When building owners face constant roof maintenance costs, weather damage, and energy inefficiency issues, finding a reliable roofing solution becomes critical. Standard Seam Roof Panel systems offer a proven answer to these challenges, delivering exceptional durability across commercial warehouses, industrial facilities, and residential properties. This comprehensive guide explores how Standard Seam Roof Panel applications span from large-scale commercial projects to custom residential installations, providing architects, contractors, and property owners with the knowledge to make informed roofing decisions.

Understanding Standard Seam Roof Panel Systems

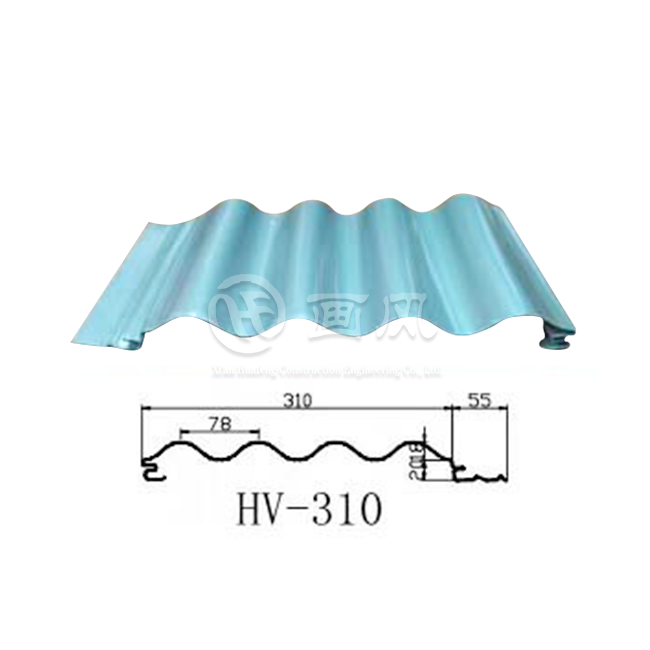

Standard seam roofing represents a sophisticated metal roofing technology that has transformed modern construction practices. This system consists of vertical metal panels featuring raised interlocking seams that create a watertight barrier, eliminating the vulnerabilities associated with exposed fasteners. The concealed fastener design inherent to Standard Seam Roof Panel construction prevents water infiltration at penetration points, a common failure point in traditional roofing systems. These panels accommodate thermal expansion and contraction through their clip attachment method, which allows the metal to move freely without causing stress cracks or fastener failure. The structural integrity of Standard Seam Roof Panel systems comes from their engineered profile, typically featuring seam heights ranging from 25mm to 65mm, which provides both aesthetic appeal and functional performance. Manufacturing processes utilize galvanized steel, aluminum-magnesium-manganese alloys, titanium-zinc, or copper materials, each offering distinct advantages for specific environmental conditions and architectural requirements.

Material Specifications and Performance Characteristics

The technical specifications of Standard Seam Roof Panel systems directly influence their suitability for various applications. Panel thickness typically ranges from 0.5mm to 1.2mm, with commercial applications often requiring heavier gauges for enhanced structural capacity and impact resistance. Surface treatments play a crucial role in longevity, with PVDF coatings offering superior UV resistance and color retention compared to polyester alternatives, maintaining aesthetic appearance for decades in harsh climates. The coating systems applied to Standard Seam Roof Panel products undergo rigorous testing including salt spray exposure, adhesion measurements, hardness verification, and accelerated weathering protocols to ensure consistent performance. Width specifications generally fall between 300mm and 600mm, allowing for efficient coverage while maintaining structural rigidity across purlin spans. Customizable length capabilities eliminate horizontal seams on many projects, with panels manufactured up to 12 meters in continuous runs, significantly reducing potential leak points. Color selection encompasses extensive RAL and Pantone options, enabling architects to achieve specific design visions while meeting reflectivity requirements for energy codes. These Standard Seam Roof Panel systems comply with international standards including ASTM, DIN, JIS, BS, and GB/T specifications, providing specifiers with confidence in performance predictability across global markets.

