Are rising energy costs eating away at your operational budget while your building facade deteriorates under extreme weather conditions? Commercial and industrial property owners face mounting pressure to reduce energy consumption while maintaining structural integrity. Vertical Standing Seam Metal Cladding emerges as a transformative solution that addresses both challenges simultaneously, delivering measurable energy savings and exceptional durability that protects your investment for decades.

Understanding Vertical Standing Seam Metal Cladding Technology

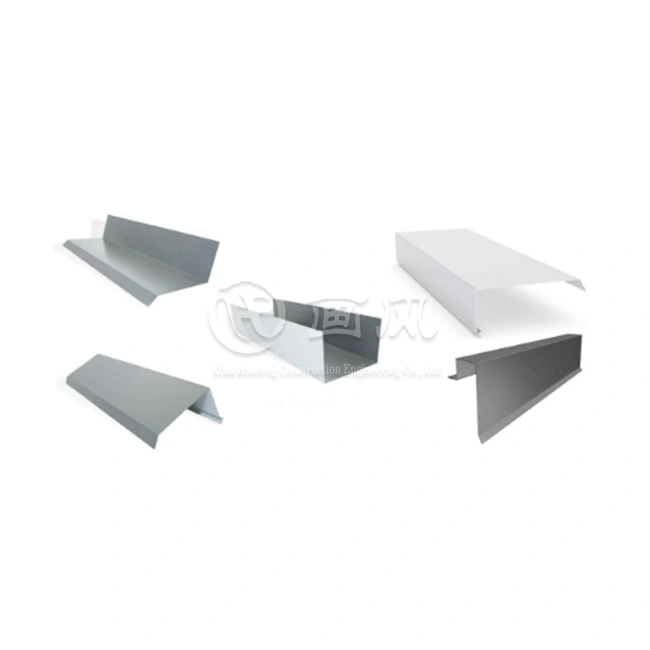

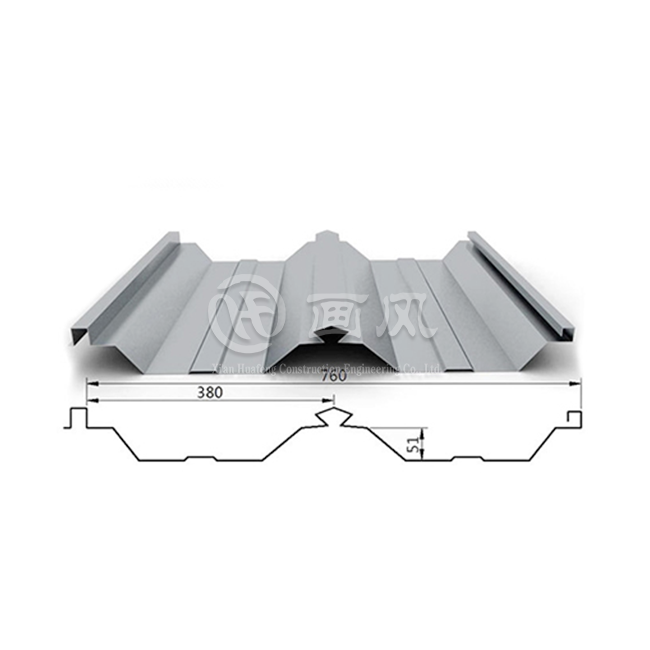

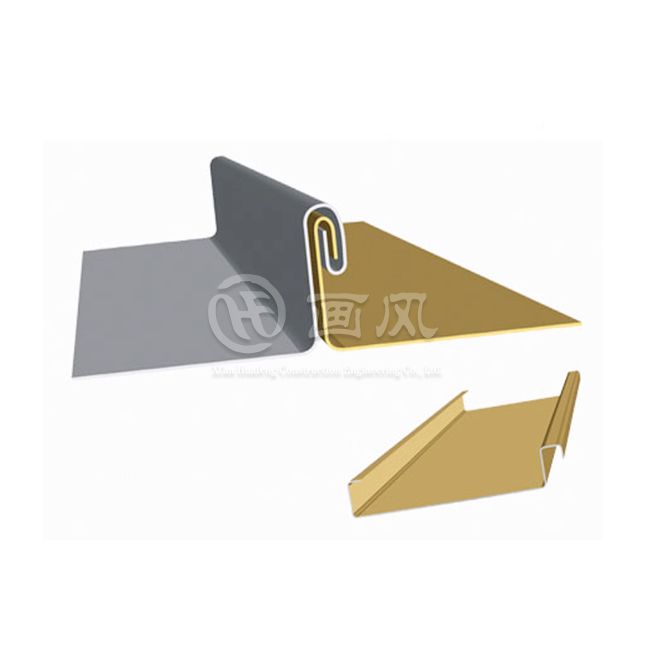

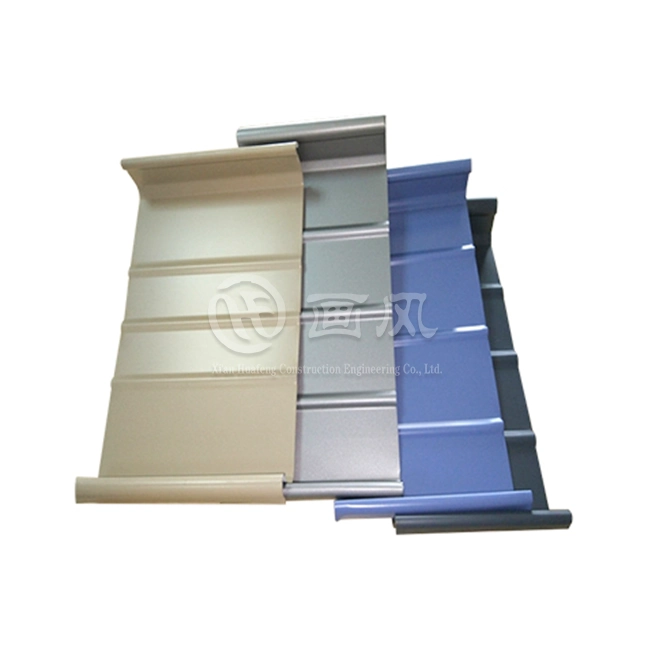

Vertical Standing Seam Metal Cladding represents an advanced enclosure system engineered specifically for modern building envelopes. This high-performance facade solution utilizes vertically oriented metal panels connected through mechanical interlocking technology, creating raised seams that stand prominently above the panel surface. Unlike traditional cladding systems that rely on exposed fasteners vulnerable to weather penetration, Vertical Standing Seam Metal Cladding incorporates concealed fastener design that ensures superior weather-tightness while presenting a sleek, contemporary aesthetic. The engineering sophistication behind Vertical Standing Seam Metal Cladding extends beyond visual appeal. Each panel spans continuously from base to top, eliminating horizontal joints that typically compromise thermal performance and water resistance. The system accommodates thermal expansion and contraction through sliding connections, preventing stress-related failures common in rigid cladding systems. This adaptive design proves particularly valuable in regions experiencing significant temperature fluctuations, where material movement must be managed without compromising building envelope integrity. With specifications ranging from 25-330mm to 65-500mm profiles and available in premium aluminum alloys, galvanized steel, and stainless steel materials, Vertical Standing Seam Metal Cladding delivers customizable solutions for diverse architectural applications.

