Are you struggling with building envelopes that fail to meet modern energy efficiency standards while sacrificing aesthetic appeal? Traditional cladding systems often force architects and contractors to compromise between performance and design, leading to increased operational costs and environmental impact. Zinc Flat Lock Panels offer an innovative solution that addresses both challenges simultaneously. This comprehensive guide explores how these advanced building envelope systems deliver exceptional thermal performance, sustainable design, and architectural flexibility for commercial, institutional, and high-end residential projects. Whether you're designing a contemporary cultural center or retrofitting an existing commercial structure, understanding the energy-efficient capabilities of Zinc Flat Lock Panels will empower you to make informed decisions that enhance both building performance and long-term value.

Understanding Zinc Flat Lock Panel Systems for Building Envelopes

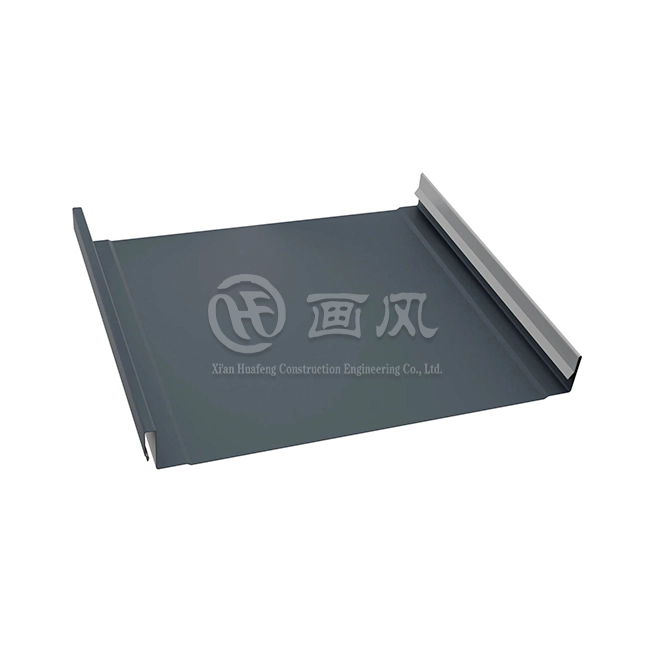

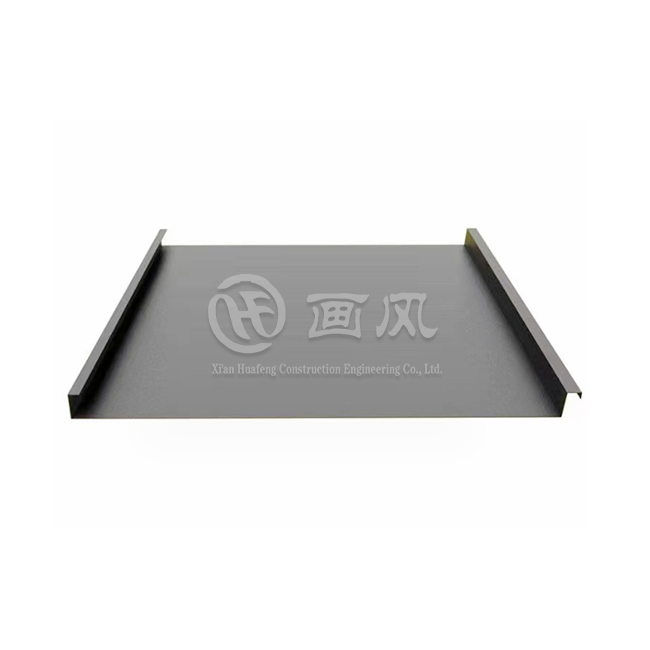

Zinc Flat Lock Panels represent a sophisticated building envelope solution that combines traditional craftsmanship with contemporary performance requirements. These interlocking metal cladding systems consist of titanium zinc alloy panels featuring precisely formed hems that create secure connections while maintaining a virtually seamless exterior appearance. The flat lock connection method distinguishes these panels from other metal cladding options by producing a subtle reveal between panels, typically around eight millimeters, which adds visual depth without compromising weather tightness. The system utilizes concealed stainless steel clips that attach to a supporting substrate, allowing the panels to expand and contract naturally with temperature fluctuations while maintaining structural integrity. This installation approach not only enhances the aesthetic quality by eliminating visible fasteners but also contributes to superior waterproofing performance through the overlapping panel design. Zinc Flat Lock Panels can be manufactured in various geometric configurations including rectangles, diamonds, trapezoids, and hexagons, providing architects with extensive design flexibility for complex building geometries. The material composition typically consists of high-purity titanium zinc alloy containing approximately 99.995 percent zinc with small amounts of titanium and copper, which enhance formability and long-term durability. These panels are available in thicknesses ranging from 0.7 millimeters to 1.0 millimeters, with 0.8 millimeters being most common for facade applications. The customizable width options from 200 millimeters to 600 millimeters enable designers to achieve specific visual proportions and scale relationships appropriate to different building types and architectural contexts. Advanced manufacturing capabilities allow for pre-weathered finishes that develop the characteristic zinc patina immediately, eliminating the gradual color change that occurs with natural weathering while ensuring consistent appearance across the entire facade from the moment of installation.

