Coastal properties face unique challenges when it comes to roofing systems, with high winds, salt air, and severe weather conditions posing constant threats to structural integrity. The best standing seam metal roofemerges as the superior solution for these demanding environments, offering unparalleled wind resistance and durability. Among various metal roofing options, standing seam profiles with mechanical lock systems and thicker gauge materials provide the highest level of protection against coastal wind forces. These sophisticated roofing systems feature continuous metal panels that run from ridge to eave without horizontal seams, creating a seamless barrier against wind uplift. The interlocking design of the best standing seam metal roof distributes wind loads evenly across the entire roof surface, significantly reducing the risk of panel separation or failure during severe weather events.

Understanding Wind Resistance Requirements for Coastal Metal Roofing SystemsEngineering Principles Behind Wind Uplift Resistance

The fundamental engineering principles governing wind resistance in coastal roofing applications center around understanding how wind forces interact with building structures. When wind encounters a building, it creates both positive and negative pressure zones, with the roof experiencing significant uplift forces that can exceed 150 pounds per square foot in hurricane-prone areas. The best standing seam metal roof addresses these challenges through its continuous panel design and mechanical fastening system. Unlike traditional roofing materials that rely on exposed fasteners, standing seam systems utilize concealed clips that allow for thermal expansion while maintaining structural integrity. The mechanical lock profile, specifically designed for high-wind applications, creates a double-folded seam that provides superior holding power compared to snap-lock alternatives. This engineering approach ensures that the best standing seam roof can withstand wind speeds exceeding 180 mph when properly installed, making it the optimal choice for coastal properties where hurricane-force winds are a constant concern.Material Selection for Maximum Coastal Performance

