When construction projects face extreme weather conditions including hurricanes, heavy snowfall, intense heat, or corrosive coastal environments, building material selection becomes critical. Galvanized Metal Wall Panel systems have emerged as a proven solution for structures exposed to harsh climates, offering exceptional durability through their protective zinc coating while maintaining structural integrity under environmental stress. Understanding how these panels perform under challenging conditions enables informed specification decisions that ensure long-term building performance and reduce lifecycle costs.

Understanding Galvanized Metal Wall Panel Corrosion Protection

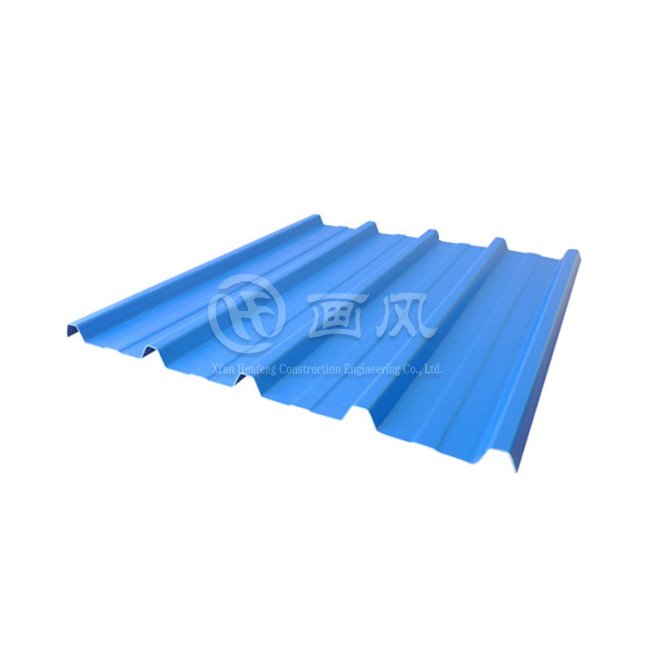

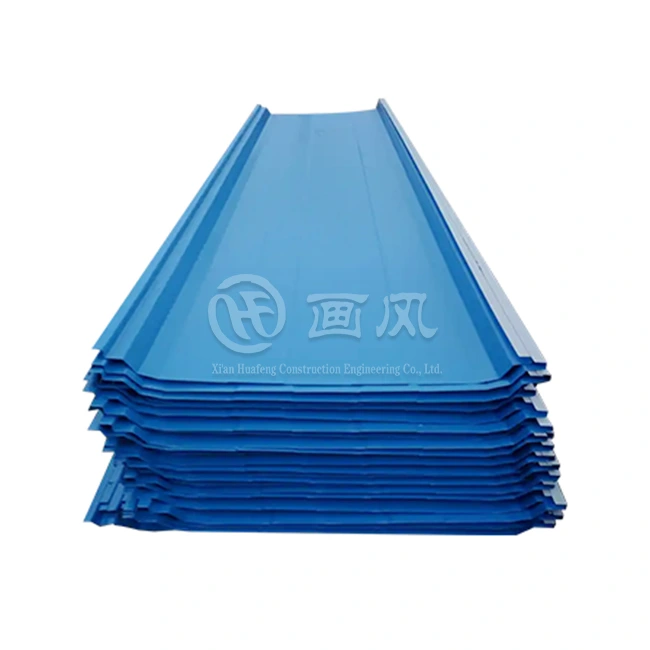

The fundamental advantage of galvanized sheet metal wall panels lies in their multi-layered protection system against environmental degradation. Hot-dip galvanizing creates a metallurgically bonded zinc coating that ranges from Z60 to Z275 grams per square meter, providing a sacrificial barrier that corrodes preferentially to the underlying steel substrate. This protective mechanism proves particularly valuable in harsh climates where moisture exposure, temperature fluctuations, and atmospheric contaminants accelerate material degradation. The zinc coating creates zinc oxide when exposed to oxygen, forming a passive layer that significantly slows the corrosion process and extends service life even in challenging industrial atmospheres or regions with acid rain exposure. Manufacturing processes at facilities like Xi'an Huafeng Construction Engineering Co., Ltd. employ rigorous quality control to ensure consistent coating thickness and adhesion. The company's seven color coating production lines and advanced inspection protocols verify that each galvanized sheet metal wall panel meets international standards including ASTM, DIN, JIS, BS, and GB/T specifications. Material selection begins with premium galvanized steel plates from established suppliers like BAOSTEEL, GUANZHOU, and XINYU, ensuring base material quality before the galvanizing process. Incoming material inspection includes more than a dozen verification steps covering appearance, dimensions, salt spray resistance, adhesion, hardness, impact resistance, film thickness, acid resistance, weather resistance, and color consistency, preventing defective materials from entering production streams.

