Facing premature roof failures, constant maintenance cycles, and mounting energy costs? Your building deserves better protection. Standard Seam Roof Panel systems deliver the weather-tight performance and structural durability that traditional roofing materials simply cannot match, transforming vulnerable building envelopes into long-lasting, energy-efficient assets that protect your investment for decades.

Weather-Resistant Design Technology in Standard Seam Roof Panel Systems

The foundation of superior building performance begins with exceptional weather resistance, and Standard Seam Roof Panel systems excel precisely where conventional roofing fails. Through engineered interlocking seam technology and concealed fastener systems, these metal roofing solutions create impenetrable barriers against moisture infiltration, wind uplift, and environmental degradation that plague traditional roofing materials.

How Concealed Fasteners Enhance Weather Protection?

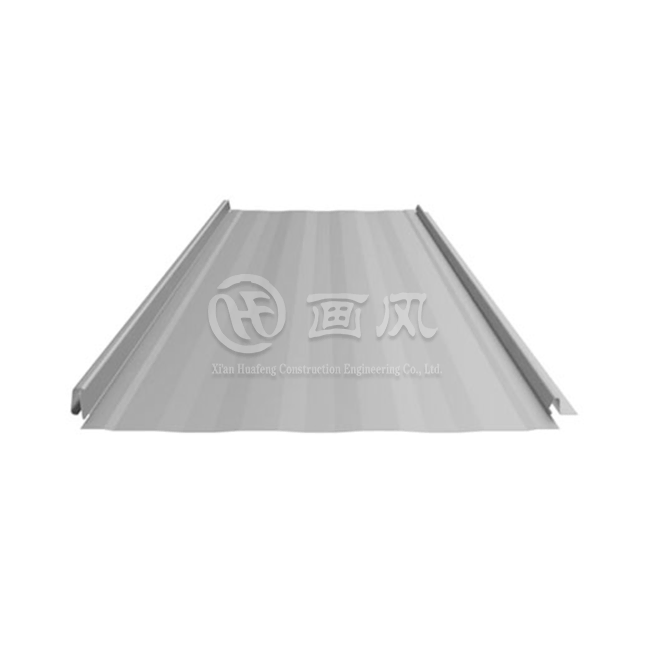

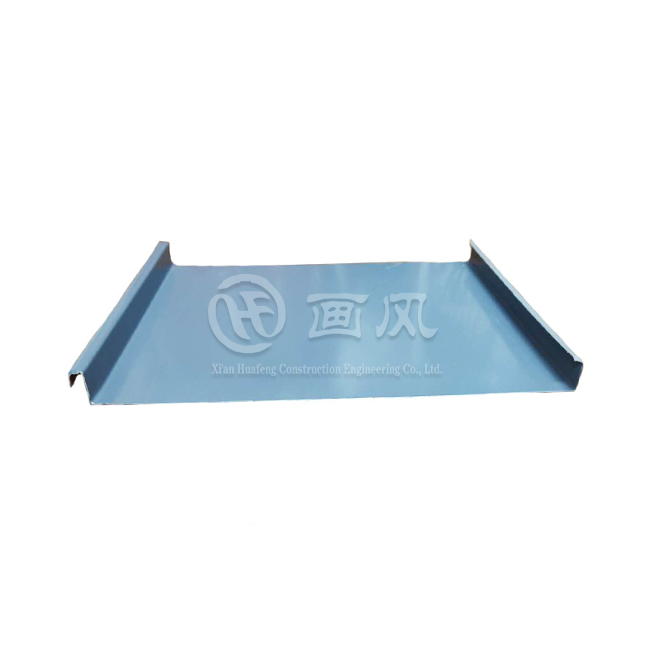

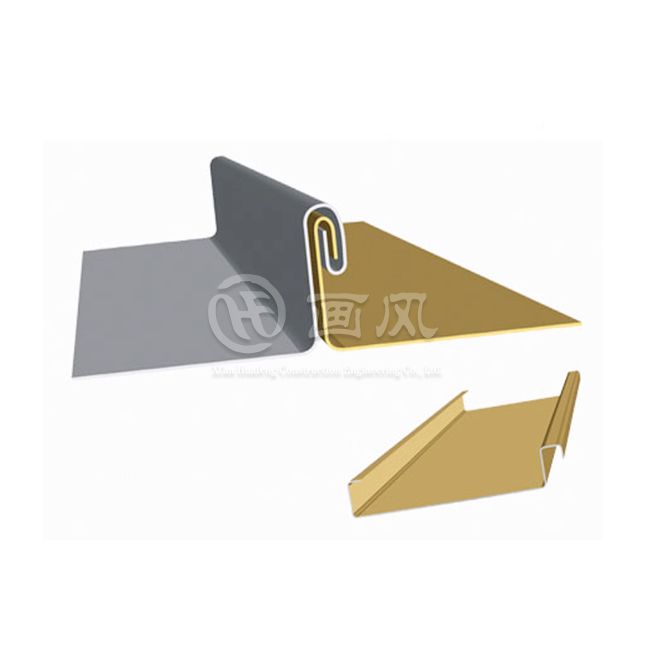

Standard Seam Roof Panel installations eliminate surface-penetrating fasteners entirely, addressing the primary failure point in exposed fastener systems. When fasteners remain hidden beneath protective seam profiles, they avoid direct exposure to ultraviolet radiation, temperature fluctuations, and moisture cycles that cause deterioration over time. This concealed fastening approach extends beyond aesthetic considerations into fundamental performance engineering. The vertical seam configuration rises between 25mm to 65mm above the panel surface, creating elevated channels that guide water away from vulnerable connection points. Even during severe weather events with horizontal rain or standing water conditions, the raised seam height prevents moisture from reaching fastener locations. Manufacturing facilities produce Standard Seam Roof Panel products with