Are you frustrated by constant roof repairs, skyrocketing energy bills, and the worry that your current roofing system won't survive the next severe storm? The 12 standing seam metal roof has emerged as the solution that addresses these critical pain points while delivering exceptional durability, weather protection, and aesthetic appeal that transforms both residential and commercial properties. Understanding the essential features of this roofing system empowers property owners to make informed decisions that protect their investment for decades to come.

Understanding the 12 Standing Seam Metal Roof System

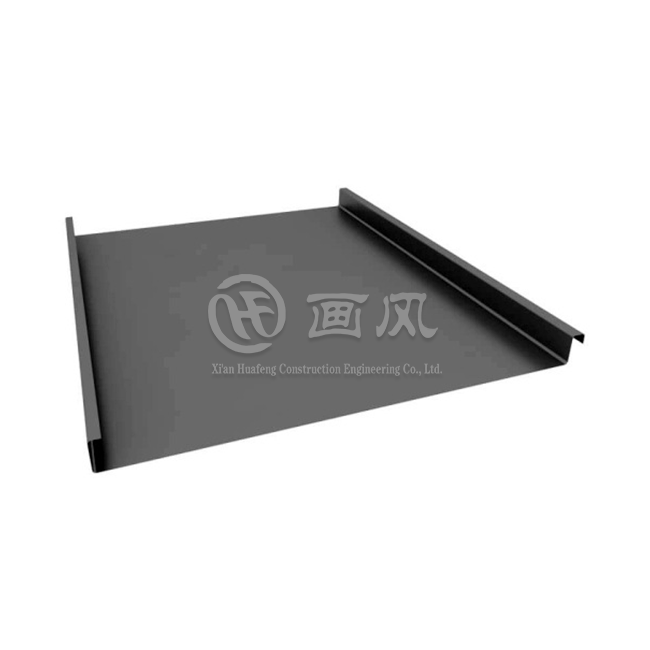

The 12 standing seam metal roof represents a sophisticated roofing solution characterized by panels with 12-inch spacing between raised vertical seams. This specific configuration strikes an optimal balance between structural performance and architectural elegance, making it particularly suitable for projects where both functionality and visual appeal matter. The system features concealed fasteners that eliminate penetrations through the panel surface, dramatically reducing potential leak points that plague traditional roofing systems. Unlike exposed fastener panels commonly found in agricultural applications, the 12 standing seam metal roof employs hidden clips or fastening flanges that allow panels to expand and contract naturally with temperature fluctuations. This design consideration extends the roof's lifespan by preventing stress-related failures that occur when thermal movement is restricted. The 12-inch panel width provides architectural scaling appropriate for residential homes, eliminating the industrial appearance associated with wider commercial panels while maintaining superior weather resistance.

Material Options for Maximum Performance

The versatility of 12 standing seam metal roof systems lies in their diverse material choices, each offering distinct advantages for specific applications and environments. Aluminum alloy panels provide exceptional corrosion resistance, making them ideal for coastal regions where salt exposure accelerates deterioration of lesser materials. With thickness options ranging from 0.5mm to 1.2mm, property owners can select specifications that match their structural requirements and budget constraints while ensuring compliance with local building codes. Steel panels, whether galvanized or galvalume-coated, deliver outstanding strength-to-weight ratios for projects requiring maximum load-bearing capacity. The HF brand standing seam metal roof manufactured by Xi'an Huafeng Construction Engineering incorporates premium materials including stainless steel grades 304 and 316 for applications demanding ultimate durability, copper for distinctive patina development, and titanium-zinc for sustainable, self-healing properties. Each material undergoes rigorous quality testing including salt spray resistance, adhesion verification, and weather resistance evaluation to ensure performance standards exceed industry expectations.