Energy Efficiency Through Advanced Thermal Performance

Solar Heat Reflection and Cooling Cost Reduction

Vertical Standing Seam Metal Cladding fundamentally transforms building energy performance through superior solar reflectivity characteristics. Metal panels coated with high-reflectance finishes including PVDF, HDP, and PE coatings effectively redirect solar radiation away from building surfaces, substantially reducing heat absorption that drives cooling demands. Studies demonstrate that reflective metal cladding systems can reduce surface temperatures by 50-60 degrees Fahrenheit compared to conventional materials, translating directly into reduced air conditioning loads and lower electricity consumption during peak demand periods. The thermal benefits extend throughout building operations. During summer months when cooling represents the dominant energy expense for commercial facilities, Vertical Standing Seam Metal Cladding acts as a first line of defense against solar heat gain. The vertical orientation maximizes reflective effectiveness during midday when solar intensity peaks, while the continuous panel design eliminates thermal bridges that allow heat transfer through building envelopes. For manufacturing facilities, warehouses, and commercial buildings where internal heat generation already challenges HVAC systems, this external thermal barrier provides crucial support for maintaining comfortable interior conditions without excessive mechanical cooling. Property owners consistently report cooling cost reductions of 15-25% following Vertical Standing Seam Metal Cladding installation, with payback periods typically ranging from 5-8 years depending on local energy rates and climate conditions.

Insulation Compatibility and Thermal Envelope Optimization

The structural design of Vertical Standing Seam Metal Cladding creates exceptional compatibility with advanced insulation systems, enabling comprehensive thermal envelope optimization. The vertical cavity formed behind panels accommodates rigid foam insulation boards, mineral wool batts, or spray-applied insulation products without compression or performance degradation. This integration capability allows designers to achieve targeted R-values appropriate for specific climate zones and building usage patterns, ensuring compliance with increasingly stringent energy codes while providing operational cost benefits. Proper thermal envelope design incorporating Vertical Standing Seam Metal Cladding addresses both conductive heat transfer through building materials and convective air movement that compromises insulation effectiveness. The concealed fastener system eliminates thermal bridging pathways that penetrate insulation layers in conventional cladding installations. Hidden clips maintain panel attachment without creating metal-to-metal connections that conduct thermal energy across the insulation barrier. Meanwhile, the weather-tight seam design prevents wind-driven air infiltration that reduces insulation performance by carrying thermal energy through gaps and cracks. Building envelope testing confirms that properly installed Vertical Standing Seam Metal Cladding systems achieve air leakage rates below 0.02 cubic feet per minute per square foot at 75 Pascal pressure differential, meeting or exceeding performance requirements for high-efficiency building standards including LEED certification and net-zero energy targets.

Durability Benefits That Enhance Long-Term Energy Performance

Weather Resistance and Building Envelope Protection

Vertical Standing Seam Metal Cladding delivers uncompromising protection against environmental elements that degrade conventional facade systems and compromise energy performance over time. The raised interlocking seam design creates a double-barrier defense against water penetration, with primary weather-tightness provided by the mechanical seam lock and secondary protection through concealed drainage channels that redirect incidental moisture away from building substrates. This engineered redundancy proves critical for maintaining thermal insulation effectiveness, as moisture saturation dramatically reduces insulation R-values and can lead to mold growth, structural deterioration, and energy performance degradation. Wind resistance capabilities distinguish Vertical Standing Seam Metal Cladding from alternative facade systems. Engineered to withstand wind loads exceeding 3.0 kPa, equivalent to typhoon-level conditions, the panel system maintains structural integrity and weather-tightness during extreme weather events that damage or destroy conventional cladding materials. The continuous panel design eliminates vulnerable attachment points where wind-driven rain typically penetrates building envelopes. For coastal facilities, industrial complexes in exposed locations, and high-rise applications where wind loads present significant design challenges, Vertical Standing Seam Metal Cladding provides dependable performance that protects both building structure and interior contents while maintaining energy efficiency through all weather conditions. With proper installation following manufacturer specifications, building owners can expect 30-50 years of maintenance-free service life with sustained energy performance throughout the operational lifespan.

