In today's competitive architectural landscape, selecting the right roofing system can make or break a project's success. Metal Standing Seam Roofing systems have emerged as the gold standard for architects seeking uncompromising performance, aesthetic appeal, and long-term value. These sophisticated roofing solutions combine cutting-edge engineering with proven durability, offering architects the flexibility to create stunning designs while meeting the most demanding structural requirements. From iconic airport terminals to state-of-the-art sports stadiums, Metal Standing Seam Roofing systems deliver exceptional performance across diverse applications, making them the preferred choice for discerning architectural professionals worldwide.

Superior Structural Performance and Engineering Excellence

Metal Standing Seam Roofing systems represent the pinnacle of structural engineering in modern roofing technology. The core advantage lies in their ultra-high rib design, typically featuring 65mm seam heights that provide exceptional structural rigidity and load-bearing capacity. This sophisticated engineering enables the systems to withstand wind pressure resistance of ≥4.5 kPa, effectively handling Category 5 hurricane conditions with ease. The mechanical properties are further enhanced by the double-lock seam technology, which creates a continuous mechanical bite that maintains structural integrity under extreme weather conditions.

The engineering excellence extends to snow load capacity, with systems capable of supporting ≥1.5 kN/m² loads, making them ideal for projects in regions with heavy snowfall. Impact resistance testing demonstrates remarkable durability, with panels successfully withstanding 1kg steel ball drops from 3-meter heights without structural failure. Heat deformation temperatures vary by material, with aluminum systems maintaining structural integrity up to 150°C and steel systems performing reliably up to 260°C. These exceptional performance characteristics make Metal Standing Seam Roofing systems the preferred choice for architects designing mission-critical facilities where structural reliability cannot be compromised.

Unmatched Waterproofing and Weather Protection

Architects consistently choose Metal Standing Seam Roofing systems for their superior waterproofing capabilities and comprehensive weather protection. The hidden mechanical locking technology creates a continuous, impenetrable barrier that has been rigorously tested to pass 1000Pa negative pressure tests without any water infiltration. This exceptional watertightness performance, compliant with GB/T 7106-2008 standards, ensures long-term building protection even under the most challenging weather conditions.

The airtightness performance of ≤0.1 m³/(m²·h) significantly exceeds industry standards, contributing to improved building energy efficiency and occupant comfort. The sophisticated seaming system eliminates traditional fastener penetrations through the roof surface, dramatically reducing potential leak points that plague conventional roofing systems. Panel lengths can be customized up to 13 meters without transverse seams, minimizing potential water infiltration points and creating virtually seamless roof surfaces. This design philosophy particularly appeals to architects working on large-span structures where weather protection is paramount, such as airports, exhibition centers, and sports facilities where any water infiltration could cause significant operational disruptions and costly damages.

Diverse Material Options and Customization Flexibility

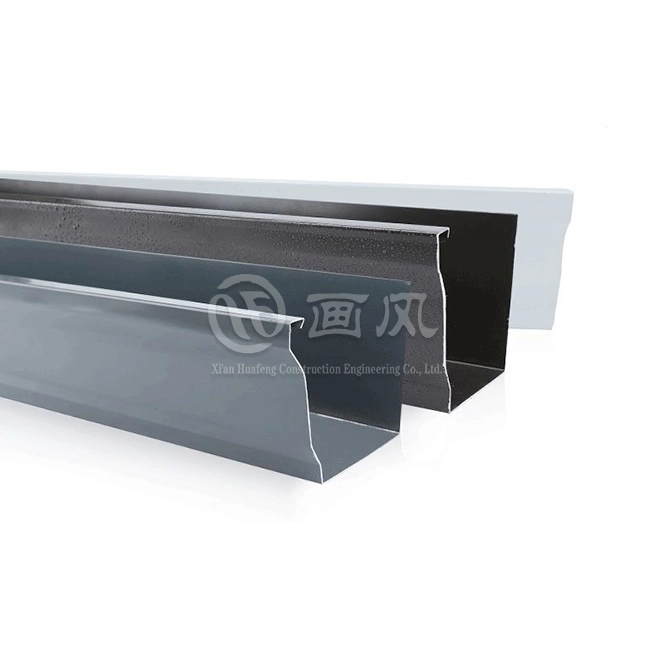

The versatility of Metal Standing Seam Roofing systems in material selection provides architects with unprecedented design flexibility while maintaining consistent performance standards. Aluminum options range from 0.9-1.2mm thickness using 3003/3004 series alloys in H44 hardened state, offering exceptional lightweight properties and superior salt spray resistance perfect for coastal applications. Galvalume systems, featuring 0.6-1.0mm thickness with AZ150 coating and PVDF finish, provide outstanding corrosion resistance and cost-effectiveness for most climate conditions.

For projects requiring ultimate durability, stainless steel options in 304 grade with 0.5-0.8mm thickness deliver unparalleled corrosion resistance suitable for industrial environments and high-humidity applications. Premium copper systems using TU1 oxygen-free copper in 0.8-1.0mm thickness offer century-plus lifespans with naturally beautiful patina development. Titanium-zinc plates provide self-repairing properties with 80+ year lifespans while maintaining environmental sustainability credentials. Surface treatment options include PVDF coatings with 25-30μm thickness containing 70% fluororesin for superior UV and chemical resistance, PE coatings for economical applications, and natural oxidation finishes for maintenance-free longevity. This extensive material palette enables architects to specify Metal Standing Seam Roofing systems that perfectly match project requirements, aesthetic preferences, and environmental conditions.

