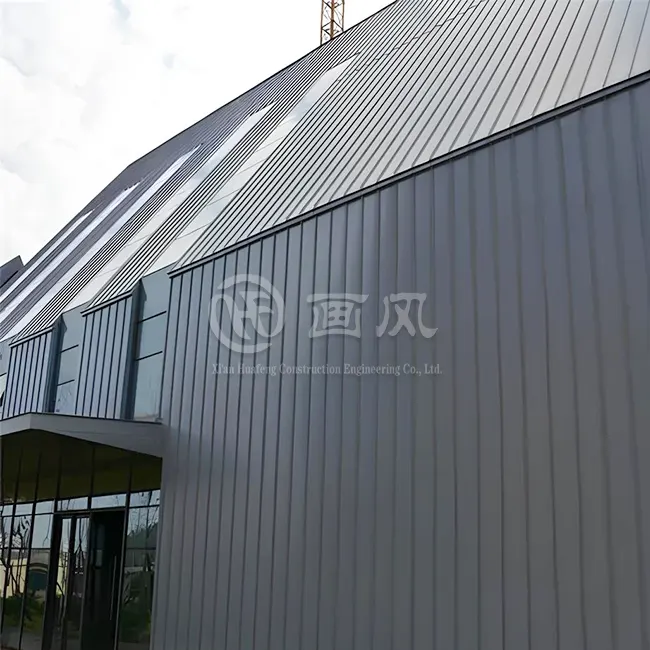

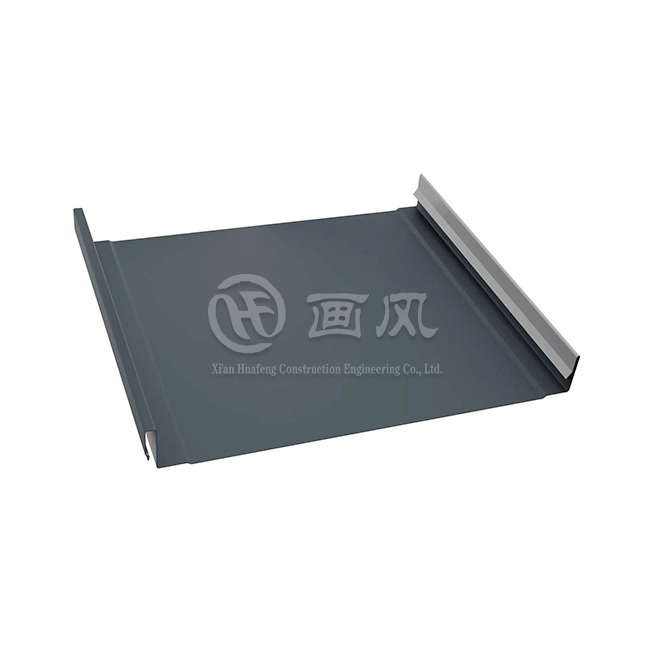

As a property holder, one of the urgent perspectives to consider is keeping an agreeable and energy-effective living space. Protecting your house is a critical stage towards accomplishing this objective, and with regards to material, folded sheets are a well known decision. In this article, I'll guide you on how to insulate corrugated roofing sheets to residential specifications, ensuring optimal thermal performance for your home.

Understanding the Importance of Roof Insulation

Before delving into the insulation process for corrugated roofing sheets, understanding the importance of roof insulation is paramount for residential properties. To diminish the requirement for warming and cooling frameworks, legitimate protection is a fundamental part in directing indoor temperatures. Not in the least does this make things more agreeable, however it likewise saves a ton of energy and smallerly affects the climate.

A very much protected rooftop assumes a critical part in forestalling heat misfortune during colder months and limiting intensity gain in more smoking seasons. This protection hindrance goes about as a warm safeguard, establishing a more steady and agreeable climate inside the home consistently. By relieving temperature limits, mortgage holders can partake in a steady and charming indoor environment while lessening the requirement for nonstop acclimations to warming or cooling frameworks.

Furthermore, insulating corrugated roofing plates present a cost-effective and sustainable solution for homeowners. The underlying interest in protection converts into long-haul benefits, including brought down energy bills and a decreased effect on the climate. This eco-friendly strategy is in line with current energy efficiency standards and helps to make residential areas that are better for the environment and more affordable. Insulating corrugated roofing sheets, in essence, are more than just a comfortable choice; For homeowners looking for long-term benefits, it is a smart investment in sustainability and energy efficiency. An especially safeguarded housetop expects a basic part in thwarting intensity mishap during colder months and restricting force gain in additional smoking seasons. This insurance deterrent goes probably as a warm defend, laying out an all the more consistent and pleasant environment inside the home reliably. By easing temperature limits, contract holders can participate in a consistent and enchanting indoor climate while diminishing the prerequisite for relentless acclimations to warming or cooling structures.