Commercial Building Applications

Commercial property owners increasingly specify Standard Seam Roof Panel systems for new construction and retrofit projects due to their exceptional life-cycle value proposition. Large-format retail centers benefit from the long-span capabilities and minimal maintenance requirements, with panels covering vast roof areas without intermediate supports that would complicate interior layouts. Office buildings utilize Standard Seam Roof Panel installations to achieve modern aesthetic profiles while meeting stringent energy codes through reflective coating options that reduce cooling loads. The concealed fastener design proves particularly valuable in commercial settings where roof access for HVAC equipment, solar installations, and communication devices requires a stable, penetration-free surface. Shopping malls and mixed-use developments appreciate the architectural flexibility of Standard Seam Roof Panel systems, which accommodate complex roof geometries including curved sections, transitions between elevations, and integration with glazing systems. Warehouse facilities rely on the wind uplift resistance inherent in mechanically seamed installations, with testing demonstrating performance exceeding Class 90 wind ratings in hurricane-prone regions.

Industrial Facility Requirements

Manufacturing plants and industrial complexes present unique challenges that Standard Seam Roof Panel systems address effectively through their robust construction and chemical resistance properties. Factory environments generating heat, humidity, and corrosive atmospheres demand roofing materials capable of withstanding these aggressive conditions without premature degradation. Standard Seam Roof Panel installations with appropriate coatings resist acid rain, industrial emissions, and cleaning chemical exposure that would compromise lesser roofing materials. Airport hangars and transportation facilities utilize these systems for their fire resistance classifications, achieving Class A ratings essential for insurance requirements and code compliance. The thermal efficiency capabilities of Standard Seam Roof Panel assemblies prove valuable in temperature-controlled warehouses and cold storage facilities, where insulation integration and thermal bridging elimination contribute to operational cost reductions. Manufacturing operations benefit from the sustainable profile of metal roofing, as Standard Seam Roof Panel products contain significant recycled content and remain fully recyclable at end of service life, supporting corporate environmental initiatives and LEED certification objectives.

Residential Applications

Homeowners seeking premium roofing solutions increasingly turn to Standard Seam Roof Panel systems for their combination of longevity, aesthetics, and performance advantages over traditional residential roofing materials. Modern architectural designs featuring clean lines and contemporary profiles showcase the sleek appearance of standing seam metal roofing, with concealed fasteners creating uninterrupted visual planes. Luxury residential projects specify Standard Seam Roof Panel installations for their exceptional weather resistance, particularly in regions experiencing severe storms, heavy snow loads, or wildfire threats where Class A fire ratings provide critical protection. The energy efficiency potential attracts environmentally conscious homeowners, as reflective coatings combined with ventilated assemblies significantly reduce cooling costs in warm climates. Coastal properties face aggressive salt air exposure that accelerates deterioration of conventional roofing materials, making the corrosion resistance of properly coated Standard Seam Roof Panel systems essential for long-term performance. Historical renovation projects incorporate metal roofing to replicate traditional standing seam profiles while providing modern waterproofing technology and extending maintenance intervals compared to original materials.

Residential Design Flexibility

Custom home construction benefits from the design versatility inherent in Standard Seam Roof Panel applications, accommodating steep slopes, complex valleys, and architectural features that challenge other roofing systems. The lightweight nature of metal roofing reduces structural loading requirements, enabling designers to optimize framing systems and potentially reduce construction costs despite premium material investment. Color customization allows homeowners to coordinate roofing with exterior palettes, achieving cohesive aesthetic presentations that enhance property values and curb appeal. Standard Seam Roof Panel systems integrate seamlessly with solar panel installations through specialized mounting clips that preserve weathertight integrity while supporting renewable energy generation. Residential applications appreciate the sound damping characteristics achieved through proper substrate selection and insulation integration, addressing concerns about rain noise that sometimes accompany metal roofing. The exceptional lifespan potential of 30 to 50 years significantly exceeds asphalt shingle alternatives, reducing lifecycle replacement costs and minimizing environmental impact through decreased material consumption over building ownership periods.