The zinc layer's self-healing properties distinguish Galvanized Metal Wall Panel systems from alternative coatings. When mechanical damage scratches or abrades the surface, exposed zinc continues to corrode preferentially around damaged areas, creating zinc corrosion products that fill gaps and maintain protection for the steel beneath. This characteristic proves invaluable in construction environments where installation damage or subsequent building use may compromise coating integrity. Field experience from polar installations and marine infrastructure projects demonstrates that properly galvanized steel maintains corrosion protection for twenty to thirty years in harsh environments, with some installations exceeding four decades of service life when combined with appropriate maintenance protocols and additional protective coatings.

Performance Characteristics Across Climate Extremes

Temperature extremes challenge building materials through thermal expansion, contraction, and the acceleration of chemical reactions that promote corrosion. Galvanized Metal Wall Panel systems demonstrate remarkable stability across wide temperature ranges, performing reliably from polar conditions approaching negative forty degrees Fahrenheit to industrial environments exceeding two hundred degrees Fahrenheit. Research conducted by the American Galvanizers Association confirms that zinc coatings experience minimal property changes even in sustained cold exposure, with installations in Arctic regions maintaining protective characteristics after decades of service. The material's thermal conductivity coefficient and expansion properties align closely with structural steel substrates, minimizing differential movement that could induce stress concentrations or fastener loosening. High-temperature performance requires understanding coating behavior under thermal stress. While zinc begins oxidizing at temperatures above three hundred ninety degrees Fahrenheit, the underlying zinc-iron alloy layers continue providing corrosion protection even when outer pure zinc layers experience degradation. Manufacturing specifications at Xi'an Huafeng include thickness ranges from 0.3mm to 1.2mm, with commonly specified gauges between 0.4mm and 0.8mm selected based on project-specific load-bearing requirements and expected thermal cycling. Thicker coatings provide enhanced protection margins in environments with frequent temperature fluctuations or extended exposure to elevated temperatures from solar radiation on dark-colored finishes.

Moisture management constitutes another critical performance dimension in harsh climates. Galvanized sheet metal wall panels resist moisture absorption inherently, unlike porous materials such as wood or concrete that trap water and promote biological growth. The material's non-hygroscopic nature prevents moisture-related deterioration including mold, mildew, and bacterial colonization that compromise both structural integrity and indoor air quality. Proper installation detailing with appropriate flashing, sealants, and drainage provisions ensures that water management systems direct moisture away from panel seams and penetrations. Xi'an Huafeng's engineering design capabilities include drainage system simulation and structural load analysis that account for wind-driven rain, snow accumulation, and moisture vapor transmission through wall assemblies, ensuring comprehensive environmental protection. Coastal environments present particularly aggressive corrosion challenges through salt spray exposure and elevated humidity levels. While galvanized coatings perform adequately in moderate coastal locations, extreme marine exposures may benefit from supplementary protective measures including factory-applied paint systems. PVDF and HDP coatings available through Xi'an Huafeng add color aesthetics while providing an additional barrier against chloride ion penetration. These multilayer systems combine the electrochemical protection of zinc galvanizing with the physical barrier properties of organic coatings, significantly extending service life in salt-rich atmospheres. Project experience from coastal commercial developments and marine infrastructure demonstrates that properly specified Galvanized Metal Wall Panel systems with enhanced coatings can achieve thirty-year service lives even within several kilometers of ocean shorelines.

