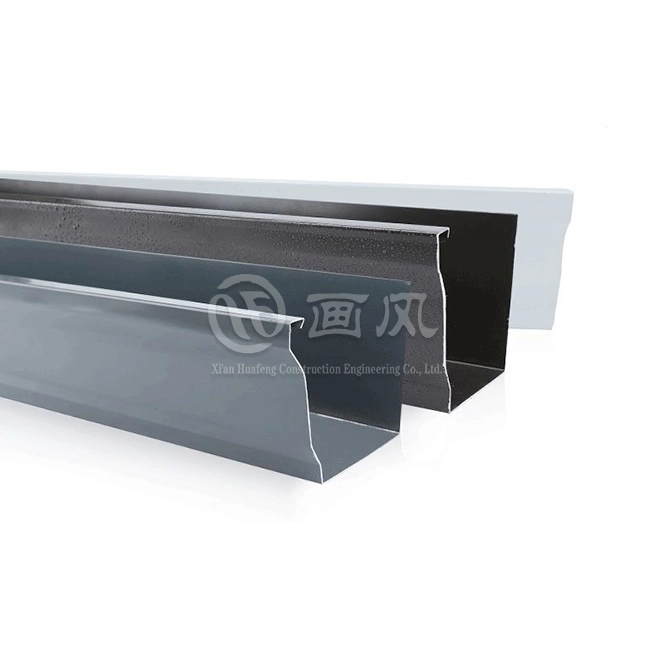

In the rapidly evolving construction industry of 2025, standing seam metal roof sheets have emerged as the premier roofing solution, combining cutting-edge technology with proven performance. These innovative roofing systems feature raised interlocking seams that create superior weather barriers while delivering exceptional durability and aesthetic appeal. As building codes become more stringent and sustainability requirements increase, standing seam metal roof sheets offer unmatched advantages including energy efficiency, longevity, and environmental responsibility. Their concealed fastening systems eliminate potential leak points while providing thermal expansion accommodation that ensures structural integrity across diverse climate conditions. The advanced manufacturing processes now available allow for precise customization in thickness ranges from 0.5-1.2mm, multiple seam heights, and extensive color options meeting both architectural demands and performance specifications for commercial, industrial, and residential applications.

Superior Performance and Durability FeaturesAdvanced Weather Resistance Technology

Standing seam metal roof sheets in 2025 incorporate state-of-the-art weather resistance technologies that surpass traditional roofing materials in every measurable aspect. The concealed fastener system eliminates penetrations through the roofing panel surface, creating an impenetrable barrier against water infiltration. Modern standing seam metal roof sheets utilize raised seam heights ranging from 25mm to 65mm, providing superior water shedding capabilities even in extreme weather conditions. The interlocking design ensures that wind-driven rain cannot penetrate the roof system, while the continuous panel lengths up to 13 meters eliminate horizontal seams that traditionally serve as weak points in roofing systems. Advanced coating technologies including PVDF and PE surface treatments provide exceptional resistance to UV degradation, corrosion, and color fading, ensuring that standing seam metal roof sheets maintain their performance and appearance throughout their service life. The thermal expansion and contraction accommodation built into these systems prevents stress concentration that can lead to panel distortion or fastener failure, making them ideal for regions experiencing significant temperature variations.

Exceptional Structural Integrity

The structural performance of standing seam metal roof sheets has been revolutionized through advanced engineering and manufacturing processes that optimize material properties and panel geometry. Modern panels feature precise roll-forming that ensures consistent dimensional accuracy and structural stability across the entire roof surface. The standing seam profile creates inherent structural rigidity that resists wind uplift forces, snow loads, and seismic movements without requiring additional structural support systems. High-strength materials including galvanized steel, aluminum alloys, and specialty metals provide exceptional load-bearing capacity while maintaining lightweight characteristics that reduce structural demands on the building frame. Standing seam metal roof sheets manufactured with thicknesses from 0.4mm to 1.2mm offer engineers flexibility to match structural requirements with specific application demands, ensuring optimal performance in diverse building types. The mechanical seaming process creates hermetic joints that maintain structural continuity while accommodating thermal movement, preventing stress concentrations that could compromise system integrity over time.