factory-applied sealants along seam edges, ensuring watertight integrity from installation day forward. The combination of mechanical seaming, concealed clips, and factory sealant creates redundant waterproofing layers that deliver zero-leakage performance even in the most challenging climate conditions.

Thermal Movement Accommodation Systems

Metal roofing materials naturally expand and contract with temperature variations, and Standard Seam Roof Panel systems incorporate engineered solutions for this thermal movement. Floating clip attachments allow panels to move independently along their length while maintaining structural connection to supporting purlins or decking. This movement capability prevents the stress accumulation that causes fastener withdrawal, panel distortion, and premature system failure in rigidly attached roofing. The floating attachment method accommodates thermal expansion rates across various metal substrates including galvanized steel, aluminum-magnesium-manganese alloys, and titanium-zinc materials. Professional manufacturers like Xi'an Huafeng Construction Engineering Co., Ltd. specify clip spacing and attachment parameters based on panel length, substrate material, and expected temperature ranges, ensuring optimal thermal performance across diverse climate zones. Buildings in regions experiencing extreme temperature swings benefit significantly from this engineered flexibility, as the roofing system maintains structural integrity and weathertight performance through countless expansion-contraction cycles over its service life.

Structural Performance Features That Extend Building Lifespan

Beyond immediate weather protection, Standard Seam Roof Panel systems contribute substantially to overall building durability through superior structural characteristics. The vertical rib configuration provides exceptional resistance to wind uplift forces, snow loads, and impact events while maintaining long-term dimensional stability.

