Picture this: you're standing before a landmark building, its facade gleaming seamlessly under the sun with no visible fasteners disrupting its monolithic elegance. How did the architects achieve this flawless, weather-resistant exterior that seems to defy conventional construction limitations? The answer lies in Flat Lock Metal Wall Sheets, an advanced cladding solution that has revolutionized contemporary architectural design by offering unmatched aesthetic versatility, structural integrity, and long-term durability for projects ranging from cultural institutions to high-end commercial developments.

Understanding Flat Lock Metal Wall Panel Systems in Modern Construction

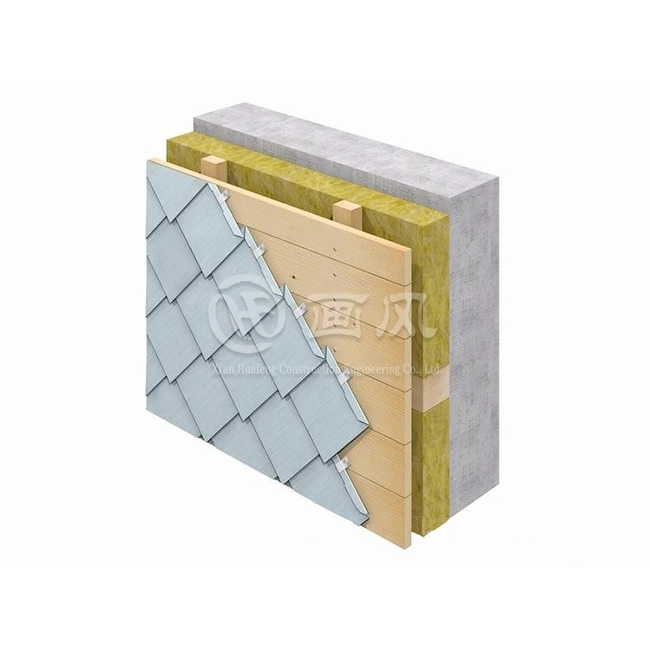

Flat lock metal wall panels represent a sophisticated evolution in architectural cladding technology, merging traditional craftsmanship with modern precision engineering. These panels create a flush, nearly monolithic surface through an overlapping installation method that utilizes concealed fastening systems, eliminating the visual disruption of exposed screws or clips that compromise the clean lines architects demand in contemporary design. The fundamental construction of Flat Lock Metal Wall Sheets involves precision-bent metal panels with interlocking edges that form weathertight seams when properly installed. Unlike standing seam systems that create pronounced vertical ribs, flat lock metal wall panels achieve a remarkably smooth surface profile that emphasizes the material's inherent beauty while maintaining exceptional weather resistance. This characteristic makes them particularly valuable for projects where aesthetic refinement cannot be compromised by functional requirements.

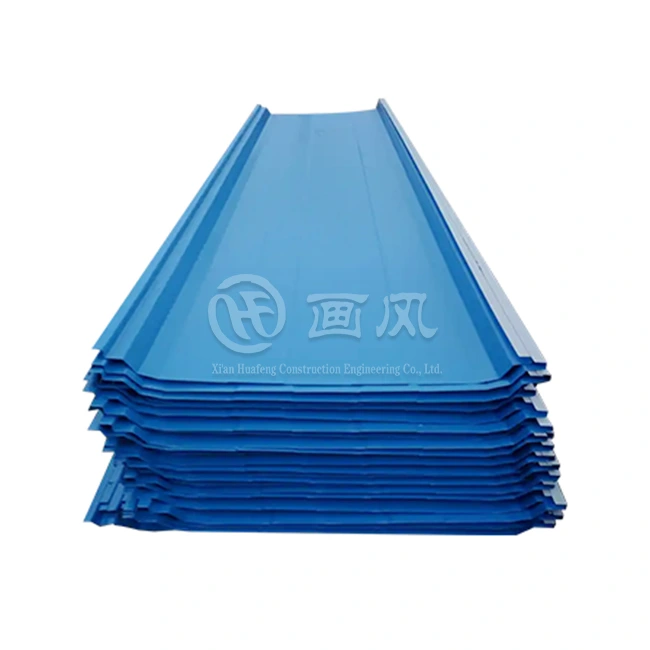

Manufacturing these panels requires specialized equipment capable of achieving tolerances measured in fractions of millimeters. The process begins with premium-grade metal coils or sheets sourced from verified suppliers, then proceeds through roll-forming operations that create the characteristic fold patterns on all four panel edges. Advanced manufacturers like Xi'an Huafeng Construction Engineering Co., Ltd. operate multiple production lines equipped with CNC-controlled bending machines, automated punching systems, and quality verification stations that ensure every panel meets exacting dimensional specifications before leaving the factory. The versatility of flat lock metal wall panels extends beyond their appearance to encompass their material composition. Architects can specify aluminum for its lightweight properties and corrosion resistance, stainless steel for maximum durability in harsh environments, copper for its distinctive patina development over time, or titanium-zinc alloys that combine strength with natural weathering characteristics. Each material brings unique performance attributes that address specific project requirements, from coastal installations requiring marine-grade corrosion resistance to heritage renovations demanding historically accurate material selections.