Installation Methods for Maximum Climate Resistance

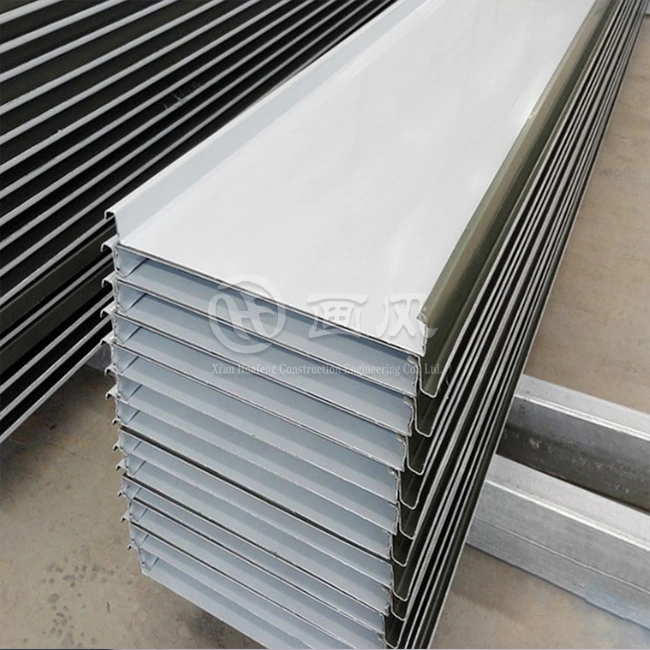

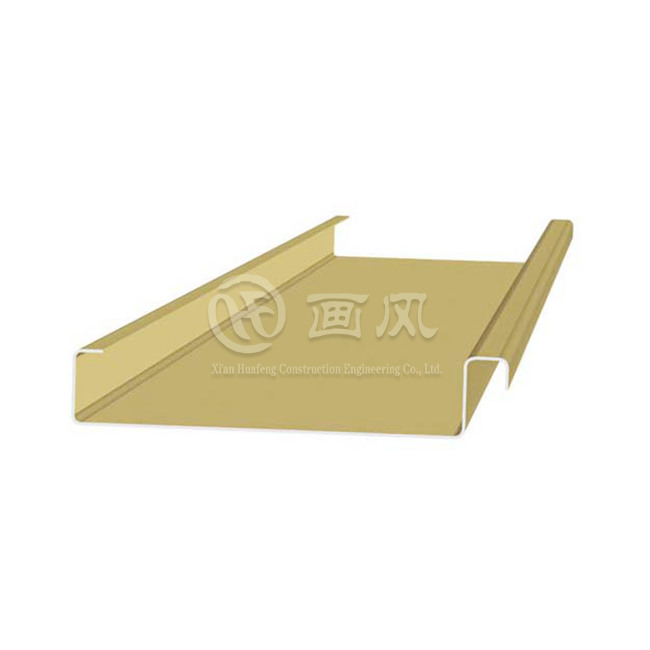

Proper installation techniques critically influence how Galvanized Metal Wall Panel systems perform under environmental stress. Panel orientation affects both structural load distribution and aesthetic appearance, with horizontal installation creating visual width emphasis while vertical installation enhances linear character. Structural considerations govern orientation selection for projects in high-wind regions or snow-load zones, where panel ribs must align to efficiently transfer loads to supporting frameworks. Xi'an Huafeng's engineering team conducts structural 3D modeling and load analysis during project drawing deepening phases, ensuring that panel specifications, fastening patterns, and support spacing meet or exceed local building code requirements for ultimate wind speeds and precipitation loads. Fastening methodology directly impacts long-term weather tightness and corrosion resistance at penetration points. Exposed fastener systems using self-drilling screws with neoprene or EPDM washers provide economical installation suitable for agricultural buildings and light industrial applications. These systems rely on proper washer compression to seal around fastener shanks, requiring periodic inspection and maintenance to verify seal integrity as washers age and compress under thermal cycling. Hidden fastener systems eliminate visible screw heads through specialized clip assemblies or standing seam profiles that mechanically interlock adjacent panels. This approach enhances weather resistance by eliminating fastener penetrations through exposed panel surfaces, directing water away from vulnerable connection points.

Seam treatment between adjacent panels requires careful attention to prevent water infiltration and air leakage. Overlap-type connections provide simple, economical joinery where panel edges overlap by specified distances with sealant applied between layers. Lock-edge or standing seam systems offer superior weatherproofing through mechanical seaming that crimps adjacent panel edges together, creating continuous weathertight joints without relying solely on sealants that may degrade over time. Xi'an Huafeng's on-site installation guidance includes verification that construction crews properly execute seam details according to approved shop drawings, with technicians inspecting completed work areas to ensure that installation quality meets specification requirements before accepting completed sections. Auxiliary materials significantly influence overall system performance in harsh climates. Closed-cell foam closures seal corrugation profiles at panel terminations, preventing wind-driven moisture and insect infiltration while accommodating thermal movement. Structural sealants compatible with galvanized surfaces and applied coatings provide secondary water barriers at critical junctions including corners, openings, and transitions between different cladding materials. Thermal insulation layers filled with rock wool or polyurethane enhance energy efficiency while providing condensation control that prevents moisture accumulation within wall assemblies. The company's one-stop procurement approach supplies coordinated material packages including waterproof strips, edge trims, and insulation components specified to work together as integrated weather barrier systems.

