Winter snow accumulation on metal roofing can create significant hazards when it suddenly slides off, potentially causing damage to property and injury to people below. Standing Seam Roof Snow Guards provide an effective solution to this problem by controlling the snow's movement across the roof surface. These specialized devices are designed specifically for standing seam metal roofs, which have become increasingly popular in commercial and residential construction due to their durability and aesthetic appeal. This article explores the various types of snow guards suitable for standing seam roofs, their installation methods, and factors to consider when selecting the right snow retention system for your specific needs.

Types of Snow Guards for Standing Seam Metal Roofs

Standing seam metal roofs require specialized snow retention systems that can be installed without penetrating the metal panels. The right selection depends on multiple factors including roof pitch, snow load, and aesthetic requirements. Here are the primary types available:

Clamp-On Snow Guards

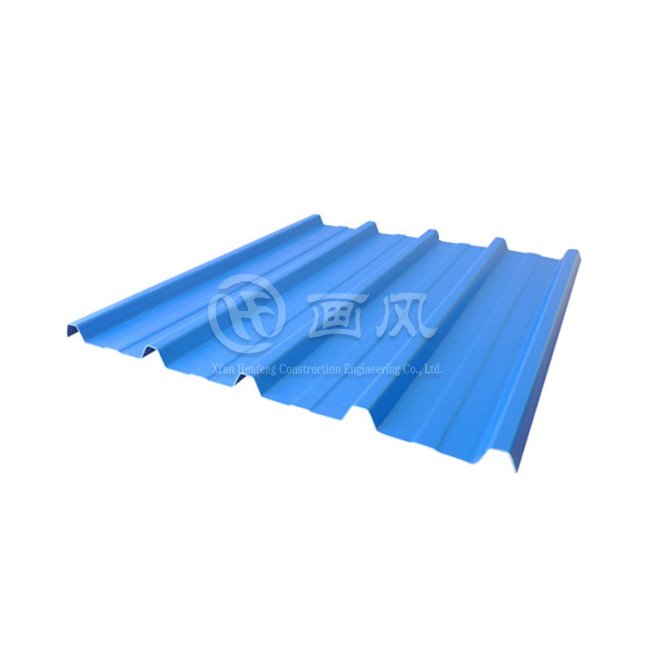

Clamp-on snow guards are among the most popular options for standing seam roofs due to their non-penetrating installation method. These Standing Seam Roof Snow Guards utilize mechanical fasteners that clamp directly onto the seams of the metal roof without requiring any holes or penetrations in the roofing material. Made from high-quality materials such as aluminum alloy, copper, or stainless steel, these snow guards are designed to withstand significant snow loads while maintaining the integrity of the roof structure. The clamp-on design distributes the force of sliding snow across multiple attachment points, preventing damage to both the snow guard system and the roof itself. Available in various colors including black, gray, and brick red, these snow guards can be customized to match or complement the roof's appearance. Their durability makes them suitable for regions with heavy snowfall, capable of effectively managing snow accumulations of 20-50 cm thick under normal conditions. With proper installation and maintenance, clamp-on snow guards can provide reliable snow retention for the life of the metal roof, typically 15-20 years or more depending on environmental conditions.