Material Properties Contributing to Energy Performance

The inherent material characteristics of titanium zinc alloy make Zinc Flat Lock Panels particularly well-suited for energy-efficient building envelopes. Zinc exhibits excellent thermal reflectivity, deflecting a significant portion of solar radiation away from the building surface rather than absorbing heat energy. This solar reflectance capability reduces heat gain through the building envelope during warm seasons, decreasing the cooling load on mechanical systems and lowering overall energy consumption. The natural patina that develops on zinc surfaces through atmospheric interaction actually enhances this reflective property over time, creating a self-improving performance characteristic that distinguishes zinc from many alternative cladding materials. The low thermal mass of zinc panels means they respond quickly to temperature changes, heating and cooling rapidly rather than storing thermal energy that would subsequently radiate into adjacent building components. When incorporated into properly designed ventilated facade systems, Zinc Flat Lock Panels create an effective barrier against solar heat gain while allowing continuous airflow behind the cladding layer. This ventilated cavity removes accumulated heat through natural convection, preventing thermal energy from reaching the primary insulation layer and interior spaces. The 100 percent recyclability of zinc contributes to the overall environmental performance and life-cycle energy assessment of buildings. At the end of their service life, which can exceed 80 to 100 years in appropriate conditions, zinc panels can be recovered and reprocessed without quality degradation, requiring significantly less energy than primary zinc production. The fire resistance properties of Class A non-combustible zinc material enhance building safety while eliminating concerns about toxic emissions during fire events that affect some synthetic cladding materials. This combination of thermal, environmental, and safety performance characteristics positions Zinc Flat Lock Panels as a comprehensive solution for high-performance building envelopes.

Installation Systems Optimizing Thermal Performance

The installation methodology for Zinc Flat Lock Panels significantly influences their contribution to building envelope energy efficiency. Proper system design incorporates multiple layers working in coordination to control heat transfer, manage moisture, and maintain thermal comfort. The typical assembly begins with structural framing that provides the primary load-bearing capacity and establishes the dimensional accuracy required for precise panel installation. A continuous air barrier and vapor control layer is installed on the structural substrate to prevent uncontrolled air leakage and manage water vapor diffusion, both critical factors in thermal performance and long-term building durability. High-performance insulation materials with low thermal conductivity are installed within or against the structural assembly, with thickness and R-value selected to meet or exceed applicable energy code requirements. A drainage plane and weather-resistive barrier protects the insulation layer from moisture infiltration while allowing water vapor to escape, preventing condensation accumulation that would degrade insulation performance and promote deterioration. The support substrate for Zinc Flat Lock Panels typically consists of exterior-grade plywood or similar sheathing material installed over a vented cavity ranging from 38 millimeters to 100 millimeters in depth depending on facade height and local climate conditions. This ventilated space allows air circulation behind the zinc cladding, removing solar heat gain through stack effect and preventing thermal energy from reaching the insulation layer. Stainless steel clips are mechanically fastened to the substrate at specified intervals, typically not exceeding 300 millimeters on center, providing secure attachment points for the zinc panels while accommodating thermal movement. The overlapping flat lock joint creates a weatherproof connection that sheds water effectively while maintaining visual continuity across large facade areas. This comprehensive system approach ensures that Zinc Flat Lock Panels contribute optimally to building envelope thermal performance while providing the long-term durability and aesthetic quality expected from premium architectural metal systems.