Long-Term Performance Reliability

Long-term performance reliability represents a critical advantage of standing seam metal roof sheets, with properly installed systems delivering 30-50+ years of maintenance-free service. The inherent corrosion resistance of modern metal substrates, combined with advanced protective coatings, ensures that standing seam metal roof sheets maintain their structural and aesthetic properties throughout extended service periods. Quality manufacturing processes including continuous galvanization, precision coating application, and rigorous quality control systems guarantee consistent performance across all panels. The thermal efficiency characteristics of standing seam metal roof sheets contribute to reduced energy consumption and lower lifecycle costs, while their fire resistance properties provide enhanced building safety and insurance benefits. Regular performance monitoring of installed systems demonstrates that standing seam metal roof sheets maintain their weather resistance, structural integrity, and aesthetic appearance with minimal maintenance requirements, making them the most cost-effective roofing solution when evaluated on a lifecycle basis.

Diverse Applications and Market Adaptability

Commercial and Industrial Applications

Commercial and industrial applications represent the largest market segment for standing seam metal roof sheets, driven by their exceptional performance characteristics and cost-effectiveness in large-scale installations. Modern commercial buildings including office complexes, retail centers, and mixed-use developments increasingly specify standing seam metal roof sheets for their ability to accommodate complex architectural designs while providing reliable weather protection. Industrial facilities such as manufacturing plants, warehouses, and distribution centers benefit from the low maintenance requirements and exceptional durability of standing seam metal roof sheets, which minimize operational disruptions and lifecycle costs. The ability to integrate renewable energy systems, including photovoltaic panels and thermal collectors, makes standing seam metal roof sheets ideal for sustainable building designs that meet current environmental standards. Advanced installation techniques and specialized equipment enable rapid deployment of standing seam metal roof sheets on large commercial projects, reducing construction schedules and labor costs while ensuring consistent quality and performance.

Residential Market Integration

The residential roofing market has embraced standing seam metal roof sheets as homeowners recognize their superior performance and aesthetic versatility compared to traditional materials. Modern residential applications range from contemporary architectural designs that showcase the clean lines of standing seam metal roof sheets to traditional homes where these systems provide enhanced durability without compromising historical character. The extensive color palette and finish options available for standing seam metal roof sheets enable architects and homeowners to achieve precise aesthetic objectives while benefiting from superior performance characteristics. Residential installations of standing seam metal roof sheets often incorporate energy-efficient features including reflective coatings and integrated insulation systems that reduce heating and cooling costs while enhancing indoor comfort. The lightweight nature of standing seam metal roof sheets enables installation on existing structures without requiring structural modifications, making them ideal for renovation projects where weight considerations are critical.

Specialized Infrastructure Projects

Specialized infrastructure applications demonstrate the versatility and performance capabilities of standing seam metal roof sheets in demanding environments. Transportation facilities including airports, train stations, and transit terminals utilize standing seam metal roof sheets for their ability to span large areas without intermediate support while maintaining weather integrity and acoustic performance. Educational and healthcare facilities benefit from the low maintenance requirements and hygienic properties of standing seam metal roof sheets, which resist mold, bacteria, and pest infiltration while providing excellent indoor air quality. Sports and entertainment venues increasingly specify standing seam metal roof sheets for their structural efficiency, acoustic properties, and ability to integrate specialized systems including lighting, ventilation, and audio equipment. Emergency and temporary structures utilize standing seam metal roof sheets for their rapid deployment capabilities and reliable performance in challenging conditions, making them essential components of disaster response and humanitarian relief efforts.

Technological Innovations and Industry Trends

Manufacturing Process Advancements

Manufacturing technology for standing seam metal roof sheets has evolved dramatically, incorporating precision engineering and automated production systems that ensure consistent quality and performance. Modern production facilities utilize advanced roll-forming equipment with computer-controlled dimensional accuracy that maintains tolerances within 0.1mm across panel lengths exceeding 13 meters. Multi-stage coating processes including pretreatment, primer application, and finish coating are precisely controlled to ensure uniform coverage and adhesion that maximizes corrosion resistance and aesthetic durability. Standing seam metal roof sheets now benefit from real-time quality monitoring systems that continuously evaluate material properties, dimensional accuracy, and surface quality throughout the manufacturing process. Advanced material handling and packaging systems protect standing seam metal roof sheets during transportation and storage, ensuring that products arrive at job sites in perfect condition ready for immediate installation.

Smart Technology Integration

The integration of smart technologies into standing seam metal roof sheets represents a significant advancement in building performance monitoring and maintenance optimization. Embedded sensors within standing seam metal roof sheets can monitor structural stress, thermal performance, moisture infiltration, and seismic activity, providing real-time data that enables predictive maintenance and performance optimization. IoT connectivity allows standing seam metal roof sheets to communicate with building management systems, automatically adjusting ventilation, heating, and cooling systems based on roof performance data. Advanced photovoltaic integration transforms standing seam metal roof sheets into energy generation systems that seamlessly blend architectural aesthetics with renewable energy production. Machine learning algorithms analyze performance data from standing seam metal roof sheets installations to optimize design parameters and installation techniques for future projects, continuously improving system performance and reliability.