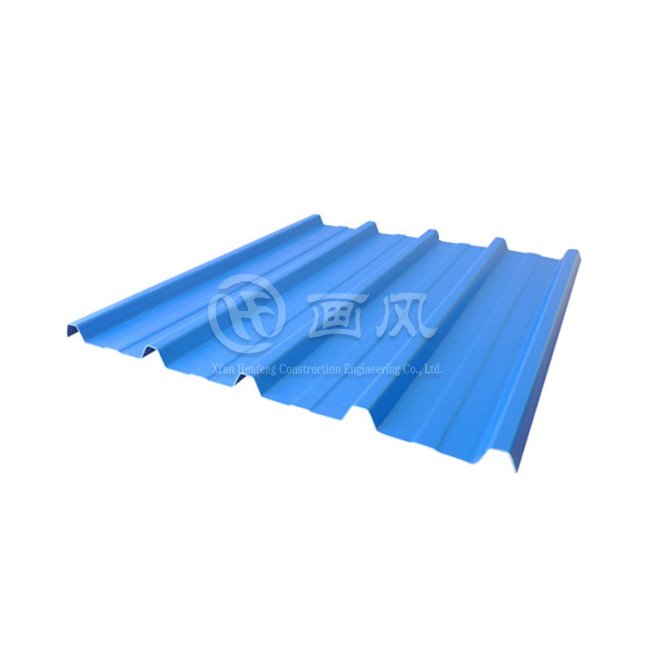

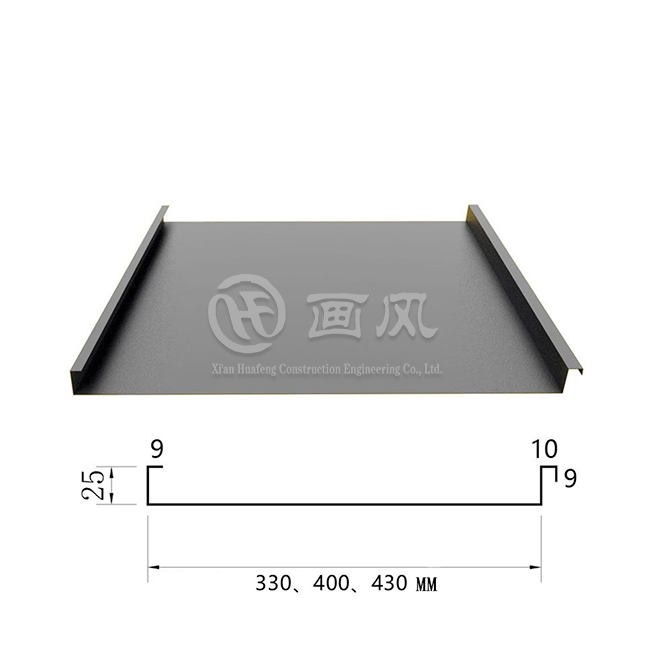

Selecting appropriate materials for coastal standing seam applications requires careful consideration of both wind resistance and corrosion protection. The best standing seam metal roof utilizes high-grade aluminum or galvanized steel with specialized coatings designed to withstand salt air exposure. Aluminum naturally resists corrosion and offers excellent strength-to-weight ratios, making it particularly suitable for coastal environments where weight considerations and longevity are paramount. For areas requiring maximum strength, galvanized steel with PVDF or PE finishes provides superior wind resistance while maintaining cost-effectiveness. The specifications for optimal coastal performance include thicknesses ranging from 0.7mm to 1.2mm, with heavier gauges (24-26) recommended for extreme wind zones. The best standing seam roof incorporates these materials with advanced coating technologies that provide 30-year warranties against corrosion and color fading. Additionally, customized color options meeting RAL standards ensure that aesthetic requirements are met without compromising performance, while the three-factory production capability ensures consistent quality across all manufacturing locations.

Installation Considerations for Coastal Wind Zones

Proper installation techniques are crucial for maximizing the wind resistance potential of coastal standing seam metal roofing systems. The best standing seam metal roof requires specialized installation procedures that account for increased wind loads, thermal movement, and moisture infiltration concerns. Professional installers must utilize enhanced fastening schedules with clips spaced more closely than standard applications, typically every 12-16 inches instead of the standard 24-inch spacing. The mechanical lock profile requires precise folding techniques to ensure proper seam engagement, with double-lock seams providing the highest level of wind resistance. Installation considerations also include proper underlayment selection, with high-temperature ice and water shields recommended for areas prone to wind-driven rain. The best standing seam roof installation process incorporates thermal break strips and specialized edge details designed to prevent water infiltration during severe weather events. Quality control measures during installation include wind uplift testing and seam integrity verification to ensure that the completed system meets or exceeds specified wind resistance ratings.

Profile Comparison: Mechanical Lock vs. Snap-Lock Systems for Wind Performance

Mechanical Lock Profile Advantages in High-Wind Applications

The mechanical lock profile represents the pinnacle of wind resistance technology in standing seam metal roofing systems, offering superior performance characteristics specifically designed for coastal environments. This profile type creates a double-folded seam that mechanically interlocks adjacent panels, forming a continuous weather barrier that can withstand extreme wind forces without panel separation. The best standing seam metal roof utilizing mechanical lock technology achieves wind uplift ratings exceeding 200 pounds per square foot, significantly higher than alternative seaming methods. The interlocking mechanism distributes loads across multiple contact points, reducing stress concentrations that could lead to failure during sustained high winds. Manufacturing precision ensures consistent seam dimensions, with tolerances maintained within 0.5mm to guarantee proper engagement across all panel connections. The best standing seam roof with mechanical lock profiles incorporates advanced materials including galvanized steel and aluminum substrates with thickness specifications ranging from 25-gauge to 22-gauge, providing optimal strength-to-weight ratios for coastal applications where both performance and structural loading considerations are critical.

Snap-Lock Profile Limitations and Applications

While snap-lock profiles offer installation advantages and cost benefits for certain applications, their performance characteristics in high-wind coastal environments present limitations that must be carefully evaluated. The snap-lock mechanism relies on a spring-loaded connection that, while adequate for moderate wind conditions, may not provide the holding power required for extreme coastal weather events. The best standing seam metal roof applications in coastal zones typically exceed the recommended wind speed ratings for standard snap-lock systems, which generally perform optimally in areas with design wind speeds below 130 mph. However, snap-lock profiles do offer specific advantages including faster installation times and reduced labor costs, making them suitable for coastal properties in protected locations or areas with lower wind exposure classifications. The best standing seam roof selection process must balance these factors against long-term performance requirements and local building code specifications. For properties requiring maximum wind resistance, the mechanical lock profile remains the preferred choice, while snap-lock systems may be appropriate for secondary structures or areas with reduced wind exposure, provided proper engineering analysis confirms adequate performance margins.