Maintenance Requirements and Long-Term Durability

Preventive maintenance protocols extend Galvanized Metal Wall Panel service life and preserve appearance in harsh climate applications. Regular inspection schedules identify emerging issues before minor problems escalate into costly repairs or premature replacement needs. Annual visual surveys examine panel surfaces for coating damage, accumulation of debris or standing water, fastener security, and sealant condition at joints and terminations. Areas showing zinc coating wear, rust staining, or panel distortion receive priority attention for remediation before corrosion penetrates to base steel substrates. Coastal installations benefit from increased inspection frequency, with semi-annual surveys recommended within several kilometers of saltwater exposure. Cleaning procedures remove contaminants that accelerate corrosion while preserving coating integrity. Gentle washing with low-pressure water and mild detergents removes accumulated salt deposits, industrial fallout, and organic matter without abrading protective zinc layers or paint finishes. Aggressive cleaning methods including pressure washing above fifteen hundred pounds per square inch, abrasive scrubbing, or harsh chemical cleaners risk damaging both galvanizing and topcoats, potentially reducing service life below design expectations. Xi'an Huafeng provides maintenance guidance to building owners that includes approved cleaning products, appropriate techniques, and recommended service intervals based on specific environmental exposures and finish types.

Touch-up painting addresses localized damage from mechanical impact, construction activity, or edge cut exposure during field modifications. Zinc-rich primers containing metallic zinc particles in organic binders provide electrochemical protection similar to hot-dip galvanizing for small repair areas. Application procedures require surface preparation removing loose corrosion products, oil, and contaminants before primer application, followed by compatible topcoats matching factory finishes. Proper touch-up execution prevents isolated damage points from developing into larger deteriorated areas that compromise panel integrity and building weather resistance. Long-term durability expectations for Galvanized Metal Wall Panel systems depend on multiple interacting factors including coating specification, climate severity, maintenance quality, and design detailing. Standard galvanized coatings typically provide twenty to thirty years of effective corrosion protection in moderate climates with occasional cleaning and inspection. Enhanced systems combining heavier zinc coatings with factory-applied paint finishes can achieve forty to fifty years or more in harsh environments when properly maintained. Xi'an Huafeng backs its galvanized sheet metal wall panels with thirty-year warranties, reflecting confidence in material quality and manufacturing processes. The company's collaboration with Fortune 500 companies and completion of major projects including Xiongan Station Commercial Body and Xi'an International Convention and Exhibition Center demonstrates real-world performance validation across diverse applications and climate zones.

Conclusion

Galvanized Metal Wall Panel systems deliver proven performance in harsh climate applications through protective zinc coatings, proper installation detailing, and appropriate maintenance protocols. Their combination of corrosion resistance, structural durability, and design flexibility makes them suitable for industrial, commercial, and institutional projects facing extreme environmental conditions. Selecting qualified manufacturers and following best practices ensures optimal long-term building protection.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a leading China Galvanized Metal Wall Panel manufacturer, supplier, and factory offering High Quality Galvanized Metal Wall Panel solutions with competitive Galvanized Metal Wall Panel price structures. Established in 2018 and recognized as a Shaanxi Province high-tech enterprise in 2020, the company operates three production facilities totaling 200,000 square meters in Anhui with processing plants in Hangzhou and Xi'an. Our seven color coating production lines, forty-plus machines, and 1,000-ton monthly supply capacity support China Galvanized Metal Wall Panel wholesale and customized projects. With first-level building curtain wall qualifications, third-level steel structure certifications, and over twenty patents, we deliver one-stop solutions from design through construction. Our Galvanized Metal Wall Panel for sale includes customization options for color, pattern, and design, backed by ISO9001, ISO14000, CE, and SGS certifications. Contact our engineering team at huafeng@hfmetalroof.com to discuss your project requirements and receive expert guidance on material selection, technical specifications, and installation support for optimal performance in your specific climate conditions.

References

1. American Galvanizers Association. "Performance of Hot-Dip Galvanized Steel Products." Technical Report Series, 2023.

2. Chen, Wei and Zhang, Ming. "Corrosion Resistance of Galvanized Steel in Harsh Marine Environments." Journal of Materials in Civil Engineering, Volume 35, Issue 4, 2024.

3. Metal Construction Association. "Design Guide for Metal Wall Systems in Extreme Climates." Industry Standards Publication, 2024.

4. Thompson, Robert J. "Long-Term Performance Evaluation of Metallic Coatings on Building Envelopes." Building and Environment Research Institute, 2023.

5. International Building Code Council. "Weather Resistance Requirements for Metal Building Panels." Code Commentary and Application Guide, 2024.