Installation Considerations and Best Practices

Successful Standard Seam Roof Panel installations require careful attention to substrate preparation, panel handling procedures, and seaming techniques that ensure long-term performance. Roof deck conditions must provide adequate structural support and proper ventilation pathways, with plywood or oriented strand board substrates offering stable attachment surfaces for clip fasteners. Underlayment selection plays a critical role in waterproofing redundancy, with high-temperature synthetic materials providing protection during installation and serving as backup barriers throughout the roof's service life. Panel layout planning optimizes material utilization while accommodating thermal movement zones, expansion joints, and transitions to adjacent roofing systems or wall assemblies. Seaming operations demand precision, whether utilizing snap-lock systems for residential applications or mechanical seamers for commercial installations requiring enhanced performance specifications. Clip spacing and fastener patterns follow engineering specifications based on wind exposure categories, with coastal and high-wind regions requiring more aggressive attachment schedules than interior locations. Trim fabrication and installation determine the success of perimeter details, eave conditions, ridge assemblies, and penetration flashings that must maintain weathertight integrity while accommodating panel movement.

Conclusion

Standard Seam Roof Panel systems deliver unmatched versatility across commercial and residential applications, providing architects, contractors, and property owners with roofing solutions that balance performance, aesthetics, and lifecycle value in a comprehensive package.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a leading China Standard Seam Roof Panel manufacturer and China Standard Seam Roof Panel factory, specializing in high-quality metal roofing systems since 2018. Our China Standard Seam Roof Panel supplier capabilities include comprehensive design, production, and installation services backed by first-level curtain wall qualifications and third-level steel structure certifications. As a recognized high-tech enterprise with over 20 registered patents, we offer China Standard Seam Roof Panel wholesale solutions with competitive Standard Seam Roof Panel price structures. Our High Quality Standard Seam Roof Panel for sale features PVDF/PE surface treatments, thickness options from 0.5-1.2mm, and customizable specifications including 25-330/400/430, 32-410, 45-400, and 65-400/430 profiles. With three factories, seven color coating production lines, and more than 40 specialized machines, we maintain 1000 tons monthly supply capacity and 15-20 day delivery schedules. Our one-stop service encompasses structural 3D modeling, drainage simulation, material specification advisory, factory sample production, precision manufacturing with real-time quality control, and seamless installation with on-site project management. Serving Fortune 500 companies and prestigious projects including Xiongan Station and Xi'an International Convention Center, we provide ISO9001, ISO14001, and SGS certified solutions with 30-year warranties. Contact our experienced team at huafeng@hfmetalroof.com to discuss your Standard Seam Roof Panel requirements and discover how our engineering expertise, customized production capabilities, and commitment to sustainable development create exceptional value for your commercial or residential roofing projects.

References

1. Metal Construction Association. "Guide Specification for Standing Seam Metal Roof Systems." Technical standards document covering design, materials, and installation requirements for commercial and residential applications.

2. Smith, J. R., & Thompson, M. K. "Performance Evaluation of Standing Seam Metal Roofing in Various Climate Zones." Journal of Building Engineering, examining durability and weather resistance across different environmental conditions.

3. National Roofing Contractors Association. "Metal Roofing Systems: Design and Installation Manual." Comprehensive resource detailing best practices for concealed fastener systems in commercial and residential construction.

4. Chen, L., & Williams, P. D. "Comparative Life Cycle Assessment of Commercial Roofing Systems." Building and Environment, analyzing environmental impact and longevity of various roofing materials including standing seam metal.

5. American Architectural Manufacturers Association. "AAMA 1503: Voluntary Test Method for Thermal Cycling of Exterior Walls." Standard addressing thermal movement accommodation in metal building envelope systems including roofing panels.