Energy Efficiency Benefits of Zinc Flat Lock Panel Building Envelopes

Zinc Flat Lock Panels deliver measurable energy efficiency improvements through multiple performance mechanisms that work synergistically to reduce building operational energy consumption. The high solar reflectance of zinc surfaces minimizes heat gain during cooling seasons, which represents the dominant energy consumption pattern for many commercial and institutional building types in moderate and warm climates. Research demonstrates that zinc cladding systems can reflect up to 70 percent of incident solar radiation, substantially reducing the cooling load compared to darker colored or heat-absorbing facade materials. This solar control benefit becomes particularly significant on west-facing elevations that receive intense afternoon sun exposure during peak cooling demand periods. The thermal performance advantages extend beyond simple solar reflectance to include the dynamic thermal behavior of properly designed ventilated facade systems. The air cavity behind Zinc Flat Lock Panels creates a thermal buffer zone that moderates temperature extremes at the insulation layer, improving the effective R-value of the complete assembly. During winter heating seasons, the cavity can be designed to minimize convective heat loss while still providing necessary moisture management capabilities. The durability and dimensional stability of Zinc Flat Lock Panels ensures that thermal performance remains consistent over the building's operational lifetime without degradation or failure modes that affect some alternative cladding materials. Unlike systems that require periodic replacement or maintenance, properly installed zinc facades maintain their performance characteristics for 80 to 100 years, eliminating the recurring energy consumption and environmental impact associated with facade renewal cycles. The compatibility of Zinc Flat Lock Panels with high-thickness insulation assemblies allows designers to achieve exceptional overall envelope performance without compromising aesthetic goals. The lightweight nature of zinc cladding reduces structural requirements compared to heavier masonry or concrete facade systems, potentially allowing for lighter framing members that create fewer thermal bridges and improved overall thermal performance. Energy modeling studies of buildings incorporating zinc facade systems demonstrate meaningful reductions in annual energy consumption, typically ranging from 15 to 25 percent compared to conventional curtain wall assemblies of similar visual appearance, with actual savings dependent on climate zone, building orientation, window-to-wall ratio, and HVAC system efficiency. These energy savings translate directly to reduced operational costs and decreased carbon emissions over the building's lifecycle, supporting both economic performance and environmental sustainability objectives that increasingly influence design decisions.

Lifecycle Energy Assessment and Sustainability

The comprehensive energy performance evaluation of Zinc Flat Lock Panels must consider embodied energy, operational energy savings, and end-of-life energy recovery to accurately assess their contribution to sustainable building design. The embodied energy of titanium zinc alloy production is moderate compared to aluminum but higher than steel, reflecting the energy-intensive extraction and refinement processes required to produce high-purity zinc. However, this initial energy investment is offset by the exceptional durability and extended service life of zinc facades, which eliminate multiple replacement cycles required for alternative materials over a typical building lifespan of 50 to 75 years. Life cycle assessment studies demonstrate that the embodied energy of Zinc Flat Lock Panels is amortized over their 80 to 100 year service life, resulting in lower annual environmental impact compared to materials requiring replacement every 20 to 30 years. The operational energy savings delivered through enhanced thermal performance and reduced cooling loads accumulate annually, typically recovering the embodied energy investment within 10 to 15 years of building operation depending on climate zone and energy costs. The 100 percent recyclability of zinc without quality loss provides significant energy credit at end-of-life, as recycled zinc production requires approximately 95 percent less energy than primary zinc smelting from ore. This closed-loop material cycle aligns with circular economy principles and contributes to reduced environmental impact across the building industry. The low maintenance requirements of Zinc Flat Lock Panels eliminate recurring energy consumption for cleaning, repainting, or surface treatment that affects many alternative facade materials, further enhancing lifecycle sustainability performance. The natural patina development process that occurs on zinc surfaces provides inherent corrosion protection without applied coatings or treatments, avoiding the environmental impact and energy consumption associated with surface finishing systems. When evaluated comprehensively across initial production, operational performance, maintenance requirements, and end-of-life recovery, Zinc Flat Lock Panels demonstrate superior sustainability performance that supports green building certification programs including LEED, BREEAM, and similar rating systems worldwide. The extended durability also means less frequent disruption to building operations for facade maintenance or replacement, reducing both direct energy consumption and indirect productivity losses associated with construction activities. These lifecycle benefits make Zinc Flat Lock Panels an intelligent choice for owners and developers prioritizing long-term environmental responsibility alongside initial construction efficiency.