Critical Features That Define Quality 12 Standing Seam Metal Roof Systems

Concealed Fastener Technology

The concealed fastener design represents the most significant advancement in metal roofing technology, fundamentally changing how 12 standing seam metal roof systems perform over their operational lifetime. Traditional exposed fastener systems create hundreds of potential penetration points where water can infiltrate, with each screw requiring rubber washers that degrade under UV exposure and temperature cycling. The standing seam approach eliminates this vulnerability entirely by securing panels through clips or flanges positioned beneath the seam, where they remain protected from weather exposure. This engineering innovation delivers multiple performance benefits beyond weather-tightness. Concealed fasteners enable thermal movement accommodation, allowing panels to expand up to several inches during temperature swings without transferring stress to attachment points. Property owners avoid the maintenance nightmare of periodically replacing worn fasteners, a costly obligation that plagues exposed fastener systems every five to ten years. The clean aesthetic achieved through concealed fastening also enhances property value, particularly important for residential applications where curb appeal directly impacts marketability.

Advanced Surface Finishes

Surface finish selection profoundly impacts the long-term performance and appearance retention of 12 standing seam metal roof installations. PVDF (Polyvinylidene Fluoride) coatings represent the premium choice, offering exceptional resistance to UV degradation, chemical exposure, and color fading that would compromise lesser finishes within years. This fluoropolymer technology maintains its appearance and protective properties for decades, backed by warranties extending up to 30 years that provide property owners with financial protection against premature failure. PE (Polyester) finishes offer an economical alternative for applications where budget constraints exist, though they sacrifice some longevity compared to PVDF options. The coating selection process must consider environmental factors including UV intensity, atmospheric pollution levels, and proximity to corrosive elements. Xi'an Huafeng Construction Engineering applies these advanced finishes through precisely controlled processes in their seven color coating production lines, ensuring consistent film thickness, adhesion, and coverage that meets stringent ASTM, DIN, JIS, BS, and GB/T standards verified through third-party testing protocols.

Precision Manufacturing Standards

Manufacturing precision directly determines the field performance and installation efficiency of 12 standing seam metal roof systems. State-of-the-art roll-forming equipment produces panels with tolerances measured in fractions of millimeters, ensuring consistent seam engagement and weather-tight assembly. Xi'an Huafeng Construction Engineering operates three manufacturing facilities equipped with over 40 specialized machines including fully automatic punching systems, longitudinal and transverse shearing lines, and precision bending equipment that transforms raw coil stock into finished panels meeting exact project specifications. Quality control protocols implemented throughout the manufacturing process include incoming material inspection with verification of mill certifications and third-party test reports confirming chemical composition and mechanical properties. Production monitoring tracks dimensional accuracy, coating thickness, and surface quality at multiple checkpoints, while finished product inspection verifies flatness, curvature compliance, and freedom from cosmetic defects. This comprehensive approach ensures that every panel leaving the factory meets performance requirements, reducing field installation problems and warranty claims that plague lower-quality alternatives.

Installation Excellence and Long-Term Performance

Engineered Clip Systems

The clip system forms the critical interface between 12 standing seam metal roof panels and the underlying structure, directly influencing weather-tightness, thermal movement accommodation, and wind uplift resistance. High-gauge steel clips manufactured to precise specifications integrate with panel male and female legs, creating secure mechanical connections that withstand design loads while permitting controlled movement. Clip spacing, typically ranging from 12 to 24 inches depending on wind exposure and panel span, must follow engineering calculations that account for local climate conditions and building geometry. Proper clip installation requires attention to fastener placement within elongated holes, allowing panels to slide longitudinally as thermal expansion occurs. Over-driven fasteners that eliminate this movement capacity generate panel stress that manifests as oil canning, buckling, or premature coating failure. Professional installers understand these critical details, positioning clips according to manufacturer specifications and using calibrated tools that prevent over-torquing. The investment in engineered clip systems and proper installation techniques pays dividends through decades of trouble-free performance that justifies the initial premium over nail strip alternatives.