Bar-Type Snow Retention Systems

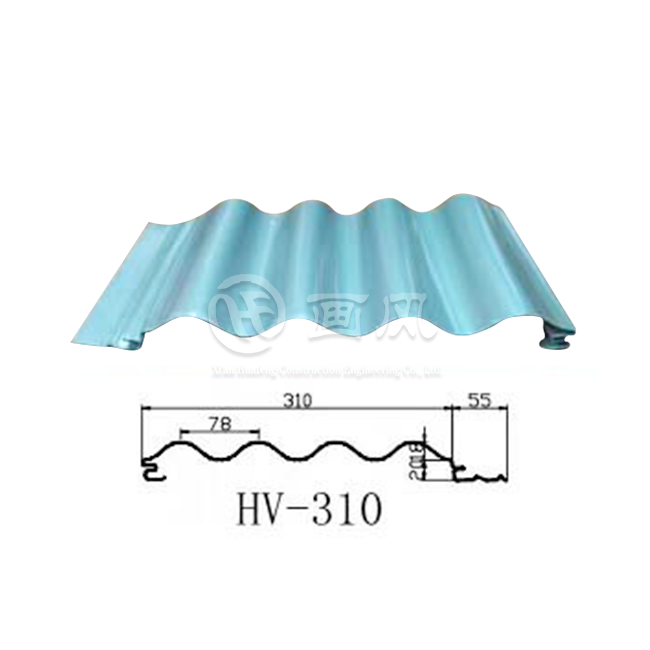

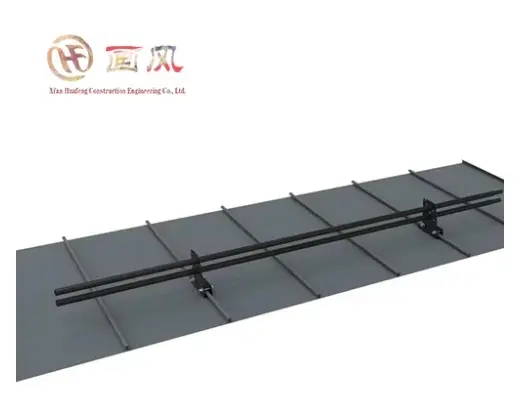

Bar-type snow retention systems represent a more robust solution for standing seam roofs subjected to heavy snow loads. These Standing Seam Roof Snow Guards consist of horizontal bars or rails that run perpendicular to the roof slope, attached to the standing seams using non-penetrating clamps. The bars create a continuous barrier that prevents large masses of snow from sliding off the roof all at once. Xi'an Huafeng Construction Engineering offers these systems in specifications ranging from 1.2-2.4m in length, making them adaptable to various roof sizes and configurations. The bars are typically manufactured from magnesium-aluminum-zinc sheet, aluminum alloy, or stainless steel, providing exceptional strength and corrosion resistance even in harsh winter environments. These materials allow the snow retention system to withstand wind speeds of 10-20 meters per second while maintaining their structural integrity. Bar-type systems are particularly effective for longer roof spans and steeper pitches where snow loads can exert significant pressure. Their modular design allows for custom configurations based on specific roof characteristics and local snow load requirements. The PVDF/PE finishes available for these systems ensure long-term color retention and protection against UV degradation, maintaining their appearance and functionality throughout years of winter weather exposure.

Pad-Style Snow Guards

Pad-style snow guards offer a more discrete option for standing seam metal roofs where aesthetics are a primary concern. These Standing Seam Roof Snow Guards feature a low-profile design that minimizes visual impact while still providing effective snow retention. Typically installed in a staggered pattern across the roof surface, pad-style guards work by creating multiple small obstacles that break up snow masses and prevent avalanche-like slides. Xi'an Huafeng Construction Engineering manufactures these guards from premium materials including aluminum alloy, copper, and stainless steel, ensuring they can withstand heavy pressure and harsh weather conditions. The surface of these metal components is often painted with high-quality finishes to enhance their appearance and provide additional protection against corrosion. Pad-style guards are particularly suitable for residential applications and projects where maintaining the clean lines of the standing seam roof is desired. They can be effectively deployed on various roof types including cement tiles, ceramic tiles, metal tiles, and asphalt tiles. While individual pad-style guards may have less snow retention capacity than bar systems, when properly spaced according to roof pitch and expected snow loads, they provide reliable performance. For regions with moderate snowfall, these guards can effectively manage snow accumulations while maintaining a sleek, unobtrusive profile that complements the modern aesthetic of standing seam metal roofing.

Installation Methods and Considerations

The effectiveness of snow guards depends significantly on proper installation. Understanding the various installation methods and key considerations will help ensure optimal performance of your snow retention system.

