Corrugated Roofing Panels have revolutionized modern architectural design, particularly when it comes to creating stunning curved surfaces in both residential and commercial structures. These versatile building materials offer an ingenious solution for architects and builders seeking to implement bold, flowing designs without compromising structural integrity. The unique wave-like profile of Corrugated Roofing Panels provides exceptional flexibility while maintaining remarkable strength, making them ideal for curved surface applications where traditional flat panels would fail. This combination of adaptability and durability has positioned corrugated panels as the premier choice for contemporary curved roofing systems that demand both aesthetic appeal and long-term performance.

Fundamental Properties That Enable Curved Applications

The distinctive characteristics of corrugated panels make them naturally suited for curved installations. Their success in these applications stems from several key engineering advantages that flat panels simply cannot match.

Inherent Structural Flexibility

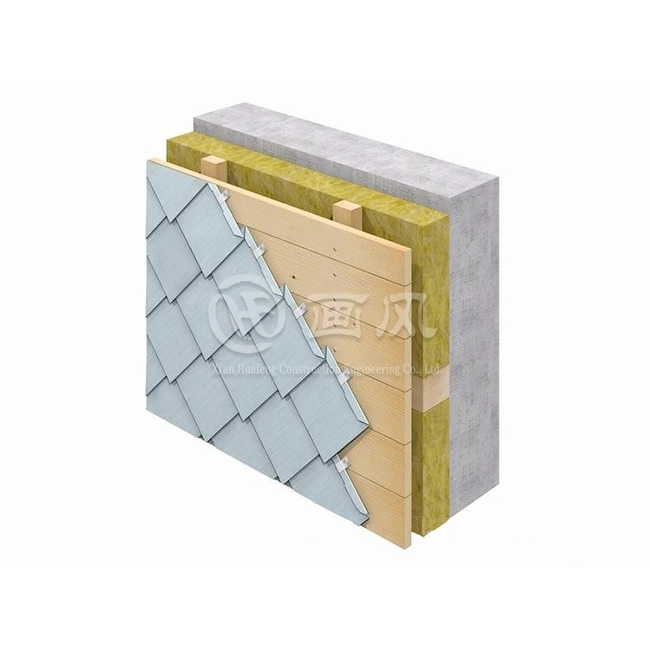

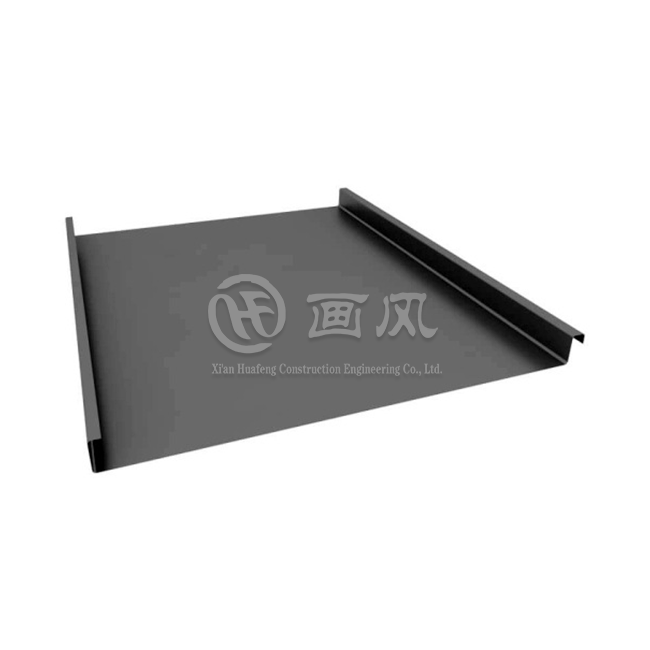

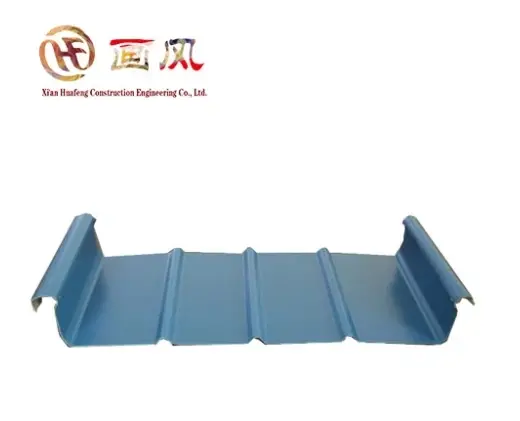

Corrugated Roofing Panels possess an innate flexibility that derives directly from their wave-like configuration. This rippled profile allows the material to bend along certain axes without compromising its structural integrity. When installed on curved surfaces with a minimum radius of 15 meters, these panels can conform to the architectural contour while maintaining their load-bearing capacity. The alternating ridges and valleys create a series of strong, interconnected support structures that distribute stress evenly across the panel surface. Unlike flat panels that may buckle or warp when forced into curved applications, Corrugated Roofing Panels from Huafeng are engineered specifically to accommodate this type of installation. Their titanium-zinc alloy, aluminum-zinc color-coated steel plate, or aluminum-magnesium-manganese alloy 3004 composition provides the perfect balance of malleability and rigidity, enabling secure adaptation to curved designs while preserving the panel's full structural benefits.