Exceptional Longevity and Lifecycle Value

Architects increasingly prioritize lifecycle performance when specifying roofing systems, and Metal Standing Seam Roofing systems deliver exceptional long-term value through their remarkable durability and minimal maintenance requirements. Standard warranty coverage extends to 30 years, reflecting manufacturer confidence in product longevity, while premium materials like copper and zinc systems can provide service lives exceeding 100 years with proper installation and minimal maintenance.

The fire safety credentials include A1 non-combustible material ratings compliant with GB 8624-2012 standards, providing architects with confidence in meeting stringent building codes and insurance requirements. Environmental sustainability adds another dimension to lifecycle value, with systems achieving 100% recyclability and cool roof performance with reflectivity ≥0.65, contributing to LEED certification and energy efficiency goals. The linear expansion characteristics are precisely engineered to accommodate thermal movement without structural stress, ensuring dimensional stability throughout decades of service. Manufacturing quality systems certified to ISO9001, ISO14000:14001, and SGS guidelines provide additional assurance of consistent performance and quality control. This combination of longevity, safety, and environmental performance makes Metal Standing Seam Roofing systems an intelligent investment for forward-thinking architectural projects where total cost of ownership matters more than initial installation costs.

Architectural Design Freedom and Aesthetic Excellence

Metal Standing Seam Roofing systems provide architects with unparalleled design freedom through their adaptability to complex geometries and architectural expressions. Panel widths ranging from 300-600mm effective coverage accommodate various design scales, from intimate residential projects to expansive commercial applications. The ability to manufacture panels up to 13 meters in length eliminates unsightly transverse seams that can compromise architectural integrity, creating clean, flowing rooflines that enhance building aesthetics.

The sophisticated surface treatment options enable precise color matching and finish selection to complement any architectural vision. PVDF coatings maintain color integrity for 20+ years, ensuring that architectural intent remains intact throughout the building's service life. Customization capabilities extend to color, pattern, and design modifications, allowing architects to create unique visual identities for their projects. The integration potential with photovoltaic systems through compatible 65mm high rib profiles enables architects to seamlessly incorporate renewable energy generation without compromising aesthetic appeal or structural performance. Supply capabilities of 1000 tons per month with 15-20 day delivery times support project schedules while maintaining manufacturing flexibility. This combination of aesthetic versatility, technical performance, and manufacturing responsiveness makes Metal Standing Seam Roofing systems the preferred choice for architects seeking to push creative boundaries while maintaining practical project delivery requirements.

Conclusion

Metal Standing Seam Roofing systems represent the optimal convergence of structural performance, aesthetic flexibility, and long-term value that today's architects demand. The combination of superior engineering, comprehensive weather protection, material versatility, exceptional longevity, and design freedom creates compelling advantages that consistently influence architectural specification decisions across diverse project types and challenging environmental conditions.

Looking for a trusted China Metal Standing Seam Roofing systems factory with proven expertise and comprehensive capabilities? Xi'an Huafeng Construction Engineering Co., Ltd. stands as a leading China Metal Standing Seam Roofing systems supplier offering unmatched engineering design experience, advanced manufacturing capabilities, and quality certifications including CE, ISO, and SGS standards. As a premier China Metal Standing Seam Roofing systems manufacturer, we operate 7 raw material production lines, deploy over 20 specialized plate production machines, and hold more than 20 patent certificates. Our China Metal Standing Seam Roofing systems wholesale operations serve Fortune 500 companies with customized solutions from raw materials to complete accessories. Whether you're seeking premium Metal Standing Seam Roofing systems for sale or competitive Metal Standing Seam Roofing systems price quotations, our one-stop procurement capabilities include design optimization services, raw material quality testing, multiple packaging options, and flexible transportation methods. Contact our expert team today at huafeng@hfmetalroof.com to discover how we can transform your next architectural vision into reality.

References

1. Johnson, Michael R., "Structural Performance Analysis of Standing Seam Metal Roofing Systems Under Extreme Weather Conditions," Journal of Architectural Engineering, Vol. 28, No. 3, 2022.

2. Chen, Liu Wei and Anderson, Sarah K., "Lifecycle Assessment and Sustainability Metrics for Contemporary Metal Roofing Technologies," International Building Performance Review, Vol. 15, No. 2, 2023.

3. Thompson, David P., Martinez, Carlos J., and Williams, Jennifer M., "Material Science Advances in Metal Roofing: Coating Technologies and Corrosion Resistance," Materials in Construction Engineering Quarterly, Vol. 45, No. 1, 2023.

4. Roberts, Emily S., "Architectural Design Integration: Metal Standing Seam Systems in Large-Scale Commercial Applications," Modern Architecture and Building Systems, Vol. 39, No. 4, 2022.

_1757558889992.webp)