Contemporary Architectural Applications of Flat Lock Metal Wall Sheets

The application spectrum for Flat Lock Metal Wall Sheets has expanded dramatically as architects recognize their potential to solve complex design challenges across diverse building typologies. In commercial architecture, these panels have become the preferred solution for corporate headquarters seeking to project an image of precision and technological sophistication. The seamless appearance created by flat lock metal wall panels communicates brand values of attention to detail and commitment to quality, while the material's durability ensures the facade maintains its pristine appearance decades into the future with minimal maintenance intervention. Cultural institutions including museums, performing arts centers, and educational facilities have embraced Flat Lock Metal Wall Sheets for their ability to create distinctive architectural identities without sacrificing functional performance. The modular nature of the panel system allows designers to incorporate complex geometric patterns, varied panel orientations, and mixed material finishes within a single facade composition. This design freedom has enabled landmark projects to achieve signature appearances that enhance their urban contexts while meeting stringent requirements for weather protection, thermal performance, and accessibility to interior climate control systems.

Luxury residential developments represent another growing application sector for flat lock metal wall panels, particularly in urban markets where discerning clients demand architectural distinctiveness combined with proven long-term performance. High-rise condominiums clad in precisely engineered Flat Lock Metal Wall Sheets offer residents the assurance that their building envelope will maintain its appearance and protective functions throughout their ownership period. The material's inherent fire resistance, typically achieving A2 non-combustible or Class A fire ratings depending on substrate configuration, provides additional safety benefits critical in multi-family residential construction. Renovation and adaptive reuse projects leverage Flat Lock Metal Wall Sheets to transform aging structures into contemporary architectural assets. The lightweight nature of the panel system minimizes additional structural loading on existing buildings, often eliminating the need for foundation reinforcement that would escalate project costs. Installation can proceed without complete building evacuation, allowing continued occupancy during facade replacement programs. This characteristic has proven particularly valuable for historic preservation projects where new cladding must protect deteriorating original materials while respecting the building's architectural character through careful material selection and detail coordination.

Material Selection and Performance Characteristics

Selecting appropriate materials for Flat Lock Metal Wall Sheets requires careful consideration of multiple performance criteria beyond initial aesthetic preferences. Aluminum panels, available in alloys such as 3003, 3004, and 5052, offer exceptional strength-to-weight ratios that reduce structural support requirements while providing excellent corrosion resistance in diverse environmental conditions. Surface treatments including PVDF coatings, anodizing, and powder coating extend service life while offering extensive color options that maintain their vibrancy through decades of UV exposure and weathering cycles. Stainless steel flat lock metal wall panels deliver maximum durability in the most demanding applications, from coastal installations subject to salt spray exposure to industrial facilities where chemical resistance becomes paramount. Grade 316 stainless steel, specified by manufacturers including Baosteel and Tsingshan, provides superior corrosion resistance through its molybdenum content, while grade 304 offers cost-effective performance for less aggressive environments. The material's inherent fire resistance and dimensional stability across extreme temperature ranges make it ideal for high-performance building envelopes where failure is not acceptable.

Copper remains a prestigious choice for Flat Lock Metal Wall Sheets on projects where natural material aging contributes to architectural character development. The metal's distinctive patina evolution, transitioning from bright metallic tones through bronze hues to mature blue-green surfaces, creates dynamic facades that document the passage of time. Copper's antimicrobial properties provide additional benefits in healthcare facilities and public spaces where surface hygiene concerns influence material selection. Manufacturers can supply copper panels in various tempers and thicknesses from suppliers like Chinalco, ensuring appropriate material specifications for specific structural and aesthetic requirements. Titanium-zinc alloys, such as those produced by NedZink, combine copper's aesthetic advantages with enhanced mechanical properties and superior weathering performance. These materials develop stable protective patinas that self-heal minor surface damage, effectively eliminating maintenance requirements for the building's service life. The material's formability allows fabrication of complex panel shapes and integrated details that would prove challenging with harder metals. Environmental sustainability considerations favor zinc for its complete recyclability and lower embodied energy compared to many competing facade materials.

