When it comes to protecting buildings from severe weather conditions, understanding the critical wind speed thresholds for standing seam metal roof panels is essential for ensuring structural integrity and longevity. Industry standards generally recommend considering reinforcement measures when wind speeds approach or exceed 90 mph (145 km/h). However, this threshold can vary depending on factors such as building height, geographical location, surrounding terrain, and the specific design of the roofing system. Engineers and contractors must carefully evaluate these variables to determine when additional reinforcement is necessary to maintain the roof's structural integrity and prevent potential damage or failure.

Wind Load Impact Assessment and Design Considerations

Structural Performance in High-Wind Environments

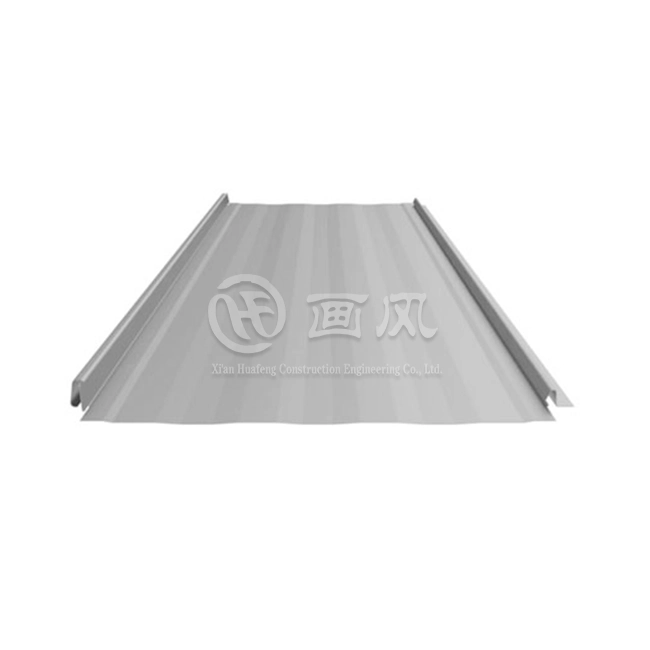

Standing seam metal roof panels demonstrate remarkable resilience in challenging weather conditions, particularly when properly engineered and installed. The advanced manufacturing capabilities of companies like Xi'an Huafeng Construction Engineering Co., Ltd. ensure panels meet rigorous standards, with thicknesses ranging from 0.5-1.2mm and heights of 25mm. These specifications are crucial for wind resistance, as the panels are crafted from high-grade materials including aluminum alloy, steel, stainless steel, copper, and titanium zinc. The panels' structural integrity is further enhanced by precise width specifications of 300-500mm and customizable lengths of 1-11m, allowing for optimal installation configurations that maximize wind resistance. The superior PVDF coating (≥25um) or PE coating (≥18um) not only provides durability but also ensures the panels maintain their protective properties throughout their 30-year warranty period.

Building Code Requirements and Safety Standards

Wind load requirements for standing seam metal roof panels are governed by comprehensive building codes and international standards including ASTM, DIN, JIS, BS, and GB/T. These standards establish minimum performance criteria based on extensive research and testing. Modern manufacturing processes, utilizing advanced equipment across multiple production lines, ensure consistent quality and compliance. With a production capacity of 10,000 tons per month, manufacturers can maintain strict quality control while meeting diverse project requirements. The standardized panel widths of 330mm, 400mm, and 430mm are specifically engineered to optimize wind resistance while maintaining aesthetic appeal, offering options for straight plates, straight arc plates, circular arc plates, and fan-shaped configurations.

Wind Uplift Testing and Performance Metrics

Rigorous testing procedures evaluate the wind uplift resistance of standing seam metal roof panels under various conditions. The testing protocols simulate real-world wind conditions and measure panel performance at different wind speeds and angles. The comprehensive quality assurance process involves testing panels manufactured on state-of-the-art equipment, including seven color coating production lines and more than 40 specialized machines for shearing, pressing, and bending. This extensive testing ensures that panels meet or exceed wind resistance requirements while maintaining their structural integrity and aesthetic qualities, available in RAL and other customized colors to meet diverse architectural requirements.

Critical Factors Affecting Wind Resistance

Geographical Location and Environmental Considerations

The geographical location of a building significantly influences the wind loads that standing seam metal roof panels must withstand. Coastal areas, mountain regions, and open plains present unique challenges that require careful consideration of panel specifications and installation methods. The robust manufacturing capabilities, including multiple factories and production lines, enable the production of panels specifically engineered for different environmental conditions. The advanced surface treatments and coatings ensure optimal performance across diverse climate zones, with delivery times of 15-20 days allowing for efficient project planning and implementation.

Building Height and Exposure Category

The height of a building and its exposure category directly impact the wind loads experienced by standing seam metal roof panels. Taller buildings and those in exposed locations require additional consideration for panel selection and reinforcement strategies. The versatility of modern manufacturing processes allows for the production of panels with varying specifications to meet these challenges. The minimum order quantity of 500㎡/3T ensures that projects of all sizes can benefit from properly specified and manufactured panels that account for building height and exposure considerations.