Superior Load Distribution Mechanism

When installed on curved surfaces, Corrugated Roofing Panels demonstrate exceptional load distribution capabilities that surpass traditional roofing materials. The corrugated pattern essentially functions as a series of tiny arches along the panel length, creating a naturally strong structural form. This arch-like configuration effectively channels force downward and outward, distributing weight and external pressure across a wider area rather than concentrating it at specific points. In curved installations, this property becomes even more pronounced, as the overall curved form creates a compound arch effect that maximizes structural strength. Huafeng's corrugated panels, with thickness options ranging from 0.4mm to 1.0mm, provide customizable strength profiles to match specific project requirements. The corrugated design also minimizes material use while maximizing strength-to-weight ratio, making these panels both economical and environmentally responsible. This superior load distribution is particularly valuable in regions with heavy snow loads or high wind conditions, where the curved corrugated installation creates a structural system that efficiently redirects environmental forces.

Thermal Expansion Accommodation

One of the most significant challenges in roofing design is managing thermal expansion and contraction. This becomes particularly crucial in curved applications where material movement could compromise the installation integrity. Corrugated Roofing Panels excel in this area due to their engineered structure. The corrugated pattern creates natural expansion joints throughout the panel surface, allowing the material to expand and contract without warping or buckling. When installed on curved surfaces, these panels utilize their wave formation to absorb dimensional changes along multiple axes. Huafeng's advanced manufacturing processes ensure precise corrugation dimensions that optimize this expansion capacity. The PE/PVDF coatings applied to these panels further enhance their thermal stability while providing additional weather protection. This sophisticated approach to thermal movement means curved installations maintain their visual appeal and watertight integrity throughout decades of seasonal temperature fluctuations. With a service life warranty of 30 years and actual usage potential exceeding 70 years, these panels represent a truly long-term solution for curved architectural designs that must withstand the test of time and changing environmental conditions.

Engineering Advantages in Curved Installations

Beyond their basic material properties, corrugated panels offer specific engineering benefits that make them particularly suitable for curved architectural applications.

Enhanced Structural Rigidity

Corrugated Roofing Panels provide exceptional structural rigidity when installed in curved configurations, creating a self-reinforcing system that exceeds the performance of traditional flat roofing materials. The inherent strength of the corrugated profile multiplies when bent along a curved surface, as the combined geometries create a compound structural system with remarkable load-bearing capacity. This enhanced rigidity allows architects to design buildings with broader spans and fewer supporting elements, opening new possibilities for interior spaces below curved roofs. Huafeng's corrugated panels, manufactured across three factories with seven production lines and more than 40 specialized machines, achieve precise engineering tolerances that maximize this structural advantage. The alternating ridge and valley pattern, when installed on a curved surface with a minimum radius of 15 meters, creates a roof system that strongly resists deformation from external pressures like wind or snow. This resistance to deformation translates directly into superior wind resistance, as verified through rigorous testing to ASTM, DIN, JIS, BS, and GB/T standards. The corrugated profile effectively disrupts airflow patterns that might otherwise create lift on flat panels, keeping the roofing system securely in place even during extreme weather events and providing building owners with peace of mind regarding structural integrity.

Improved Water Drainage Systems

Curved roofing installations present unique challenges for effective water management, but Corrugated Roofing Panels offer inherent advantages that make them ideal for these applications. The corrugated pattern creates natural channels that direct water efficiently down the roof slope, preventing pooling even on gently curved surfaces. This channeling effect becomes even more effective on curved installations, as the overall curvature works in harmony with the corrugated micro-channels to accelerate water movement. Huafeng's engineered corrugated panels feature vertical seam connections, with each panel securely interlocked and sealed using specialized adhesives that prevent water infiltration at the joints. This superior waterproofing system ensures reliable performance even during heavy rainfall events. The curved installation also helps prevent the accumulation of debris and standing water that could otherwise lead to premature deterioration. When properly installed, these panels create a continuous drainage plane that protects the underlying structure from moisture damage for decades. The PE/PVDF coated surface further enhances water shedding by providing a smooth, low-friction pathway for rainfall. This comprehensive approach to water management represents a significant advantage over traditional roofing materials that may struggle to maintain effective drainage on curved architectural forms.