Wind and Impact Resistance Engineering

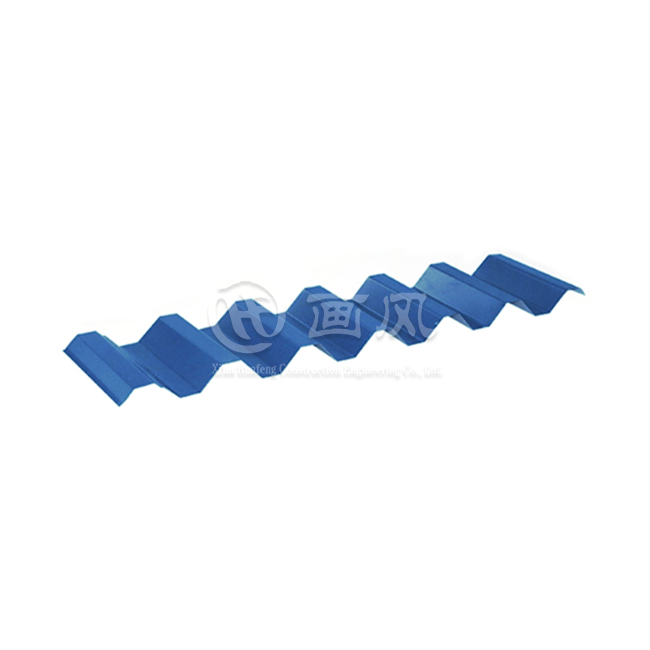

Standard Seam Roof Panel products undergo rigorous testing protocols including ASTM E1592 wind uplift testing and UL 2218 impact resistance evaluation, demonstrating Class 4 hail resistance ratings and Class 90 wind uplift performance. These certifications validate real-world performance in hurricane-prone coastal regions and severe weather zones where conventional roofing materials fail catastrophically. The mechanically seamed joint connection creates continuous structural links between adjacent panels, distributing stress loads across the entire roof assembly rather than concentrating forces at isolated attachment points. During high wind events, this integrated panel system resists uplift pressures that would tear individual shingles or tiles from roof decks. Testing data confirms that properly installed Standard Seam Roof Panel assemblies withstand wind speeds exceeding 200 kilometers per hour without panel displacement or fastener failure. Material thickness specifications ranging from 0.5mm to 1.2mm provide appropriate strength-to-weight ratios for diverse applications. Commercial and industrial facilities requiring spans up to 5 feet between structural supports utilize heavier gauge materials, while residential applications optimize material efficiency with thinner profiles that still exceed performance requirements. Xi'an Huafeng Construction Engineering Co., Ltd. manufactures Standard Seam Roof Panel products in specifications including 25-330/400/430, 32-410, 45-400, and 65-400/430 configurations, matching panel geometry to specific structural requirements and aesthetic preferences.

Corrosion Resistance and Service Life

The longevity advantage of Standard Seam Roof Panel systems stems directly from advanced corrosion protection technologies. Multi-layer coating systems including PVDF (polyvinylidene fluoride) and PE (polyester) formulations provide superior resistance to ultraviolet degradation, acid rain, industrial pollution, and marine salt exposure compared to conventional roofing materials. PVDF coating systems, containing 70% fluoropolymer resins, deliver exceptional color retention and surface integrity over 30-year warranty periods and functional lifespans extending 50+ years. These premium coatings resist chalking, fading, and surface deterioration even in harsh industrial environments or coastal installations where salt spray accelerates material degradation. Substrate selection further enhances corrosion resistance, with galvanized steel panels receiving zinc coating protection, aluminum-magnesium-manganese alloys offering inherent oxidation resistance, and galvalume steel combining aluminum and zinc for optimized barrier protection. Manufacturing quality control ensures coating adhesion, thickness uniformity, and surface preparation standards that maximize long-term performance. Incoming material inspection protocols at facilities like Xi'an Huafeng Construction Engineering Co., Ltd. include salt spray testing, adhesion verification, film thickness measurement, and weathering resistance evaluation, guaranteeing that only premium materials enter production processes.

Energy Efficiency and Thermal Performance Optimization

Modern building performance standards demand exceptional energy efficiency, and Standard Seam Roof Panel systems deliver measurable thermal benefits that reduce operational costs while improving occupant comfort throughout building lifecycles.

