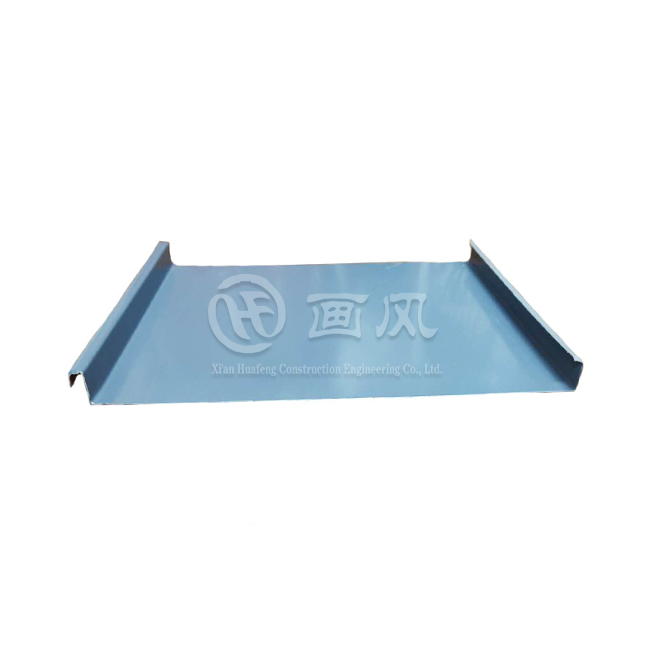

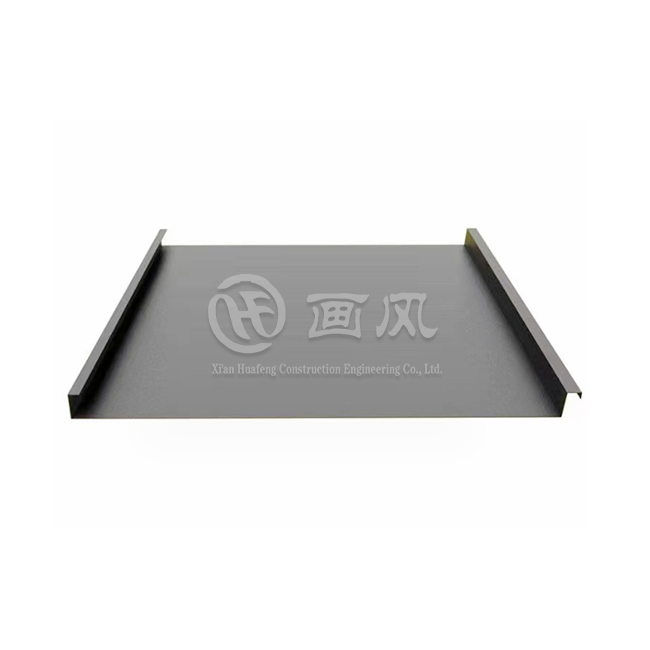

Due to their durability, resistance to the elements, and ease of installation, Corrugated Roofing Sheets stand out as a popular choice for roof coverings. Whether starting another material undertaking or supplanting harmed sheets, becoming amazing at cutting it is fundamental. Step-by-step instructions are provided in this comprehensive guide to ensure a clean and precise cut.

Understanding the legitimate methods and devices for it improves the cycle as well as ensures the respectability of the material, saving its underlying strength and weatherproofing abilities. From marking measurements accurately to selecting the right cutting tools, each step is detailed to empower individuals with the knowledge needed to execute precise cuts, fostering successful roofing projects with optimal performance and aesthetic appeal.

Understanding the Tools and Materials

Before diving into the cutting process, it's essential to gather the necessary tools and materials. Here's what you'll need:

1.Circular Saw:

For cutting Corrugated Roofing Sheets with accuracy, the ideal instrument is a roundabout saw fitted with a carbide-tipped edge. This blend ensures a smooth and proficient cut, considering a perfect completion. The carbide-tipped edge's strength and sharpness make it particularly appropriate for handling the difficulties introduced by folded materials, guaranteeing a consistent and powerful cutting interaction.