Comprehensive Warranty Protection

The 30-year warranty backing 12 standing seam metal roof systems manufactured by Xi'an Huafeng Construction Engineering provides property owners with exceptional long-term value protection. This comprehensive coverage encompasses coating integrity, structural performance, and weather-tightness, demonstrating manufacturer confidence in product quality and durability. Unlike short-term warranties offered on conventional roofing materials requiring replacement every 15 to 20 years, the extended protection reflects the superior lifespan expectations of properly installed metal roofing systems. Warranty terms typically address coating fade and chalk resistance, ensuring that color retention meets specified standards throughout the coverage period. Structural warranties protect against panel perforation from corrosion, a failure mode that signals fundamental material deficiency. Weather-tightness guarantees provide recourse if leaks develop from manufacturing defects, though proper installation remains essential for warranty validity. Property owners should carefully review warranty documentation, understanding coverage limitations, maintenance requirements, and claim procedures that preserve their rights should performance issues arise during the warranty period.

Customization Capabilities

Project-specific customization separates premium 12 standing seam metal roof manufacturers from commodity suppliers offering limited standard configurations. Xi'an Huafeng Construction Engineering provides comprehensive customization services encompassing material selection, thickness specification, color matching to any RAL standard or custom sample, and dimensional fabrication up to project-specific length requirements. This flexibility eliminates field splicing that creates potential weak points, while custom color capabilities ensure architectural vision realization without compromise. The customization process begins with detailed project drawing analysis, where engineering teams evaluate architectural plans, elevation details, and node configurations to identify optimal panel specifications. Computer-aided design tools generate precise fabrication drawings that account for thermal movement allowances, drainage requirements, and interface details with adjacent building elements. Manufacturing flexibility supported by substantial production capacity—capable of producing 1000 tons monthly across three factory locations—enables rapid turnaround on custom orders, with typical delivery timeframes of 15 to 20 days from order confirmation to shipment.

Technical Specifications and Performance Characteristics

Dimensional Accuracy and Panel Configuration

The 12-inch coverage width that defines this standing seam metal roof system provides optimal architectural proportions for residential and light commercial applications. Panel height options ranging from 25mm to 65mm (1 inch to 2.55 inches) accommodate various aesthetic preferences and structural requirements, with taller seams offering enhanced visual depth and improved water shedding capacity. These dimensional parameters result from extensive engineering analysis balancing appearance, performance, and cost-effectiveness across diverse project types. Manufacturing tolerances maintained throughout production ensure consistent panel dimensions that facilitate efficient field installation. Width variation held within ±2mm prevents accumulation of dimensional errors across multiple panels that could compromise seam alignment and weather-tightness. Straightness specifications prevent bowing or twisting that complicates handling and installation, particularly critical for longer panels where even slight deviations multiply across length. The combination of precise dimensions and quality material selection enables the superior fit and finish that distinguishes professionally engineered systems from lower-grade alternatives.

Load-Bearing Capacity and Structural Performance

Structural engineering calculations determine the load-bearing capacity of 12 standing seam metal roof systems, accounting for dead loads, live loads, wind uplift forces, and snow accumulation based on geographic location and building occupancy. Panel gauge selection—typically 24-gauge for residential applications and heavier gauges for commercial projects—directly influences strength characteristics and deflection behavior under load. The standing seam configuration provides inherent structural stiffness through vertical rib geometry, enabling longer unsupported spans than flat panels of equivalent thickness. Wind uplift resistance, critical for buildings in hurricane-prone regions or exposed hilltop sites, depends on proper clip selection, spacing, and attachment to structural supports. Testing protocols verify system performance under simulated wind conditions, with results documented through engineering reports that support building permit applications and insurance underwriting. Snow load capacity calculations consider panel strength, support spacing, and potential unbalanced loading scenarios that might occur during partial melting or drifting conditions, ensuring adequate safety factors protect building occupants and contents.