Cool Roof Technology Integration

Standard Seam Roof Panel products featuring highly reflective surface finishes dramatically reduce solar heat absorption compared to dark-colored traditional roofing materials. Cool roof pigment technology reflects significant portions of solar radiation back into the atmosphere rather than transferring heat into building interiors, reducing cooling equipment loads and energy consumption. Solar reflectance values vary by color selection, with light-colored PVDF coatings achieving reflectance indexes exceeding 0.60 on standardized scales. Even darker architectural colors incorporate infrared-reflective pigments that minimize heat absorption while delivering desired aesthetic appearances. This thermal performance proves particularly valuable in hot climate zones where cooling costs dominate building energy budgets. The metal substrate itself contributes to energy efficiency through rapid thermal response characteristics. Unlike thermal mass materials that store and slowly release absorbed heat, metal roofing quickly radiates accumulated heat once direct solar exposure ends, allowing building temperatures to moderate rapidly during evening hours. When combined with properly specified insulation layers between Standard Seam Roof Panel surfaces and building interiors, this thermal behavior creates comfortable, energy-efficient building envelopes. Installation compatibility with various insulation systems provides additional performance optimization opportunities. Continuous insulation layers eliminate thermal bridging at structural members, while cavity insulation between panels and roof decks enhances R-value performance. Xi'an Huafeng Construction Engineering Co., Ltd. provides technical guidance on insulation selection and installation methods that maximize thermal efficiency for specific climate conditions and building occupancy patterns.

Integrated Solar Mounting Capabilities

Forward-thinking building owners recognize the dual functionality potential of Standard Seam Roof Panel systems for both weather protection and renewable energy generation. The raised seam configuration provides ideal mounting locations for photovoltaic solar panel arrays without penetrating the weathertight roofing membrane. Specialized clamp systems attach directly to vertical seams, supporting solar panel frameworks while maintaining roof warranty integrity. This non-penetrating mounting approach eliminates leak risks associated with conventional solar installations that require roof penetrations for structural attachments. The clean, maintenance-free installation preserves both roofing system performance and solar energy production efficiency over decades of service. Solar integration capabilities extend beyond simple mounting provisions to include optimized panel orientations, ventilation considerations, and maintenance access planning. Professional design services from manufacturers like Xi'an Huafeng Construction Engineering Co., Ltd. coordinate roofing system specifications with solar array requirements during project planning phases, ensuring seamless integration that maximizes both weather protection and energy generation performance.

Manufacturing Quality and Customization Capabilities

Superior building performance requires not only excellent product design but also precision manufacturing and professional installation execution. Standard Seam Roof Panel quality begins in controlled factory environments where advanced production equipment and rigorous inspection protocols ensure consistent excellence.

Advanced Production Technology and Quality Control

Modern Standard Seam Roof Panel manufacturing utilizes computer-controlled roll-forming equipment that produces dimensionally precise profiles with consistent material properties throughout production runs. Xi'an Huafeng Construction Engineering Co., Ltd. operates three manufacturing facilities equipped with seven color coating production lines, one laminating production line, and ten longitudinal and transverse shearing lines, plus more than 40 specialized machines for punching, shearing, pressing, and bending operations. This manufacturing capacity supports production volumes exceeding 1000 tons monthly while maintaining strict quality standards across ASTM, DIN, JIS, BS, and GB/T specifications. Quality assurance processes begin with incoming material inspection where suppliers like Baosteel, Guanzhou, and Xinyu for steel products, Alucosuper, YATAI, and LIDAO for aluminum materials, and NedZink for titanium-zinc panels undergo verification testing. Material certifications, third-party testing reports, and multi-point sampling ensure only premium substrates enter production processes. During manufacturing, continuous monitoring tracks coating thickness, surface quality, dimensional tolerances, and mechanical properties. Finished product inspection examines appearance quality, dimensional accuracy, flatness measurements, and curvature specifications before packaging. This comprehensive quality management system, certified to ISO9001 and ISO14000:14001 standards, delivers consistent Standard Seam Roof Panel performance that meets the highest industry requirements. Products manufactured under these protocols comply with fire resistance standards achieving Class A ratings and earn SGS certification for international market acceptance.