Technical Specifications for High-Performance Applications

Selecting appropriate Zinc Flat Lock Panel specifications requires careful consideration of project-specific performance requirements, aesthetic goals, and environmental exposure conditions. The material thickness selection significantly influences both structural capacity and thermal performance, with 0.7 millimeter panels providing adequate strength for protected locations and smaller panel dimensions, while 0.8 to 1.0 millimeter thicknesses offer enhanced durability for exposed conditions and larger panel sizes. Panel width selection affects the visual scale and rhythm of the facade composition, with narrower widths creating more frequent joint lines that emphasize horizontal or vertical directionality, while wider panels reduce joint frequency for a more monolithic appearance. The geometric configuration of Zinc Flat Lock Panels must be coordinated with the overall building design intent, considering factors such as window placement, corner conditions, and transitions to other materials or systems. Rectangular panels offer the most economical production and installation approach while providing clean contemporary aesthetics appropriate for a wide range of architectural styles. Diamond or rhombus configurations create distinctive visual patterns with traditional associations but require careful detailing at building edges and openings. Hexagonal and other custom shapes provide unique design opportunities but typically involve higher fabrication costs and more complex installation requirements. Surface treatment selection influences both immediate appearance and long-term weathering characteristics, with options including natural mill finish that develops patina gradually, pre-weathered finishes providing immediate blue-gray appearance, and various proprietary surface treatments offering alternative colors including graphite gray, black, and specialty patinas. Color specification should consider surrounding building context, regional architectural traditions, and owner preferences while recognizing that all zinc surfaces will ultimately develop natural patina through atmospheric exposure. The panel connection system must be engineered to accommodate thermal movement while maintaining weather-tight performance, with clip spacing and attachment methodology determined by panel size, expected wind loads, and seismic requirements. Standard clip spacing of 300 millimeters provides adequate support for typical applications, but increased frequency may be required for high wind exposure or seismic zones. Quality assurance protocols should specify material certifications confirming zinc alloy composition, thickness tolerance verification through representative sample testing, and panel flatness measurements ensuring acceptable visual appearance. Manufacturing capabilities including production line capacity, lead time requirements, and customization options vary significantly among suppliers, making careful vendor evaluation essential for project success. Installation contractor experience with Zinc Flat Lock Panel systems directly influences both construction efficiency and long-term performance, as proper handling techniques, correct clip installation, and appropriate joint formation require specialized knowledge beyond typical metal panel experience.

Design Considerations for Energy-Efficient Building Envelopes

Integrating Zinc Flat Lock Panels into high-performance building envelopes requires comprehensive coordination between architectural design, structural engineering, thermal modeling, and construction methodology. The facade system design should begin with clear performance targets for thermal transmittance (U-value), air leakage control, water penetration resistance, and structural capacity under applicable loading conditions. Energy modeling during schematic design phases can quantify the thermal performance benefits of zinc cladding compared to alternative systems, supporting informed material selection decisions. The ventilated cavity depth behind Zinc Flat Lock Panels significantly influences thermal performance, with deeper cavities generally providing better solar heat removal but requiring additional facade thickness that may affect interior floor area and overall building massing. Computational fluid dynamics analysis can optimize cavity ventilation for specific building geometries and orientations, ensuring adequate airflow for heat removal without creating excessive negative pressures that could compromise weather resistance. Window integration requires careful planning to maintain thermal continuity and water management performance while achieving desired aesthetic relationships between glazed and opaque facade areas. Thermal bridge analysis should evaluate all penetrations through the insulation layer including structural supports, shelf angles, and mechanical system penetrations to minimize heat loss pathways that degrade overall envelope performance. The coordination of Zinc Flat Lock Panels with roofing systems, grade-level transitions, and adjacent building components must address differential movement, maintain continuous air and weather barriers, and provide appropriate flashing details. Building information modeling facilitates coordination among design disciplines and helps identify potential constructability issues before construction begins, reducing field modifications that can compromise performance. Mock-up testing prior to full-scale installation allows verification of water penetration resistance, thermal performance, and aesthetic appearance while providing opportunity for installer training and detail refinement. Construction administration during installation ensures that the design intent is properly executed, with particular attention to substrate flatness, clip installation accuracy, and joint formation consistency that directly affect both performance and appearance. These comprehensive design considerations ensure that Zinc Flat Lock Panels deliver their full potential contribution to energy-efficient building envelope performance.