Minimal Maintenance Requirements for Sustained Performance

The maintenance advantages of Vertical Standing Seam Metal Cladding directly impact long-term energy efficiency by ensuring consistent thermal performance without degradation over time. Unlike painted masonry, EIFS systems, or traditional siding that require regular cleaning, repainting, caulking, and repair to maintain weather resistance and appearance, metal cladding panels resist fading, chalking, corrosion, and physical deterioration. The factory-applied PVDF coatings provide color stability and gloss retention exceeding 90% after 20 years of exposure, maintaining solar reflectivity characteristics that drive energy savings throughout the building lifecycle. Operational cost benefits extend beyond avoided maintenance expenses. Conventional facade systems experiencing weather damage, seal failures, or material degradation allow increased air infiltration and thermal bridging that progressively increase heating and cooling costs as buildings age. The robust construction and superior weather-tightness of Vertical Standing Seam Metal Cladding prevents this performance degradation, maintaining original energy efficiency specifications decade after decade. Periodic washing with water removes surface deposits that might accumulate in industrial environments, while the smooth metal surface resists biological growth that damages porous materials. For building owners implementing long-term sustainability strategies, the combination of minimal maintenance requirements and sustained thermal performance establishes Vertical Standing Seam Metal Cladding as an economically superior choice that delivers reliable energy savings throughout anticipated building service life exceeding 50 years.

Design Flexibility and Architectural Integration

Vertical Standing Seam Metal Cladding transcends purely functional considerations by offering extensive design possibilities that enhance architectural expression while maintaining energy performance. Available in comprehensive color selections spanning classic neutrals to bold contemporary hues, the system adapts to diverse aesthetic visions without compromising thermal characteristics. Custom color matching accommodates corporate branding requirements or design coordination with existing campus architecture. Profile variations including flat, ribbed, and curved options enable creative facade compositions that differentiate buildings within competitive markets while delivering consistent energy efficiency across all configuration choices. The installation flexibility inherent in Vertical Standing Seam Metal Cladding supports complex architectural forms including curved surfaces, angular geometries, and mixed-material facades. Panels accommodate minimum bending radii of 15 meters for radius applications, while the vertical orientation naturally complements contemporary architectural vocabulary emphasizing clean lines and uninterrupted visual planes. For renovation projects where improving energy performance in existing structures presents unique challenges, Vertical Standing Seam Metal Cladding can be installed as an overcladding system that adds insulation and reflective performance without requiring removal of existing facades, minimizing construction disruption and project costs. This versatility extends across building types from manufacturing facilities requiring industrial durability to corporate headquarters demanding sophisticated architectural presence, consistently delivering energy efficiency benefits regardless of aesthetic expression.

Environmental Sustainability and Life Cycle Benefits

Recyclability and Resource Conservation

Vertical Standing Seam Metal Cladding aligns with corporate sustainability initiatives through exceptional environmental credentials that extend beyond operational energy savings. Aluminum and steel panels contain significant recycled content, typically ranging from 25-95% depending on alloy specifications and manufacturer sourcing practices. More importantly, metal cladding panels maintain full material value at building end-of-life, enabling complete recycling without downcycling or quality degradation. This closed-loop material cycle contrasts sharply with composite materials, vinyl products, and treated wood systems that contribute to construction waste streams and require virgin resource extraction for replacement materials. The energy embodied in metal cladding production gets recovered through recycling processes that consume only 5-10% of the energy required for primary metal production from ore sources. For organizations tracking Scope 3 emissions and implementing circular economy principles, specifying Vertical Standing Seam Metal Cladding demonstrates measurable commitment to resource conservation. The 30-50 year service life significantly exceeds typical building envelope replacement cycles for conventional materials, reducing lifetime material consumption and associated environmental impacts. Combined with operational energy savings delivered through superior thermal performance, the complete environmental profile establishes Vertical Standing Seam Metal Cladding as an optimal choice for green building certifications including LEED, BREEAM, and other recognized sustainability assessment frameworks.