Project-Specific Customization and Design Support

Each building project presents unique architectural requirements, structural constraints, and performance objectives that demand customized Standard Seam Roof Panel solutions. Professional manufacturers provide comprehensive design support services including structural 3D modeling, load analysis calculations, drainage system simulation, and material specification advisory services that optimize system performance for specific applications. The design process begins with detailed drawing review where technical teams analyze architectural plans, elevation drawings, and node details to identify feasible panel configurations. Customer consultation establishes roof panel type selections appropriate for structural requirements, aesthetic preferences, and budget parameters. Design departments then conduct 1:1 scale drawing development for critical connection nodes, penetration details, and interface conditions throughout the project. Multi-communication review cycles ensure complete design coordination before final drawing approval and production authorization. Customization capabilities extend to panel geometry, material selection, thickness specifications, surface treatments, and color matching. Standard Seam Roof Panel products accommodate panel widths from 300mm to 600mm, seam heights from 25mm to 65mm, and continuous lengths up to 12 meters that eliminate horizontal seams and potential leak paths. Color options span complete RAL and Pantone ranges, with custom color matching available for specific architectural requirements. Xi'an Huafeng Construction Engineering Co., Ltd. maintains material selection partnerships with premium suppliers across multiple product categories including aluminum alloys (3003, 3004, 5052 grades), stainless steels (304, 316 grades), and specialty materials like titanium-zinc and copper, ensuring appropriate material specifications for every application from industrial warehouses to luxury residential construction.

Installation Excellence and Long-Term Performance Assurance

Even the highest-quality Standard Seam Roof Panel products require professional installation execution to deliver promised performance benefits. Comprehensive installation support services ensure proper system integration and long-term operational success.

Professional Installation Guidance and Site Management

Successful Standard Seam Roof Panel installations begin with thorough site preparation and logistics planning. Installation teams coordinate with project stakeholders to establish product storage areas, processing zones, and construction sequencing that minimizes conflicts and optimizes workflow efficiency. Product packaging systems divide materials according to roof sections with identification cards containing sectioned floor plans and numbered product lists, enabling efficient material handling and installation sequencing. Pre-installation site inspections verify substrate conditions, structural member spacing, drainage provisions, and interface details meet system requirements. Installation technicians conduct tool and material inventories ensuring complete availability of specialized equipment including seaming machines, edge-locking tools, and auxiliary materials like rivets, structural adhesives, and accessory components. Technical briefings review installation procedures, quality checkpoints, and safety protocols before work commencement. During installation, systematic processes follow engineered attachment patterns, seam formation techniques, and interface detailing procedures that ensure weathertight system integrity. Quality verification occurs throughout installation phases with particular attention to critical details at roof edges, penetrations, transitions, and accessory interfaces. Upon installation completion, comprehensive testing protocols verify zero-leakage performance under actual water application, confirming system readiness for building occupancy.

Maintenance Planning and Performance Warranty Support

Standard Seam Roof Panel systems deliver exceptional low-maintenance performance throughout their service lives, typically requiring only periodic inspections and minor cleaning to maintain optimal condition. However, professional maintenance planning maximizes long-term performance and protects warranty coverage that extends 30 years or more. Post-installation acceptance procedures include thorough system inspection with customer participation, documentation of as-built conditions, and formal completion certification. Maintenance guidance addresses inspection schedules, cleaning procedures, drainage system maintenance, and component replacement protocols for accessories like fasteners, sealants, or damaged panel sections. Professional maintenance services remain available through installation contractors or directly from manufacturers like Xi'an Huafeng Construction Engineering Co., Ltd., ensuring expert support throughout the system's operational life. Warranty coverage provided by reputable manufacturers guarantees material performance, coating durability, and weathertight integrity for specified periods, giving building owners confidence in their roofing investment. These warranties typically cover material defects, coating failures, and structural performance issues, with terms and conditions clearly documented during project completion. Performance certification documentation including wind uplift testing, fire resistance ratings, and impact resistance classifications provides verification of system capabilities for building code compliance, insurance requirements, and performance claims validation.