Energy Efficiency and Thermal Performance

The energy efficiency advantages of 12 standing seam metal roof systems deliver measurable operational cost savings throughout the building's lifetime. Reflective coating technologies, particularly light-colored finishes with high solar reflectance values, reduce heat absorption that drives cooling costs during warm weather. This "cool roof" effect can lower surface temperatures by 50 degrees Fahrenheit compared to dark asphalt shingles, translating to substantial reductions in air conditioning loads for buildings with insufficient attic insulation or ventilation. Thermal emittance characteristics determine how effectively absorbed heat radiates back to the atmosphere rather than transferring into the building interior. High-emittance coatings combined with proper ventilation design create optimal thermal performance, particularly valuable for warehouses, manufacturing facilities, and commercial buildings where air conditioning costs represent significant operational expenses. The metal panel's low thermal mass prevents heat storage that would continue radiating inward after sunset, unlike masonry or concrete materials that retain absorbed solar energy for hours.

Conclusion

The 12 standing seam metal roof delivers unmatched performance through concealed fastener technology, premium material options, advanced surface finishes, and precision manufacturing standards that ensure decades of reliable protection. Property owners investing in this superior roofing system gain exceptional value through extended lifespan, minimal maintenance requirements, energy efficiency benefits, and aesthetic versatility that enhances property value while eliminating the recurring costs and disruptions associated with conventional roofing materials.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

As a China 12 Standing Seam Metal Roof manufacturer and China 12 Standing Seam Metal Roof supplier, Xi'an Huafeng Construction Engineering Co., Ltd. offers High Quality 12 Standing Seam Metal Roof solutions with competitive 12 Standing Seam Metal Roof price and extensive 12 Standing Seam Metal Roof for sale inventory. Recognized as a high-tech enterprise in Shaanxi Province since 2020, our company operates three factories with seven color coating production lines, one laminating production line, and over 40 specialized machines across 200,000 square meters of manufacturing space in Anhui, with additional processing facilities in Hangzhou and Xi'an.

Our one-stop solution encompasses engineering design optimization, structural 3D modeling, drainage system simulation, raw material quality testing with certifications from premium brands including Baosteel, Tsingshan, and NedZink, customized production meeting ASTM, DIN, JIS, BS, and GB/T standards, comprehensive quality inspection protocols, and seamless on-site installation guidance. As a trusted China 12 Standing Seam Metal Roof factory and China 12 Standing Seam Metal Roof wholesale provider, we collaborate with Fortune 500 companies while maintaining over 20 patent certificates, ISO9001, ISO14000:14001, CE, and SGS certifications that demonstrate our commitment to excellence.

Transform your roofing project with our proven expertise demonstrated through successful installations at Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, Xi'an Station East Auxiliary Building, and numerous other prestigious projects. Contact our team at huafeng@hfmetalroof.com to discuss your specific requirements and receive a detailed quotation. Bookmark this resource for future reference as you plan your roofing investment, ensuring you have immediate access to the technical information and manufacturer contact details needed to move forward with confidence.

References

1. Metal Construction Association. "Certified Roofing Panels Program: Standing Seam Metal Roof Systems Performance Standards." Technical Publication MCA-SS-2024.

2. Sheffield Metals International. "Engineering Guide for Standing Seam Metal Roofing Systems." Research and Development Department, 2024.

3. American Society for Testing and Materials. "ASTM E1592: Standard Test Method for Structural Performance of Sheet Metal Roof and Siding Systems by Uniform Static Air Pressure Difference." ASTM International Standards Committee.

4. National Roofing Contractors Association. "The NRCA Metal Panel and SPF Roof Systems Manual." NRCA Technical Services Department, 2024 Edition.

5. Cool Roof Rating Council. "CRRC-1 Standard: Product Rating Program for Radiative Properties of Roofing Products." Cool Roof Rating Council Technical Committee, 2024.