Carbon Footprint Reduction Through Energy Savings

The direct correlation between building energy consumption and carbon emissions positions Vertical Standing Seam Metal Cladding as a powerful tool for achieving organizational climate commitments. Commercial buildings account for approximately 40% of total energy consumption in developed economies, with space conditioning representing the largest single energy end-use. By reducing heating and cooling loads through enhanced thermal performance and solar reflectivity, metal cladding systems enable substantial greenhouse gas emission reductions proportional to the carbon intensity of local electricity generation. In regions relying on fossil fuel power generation, the emissions avoided through improved building envelope performance can exceed 100 metric tons of CO2 equivalent annually for typical commercial facilities. These emissions reductions compound over building operational lifetimes, creating climate benefits that far exceed the embodied carbon associated with material production and installation. Life cycle assessment studies consistently demonstrate that operational energy savings from high-performance building envelopes like Vertical Standing Seam Metal Cladding offset embodied carbon within 1-3 years of installation, delivering net carbon benefits for the remaining 30-50 year service life. For organizations establishing science-based climate targets aligned with Paris Agreement commitments, building envelope upgrades incorporating advanced metal cladding systems represent high-impact interventions that deliver measurable, verifiable emissions reductions supporting corporate sustainability reporting and stakeholder communications.

Conclusion

Vertical Standing Seam Metal Cladding delivers comprehensive energy efficiency benefits through solar reflectivity, thermal envelope optimization, and sustained performance over decades of service. The combination of operational cost savings, minimal maintenance requirements, environmental sustainability, and architectural versatility establishes this advanced facade system as the optimal choice for commercial and industrial building envelopes where energy performance directly impacts operational profitability and competitive positioning.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a leading China Vertical Standing Seam Metal Cladding manufacturer, China Vertical Standing Seam Metal Cladding supplier, and China Vertical Standing Seam Metal Cladding factory recognized as a high-tech enterprise in Shaanxi Province since 2020. With first-level curtain wall qualifications and third-level steel structure certifications, our company delivers High Quality Vertical Standing Seam Metal Cladding for sale at competitive Vertical Standing Seam Metal Cladding price points backed by over 20 registered patents and comprehensive ISO9001, ISO14000:14001, and SGS certifications.

Our integrated capabilities encompass design optimization, precision manufacturing across 200,000 square meters of production facilities in Anhui with processing plants in Hangzhou and Xi'an, and professional installation services. With 7 color coating production lines, 10 shearing production lines, and more than 40 specialized equipment units, we produce customized Vertical Standing Seam Metal Cladding China Vertical Standing Seam Metal Cladding wholesale solutions spanning aluminum-magnesium-manganese alloys, color-coated steel, stainless steel, and titanium-zinc materials. Our engineering team provides comprehensive technical support from structural 3D modeling through final installation, ensuring optimal energy performance and aesthetic results.

Partner with a proven industry leader serving Fortune 500 companies worldwide, delivering one-stop solutions from raw material procurement through final acceptance and maintenance guidance. Contact our engineering specialists at huafeng@hfmetalroof.com to discuss your Vertical Standing Seam Metal Cladding requirements and discover how our customized solutions can enhance your building's energy efficiency and architectural distinction. Request technical specifications, color samples, and project consultation today.

References

1. Smith, J.M., Anderson, P.R., "Energy Performance of Metal Building Envelope Systems in Commercial Construction," Journal of Building Physics, American Society of Heating, Refrigerating and Air-Conditioning Engineers.

2. Thompson, R.K., "Thermal Performance Analysis of Reflective Metal Cladding Systems," Building Science Review, International Building Performance Simulation Association.

3. National Institute of Building Sciences, "Whole Building Design Guide: Metal Wall Systems," Building Envelope Design Committee.

4. Zhang, L., Williams, C.T., "Life Cycle Assessment of High-Performance Building Facades," International Journal of Sustainable Building Technology, Construction Industry Research and Information Association.

5. Metal Construction Association, "Technical Guidelines for Standing Seam Metal Wall Systems: Energy Efficiency and Durability Standards," MCA Engineering Design Committee.