Non-Penetrating Attachment Methods

Non-penetrating attachment methods are crucial for maintaining the integrity of standing seam metal roofs. Standing Seam Roof Snow Guards utilizing these methods preserve the waterproof characteristics of the roof by eliminating the need for holes or penetrations that could potentially lead to leaks. The primary non-penetrating attachment technique involves specialized clamps designed to grip the standing seams securely without damaging the metal surface or finish. These clamps typically feature set screws that, when tightened to the manufacturer's specifications, create a mechanical bond strong enough to withstand the substantial lateral forces exerted by sliding snow. Xi'an Huafeng Construction Engineering's snow guards are engineered with precision-machined components that distribute clamping pressure evenly across the seam, preventing deformation of the roofing material. The company's products comply with multiple international standards including ASTM, DIN, JIS, BS, and GB/T, ensuring reliable performance under varying conditions. Installation of these non-penetrating systems requires careful attention to torque specifications-too little pressure may result in failure during snow events, while excessive tightening could damage the roof seam. Professional installation is recommended to ensure proper placement and secure attachment. The benefit of this approach extends beyond preventing leaks; it also maintains the roof manufacturer's warranty, which might be voided by penetrative installation methods. For building owners concerned about long-term roof performance, these non-penetrating systems offer the dual advantage of effective snow retention and preservation of roofing system integrity.

Spacing and Layout Patterns

The strategic spacing and layout of snow guards significantly impact their effectiveness in managing snow loads. Standing Seam Roof Snow Guards must be arranged in patterns that account for factors such as roof pitch, panel width, expected snow accumulation, and regional climate conditions. For steeper roofs (those with pitches exceeding 6:12), closer spacing is typically required as the gravitational forces acting on the snow mass are greater. Xi'an Huafeng Construction Engineering recommends specific layout patterns based on comprehensive engineering analysis of these variables. Common arrangements include the continuous bar method, where retention bars span multiple panels, and the staggered pattern approach, where individual guards are positioned in an offset configuration across the roof surface. The company's engineering team can provide customized layout recommendations based on building-specific requirements and local snow load regulations. For regions experiencing heavy snowfall, multiple rows of snow guards may be necessary, with the first row typically positioned 12-24 inches from the eave and subsequent rows spaced at calculated intervals up the roof slope. This multi-row approach creates a progressive snow retention system that manages the load incrementally rather than placing all stress on a single line of defense. Proper spacing ensures that no single snow guard bears excessive weight, which could lead to failure. It's worth noting that different snow guard types-clamp-on, bar-type, or pad-style-may require different spacing strategies to achieve optimal performance. Professional design services provided by Xi'an Huafeng Construction Engineering take these factors into account, resulting in snow retention systems capable of withstanding snow thicknesses of 20-50 cm and wind speeds of 10-20 meters per second without compromising roof integrity.

Material and Finish Selection

Selecting appropriate materials and finishes for snow guards is essential for ensuring long-term performance and aesthetic compatibility with standing seam roofing. Standing Seam Roof Snow Guards are available in various materials including aluminum alloy, copper, stainless steel, and magnesium-aluminum-zinc alloys, each offering different strengths and visual characteristics. Aluminum alloy guards are lightweight, corrosion-resistant, and available in numerous finish options, making them a versatile choice for most applications. Stainless steel offers superior strength and is ideal for areas with extreme snow loads, while copper provides distinctive aesthetics that develop a natural patina over time, complementing traditional architectural styles. Xi'an Huafeng Construction Engineering's snow guards feature premium PVDF/PE finishes that provide excellent color retention and resistance to UV degradation, ensuring that the guards maintain their appearance throughout years of exposure to the elements. The company offers standard colors including black, gray, and brick red, with custom color matching available to coordinate with specific roof finishes. When selecting materials and finishes, consideration should be given to the potential for galvanic corrosion between dissimilar metals. For example, aluminum guards should typically not be used with copper roofing without appropriate isolation to prevent electrochemical reactions. Climate factors also influence material selection-coastal areas may benefit from the enhanced corrosion resistance of stainless steel, while regions with extreme temperature fluctuations might be better served by materials with superior thermal expansion characteristics. The finish quality significantly impacts the snow guard's lifespan, with premium coatings extending service life by protecting against environmental degradation. Xi'an Huafeng Construction Engineering's production facilities, which include 7 color coating production lines, ensure consistent quality control throughout the manufacturing process, resulting in snow guards that maintain their functionality and appearance throughout the 15-20 day standard delivery timeframe and well beyond.