Installation Methodology and Quality Assurance

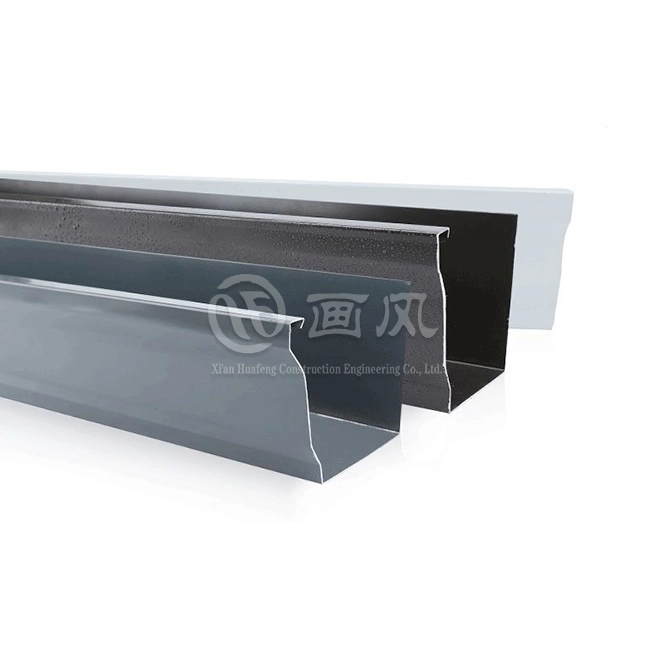

Successful installation of flat lock metal wall panels demands rigorous attention to substrate preparation, fastening system design, and workmanship standards that directly influence long-term performance. The process begins with verification that the substrate provides a continuous, structurally sound, and dimensionally accurate mounting surface. Irregularities in the substrate telegraph through the finished cladding, creating visible waves or buckles that compromise the intended flush appearance. Qualified installers conduct comprehensive substrate inspections before panel installation commences, identifying and correcting deficiencies that would otherwise manifest as aesthetic or functional failures. Concealed fastening systems for Flat Lock Metal Wall Sheets typically employ factory-formed clips that engage the panel edges and attach to the substrate through stainless steel fasteners. Proper clip spacing, determined through engineering analysis considering wind loads and seismic requirements, ensures adequate panel retention without over-constraining the metal and restricting natural thermal expansion. Installation technicians must verify clip positioning against approved shop drawings, maintaining consistent spacing and alignment that prevents stress concentrations capable of causing panel distortion or fastener failure over time.

Panel installation sequencing follows carefully planned layouts that account for building geometry, drainage paths, and accessibility for future maintenance operations. Each panel receives individual verification of dimensional accuracy and surface condition before installation, with defective units segregated for repair or replacement. Proper panel orientation ensures that overlapping seams direct water away from building interiors, while maintaining visual continuity across the facade. Skilled installers recognize that achieving the intended monolithic appearance requires meticulous attention to alignment and spacing throughout the entire installation process. Quality assurance protocols implemented by professional contractors like Xi'an Huafeng Construction Engineering Co., Ltd. include comprehensive testing programs that verify system performance before final acceptance. Water testing confirms weathertight integrity across representative facade sections, identifying potential leakage paths that require corrective action. Structural testing validates wind load resistance and seismic performance, ensuring the installed system meets or exceeds design specifications. Documentation of all testing activities provides building owners with verifiable evidence of system performance, supporting warranty claims and facilitating future maintenance planning.

Conclusion

Flat Lock Metal Wall Sheets have established themselves as indispensable solutions for architects demanding uncompromising aesthetic refinement combined with proven long-term performance in contemporary building design.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

As a certified China Flat Lock Metal Wall Sheets manufacturer, Xi'an Huafeng Construction Engineering Co., Ltd. delivers High Quality Flat Lock Metal Wall Sheets through our comprehensive capabilities as both China Flat Lock Metal Wall Sheets supplier and China Flat Lock Metal Wall Sheets factory. Our competitive Flat Lock Metal Wall Sheets price reflects direct China Flat Lock Metal Wall Sheets wholesale access, with Flat Lock Metal Wall Sheets for sale through our integrated production network. Established in 2018 and recognized as a Shaanxi Province high-tech enterprise in 2020, we maintain three factories spanning 200,000 square meters in Anhui plus processing facilities in Hangzhou and Xi'an. Our 7 color coating production lines, 10 shearing systems, and over 40 precision machines support 1,000-ton monthly output with 15-20 day delivery. We hold first-level curtain wall and third-level steel structure qualifications, backed by ISO9001, ISO14001, SGS certifications, and 20+ patents. From structural 3D modeling through on-site installation and zero-leakage testing, our one-stop service includes customized solutions, material traceability using brands like Alucosuper aluminum and Baosteel steel, and comprehensive quality control. Contact huafeng@hfmetalroof.com today to discuss your project requirements and experience manufacturing excellence that transforms architectural visions into lasting reality.

References

1. Copper Development Association. "Architectural Details: Wall Cladding Systems - Horizontal Flat Lock Applications." Technical Standards for Metal Building Envelopes.

2. American Society of Architectural Metal Manufacturers. "Performance Specifications for Concealed Fastener Metal Panel Systems." Journal of Building Envelope Design, Vol. 12, No. 3.

3. National Roofing Contractors Association. "Installation Standards for Flat Seam Metal Cladding on Vertical Surfaces." Professional Roofing Magazine Technical Section.

4. Metal Construction Association. "Design Guide for Modular Metal Panel Systems in Contemporary Architecture." MCA Technical Bulletin Series.

5. International Code Council. "Fire Resistance and Weather Performance Testing Protocols for Metal Wall Assemblies." ICC Evaluation Service Reports.