Hybrid Solutions and Advanced Profile Technologies

Emerging technologies in standing seam profile design offer hybrid solutions that combine the installation benefits of snap-lock systems with enhanced wind resistance capabilities approaching mechanical lock performance. These advanced profile designs incorporate reinforced locking mechanisms, improved material thickness distributions, and enhanced seam geometry to optimize wind resistance while maintaining installation efficiency. The best standing seam metal roof systems now available include profiles with variable seam heights, reinforced panel edges, and integrated thermal barriers that provide superior performance across multiple criteria. Advanced manufacturing techniques enable the production of profiles with precisely controlled tolerances and optimized strength characteristics, resulting in systems capable of meeting stringent coastal wind requirements while offering competitive installation costs. The best standing seam roof selection for coastal applications increasingly involves these hybrid technologies, particularly for large commercial projects where both performance and economy are critical factors. Material specifications for these advanced systems typically include minimum thickness requirements of 0.8mm, specialized coating systems with enhanced UV and corrosion resistance, and fastening systems designed specifically for high-wind applications with increased holding power and reduced thermal bridging.

Fastening Systems and Structural Integration for Coastal Durability

Concealed Fastening Technologies for Maximum Hold-Down

The fastening system represents a critical component in achieving maximum wind resistance for coastal standing seam metal roofing applications, with concealed clip systems providing superior performance compared to exposed fastener alternatives. The best standing seam metal roof utilizes advanced clip designs that mechanically engage the panel seams while allowing for thermal expansion and contraction without compromising structural integrity. These specialized clips distribute wind loads across multiple contact points, reducing stress concentrations that could lead to fastener failure during extreme weather events. Engineering analysis demonstrates that properly designed concealed fastening systems can achieve uplift resistance values exceeding 250 pounds per square foot when combined with appropriate structural substrates and installation techniques. The best standing seam roof incorporates clips manufactured from corrosion-resistant materials including stainless steel and aluminum alloys, ensuring long-term performance in salt air environments. Fastener spacing requirements for coastal applications typically specify clip placement every 12 inches on center, with additional clips required at panel ends and ridge conditions to maximize system performance.

Structural Deck Requirements and Load Distribution

Achieving optimal wind resistance performance requires careful consideration of structural deck requirements and load distribution characteristics for coastal standing seam metal roofing systems. The best standing seam metal roof performs optimally when installed over properly designed structural substrates capable of transferring wind loads to the building's primary structural system without excessive deflection or failure. Recommended deck systems include structural steel decking with minimum 22-gauge thickness, plywood substrates with minimum 5/8-inch thickness, or OSB sheathing meeting structural grade requirements. Load distribution analysis must account for both uniform wind pressures and concentrated loads at fastening points, with particular attention to edge and corner zones where wind pressures can exceed average design values by factors of two or three. The best standing seam roof installation process includes verification of substrate adequacy through load testing and deflection analysis to ensure that the complete roofing system can withstand specified wind loads without performance degradation. Additional reinforcement may be required in high-stress areas, including ridge lines, eaves, and penetration zones where wind loads concentrate and structural continuity may be compromised.