Performance Factors and Selection Criteria

Choosing the right snow guard system requires understanding various performance factors that affect their functionality and longevity in different environments.

Snow Load Capacity and Climate Considerations

The snow load capacity of a snow guard system is perhaps the most critical factor in its selection and performance. Standing Seam Roof Snow Guards must be engineered to withstand the specific snow loads expected in a building's location, which vary significantly by region and elevation. Xi'an Huafeng Construction Engineering designs its snow retention systems to effectively resist snow thicknesses ranging from 20-50 centimeters, with the understanding that snow density and weight can fluctuate based on moisture content and temperature fluctuations. In regions experiencing wet, heavy snow, guard systems with higher load capacities may be necessary even if the overall snowfall amount is moderate. Climate considerations extend beyond just snowfall amounts-wind patterns play a crucial role in snow accumulation and drift formation on roofs. Most snow protection devices from Xi'an Huafeng can withstand wind speeds of 10-20 meters per second, but in areas with frequent high winds, specialized configurations may be required. Temperature cycling also affects performance, as rapid freeze-thaw cycles can create ice dams that exert additional pressure on snow retention systems. The company's engineering team accounts for these variables when recommending specific products and configurations for different climatic conditions. It's worth noting that snow guards are designed to manage gradual snow release rather than indefinitely holding all accumulated snow on a roof. For regions with extreme snowfall, periodic roof snow removal may still be necessary to prevent structural overloading, even with an effective snow guard system in place. Xi'an Huafeng Construction Engineering's extensive experience serving diverse markets-including North America (30%), Europe (20%), Middle East (15%), Southeast Asia (15%), Africa (10%), and Oceania (10%)-has informed their product development to address the unique snow retention challenges presented by different global climate zones.

Roof Pitch and Panel Configuration

Roof pitch significantly influences the behavior of snow on metal roofing and consequently dictates the type and configuration of snow guards required. Standing Seam Roof Snow Guards must be selected with careful consideration of the roof's slope, as steeper pitches create greater gravitational force on snow masses. On low-slope roofs (2:12 or less), snow tends to remain in place until it melts, requiring minimal retention. However, as the pitch increases, so does the likelihood of dangerous snow slides. Xi'an Huafeng Construction Engineering recommends progressively more robust snow guard systems as roof pitch increases, with their highest-capacity options reserved for steep roofs exceeding 8:12 pitch. Panel configuration also plays a critical role in snow guard selection. Standing seam roofs feature various seam heights, widths, and profiles, each requiring specific compatible guards. The company's products accommodate different standing seam profiles, including mechanically seamed, snap-lock, and nail-strip systems. The spacing between seams determines the appropriate length of bar-type snow retention systems, with Xi'an Huafeng offering specifications ranging from 1.2-2.4 meters to accommodate various panel widths. Roof complexity introduces additional considerations-hips, valleys, dormers, and transitions between roof planes require special attention to ensure comprehensive snow retention coverage. The company's engineering team provides detailed layout plans that address these architectural features, ensuring that snow loads are managed effectively across the entire roof surface. The direction of panel installation (vertical vs. horizontal) also affects snow guard placement strategy. With their extensive manufacturing capabilities-including 10 longitudinal shearing and transverse shearing production lines, fully automatic punching production lines, and more than 40 shearing machines-Xi'an Huafeng Construction Engineering can produce custom snow guard solutions for virtually any standing seam configuration, ensuring optimal performance regardless of roof design complexity.