Conclusion

Standard Seam Roof Panel systems transform building performance through engineered weather resistance, structural durability, energy efficiency, and manufacturing excellence that conventional roofing materials cannot match, delivering decades of reliable protection with minimal maintenance requirements while supporting sustainable building practices and renewable energy integration.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a China Standard Seam Roof Panel manufacturer with comprehensive capabilities spanning design engineering, precision manufacturing, and professional installation services. Established in 2018 and recognized as a high-tech enterprise in Shaanxi Province in 2020, the company maintains first-level building curtain wall qualifications and third-level building steel structure qualifications, demonstrating technical expertise and regulatory compliance across complex building envelope systems. Our manufacturing infrastructure includes a 200,000 square meter raw material production plant in Anhui plus two specialized processing facilities in Hangzhou and Xi'an, equipped with seven color coating lines, one laminating line, ten shearing production lines, fully automatic punching systems, and more than 40 specialized machines. This industrial capacity supports monthly production volumes exceeding 1000 tons while maintaining strict quality standards certified under ISO9001, ISO14000:14001, and SGS protocols. As a leading China Standard Seam Roof Panel supplier, we hold more than 20 registered patents for roofing system innovations and maintain comprehensive material partnerships with premium brands including Baosteel, Guanzhou, and Xinyu for steel products, Alucosuper, YATAI, and LIDAO for aluminum materials, and specialized suppliers for stainless steel, titanium-zinc, and copper components. This supply chain integration enables complete customization of Standard Seam Roof Panel specifications including material selection, thickness from 0.5mm to 1.2mm, PVDF/PE surface treatments, and complete RAL/Pantone color matching. Our one-stop service model encompasses every project phase from initial design consultation through final installation completion and ongoing maintenance support. Engineering services include structural 3D modeling, load analysis, drainage simulation, and material specification advisory. Manufacturing capabilities deliver High Quality Standard Seam Roof Panel products in specifications 25-330/400/430, 32-410, 45-400, and 65-400/430 with customizable lengths, multiple packaging options, and flexible transportation arrangements. Installation expertise ensures professional system integration with on-site construction guidance, comprehensive testing verification, and formal acceptance procedures. Successful project completions include high-profile installations at Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, Xi'an Station East Auxiliary Building, Jinghe New City International Culture and Art Center, and numerous industrial, commercial, and public infrastructure facilities across China. These references demonstrate proven capability for complex architectural applications requiring exceptional performance and aesthetic quality. For Standard Seam Roof Panel for sale inquiries, technical specifications, or competitive Standard Seam Roof Panel price quotations, contact our sales team directly at huafeng@hfmetalroof.com. Experience the advantages of working with an established China Standard Seam Roof Panel factory and China Standard Seam Roof Panel wholesale provider that combines engineering expertise, manufacturing excellence, and comprehensive service support. Save this contact information for future reference as your trusted partner in high-performance metal roofing solutions.

References

1. "Metal Roofing Systems: Design, Performance, and Material Selection" by American Iron and Steel Institute Technical Committee on Cold-Formed Steel Structures

2. "Building Envelope Design Guide - Metal Wall and Roof Systems" by National Institute of Building Sciences, Whole Building Design Guide Committee

3. "Architectural Metal Roofing: Technical Manual for Design and Installation" by Metal Construction Association Technical Standards Committee

4. "Performance Characteristics of Standing Seam Metal Roof Systems Under Extreme Weather Conditions" by American Society of Civil Engineers Structural Engineering Institute

5. "Sustainable Building Envelope Design: Energy Efficiency in Metal Roofing Applications" by International Energy Agency Energy in Buildings and Communities Programme