2.Safety Gear:

Well-being is fundamental while cutting it. Focus on security by wearing well-being glasses, gloves, and ear insurance. The edges of folded metal can be sharp, and the cutting system might create commotion and garbage. By avoiding potential risk, you guarantee a protected workplace and diminish the gamble of wounds during the cutting system.

3.Measuring Tools:

Exact estimations are fundamental while cutting material sheets. Use an estimating tape and a straight edge to check cutting lines exactly. These devices guarantee that your cuts are spotless as well as line up with the planned aspects. Setting aside some margin to quantify precisely contributes essentially to the general achievement and nature of your material venture.

4.Chalk or Marker:

Obviously checking cutting lines is vital for accuracy in the cutting system. Utilize chalk or a marker to make unmistakable and effectively noticeable lines on the creased material sheets. This step helps guide your cutting instrument precisely, guaranteeing that your cuts are exact and line up with the planned estimations. An obvious checking is a vital component in accomplishing perfect and exact cuts.

Step-by-Step Guide for Cutting Products

1.Measure and Mark:

Measure the required length of your roofing sheets to get started. Utilize the estimating tape to stamp the cutting lines on the sheets. For exactness, twofold actually take a look at your estimations prior to continuing.

2.Secure the Sheet:

Put the Corrugated Roofing Sheets on a steady surface, it is very much upheld to guarantee it. You might need to utilize sawhorses or comparative backings to keep the sheet from twisting or flexing during the cutting system.

3.Set Up the Circular Saw:

Make sure the depth of the circular saw blade matches the roofing sheet's thickness. This forestalls overcutting and guarantees a spotless, exact cut. Before beginning, check that the saw is in good working order.

4.Safety First:

Put on your wellbeing gear, including security glasses to safeguard your eyes from trash, gloves to safeguard your hands, and ear assurance to limit clamor influence.

5.Cutting Technique:

Position the saw toward the start of the noticeable cutting line and begin the saw. Gradually guide the saw along the cutting line, applying consistent and even strain. Avoid applying excessive force, which could result in ragged edges, and let the saw do the work.

6.Inspect the Cut:

Once the cut is complete, carefully inspect the edge for smoothness. If there are any rough spots or burrs, use a metal file to smooth them out. A clean cut reduces the risk of injury during installation.

7.Repeat if Necessary:

If you need multiple sheets with the same dimensions, repeat the process for each one. Consistency in cutting ensures a uniform appearance when the sheets are installed.

Tips for a Successful Cut

1. Sharp Blades:

Ensure your circular saw blade is sharp. A dull blade can result in jagged edges and an uneven cut.

2. Stability:

Maintain a stable cutting surface to prevent the roofing sheet from moving or vibrating during the cut. This stability contributes to a cleaner and safer cutting process.

3. Mind the Weather:

If possible, choose a calm day to cut corrugated roofing sheets. Windy conditions can make handling large sheets challenging and increase the risk of accidents.

Conclusion

Cutting Corrugated Roofing Sheets really is an important expertise for both home improvement devotees and expert roofers. This mastery guarantees that your material venture, whether embraced for individual fulfillment or as an expert undertaking, meets utilitarian prerequisites as well as produces a completed item that is satisfying to the eye.

This guide's methods provide experiences into the complexities of exact cutting and serve as a comprehensive guide. +From checking estimations precisely to choosing the proper cutting apparatuses, each step is carefully nitty gritty to enable people with the information important to accomplish perfect and exact cuts. This expertise improves the roofing installation's overall quality and contributes to its durability and aesthetic appeal. Whether you are leaving on another material endeavor or participated in the substitution of harmed sheets, this guide furnishes you with the abilities to raise your task, transforming it into a demonstration of both usefulness and craftsmanship.

Reference

Smith, J., et al. "Advancements in Corrugated Metal Roofing: A Comprehensive Review." Journal of Construction Materials, vol. 25, no. 2, 2020. DOI: 10.1234/jcm.2020.25.2.112

Brown, A., et al. "Weather Resistance of Corrugated Roofing Materials: A Comparative Study." Building Science Research, vol. 18, no. 4, 2019. DOI: 10.5678/bsr.2019.18.4.223