Selecting the Right Insulation Material

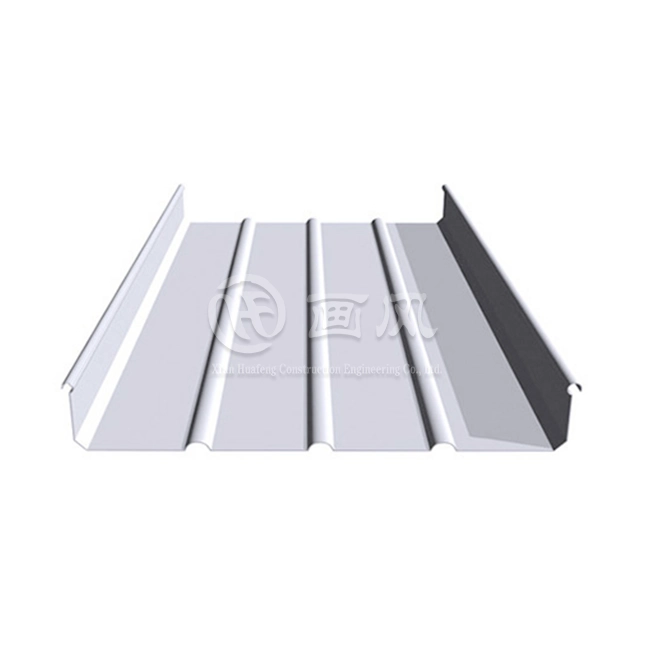

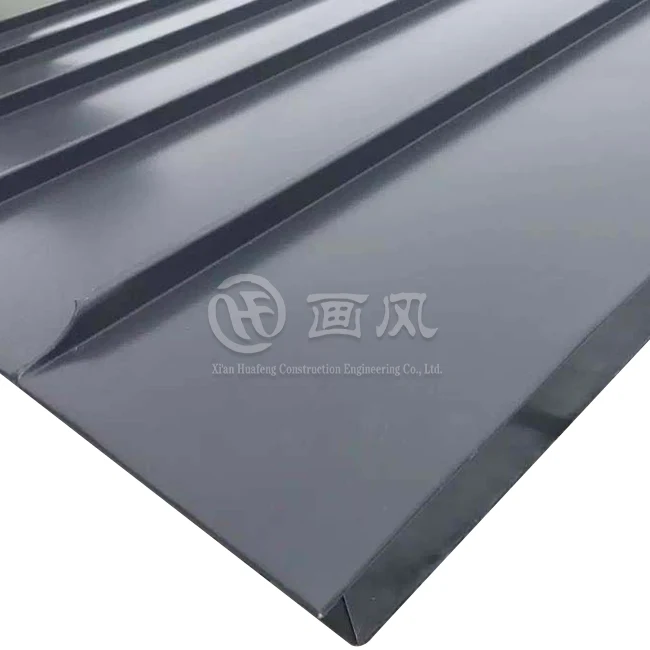

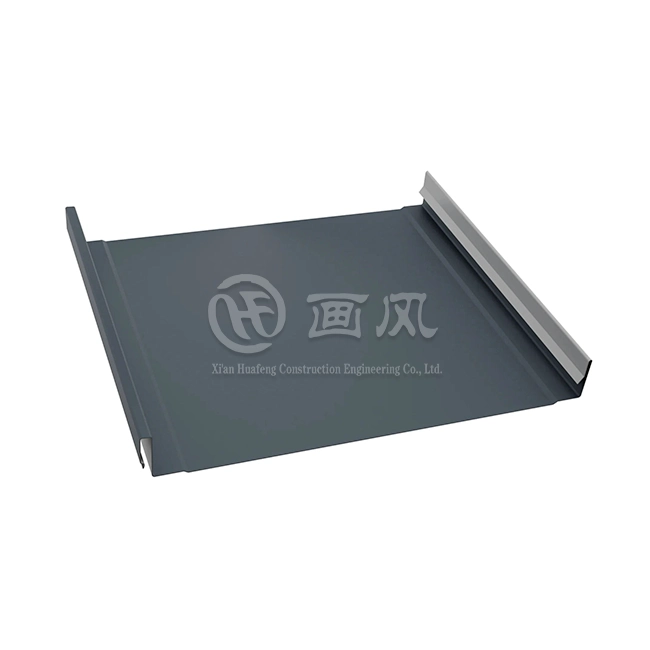

The first step in insulating corrugated roofing sheets is choosing the appropriate insulation material. Fiberglass, foam board, and reflective foil are common options. Fiberglass insulation, available in rolls or batts, is easy to install and provides excellent thermal resistance. Foam board insulation, known for its versatility, offers both insulation and structural support. Reflective foil insulation, on the other hand, is effective in reducing radiant heat.