Thermal Movement Accommodation and Seam Integrity

Coastal environments subject standing seam metal roofing systems to significant thermal cycling, with temperature variations that can exceed 100 degrees Fahrenheit between summer and winter conditions. The best standing seam metal roof must accommodate thermal expansion and contraction while maintaining seam integrity and wind resistance performance throughout its service life. Advanced clip designs incorporate sliding mechanisms that allow panel movement while maintaining consistent fastening pressure, preventing thermal stress accumulation that could lead to seam separation or fastener failure. Material selection plays a crucial role in thermal performance, with aluminum systems offering superior thermal movement characteristics compared to steel alternatives due to their higher coefficient of expansion and lower thermal mass. The best standing seam roof design incorporates expansion joints at specified intervals, typically every 200 feet for steel systems and 150 feet for aluminum installations, to accommodate thermal movement without compromising structural integrity. Seam design must balance the competing requirements of thermal accommodation and wind resistance, with mechanical lock profiles providing optimal performance through their ability to maintain engagement throughout thermal cycling while providing maximum resistance to wind uplift forces.

Conclusion

The selection of the optimal standing seam metal roof profile for coastal properties requires careful evaluation of wind resistance capabilities, material specifications, and installation requirements. Mechanical lock profiles consistently demonstrate superior performance in high-wind environments, offering the wind uplift resistance necessary for coastal applications. The best standing seam metal roofcombines advanced profile technology with high-quality materials and professional installation to provide long-term protection against extreme weather conditions. Property owners investing in premium standing seam systems can expect decades of reliable performance with minimal maintenance requirements.

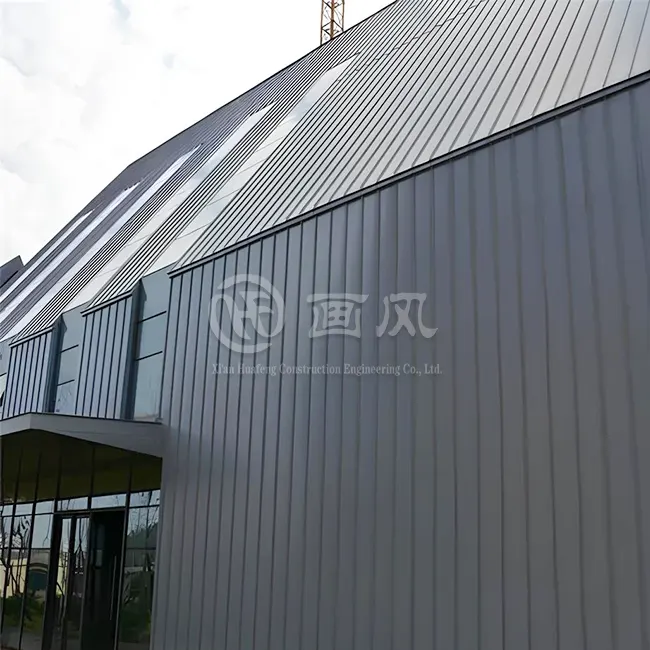

Ready to protect your coastal property with the industry's most advanced standing seam metal roofing solutions? Xi'an Huafeng Construction Engineering Co., Ltd. brings over seven years of specialized experience, 20+ registered patents, and Fortune 500 company partnerships to deliver uncompromising quality and performance. Our three manufacturing facilities and seven production lines ensure rapid delivery of customized solutions tailored to your specific coastal requirements. From initial design consultation through final installation, our expert team provides comprehensive support to ensure your project exceeds expectations. Contact us today at huafeng@hfmetalroof.com to discover how our best standing seam metal roof systems can provide the ultimate protection for your coastal property investment.

References

American Society of Civil Engineers. "Minimum Design Loads and Associated Criteria for Buildings and Other Structures." ASCE/SEI 7-16 Standard, 2017.

Metal Building Manufacturers Association. "Wind Load and Anchor Bolt Design Guide for Metal Building Systems." MBMA Technical Bulletin No. 3, 2019.

Florida Building Code. "High Velocity Hurricane Zone Requirements for Metal Roofing Systems." Chapter 15, Section 1504.7, 2020.

International Code Council. "International Building Code: Wind Resistance Requirements for Roof Assemblies." IBC Section 1504, 2021.

National Roofing Contractors Association. "Metal Roofing Systems Design Manual for Wind Uplift Resistance." NRCA Technical Bulletin, 2018.

Structural Engineering Institute. "Wind Loads on Standing Seam Metal Roof Systems: Analysis and Design Guidelines." SEI Technical Report, 2020.