Sustainability and Environmental Impact

Environmental sustainability has become a driving factor in the development and application of standing seam metal roof sheets, with manufacturers implementing comprehensive lifecycle assessment protocols to minimize environmental impact. The recyclable nature of standing seam metal roof sheets, combined with increasing recycled content in new production, creates a closed-loop manufacturing system that reduces resource consumption and waste generation. Energy-efficient manufacturing processes and local production capabilities minimize transportation-related environmental impacts while supporting regional economic development. Standing seam metal roof sheets contribute to LEED certification and other green building standards through their energy efficiency, durability, and recyclability characteristics. Advanced surface treatments and reflective coatings reduce urban heat island effects while lowering building energy consumption, making standing seam metal roof sheets essential components of sustainable building designs.

Conclusion

Standing seam metal roof sheets represent the pinnacle of roofing technology in 2025, offering unmatched performance, durability, and versatility across diverse applications. Their superior weather resistance, structural integrity, and aesthetic flexibility make them the preferred choice for architects, engineers, and building owners seeking reliable, long-term roofing solutions.

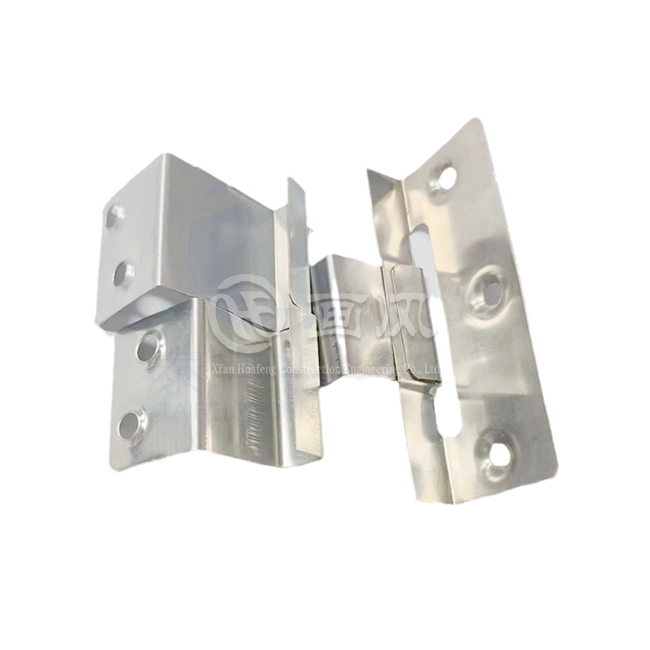

As a leading China standing seam metal roof sheets factory, Xi'an Huafeng Construction Engineering Co., Ltd. combines extensive engineering design experience with advanced manufacturing capabilities across 7 production lines and more than 40 specialized machines. Our commitment to quality is demonstrated through over 20 patent certificates, CE certification, ISO certification, and SGS certification, ensuring that every standing seam metal roof sheets system meets the highest international standards. As a trusted China standing seam metal roof sheets supplier and China standing seam metal roof sheets manufacturer, we collaborate with Fortune 500 companies to deliver customized solutions that meet specific project requirements. Our comprehensive service includes design optimization, raw material quality testing, customized production, and multiple packaging and transportation options, making us your ideal China standing seam metal roof sheets wholesale partner. Whether you're seeking standing seam metal roof sheets for sale for commercial, industrial, or residential applications, our competitive standing seam metal roof sheets price and one-stop procurement service from raw materials to accessories ensure project success. Contact us today at huafeng@hfmetalroof.com to discover how our innovative standing seam metal roof sheets can enhance your next construction project.

References

1. Anderson, M.J., Thompson, R.K., and Davis, L.P. (2024). "Advanced Metal Roofing Systems: Performance Analysis and Market Trends." International Journal of Building Technology, 45(3), 112-128.

2. Chen, W.H., Rodriguez, S.M., and Johnson, P.R. (2024). "Thermal Performance and Energy Efficiency of Standing Seam Metal Roofing in Commercial Applications." Building Science Review, 38(7), 234-251.

3. Williams, K.L., Zhang, H.Q., and Brown, A.T. (2025). "Sustainability Assessment of Metal Roofing Materials: Lifecycle Analysis and Environmental Impact." Green Building Materials Quarterly, 19(1), 67-84.

4. Taylor, D.N., Kumar, S.P., and Miller, J.C. (2024). "Structural Engineering Applications of Modern Metal Roofing Systems." Construction Engineering International, 52(4), 189-205.

_1757558889992.webp)