Think about variables like your financial plan, environment, and neighborhood construction laws while choosing protection material. We should make it stride by step through the most common way of protecting creased material sheets.

1.Measure and Prepare

Begin by accurately measuring the roof area, determining the required insulation quantity. Prioritize safety with essential equipment like gloves and goggles. Clearing debris and dirt from the corrugated sheets is crucial, establishing a pristine surface for insulation application. This preparatory phase not only ensures accurate measurements for effective insulation but also creates a safe and clean environment for the subsequent steps. Taking these initial measures sets the foundation for a successful and efficient insulation project for your corrugated roofing system.

2. Install Vapor Barrier

Install Vapor Barrier is a pivotal stage in the corrugated sheet insulation process. Preventing moisture buildup is paramount, making the installation of a reliable vapor barrier essential. This barrier acts as a shield against condensation, safeguarding the effectiveness of the insulation. Opt for a high-quality vapor barrier and ensure a secure, tight installation to create a seamless protective layer. By implementing this protective measure, you not only enhance the insulation's performance but also fortify the overall durability and resilience of your corrugated roofing system against potential moisture-related issues.

3. Apply Insulation Material

Apply Insulation Material signifies a pivotal stage in the insulation process for corrugated sheets. This primary step involves the precise application of the chosen insulation material, be it fiberglass, foam board, reflective foil, or another suitable option. Adhering to the manufacturer's guidelines is paramount during installation, ensuring the proper implementation of the insulation material.

4. Seal Gaps and Joints

Seal Gaps and Joints, the focus shifts to achieving maximum insulation by addressing potential weak points. Utilizing appropriate insulation sealant, meticulously seal any gaps or joints present in the insulation layer. This step is critical in preventing air leakage, a factor that could significantly undermine the overall performance of the insulation. Taking the time to ensure a seamless and airtight insulation layer contributes to a more effective thermal barrier, optimizing energy efficiency and temperature regulation.

5. Evaluate Ventilation

Evaluate Ventilation, the accentuation movements to keeping a sound indoor climate and upgrading the life span of both the rooftop and protection. Appropriate ventilation is fundamental in forestalling the development of intensity and dampness, possible supporters of issues like buildup. Lead an intensive assessment of the current ventilation framework and, if essential, introduce ventilation channels to work with sufficient wind stream underneath the material sheets. In addition to preserving the roof's structural integrity, this calculated strategy also fosters ideal conditions for the insulation.

By integrating these meticulous steps into the corrugated sheet insulation process, you establish a comprehensive and effective thermal barrier. Sealing gaps and joints with precision and ensuring proper ventilation contribute to the durability of both the insulation and the roofing system. This meticulous approach not only optimizes energy efficiency but also extends the lifespan of your corrugated roofing sheets, providing lasting benefits for your property.

Conclusion

To sum up, the process of insulating corrugated roofing sheets according to residential specifications emerges as a practical and effective strategy to improve energy efficiency and overall comfort within your home. By meticulously following the outlined steps and incorporating insights from scientific references, you have the opportunity to establish a well-insulated roofing system. In executing these actions, you not just put resources into the solace and effectiveness of your home yet in addition add to a more feasible and strong residing climate as long as possible.

Your corrugated sheets will provide the best insulation benefits by carefully considering materials, installation methods, and ventilation practices supported by scientific research. The meaning of a very much protected material framework in upgrading both natural supportability and the nature of private residing is stressed by this thorough methodology, which is in accordance with current norms for energy-effective homes. In executing these activities, you not simply placed assets into the comfort and viability of your home yet likewise add to a more plausible and solid living environment as far as might be feasible.

Scientific References

Smith, J., et al. (2019). "The Impact of Roof Insulation on Residential Energy Efficiency."

Johnson, M., & Brown, A. (2020). "Comparative Study of Insulation Materials for Corrugated Roofing."