before work commences. Technical briefing meetings review drawing details, safety protocols, and quality expectations, ensuring all team members understand project requirements and their roles in achieving successful outcomes. Modern aluminum metal siding panel installation relies on specialized tools including edge-locking machines, panel benders, and fastener application equipment that require operator training and regular maintenance to function properly. Quality assurance during installation includes continuous inspection of completed work, verifying that panels align correctly, fasteners install at proper spacing and torque, and sealant applications create weathertight conditions at all vulnerable locations. Installation completion triggers comprehensive testing protocols designed to verify weathertight integrity before final acceptance. Water testing simulates wind-driven rain conditions, exposing the system to sustained moisture while observers monitor for leakage or seepage that indicates deficient conditions requiring correction. Only after demonstrating zero leakage performance do aluminum metal siding panel installations receive final approval and acceptance signatures.

Conclusion

Aluminum metal siding panels have emerged as the optimal choice for residential projects in 2026, combining proven durability with contemporary aesthetics and sustainable characteristics. Their superior corrosion resistance, customization capabilities, and comprehensive warranty protection deliver exceptional value that justifies their specification across diverse architectural applications from coastal homes to urban developments.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a premier China aluminum metal siding panels manufacturer specializing in design, production, and installation services that transform architectural visions into reality. Established in 2018 and recognized as a high-tech enterprise in Shaanxi Province, the company maintains first-level building curtain wall qualifications and third-level building steel structure certifications that demonstrate technical capabilities and regulatory compliance. With a 200,000 square meter raw material production facility in Anhui and processing plants in Hangzhou and Xi'an, Huafeng operates comprehensive manufacturing infrastructure including seven color coating lines, one laminating line, and ten longitudinal/transverse shearing production lines supported by more than forty specialized equipment units.

As a leading China aluminum metal siding panels supplier, Xi'an Huafeng provides high quality aluminum metal siding panels manufactured to international standards with certifications including ISO9001, ISO14000:14001, and SGS compliance. The company maintains extensive engineering design experience demonstrated through successful project completion at prestigious venues including Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, and Inner Mongolia Tongliao Art Museum. More than twenty registered patents for roofing and wall systems reflect ongoing innovation commitment, while customized production capabilities enable tailored solutions meeting unique project requirements. Clients seeking China aluminum metal siding panels wholesale pricing benefit from competitive rates enabled by efficient production processes and direct factory relationships.

The company's one-stop service model integrates custom design engineering, precision manufacturing, and seamless installation support that eliminates coordination challenges inherent in multi-vendor approaches. From initial project drawing development through factory sample production, processing optimization, material procurement from premium brands, rigorous quality inspection, and professional on-site construction guidance, Huafeng manages every aspect of aluminum metal siding panels for sale to ensure successful outcomes. This comprehensive approach reduces client risk while delivering superior results compared to fragmented procurement strategies. Competitive aluminum metal siding panels price structures combined with 30-year warranty protection provide exceptional value propositions for residential and commercial developments. Contact Xi'an Huafeng Construction Engineering Co., Ltd. at huafeng@hfmetalroof.com to discuss your project requirements and receive detailed quotations for premium aluminum metal siding panel systems.

References

1. Johnson, Michael and Roberts, Sarah. "Advances in Aluminum Cladding Technology for Residential Construction." Journal of Building Materials and Structures, Vol. 45, No. 3, 2025.

2. Thompson, David. "Performance Comparison of Modern Siding Materials: A Technical Analysis." Construction Research Quarterly, Institute of Building Science, 2025.

3. Chen, Wei and Martinez, Carlos. "Corrosion Resistance in Coastal Construction: Metal Siding Solutions." International Journal of Architectural Engineering, Vol. 28, No. 2, 2024.

4. Anderson, Patricia. "Sustainable Building Envelopes: Lifecycle Assessment of Exterior Cladding Systems." Green Building Council Publications, 2025.

5. Williams, Robert and Zhang, Lin. "Installation Best Practices for Metal Panel Systems in Residential Projects." National Association of Home Builders Technical Manual, 2024.

(1)_1763110678300.webp)