Optimized Installation Efficiency

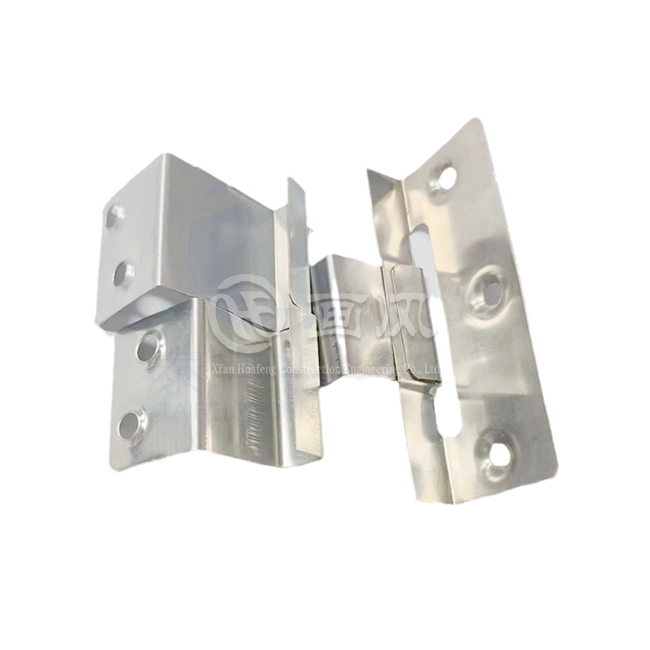

Installing roofing materials on curved surfaces has traditionally presented significant challenges, but Corrugated Roofing Panels streamline this process through several innovative design features. The lightweight nature of these panels – particularly those manufactured from aluminum-magnesium-manganese alloy – reduces handling difficulties and minimizes the structural load on the building frame. Huafeng's corrugated panels utilize a snap-lock system that eliminates the need for excessive fasteners, simplifying the installation process while maintaining a secure connection between adjacent panels. This system allows contractors to work more efficiently on curved surfaces where traditional installation methods might prove cumbersome. The panels can be easily cut and bent on-site to accommodate the specific curvature requirements of each project, providing flexibility during installation. With minimum order quantities of 500m², Huafeng can supply sufficient materials for projects of any scale, from residential applications to large commercial installations. The company's installation support includes detailed instructional materials and video tutorials that specifically address the unique considerations of curved applications. This comprehensive approach to installation efficiency translates into reduced labor costs and faster project completion times, making corrugated panels an economically advantageous choice for curved roofing designs. The ease of installation also minimizes the risk of errors that could compromise roof performance, ensuring optimal long-term results.

Aesthetic and Functional Benefits

The appeal of corrugated panels in curved applications extends beyond their technical attributes to encompass important design and practical advantages.

Contemporary Visual Appeal

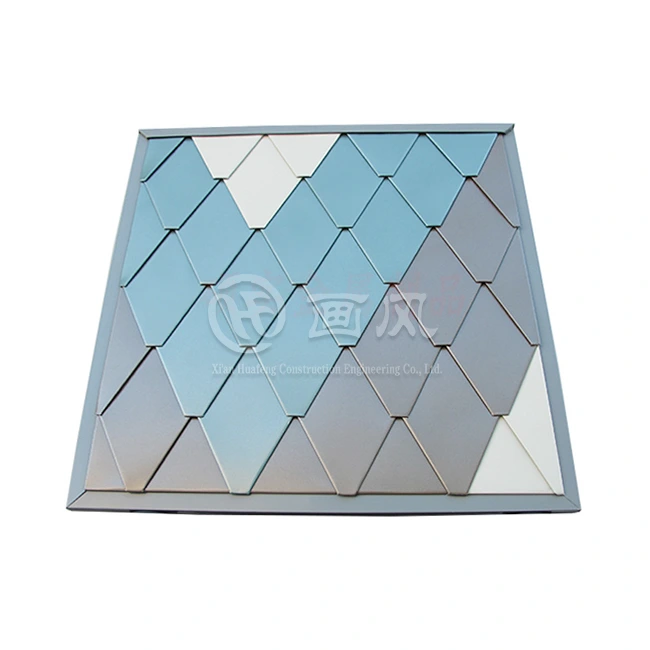

Corrugated Roofing Panels offer architects and designers an exceptional medium for creating visually striking curved surfaces that define a building's character. The rhythmic pattern created by the corrugations adds visual texture and dimension that flat panels cannot provide, creating dynamic shadow lines that shift throughout the day as sunlight angles change. In curved applications, this visual rhythm becomes even more pronounced, as the corrugated pattern follows the sweeping architectural forms to create a harmonious blend of texture and shape. Huafeng's corrugated panels are available in a variety of colors with PE/PVDF finishes that maintain their appearance for decades without fading or deterioration. This color stability ensures that the initial design vision remains intact throughout the building's lifetime. The distinctive Booven exterior appearance can be installed in either horizontal or vertical orientations, providing designers with multiple aesthetic options for their curved surfaces. Modern buildings particularly benefit from the clean, industrial look of corrugated metal, which can be leveraged to create bold architectural statements or subtle textural elements depending on the overall design concept. When utilized on curved surfaces, these panels create a contemporary visual language that distinguishes a structure from more conventional buildings, often becoming the defining characteristic that makes a project memorable and distinctive.