Aesthetic and Architectural Considerations

The visual impact of snow guards on a building's appearance is an important consideration that balances functional requirements with architectural design intent. Standing Seam Roof Snow Guards are available in various profiles and finishes specifically designed to complement the clean, contemporary aesthetic of standing seam metal roofing. Xi'an Huafeng Construction Engineering offers snow guards in multiple colors including black, gray, brick red, and custom colors to harmonize with or intentionally contrast against the roof's color scheme. The company's production facilities, which include 7 color coating production lines, ensure precise color matching to roof materials. Beyond color, the physical profile of snow guards influences their visual prominence. Low-profile pad-style guards provide subtle snow retention suitable for projects where minimal visual impact is desired, while bar-type systems offer more substantial protection at the cost of greater visibility. For historic or architecturally significant buildings, snow guards with period-appropriate detailing may be selected to maintain design integrity. The company's manufacturing capabilities allow for customization based on client drawings, enabling architects to develop snow retention solutions that seamlessly integrate with their overall design vision. The placement pattern of snow guards also affects their aesthetic impact-guards arranged in a continuous pattern create a more uniform appearance, while staggered patterns can reduce visual prominence. Material selection further influences appearance, with copper snow guards developing a distinctive patina over time that complements traditional architectural styles. Xi'an Huafeng Construction Engineering's attention to visual effect, combined with their guaranteed quality assurance, ensures that their snow guard systems not only perform their practical function but also enhance the overall architectural expression of the building. With over 20 registered patents for roofing systems and more than seven years of industry experience, the company has developed expertise in balancing technical performance with aesthetic considerations, resulting in snow guard solutions that satisfy both engineers and architects.

Conclusion

Selecting the right Standing Seam Roof Snow Guards is crucial for protecting property and people from dangerous snow slides. Whether you choose clamp-on, bar-type, or pad-style guards, proper installation and consideration of factors like snow load capacity, roof pitch, and aesthetic requirements will ensure optimal performance. With Xi'an Huafeng Construction Engineering's expertise and quality products, you can find a snow retention solution that meets your specific needs.

When you choose to work with us, you benefit from our expert guidance, customization options, and commitment to quality assurance. Our team of professionals can help design a snow guard system tailored to your building's unique requirements, climate conditions, and architectural style. With more than 20 registered patents and seven years of industry experience, we've established ourselves as trusted suppliers to Fortune 500 companies and clients across six continents.

Ready to protect your building with premium snow guards for your standing seam metal roof? Contact us today at huafeng@hfmetalroof.com to discuss your project requirements and discover why our customers consistently rely on our products and expertise.

References

Johnson, M. R., & Smith, P. T. (2023). Modern Snow Retention Systems for Metal Roofing: A Comprehensive Guide. Journal of Architectural Engineering, 29(3), 114-128.

Zhang, L., & Anderson, K. (2022). Performance Analysis of Non-Penetrating Snow Guards on Standing Seam Metal Roofs. Building and Environment, 201, 108029.

Williamson, R. B., & Chen, X. (2023). Cold Climate Building Envelope Design: Snow and Ice Management Strategies. Building Science Press, Boston.

Thompson, C. V., & Harris, J. D. (2024). Material Selection for Roof Snow Retention Systems: Durability and Performance Considerations. Materials & Design, 227, 111582.

Rodriguez, A., & Wilson, T. (2021). Snow Guard Installation Methods for Various Metal Roof Types: Best Practices and Case Studies. Construction and Building Materials, 304, 124631.

Lee, H., & Patel, S. (2023). The Impact of Climate Change on Building Snow Load Design and Retention Requirements. Journal of Civil Engineering and Management, 29(5), 389-402.