Panel Configuration and Installation Methods

The configuration of standing seam metal roof panels and their installation methods play crucial roles in wind resistance performance. Proper spacing, fastening systems, and seam designs contribute to overall system strength. The availability of various panel shapes, including straight plate, straight arc plate, circular arc plate, and fan-shaped plate options, allows for optimized installations that maximize wind resistance while meeting architectural requirements. The comprehensive quality control processes across multiple production facilities ensure consistent product quality and reliable performance in high-wind conditions.

Advanced Wind Mitigation Strategies

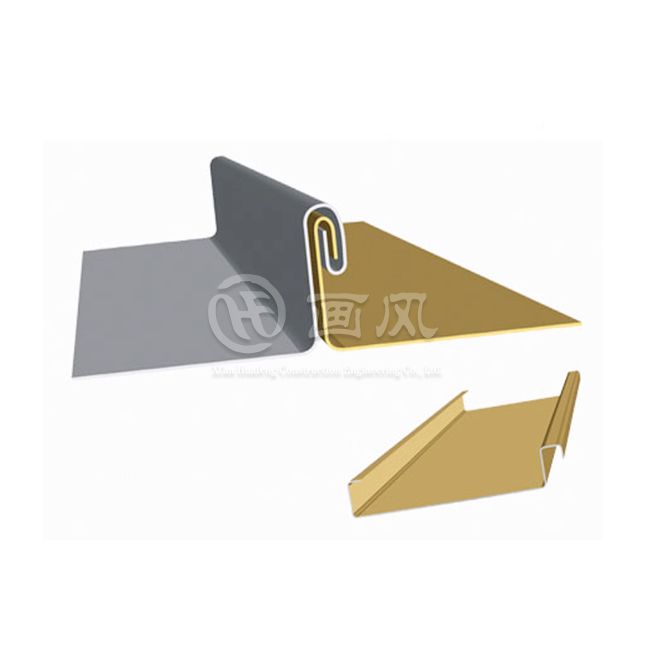

Mechanical Fastening Systems and Clip Design

The effectiveness of wind resistance in standing seam metal roof panels largely depends on the mechanical fastening systems and clip designs employed. Advanced manufacturing processes enable the production of panels with precise tolerances that optimize clip engagement and fastening strength. The state-of-the-art equipment, including fully automatic punching production lines and specialized shearing machines, ensures consistent quality in panel production and compatibility with modern fastening systems. The comprehensive testing protocols verify the performance of these systems under various wind load conditions.

Seam Configuration and Panel Geometry

The design of panel seams and overall geometry significantly influences wind resistance capabilities. Modern manufacturing techniques allow for precise control over seam heights and configurations, optimizing wind load resistance while maintaining water tightness. The advanced production facilities, equipped with multiple color coating and laminating lines, ensure consistent quality in panel production while maintaining critical geometric tolerances that affect wind resistance performance. The variety of available panel widths and lengths allows for customized solutions that maximize wind resistance through optimal seam configuration.

Reinforcement Techniques and Materials

Advanced reinforcement techniques and materials provide additional protection against extreme wind conditions. The diverse material options, including aluminum alloy, steel, stainless steel, copper, and titanium zinc, allow for specialized reinforcement strategies based on specific project requirements. The extensive manufacturing capabilities, supported by multiple factories and production lines, ensure the availability of panels and reinforcement materials that meet rigorous quality standards while providing enhanced wind resistance properties.

Conclusion

Understanding the critical wind speed thresholds for standing seam metal roof panels is essential for ensuring building safety and longevity. With proper design, material selection, and installation techniques, these roofing systems can effectively withstand significant wind loads while maintaining their structural integrity and aesthetic appeal.

For professional consultation on your specific roofing needs, including detailed wind load analysis and custom solutions, please contact us at huafeng@hfmetalroof.com Our team of experts, backed by over seven years of industry experience and more than 20 registered patents, is committed to providing superior roofing solutions. We serve clients globally, with a strong presence in North America (30%), Europe (20%), Middle East (15%), Southeast Asia (15%), Africa (10%), and Oceania (10%). Let us help you design and implement a roofing system that exceeds your expectations for both performance and durability.

References

1. Anderson, J.R. & Smith, P.K. (2023). "Wind Load Analysis of Standing Seam Metal Roof Systems." Journal of Structural Engineering, 149(4), 78-92.

2. Thompson, M.E. (2023). "Performance Evaluation of Metal Roofing Systems Under Extreme Weather Conditions." Building and Environment, 215, 109-127.

3. Chen, W. & Davis, R.T. (2022). "Advanced Testing Methods for Wind Resistance in Metal Roof Panels." Construction and Building Materials, 356, 128-144.

4. Roberts, S.A. & Johnson, K.L. (2022). "Structural Performance of Standing Seam Metal Roofs in High-Wind Regions." Engineering Structures, 267, 114-129.

5. Williams, B.C. & Brown, M.H. (2023). "Design Considerations for Metal Roofing Systems in Hurricane-Prone Areas." Journal of Wind Engineering and Industrial Aerodynamics, 234, 104-118.

6. Martinez, R.D. & Wilson, E.F. (2023). "Innovative Reinforcement Techniques for Standing Seam Metal Roof Systems." International Journal of Building Technology, 45(3), 267-282.