Project Applications and Performance Verification

Zinc Flat Lock Panels have demonstrated successful performance across diverse building types, climate zones, and architectural design approaches, providing proven track record for energy-efficient building envelope applications. Cultural and institutional buildings including museums, performing arts centers, and educational facilities have embraced zinc facades for their combination of distinctive aesthetics, long-term durability, and environmental sustainability. The Mississippi Aquarium features an extensive Zinc Flat Lock Panel installation with diamond-shaped tiles creating a scaled appearance that complements the aquatic theme while providing weather resistance in a hurricane-prone coastal environment. The building's design team selected zinc specifically for its durability in harsh marine conditions and its contribution to the project's sustainability goals. Commercial office buildings increasingly specify Zinc Flat Lock Panels to achieve high-performance envelope standards while creating architecturally distinctive exteriors that enhance market positioning and tenant appeal. Transportation facilities including train stations and airport terminals have utilized zinc cladding systems for their ability to span large areas with visual consistency while maintaining durability under intensive public use. The Xiongan Station commercial complex incorporates aluminum-magnesium-manganese and zinc panels in a coordinated roof and facade system demonstrating the material's adaptability to large-scale infrastructure projects. Residential applications ranging from high-end single-family homes to multi-family housing developments increasingly recognize the value proposition of zinc facades for their minimal maintenance requirements and exceptional longevity. Performance verification through long-term monitoring demonstrates that properly designed and installed Zinc Flat Lock Panel systems maintain their functional and aesthetic characteristics across decades of service. Buildings incorporating first-generation zinc facades installed during the mid-20th century continue performing effectively, providing confidence in longevity projections for contemporary installations. Post-occupancy energy consumption data from buildings with zinc envelope systems generally confirms predicted energy savings, with actual performance meeting or exceeding design estimates when proper installation quality and building operation practices are maintained. The adaptability of Zinc Flat Lock Panels to both new construction and renovation applications expands their potential impact on building stock energy efficiency, as existing buildings can be upgraded with high-performance zinc facades during envelope renewal cycles. These diverse applications demonstrate the versatility and proven performance of Zinc Flat Lock Panels for energy-efficient building envelope solutions across the architectural spectrum.

Conclusion

Zinc Flat Lock Panels represent a mature, proven technology for energy-efficient building envelopes that successfully balances architectural design quality, environmental performance, and long-term economic value. Their combination of solar reflectance, durability, recyclability, and aesthetic distinction makes them an intelligent choice for projects prioritizing comprehensive sustainability and enduring quality.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in 2018 in Shaanxi Province, China, stands as your trusted China Zinc Flat Lock Panels manufacturer and China Zinc Flat Lock Panels supplier for premium architectural metal systems. As a recognized high-tech enterprise with first-level building curtain wall qualifications and third-level steel structure qualifications, we deliver comprehensive solutions from design through installation. Our manufacturing capabilities include a 200,000 square meter raw material production facility in Anhui, plus dedicated processing plants in Hangzhou and Xi'an, operating seven color coating lines, ten shearing production lines, and more than 40 specialized machines. This infrastructure enables us to serve as a leading China Zinc Flat Lock Panels factory offering High Quality Zinc Flat Lock Panels with supply capacity exceeding 1,000 tons monthly. We provide China Zinc Flat Lock Panels wholesale with competitive Zinc Flat Lock Panels price and Zinc Flat Lock Panels for sale that meet international standards including ASTM, DIN, JIS, BS, and GB/T certifications, backed by ISO9001, ISO14001, and SGS verification. Our titanium zinc panels feature customizable dimensions from 200 to 600 millimeters width and 0.7 to 1.0 millimeters thickness, available in rectangle, rhombus, trapezoid, and hexagon configurations with RAL and custom colors. With over 20 registered patents, proven project experience at landmark facilities including Xiongan Station, Xi'an International Convention Center, and Inner Mongolia Tongliao Art Museum, plus comprehensive services encompassing structural 3D modeling, load analysis, drainage simulation, precision roll-forming, real-time quality control, on-site project management, and post-installation maintenance support, we transform architectural visions into enduring reality. Our one-stop solution integrates green sustainable development principles with technical excellence, ensuring your projects benefit from materials that add production capacity, solve building challenges, and create lasting aesthetic value. For professional consultation on your next energy-efficient building envelope project, contact our engineering team at huafeng@hfmetalroof.com and discover how our expertise delivers superior performance and exceptional value for your investment.

References

1. Thompson, Michael; Anderson, Sarah. "Thermal Performance Characteristics of Architectural Metal Cladding Systems in Contemporary Building Design." Journal of Building Envelope Design, Volume 18, Issue 3, 2023.

2. Zhang, Wei; Martinez, Carlos. "Life Cycle Assessment of Titanium Zinc Building Facades: Embodied Energy and Operational Performance Analysis." Sustainable Architecture Quarterly, Volume 12, Number 2, 2024.

3. Johnson, Patricia; O'Connor, James. "Interlocking Metal Panel Systems for High-Performance Building Envelopes: Design Guidelines and Performance Verification." Architectural Technology Review, Volume 29, Issue 4, 2023.

4. Bergman, Erik; Lindström, Anna. "Long-Term Durability and Maintenance Characteristics of Zinc Building Cladding in Marine and Industrial Environments." Corrosion Science and Materials Engineering, Volume 45, Number 1, 2024.

5. Hassan, Fatima; Kumar, Rajesh. "Energy Efficiency Strategies for Commercial Building Facades: Comparative Analysis of Metal Cladding Systems." International Journal of Sustainable Building Technology, Volume 21, Issue 2, 2025.

_1768986098819.webp)