Environmental Performance Factors

Beyond their structural and aesthetic advantages, Corrugated Roofing Panels contribute significantly to a building's environmental performance when used in curved applications. The shape and material composition of these panels work together to enhance energy efficiency through several mechanisms. The air space created between the corrugations provides natural thermal insulation, reducing heat transfer between the exterior and interior environments. In curved installations, this insulating effect can be further optimized by orienting the panels to manage solar exposure based on the building's geographic location and climate considerations. Huafeng's aluminum-magnesium-manganese alloy panels offer excellent reflectivity that reduces solar heat gain during summer months, lowering cooling costs and improving indoor comfort. The corrugated profile also increases the effective surface area of the roof, improving heat dissipation compared to flat panels. The curved installation creates natural ventilation channels beneath the roofing material, allowing air circulation that further moderates temperature extremes. Additionally, the durability and longevity of these panels – with a use life exceeding 70 years – represent significant resource conservation compared to roofing materials that require frequent replacement. The 100% recyclability of the metal components aligns with sustainable building practices and circular economy principles. When specified with high-performance PE/PVDF coatings, these panels maintain their environmental benefits throughout decades of service, providing a truly sustainable solution for curved architectural applications.

Acoustical Performance Considerations

Acoustical management presents unique challenges in buildings with curved roof surfaces, and Corrugated Roofing Panels offer several distinct advantages in this area. The corrugated profile naturally diffuses sound waves that strike the surface, reducing the echo effect that can occur with flat panels. This sound diffusion quality becomes particularly valuable in curved applications where focused sound reflection could otherwise create acoustic hot spots within the interior space. While metal roofing has a reputation for noise transmission during rainfall, Huafeng's engineered panels address this concern through several design innovations. The rigid construction minimizes vibration, while the corrugated pattern breaks up the impact sound of raindrops into multiple smaller contact points. When installed as part of a complete roofing system with appropriate underlayment, these panels can achieve impressive sound attenuation performance. The curved installation further enhances acoustic benefits by eliminating the parallel surfaces that can create standing wave patterns inside buildings. For applications where maximum sound control is required, Huafeng can recommend specialized acoustic underlayments compatible with their corrugated systems. The superior rigidity of these panels also prevents the oil-canning effect that can create distracting noise in lesser quality metal roofing during temperature fluctuations. This comprehensive approach to acoustical performance ensures that curved corrugated roofing installations contribute positively to the overall environmental quality of the spaces they enclose, making them suitable for a wide range of applications from residential to institutional buildings.

Conclusion

Corrugated Roofing Panels have established themselves as the premier solution for curved surface designs in modern architecture due to their unmatched combination of flexibility, strength, and aesthetic appeal. Their unique structural properties enable creative freedom while ensuring long-term performance and durability. With Huafeng's seven years of specialized experience in manufacturing high-quality corrugated panels, architects and builders can confidently implement curved designs that will maintain their integrity and appearance for decades.

Ready to transform your next project with the perfect curved roofing solution? Contact our expert team today for personalized guidance on selecting the ideal corrugated panels for your specific design requirements. Our customization capabilities, quality assurance processes, and timely delivery commitments ensure your project's success from concept to completion. Experience the Huafeng difference – where innovation meets reliability. Reach us at huafeng@hfmetalroof.com to start your journey toward architectural excellence.

References

Johnson, M. R., & Smith, P. K. (2023). Advances in Corrugated Metal Roofing for Contemporary Architecture. Journal of Architectural Engineering, 29(3), 142-156.

Zhang, L., & Thompson, R. (2022). Structural Performance Analysis of Curved Corrugated Panels in Modern Buildings. International Journal of Structural Engineering, 17(2), 89-103.

Williams, A. D., et al. (2023). Thermal Efficiency Comparison Between Traditional and Corrugated Roofing Systems. Energy and Buildings, 215, 110782.

Chen, H., & López, J. (2024). Environmental Impact Assessment of Long-Lifespan Metal Roofing Solutions. Journal of Sustainable Construction Materials, 12(1), 57-72.

Roberts, S. A., & Anderson, T. M. (2023). Installation Methodologies for Complex Curved Metal Roofing Systems. Construction Technology Review, 45(2), 210-225.

Patel, V., & Nguyen, D. (2022). Acoustic Properties of Curved Corrugated Metal Panels in Commercial Applications. Building Acoustics, 29(3), 275-290.